Abstract

A novel series of thermoresponsive shape-memory copolymer hydrogels (poly(stearyl acrylate-co-acrylamide)) were synthesized by radical copolymerization of stearyl acrylate (SA) and acrylamide (AM). The chemical structure and crystal property of the poly(SA-co-AM) hydrogels were characterized by Fourier transform infrared spectroscopy, X-ray diffraction, and differential scanning calorimeter. The thermodynamic property of the hydrogels was studied by dynamic mechanical analysis. The swelling ratio and the shape recovery ratio of the hydrogels were also investigated. The results indicate that base on a reversible order–disorder transition, the large difference in storage modulus below and above the crystal melting temperature (T m) of the poly(SA-co-AM) hydrogels. Furthermore, the prepared hydrogels can present excellent thermoresponsive shape-memory performance by changing the operation temperature below or above T m, and the highest shape recovery ratio can reach 97%.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Shape-memory polymers, which can respond to changes in the external conditions such as temperature, pH, electromagnet field, etc., have received much attention in recent years [1–10] because of desirable applications in microelectromechanical systems and biomedical devices [11]. Thermoresponsive polymers which can show shape-memory function require two components at molecular level, crosslinked network structure to determine the permanent shape and switching segments with transition temperature to fix the temporary shape [5, 12]. It is known that water-swollen polymer hydrogels in nature are generally amorphous and have no particular ordered structure at molecular level except for some biological gels [13]. However, Osada and coworkers reported that network prepared by copolymerization of stearyl acrylate (SA) and acrylic acid or methyl acrylate with methylenebisacrylamide as cross-linker, could form hydrogels with shape-memory properties [14–16].

Similar to acrylic acid, acrylamide (AM) which shows weak alkalescence is another commonly used monomer in polymerization reaction. It can react with SA to form network structure copolymer hydrogels. In this work, water-swollen hydrogels with a ordered network structure were synthesized by copolymerizing SA with AM in the presence of 2,2′-azoisobutyronitrile as radical initiator and N,N′-methylenebisacylamide as cross-linker. The whole crosslinked network structure in the poly(SA-co-AM) hydrogels can determine the permanent shape, while SA in the hydrogels is the switching segments. Thermoresponsive shape-memory effect of the hydrogels can be achieved by changing the operation temperature below or above the transition temperature [12]. The SA in the poly(SA-co-AM) hydrogels can form lamellar crystal that has the transition temperature, namely the crystal melting temperature (T m). The poly(SA-co-AM) hydrogels, which exhibit excellent thermoresponsive shape-memory performance, undergo a reversible order–disorder transition and have a dramatic difference in storage modulus with change the temperature below and above the T m.

Experimental part

Materials

Stearyl acrylate (Tianjin Tianjiao Chemical Co. Ltd., China) was recrystallized from ethanol solution. Acrylamide (Tianjin Chemical Reagent Co., China) was recrystallized from the mixture of acetone and chloroform. Initiator 2,2′-azoisobutyronitrile (AIBN) (Shanghai Siweihe Chemical Co. Ltd., China) was recrystallized from ethanol solution. Cross-linker N,N′-methylenebisacylamide (MBAA) (Tianjin Chemical Reagent Co. China) was of analysis grade and used without further purification.

Preparation

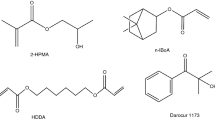

Poly(SA-co-AM) hydrogels with various SA-AM composition, were prepared by radical copolymerization (F = 0.1, 0.2, 0.3, and 0.5, F is defined as the mole fraction of SA in the total monomer). The total monomer concentration in ethanol solution was kept at 3.0 mol/L in the presence of 3.0 × 10−2 mol/L AIBN and 1.2 × 10−1 mol/L MBAA. As shown in Scheme 1, polymerization was carried out at 55 °C for 24 h under nitrogen atmosphere to form chemically crosslinked polymer gels. After polymerization, the gels were immersed in ethanol for 3 days to remove the unreacted monomers and uncrosslinked polymers and then soaked in distilled water for 7 days until reached an aqueous equilibrium state.

PSA (the homopolymer of SA) was prepared by the same procedure as the poly(SA-co-AM) hydrogels. The obtained PSA homopolymer was not gel but powder.

Swelling ratio

The swelling ratio of the poly(SA-co-AM) hydrogels was determined by gravimetric method at room temperature. Weight measurements were performed using three independent hydrogels for each F. The swelling ratio of the hydrogels was calculated by the following equation.

where parameters of W w and W d are the weights of fully swollen wet and vacuum dried hydrogels, respectively.

