Abstract

Hollow polymer microspheres with different polarity and functional group for the shell layer containing gold nanocolloid cores adsorbed on the inner surface were prepared by selective removal of sandwiched silica layer from the corresponding gold/silica/polydivinylbenzene (Au/SiO2/PDVB), Au/SiO2/poly(ethyleneglycol dimethacrylate) (Au/SiO2/PEGDMA), and Au/SiO2/poly(ethyleneglycol dimethacrylate-co-methacrylic acid) (Au/SiO2/P(EGDMA-co-MAA) tri-layer microspheres, respectively. The tri-layer microspheres were synthesized by distillation precipitation polymerizations of divinylbenzene (DVB), ethyleneglycol dimethacrylate (EGDMA), EGDMA together with methacrylic acid (MAA) in presence of 3-(methacryloxy)propyltrimethoxysilane (MPS)-modified gold/silica (Au/SiO2) core–shell particles as seeds, which were prepared by coating of a layer of silica onto the surface of Au nanocolloids with the aid of polyvinylpyrrolidone (PVP) via a modified Stöber method. The catalytic property and stability as a microreactor of the hollow polymer microspheres with Au nanocolloid cores adsorbed on the inner surface were studied by the reduction of 4-nitrophenol (4-NP) to 4-aminophenol (4-AnP) with sodium borohydride (NaBH4) as reductant. Transmission electron microscopy (TEM) and Fourier transform infrared spectra (FT-IR) were used for characterizing the morphology and structure of the resultant microspheres.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Colloidal nanoparticles with unique optical, electrical, and magnetic properties have been an important branch of chemical research and technical applications [1]. However, the high aggregation tendency of the nanocolloids prevents them from wide applications. The most essential role of the stabilizing polymer is to protect the nanoparticles from coagulation. Although soluble metallic nanocolloids stabilized by polymer have high activity, stability, and selectivity in homogeneous reactions [2–4], the recovery of the catalyst from products by conventional techniques, such as filtration and ultracentrifugation, is neither economic nor convenient.

Various physical and chemical methods have been utilized for the encapsulation of metallic nanoparticles with either an inorganic or organic shell layers [5–7]. The solid Au/SiO2 core–shell particles were conveniently prepared by a modified sol–gel procedure with the surface protection from polyvinylpyrrolidone (PVP) and the Au/SiO2 yolk–shell nanostructures were further formed via a surface-protected etching processing with sodium hydroxide for the utilization as a nanoscale reactor for catalytic reactions [5]. Spherical hollow colloids of polybenzyl methacrylate (PBzMA) containing cores of Au nanoparticles adsorbed on the inner surface were synthesized via three major steps, which included the coating of gold nanoparticles with uniform shells of amorphous silica by hydrolysis of tetraethyl orthosilicate (TEOS), surface atom transfer radical polymerization (ATRP) of benzyl methacrylate (BzMA) and the selective removal of sandwiched silica layer in aqueous hydrofluoric acid (HF) [6]. Hollow zirconia spheres with gold nanocolloids adsorbed on the inner surface were prepared by removing the silica mid-layer in 1 N aqueous sodium hydroxide solution from the corresponding Au/SiO2/ZrO2 tri-layer microspheres, which were used as catalysts for the oxidation of CO [7]. Hollow microspheres have attracted increasing attention due to their unique properties, such as low density, high specific surface area, good flow ability, and surface permeability. They have found wide applications in many fields, such as catalysis, controlled drug delivery systems, artificial cells, fillers, pigments, light-weight structural materials, nanoreactors, low dielectric constant materials, acoustic insulation, and photonic crystals [8–12]. An important concern of hollow microspheres is to accommodate guest nanoparticles in their cavity, which leads to an interesting structure as hollow microspheres with movable cores and guest nanoparticles different from those of host hollow microsphere-shell and guest nanoparticles. Nanoparticles such as gold [5–7, 13, 14], silver [15], tin [16], silica [17], and iron oxide [18, 19], have been successfully incorporated into the interior of the hollow microspheres by various techniques.

Hollow polymer microspheres have combined characteristics of precisely controllable size and shell thickness, superior monodispersity and permeability, high structural strength and fine flow ability. All of these properties enable the hollow polymer microspheres ideal shell to encapsulate the metallic nanocolloids to greatly enhance their stability against coalescence while maintaining their catalytic activity [5, 14, 20]. Bearing these in mind, the present work describes a facile route for the synthesis of hollow polymer microspheres with polymer shells having different polarity and functional groups together with movable gold nanocolloid cores via the selective removal of silica mid-layer from the corresponding Au/SiO2/polymer tri-layer microspheres, which are prepared by distillation precipitation polymerization of divinylbenzene (DVB), ethyleneglycol dimethacrylate (EGDMA), EGDMA together with methacrylic acid (MAA) in presence of 3-(methacryloxy)propyl trimethoxysilane (MPS) modified Au/SiO2 core–shell composites as seeds.

Experimental

Materials

Tetrachloro auric acid trihydrate (HAuCl4·3H2O) was obtained from Shenyang Research Institute of Nonferrous Metals, China. Poly(N-vinylpyrrolidone) with average molar masses of 10 kg/mol (PVP-10) was purchased from Tianjin Chemical Engineering Institute. Tetraethyl orthosilicate (Si(OC2H5)4, TEOS) and EGDMA were obtained from Aldrich and used without any further purification. MPS was provided by Aldrich and distilled under vacuum. Divinylbenzene (DVB, 80% of DVB isomers) was supplied as technical grade by Shengli Chemical Technical Factory, Shandong, China, which was washed with 5 wt% aqueous sodium hydroxide and water, then dried over anhydrous magnesium sulfate prior to use. Methacrylic acid (MAA) and hydrofluoric acid (containing 40 wt% of HF) were purchased from Tianjin Chemical Reagents II Co. 2,2′-Azobisisobutyronitrile (AIBN) was bought from Tianjin Chemical Reagents III Co. 4-Nitrophenol (4-NP, Tianjin Chemical Reagent Factory) was recrystallized from petroleum ether and ethyl acetate. Acetonitrile (analytical grade, Tianjin Chemical Reagents Co.) was dried over calcium hydride and purified by distillation before utilization. All the other reagents were analytical grade and used without any further treatment.

Synthesis of MPS-modified Au/SiO2 core–shell microspheres

Gold/silica (Au/SiO2) core–shell microspheres were prepared by the method reported in the literature [21]. The Au nanocolloids were synthesized via a standard sodium citrate reduction method: A 10 mL of 1 wt% sodium citrate solution was added to 90 mL of HAuCl4 aqueous solution containing 20 mg of HAuCl4 under the boiling state with vigorous stirring. The reduction was performed further for 30 min without exposure to light. Then the Au nanocolloids were cooled down to room temperature immediately. The PVP solution (0.4 g PVP-10 in 15 mL of water) was added to the Au nanocolloid solution and stirred for 12 h at room temperature to guarantee the complete adsorption of PVP-10 onto the Au nanocolloids. Subsequently, the solution was centrifugated and redispersed in a solution of isopropanol and water with the mass ratio of 4:1. Then 0.30 mL of TEOS and 2.0 mL of ammonia (29.3 wt% of NH3 in water) was added to the solution and stirred for 12 h to coat the PVP-modified Au nanocolloids with silica shell. Further, the MPS-modified Au/SiO2 core–shell microspheres were made by coupling silica alcosol particles via hydrolysis of MPS: Excess MPS of 0.20 mL was introduced into the Au/SiO2 suspension under stirring and the coating process lasted for 48 h at room temperature. The resultant MPS-modified Au/SiO2 nanocolloids were purified by three cycles of centrifugation, decantation, and resuspension in ethanol with ultrasonic irradiation and finally dried in a vacuum oven at 50 °C till constant weight.

Preparation of Au/SiO2/polymer tri-layer microspheres

The as-prepared MPS-modified Au/SiO2 microspheres were used as seeds for the further-stage distillation precipitation polymerization to afford Au/SiO2/polymer tri-layer microspheres. In a dried 50 mL two-necked flask, 0.01 g of MPS-modified Au/SiO2 seeds was ultrasonically suspended in 40 mL of acetonitrile as a red suspension. Then 0.05 g of MAA and 0.05 g of EGDMA (total as 0.25 wt% of the reaction system) and AIBN (2.0 × 10−3 g, 2 wt% relative to the monomer) were dissolved in the suspension. The two-necked flask was attached with a fractionating column, Liebig condenser and receiver and submerged in a heating mantle. The reaction mixture was heated from ambient temperature till the boiling state for 10 min, and the reaction system was kept under the refluxing state for a further 10 min. The polymerization was ended after 20 mL of acetonitrile was distilled off the reaction system within 70 min and the red color turned into pink during the heating process. After the polymerization, the resultant Au/SiO2/P(EGDMA-co-MAA) tri-layer composites were purified by repeating centrifugation, decantation, and resuspension in acetone with ultrasonic irradiation for 3 times. The tri-layer composite nanoparticles were then dried in a vacuum oven at 50 °C till constant weight.

A series of parallel synthesis using different monomers including DVB and EGDMA were carried out following the same pattern by distillation precipitation polymerization in the presence of MPS-modified Au/SiO2 seeds to obtain Au/SiO2/polymer tri-layer microspheres having polymer shells with different polarity, in which the monomers used were set as 0.10 g, respectively.

The reproducibility of the distillation precipitation polymerization for the synthesis of Au/SiO2/polymer tri-layer microspheres was confirmed through several duplicate and triplicate experiments.

Synthesis of hollow polymer microspheres containing gold nanocolloid cores adsorbed on the inner surface

The Au/SiO2/polymer tri-layer microspheres were treated with 40 wt% hydrofluoric acid solution for 2 h at room temperature to remove the silica mid-layer. Then, the hollow polymer microspheres with Au nanocolloid cores adsorbed on the inner surface were purified by several ultracentrifugation/washing cycles in water till pH 7. The resultant hollow polymer microspheres with Au nanocolloid cores adsorbed on the inner surface were then dried in a vacuum oven at 50 °C till constant weight.

Catalytic reduction of 4-nitrophenol to 4-aminophenol

To investigate the catalytic activity and stability of the hollow polymer microspheres with Au nanocolloid cores adsorbed on the inner surface, the reduction of 4-nitrophenol (4-NP) to 4-aminophenol (4-AnP) in the presence of NaBH4 as reductant was performed in aqueous solution at room temperature as a model reaction. 1 mL of 4-NP aqueous solution (0.1 mmol/L, 2 × 10−4 mol) and 0.1 mL suspension of hollow PEGDMA microspheres with Au nanocolloid cores adsorbed on the inner surface (1.0 g/L, containing 6 × 10−8 mol Au, with a PEGDMA shell thickness of 31 nm) were subsequently introduced into the quartz cell with gentle shaking. The catalytic activity was monitored by a UV–vis spectrometer with a decrease of the intensity of the peak at 400 nm attributing to the typical absorption of 4-NP.

The catalyst was recycled via centrifugation, decantation, washing and drying. After that, 1 mL of 4-NP aqueous solution (0.1 mmol/L) and 2 mL of freshly prepared NaBH4 aqueous solution (0.10 mol/L) were added to test the recycling activity of the catalyst for 3 times.

To compare the catalytic property of the hollow structures with pure Au nanoparticles, sodium citrate stabilized Au nanoparticles aqueous solution with diameter of 23 nm was prepared according to literature [15]. Typically, 100 mL of 0.25 mM HAuH4 aqueous solution was heated to boiling state with mechanical stirring. Then, 1 mL of 5 wt% sodium citrate aqueous solution was quickly added. The reaction was maintained till the color of the reaction mixture changes to wine red. The wine red mixture was cooled to room temperature and centrifuged for 40 min at 8000 rpm to obtain concentrated Au nanoparticles aqueous solution. Then, 75% of the colorless supernatant was removed and the remained solution was redispersed under gentle shaking. To study the catalytic of the as-obtained Au nanoparticles, three drops of such concentrated aqueous solution (containing 3.6 × 10−8 mol of Au atoms) were added into 2 mL of 0.1 mM 4-NP (2 × 10−7 mol) aqueous solution with gentle shaking. Then, 4 mL of 0.1 M NaBH4 (4 × 10−4 mol) aqueous solution was introduced into such mixture with gentle shaking. The catalytic reaction was detected by UV–vis spectroscopy.

Characterization

The morphology, size, and size distribution of Au nanoparticles, Au/SiO2 seeds, Au/SiO2/polymer tri-layer microspheres, and the corresponding hollow polymer microspheres with Au cores adsorbed on the inner surface were characterized by transmission electron microscopy (TEM, Technai G2 20 S-TWIN). All the size and size distribution reflect the averages about 100 particles each, which are calculated according to the following formula:

where U is the polydispersity index, D n is the number-average diameter, D w is the weight-average diameter, and D i is the particle diameters of the determined microparticles.

Fourier transform infrared spectra (FT-IR) were scanned over the range of 400–4000 cm−1 with potassium bromide plate on a Bio-Rad FTS 135 FTIR spectrometer.

UV–vis spectra were performed on a Cary 100 conc spectrometer ranging from 200 to 600 nm with water as background.

Results and discussion

Scheme 1 illustrates the synthesis of hollow polymer microspheres containing Au nanocolloid cores adsorbed on the inner surface via the selective removal of the silica mid-layer in hydrofluoric acid from the corresponding Au/SiO2/polymer tri-layer microspheres, which are prepared by distillation precipitation polymerization of DVB, EGDMA, EGDMA together with MAA to afford the polymer shell layer with different polarity and functional groups.

Preparation of MPS-modified Au/SiO2 composites

It is difficult to directly perform the polymerization on the surface of the gold nanocolloids for the synthesis of the hybrids containing noble metallic Au cores adsorbed on the inner surface and polymer shells due to the lack of an appropriate interaction between Au nanoparticles and the monomer. To solve such a problem, inserting an inter-layer between the Au nanoparticles and the polymer is necessary, which would have suitable interaction between the Au nanoparticles and the polymer components. Coating the Au nanoparticles with a silica layer accomplishes such a requirement. There are many reactive hydroxyl groups on the surface of silica layer, which enable the Au/SiO2 composites to well disperse in acetonitrile and act as ideal cores for the further-stage polymerization affording Au/SiO2/polymer tri-layer microspheres.

The Au/SiO2 core–shell particles were synthesized with the aid of amphiphilic poly(vinylpyrrolidone) according to the method as described in the reference [22]. The TEM micrograph of gold nanoparticles in Fig. 1a indicates that the Au particles prepared by the sodium citrate reduction of HAuCl4 had spherical shapes with average diameter of 28 nm and narrow dispersity index (U) of 1.044 as summarized in Table 1. A critical step for the silica-coating procedures is the transfer of Au nanocolloids to be well dispersed from aqueous solution to alcoholic solvent, where the classical Stöber process would be performed. For this, the PVP-stabilized Au nanocolloids were separated from the aqueous dispersion and redispersed in the mixture of isopropanol/water (4/1, V/V) for the hydrolysis of TEOS. In the present work, isopropanol/water (4/1, V/V) mixed solvent was used as a medium for the encapsulation of PVP-stabilized Au nanocolloids via a Stöber method to prevent the formation of the secondary-initiated silica particles, which was some different from the procedure for coating of Au nanocolloids with silica layer in ethanol [21]. This was much different from the method to encapsulate the citrate-stabilized gold nanoparticles with silica layer using the silane coupling agent (2-aminopropyl) trimethoxysilane (APS) as a primer to reach a higher affinity of the gold surface to silica [14, 23]. The amphiphilic character of PVP adsorbed onto the Au nanocolloids enables the affinity of the gold surface to silica sufficiently high enough for encapsulation of silica layer without any coupling agent, such as APS. The typical TEM micrograph of Au/SiO2 composites in Fig. 1b had core–shell structures with spherical shapes and smooth surfaces, although few of the Au nanocolloids were not coated by silica layer and some of the Au/SiO2 core–shell particles contained two or more Au nanoparticles. The size of the Au/SiO2 core–shell microspheres was significantly increased from 28 nm of the Au nanocolloid cores to 228 nm with narrow dispersity index (U) of 1.026 as shown in Table 1. This meant that the silica layer with thickness of 100 nm was successfully encapsulated over the Au nanoparticles via a modified Stöber procedure with the aid of the amphiphilic PVP-10.

Narrow disperse MPS-modified Au/SiO2 microspheres were prepared by the hydrolysis of MPS via self-condensation reaction between the hydroxyl groups of silica component to incorporate the reactive vinyl groups for further-stage polymerization, which was much similar to the modification of silica particles with MPS in the previous works [23, 24]. The modification of the Au/SiO2 microspheres via hydrolysis of MPS was confirmed by FT-IR spectrum as shown in Fig. 2a, which displayed the bands at 1632 and 1714 cm−1 attributing to the stretching vibrations of the vinyl and carbonyl groups of MPS component, respectively.

Preparation of Au/SiO2/polymer tri-layer microspheres

The residual reactive vinyl groups on the surface of polydivinylbenzene (PDVB) microspheres were essential for the growth of the polymer particles [25] and the formation of monodisperse core–shell microspheres via two-stage distillation precipitation polymerization [26], in which the newly formed oligomers and monomers were captured by these reactive vinyl groups in absence of any secondary-initiated particles. In the present work, MPS-modified Au/SiO2 particles with vinyl groups on the surfaces were used as seeds in the further-stage distillation precipitation polymerization for the formation of the polymer shell layer to afford monodisperse Au/SiO2/polymer tri-layer microspheres as shown in Scheme 1.

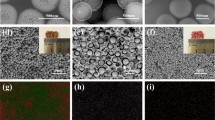

The TEM micrograph of Au/SiO2/PDVB tri-layer microspheres had spherical shapes with cauliflower-like surfaces as shown in Fig. 3a, which may be due to the rigidity of the PDVB network. The polarity of the polymer shell layer is an important factor in many applications for the resultant multi-layer composite microspheres. The typical TEM micrograph of Au/SiO2/P(EGDMA-co-MAA) tri-layer microspheres was shown in Fig. 3c, in which the di- and triple particles were observed originating from the higher reactivity of EGDMA than that of DVB [27]. Polymer microspheres with various functional groups have many applications in many fields, including solid carriers for the immobilization of biological substances, such as enzymes, antibodies, etc. [28]. The TEM micrograph of Au/SiO2/PEGDMA in Fig. 3e demonstrated that the tri-layer microspheres had spherical shapes with smooth and non-segmented surfaces. All the TEM micrographs in Fig. 3a, c, e indicated that the resultant Au/SiO2/polymer microspheres had typical tri-layer structures in absence of any secondary-initiated particles, in which the gold nanocolloids (deepest contrast) were located in the center of the particles together with a sandwiched silica layer (deeper contrast) and an outer polymer shell layer (light contrast).

TEM micrographs: a Au/SiO2/PDVB, b hollow PDVB microspheres containing Au cores adsorbed on the inner surface, c Au/SiO2/P(EGDMA-co-MAA), d hollow P(EGDMA-co-MAA) microspheres containing Au cores adsorbed on the inner surface, e Au/SiO2/PEGDMA, f hollow PEGDMA microspheres containing Au cores adsorbed on the inner surface

The reaction conditions, size, size distribution, and the conversion of the resultant Au/SiO2/polymer tri-layer microspheres for distillation precipitation polymerizations in presence of MPS-modified Au/SiO2 particles as seeds were summarized in Table 1, in which all the monomers used were set at 10/1 as mass ratio to MPS-modified Au/SiO2 seeds in order to guarantee the identical monomer concentrations for these polymerizations. The diameters of both Au/SiO2/PEGDMA and Au/SiO2/P(EGDMA-co-MAA) tri-layer microspheres were significantly increased from 228 nm of MPS-modified Au/SiO2 seeds to 289 nm, while the size of the Au/SiO2/PDVB tri-layer particles was slightly grown to 256 nm. All the resultant Au/SiO2/polymer tri-layer microspheres retained monodispersion with polydispersity index (U) lower than 1.016 as shown in Table 1. These results meant that the shell thicknesses of PDVB, PEGDMA, P(EGDMA-co-MAA) layer were 14, 31, and 31 nm, respectively. The much thinner thickness of the PDVB than those of PEGDMA and P(EGDMA-co-MAA) shell layer was originated from the much lower reactivity of DVB than those of EGDMA and MAA, which was consistent with the results reported in our previous works [26, 27]. The different reactivity of DVB, EGDMA, and MAA were also confirmed further by the conversion of the (co)monomers to the corresponding polymer shell layer as illustrated in Table 1, in which the yields of Au/SiO2/PDVB, Au/SiO2/PEGDMA, Au/SiO2/P(EGDMA-co-MAA) tri-layer microspheres were 6, 12, and 13%, respectively.

The successful encapsulation of MPS-modified Au/SiO2 with polymer shell layer having different polarity and carboxylic acid group was proven further by FT-IR spectra as shown in Fig. 2. The FT-IR spectrum in Fig. 2b of Au/SiO2/PDVB had a weak peak at 710 cm−1 corresponding to the typical adsorption of the phenyl group of PDVB component. In FT-IR spectrum of Fig. 2c for Au/SiO2/P(EGDMA-co-MAA), the absorption peak at 1473 and 1397 cm−1 was corresponding to the methyl in the ester group on the MAA molecule and the peak at 761 cm−1 was assigning to the absorption of two methylene groups on the main-chain for PEGDMA component. Figure 2d of the FT-IR spectrum for Au/SiO2/PEGDMA showed the absorption peak at 1734 and 757 cm−1 contributing to the vibration of the carbonyl unit in ester group and the vibration of the connecting two methylene groups on the PEGDMA network.

Synthesis of hollow polymer microspheres with Au cores adsorbed on the inner surface

The sandwiched silica layer of Au/SiO2/polymer tri-layer microspheres were selectively removed from the particles by the etching process with hydrofluoric acid via formation of SiF4 gas to result in the corresponding hollow polymer microspheres with Au cores adsorbed on the inner surface. The typical TEM micrographs of the hollow polymer microspheres with different shell layer containing the Au cores adsorbed on the inner surface were shown in Fig. 3b, d, f, respectively. The results in Fig. 3b indicated that the hollow PDVB microspheres had partially collapsed particles, as the PDVB shell layer with thickness of 14 nm was not thick enough to support the cavities formed during the selective etching process of silica mid-layers. Most of the Au nanoparticles were on the wall of hollow PDVB microspheres with an obvious cavity structures for the resultant hollow PDVB particles in Fig. 3b, while some of the gold nanoparticles in hollow PDVB microspheres were leached out possibly due to the occurrence of the breaking of the polymer shell during the formation of the hollow structures with much thinner (14 nm) and rigid PDVB shell layer. The hollow PEGDMA and P(EGDMA-co-MAA) microspheres with polymer shell thicknesses of 31 nm in Fig. 3d, f had convincing hollow sphere structures with the presence of circular rings of non-aggregated spheres and a cavity in the interior, in which the gold nanoparticles were attached onto the inner wall of PEGDMA and P(EGDMA-co-MAA) shell. In other words, the gold nanoparticles were movable if the cavity of the hollow polymer microspheres was full of suitable solvent, which provide the possibility to utilize these hollow polymer microspheres as a microreactor as discussed further in this paper.

Hollow polymer microspheres with gold nanocolloid cores adsorbed on the inner surface as catalytic reactor

The catalytic reduction of 4-nitrophenol (4-NP) to 4-aminophenol (4-AnP) with NaBH4 as reductant was set as a model reaction to test the activity and stability of the hollow polymer microspheres with Au nanocolloid cores adsorbed on the inner surface as a microreactor. An aqueous solution of 4-NP has a yellow color and a distinct UV–vis spectrum profile with the absorption maximum at around 400 nm. When 4-NP aqueous solution was mixed with NaBH4 only, the yellow color of the solution did not change, indicating the absence of the reduction. After the hollow P(EGDMA-co-MAA) microspheres with Au cores adsorbed on the inner surface were introduced into the mixture of 4-NP and NaBH4, the yellow color of the solution faded gradually with a significant decrease of the peak at 400 nm in UV–vis spectra as shown in Fig. 4, indicating the successful conversion of 4-NP to 4-AnP. The catalytic activity were estimated from the reaction time for the complete disappearance of the UV–vis absorption at 400 nm of 4-NP in Fig. 4, which was indicated by the disappearance of the peak at 400 nm of the UV–vis absorption after 31 min. In such a case, the hollow P(EGDMA-co-MAA) microspheres with Au cores adsorbed on the inner surface acted as a catalytic reactor to transfer the electron from NaBH4 to 4-NP for the formation of 4-AnP in aqueous solution. Since Au nanoparticles were located in the cavity of the crosslinked P(EGDMA-co-MAA) hollow microspheres and the hydrophilic nature of the polymer shell layer permitted 4-NP, NaBH4, 4-AnP molecules in aqueous solution to pass through the polymer shell layer, the cavity in the hollow P(EGDMA-co-MAA) microspheres with Au cores adsorbed on the inner surface acted as the catalytic microreactor in the aqueous solution. In the present work, the hollow P(EGDMA-co-MAA) microsphere with Au cores adsorbed on the inner surface as a heterogeneous catalytic microreactor was facilely isolated from the reaction system by simple ultracentrifugation and decantation. The heterogeneous microreactor was recovered, washed, dried and then recycled for the reduction of 4-NP to 4-AnP. The catalytic activity of the hollow P(EGDMA-co-MAA) microspheres with Au cores adsorbed on the inner surface during the recycling was quantitatively determined by the reaction time for the complete disappearance of the UV–vis absorption at 400 nm corresponding to 4-NP as summarized in Table 2. The results demonstrated that the catalytic microreactor retained high activity during the recycling, which was referred by the reaction time keeping at around 31 min even after three cycles. All these results implied that the hollow P(EGDMA-co-MAA) microspheres with Au cores adsorbed on the inner surface acted as an efficient and recyclable catalytic microreactor for the reduction of 4-NP to 4-AnP in aqueous solution.

To compare the catalytic property of the hollow structures with pure Au nanoparticles, sodium citrate stabilized Au nanoparticles with diameter of 23 nm were chosen as the comparative catalyst. It should be pointed out that the total surface area of the sodium citrate stabilized gold particles in the catalytic reaction approximately equals to that of Au nanoparticles adsorbed on the inner surface of hollow polymer microspheres used above. Three parallel reactions were processed and the mean reaction time was 420 s, which indicated that the catalytic activity of the sodium citrate stabilized 23 nm Au nanoparticles is better than that (1860 s) of the hollow microspheres with Au nanoparticle functionalized movable cores in the first catalytic cycle of the reduction. This is probably because the outer shell layer blocks the permeation of 4-NP molecule to the Au nanoparticles on the surface of movable cores. Despite of this, the Au nanoparticles adsorbed on the inner surface of hollow polymer microspheres still can be facilely separated from the reaction system by centrifugation while the pure Au nanoparticles can hardly be recovered, which showed better recycle-catalytic property after several reaction times as discussed above. On the other hand, the pure Au nanoparticles would severely aggregate after one time of catalytic reaction according to the results from Yin’s group [29], in which the aggregation would cause sharp decrease of the catalytic property. The hollow polymer microspheres with different polar and functional shell layer containing the metallic cores adsorbed on the inner surface provide the possibility for the utilization of these hollow particles as an efficient catalytic microreactor in different environment from non-polar to strong polar system. The investigation of the property and stability of these hollow functional polymer microspheres containing metallic core adsorbed on the inner surface as micro-reactor under different environments is now being carried out in our group.

Conclusion

Au/silica/polymer tri-layer microspheres with different polar and functional shell layer were prepared by distillation precipitation polymerization of DVB, EGDMA, EGDMA, and MAA in the presence of MPS-modified Au/SiO2 particles as seeds in neat acetonitrile without any additive, in which the inorganic Au/SiO2 seeds were prepared by the coating of a layer of SiO2 onto the gold nanoparticles via a modified sol–gel process with the aid of amphiphilic PVP. The hollow PDVB, PEGDMA, P(EGDMA-co-MAA) microspheres containing Au cores adsorbed on the inner surface were prepared by the selective etching of the sandwiched silica layer with hydrofluoric acid from the corresponding Au/SiO2/polymer tri-layer microspheres. The hollow P(EGDMA-co-MAA) microspheres with Au cores adsorbed on the inner surface were used as a recyclable catalytic microreactor for the effective reduction of 4-NP to 4-AnP with NaBH4 as reductant in aqueous solution.

References

Daniel MC, Astruc D (2004) Chem Rev 104:293

Yang XL, Deng ZL, Liu HF (1999) J Mol Catal A Chem 144:123

Zuo XB, Liu HF (2001) Catal Lett 12:127

Yang XL, Liu HF, Zhong H (1999) J Mol Catal A Chem 147:55

Zhang Q, Ge JP, Yin YD (2008) Nano Lett 8:2867

Arnal PM, Comotti M, Schüth F (2006) Angew Chem Int Ed 45:8224

Kamata K, Lu Y, Xia YN (2003) J Am Chem Soc 125:2384

Jiang P, Bertone JF, Colvin VL (2001) Science 291:453

Ding J, Liu GJ (1998) J Phys Chem B 102:6107

Shchukin DG, Shutava T, Shchukina E, Sukhorukov GB, Lvov YM (2004) Chem Mater 16:3446

Kim SW, Kim M, Lee WY, Hyeon T (2002) J Am Chem Soc 124:7642

Xu X, Asher SA (2004) J Am Chem Soc 126:7940

KimM SohnK, Na HB, Hyeon T (2002) Nano Lett 2:1383

Liu GY, Ji HF, Yang XL, Wang YM (2008) Langmuir 24:1019

Cheng DM, Zhou XD, Xia HB, Chan HSO (2005) Chem Mater 17:3578

Lee KT, Jung YS, Oh SM (2003) J Am Chem Soc 125:5652

Zhang K, Zhang X, Chen H, Chen X, Zhang C, Zhang J, Yang B (2004) Langmuir 20:11312

Hao LY, Zhu CL, Jiang WQ, Chen CN, Hu Y, Chen ZY (2004) J Mater Chem 14:2929

Cheng T, Pang JB, Tan G, He J, McPherson GL, Lu YF, John V, Zhan J (2007) Langmuir 23:5143

Liu W, Yang XL, He XG (2009) Chin J Polym Sci 27:275

Graf C, Dirk LJ, Vossen AI, Blaaderen AV (2003) Langmuir 19:6693

Liz-Marzan LM, Giersig M, Mulvaney P (1996) Langmuir 12:4329

Luna-Xavier JL, Guyot A, Bourgeat-Lami E (2002) J Colloid Interface Sci 250:82

Liu GY, Zhang H, Yang XL, Wang YM (2007) Polymer 48:5895

Bai F, Yang XL, Huang WQ (2004) Macromolecules 37:9746

Qi DL, Bai F, Yang XL, Huang WQ (2005) Eur Polym J 41:2320

Bai F, Yang XL, Huang WQ (2006) Eur Polym J 42:2088

Propkov NI, Gritskova IA, Charkasov VR, Chalykh AE (1996) Russ Chem Rev 45:167

Ge JP, Huynh T, Hu YX, Yin YD (2008) Nano Lett 8:931

Acknowledgement

This work was supported by the National Foundation of China with project No.: 20874049.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wang, X., Ji, H., Zhang, X. et al. Hollow polymer microspheres containing a gold nanocolloid core adsorbed on the inner surface as a catalytic microreactor. J Mater Sci 45, 3981–3989 (2010). https://doi.org/10.1007/s10853-010-4470-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-010-4470-z