Shape recovery ratio

The thermoresponsive shape-memory effect of the poly(SA-co-AM) hydrogels was examined by a bending test: a straight strip of the hydrogel was folded at 60 °C, and then cooled to maintain the deformation. The deformed hydrogel was heated again at 60 °C, and it reverted to its initial form gradually. The final angle of the hydrogel was recorded after it had been steady. For each angle reported, at least three independent samples were used for each F. The shape recovery ratio was defined by following equation.

where θ f and θ i denote the final and initial angle of the hydrogels, respectively.

Characterization

The chemical structures of the poly(SA-co-AM) hydrogels and SA monomer were characterized using Fourier transform infrared spectroscopy (FT-IR) (Tensor 37, Bruker Co., Germany) between the frequency range of 2000 and 500 cm−1. X-ray diffraction (XRD) patterns of the copolymer hydrogels and PSA homopolymer powder were recorded using an X-ray diffractometer (D8-discover, Bruker Axs Co., Germany) with a Cu Kα radiation at 40 kV. Thermal analysis of the poly(SA-co-AM) hydrogels and PSA powder were determined by a differential scanning calorimeter (DSC) (200F3, Netzsch Co., Germany) with the temperature range 0–120 °C at a rate of 10 °C/min. All samples were heated first from 0 to 120 °C and then dropped to 0 °C. Dynamic mechanical analyses (DMA) (242C, Netzsch Co., Germany) of the hydrogels were performed under a nitrogen atmosphere from 0 to 60 °C at a heating rate of 5 °C/min with a oscillation amplitude of 1 Hz.

Results and discussion

The poly(SA-co-AM) hydrogels with F = 0.1, 0.2, 0.3, and 0.5, which were prepared by radical copolymerization using MBAA as a cross-linker, can swell in water with a definite shape, but the PSA homopolymer not hydrogel was obtained when F = 1.0.

Figure 1 illustrates the FT-IR spectra of the poly(SA-co-AM) hydrogels (F = 0.2 and 0.5) and SA monomer. The absorbencies at 1633 and 994 cm−1 of the SA monomer can be ascribed to the alkylene group, while the two peaks cannot be observed in the spectra of the poly(SA-co-AM) hydrogels at the same position. Compared to SA monomer, the absorption peaks at 1670 cm−1 of the hydrogels can be attributed to the stretching of amide carbonyl group in AM. Therefore, it is reasonable to assume that the poly(SA-co-AM) copolymer hydrogels had been prepared by the radical copolymerization. The strong absorbencies at 1735 and 723 cm−1 are observed in all samples, which can be assigned to the carbonyl bond of ester group and alkyl group in SA, respectively. With increase in the feed ratio of SA, the intensities of the two absorption peaks are enhanced, suggesting an increase in SA content of the copolymer hydrogels.

The swelling behaviors of the poly(SA-co-AM) hydrogels with different F were investigated at room temperature, and the results are shown in Fig. 2 (solid square). The swelling ratio of the poly(SA-co-AM) hydrogels gradually decrease with the increase in F value, that is, the capacity of containing water of the poly(SA-co-AM) hydrogels decrease with the increase in the content of SA which has the long side chain and hydrophobic carboxylic ester functional group.

To study the crystal structure of the poly(SA-co-AM) hydrogels, as shown in Fig. 3, X-ray diffraction of the hydrogels with various F was performed. It can be found that the PSA homopolymer shows a diffraction peak at 2θ = 21.3° which is equivalent to a crystal lattice spacing of 0.42 nm. The poly(SA-co-AM) hydrogels with all F show a diffraction peak at 2θ = 21.7°, which corresponds to a crystal lattice spacing of 0.41 nm. This diffraction is attributed to the crystalline state formed by the long alkyl side chain of SA [17–19]. The crystal lattice spacing of the hydrogels is smaller 0.01 nm than that of PSA homopolymer, indicating the short side chain monomer AM is introduced to increase the crystal density of the hydrogels.

To further clarify the order structure of the hydrogels, the DSC measurement was carried out and confirmed that these hydrogels melt and crystallize with change the temperature (Fig. 4). In all samples, hysteresis is observed, that is, the crystal melting temperature (T m) is higher than the crystallization temperature (T c). The melting and crystallization peaks of the poly(SA-co-AM) hydrogel with F = 0.1 are weak and the others are intense. The relative intensities of the melting peaks as well as the crystallization peaks of the hydrogels increase significantly with the increase in F. The transition temperatures (T m and T c) of the hydrogels with all F are about 35 and 27 °C, respectively, are lower than that of PSA polymer (T m: 50 °C and T c: 42 °C), but do not depend much on the copolymer composition. The results indicate that the crystal thermal stability of the poly(SA-co-AM) hydrogels decreases by incorporation of AM.

The large difference in the modulus below and above the transition temperature is the most significant factor to induce the shape-memory behaviors. Storage modulus and loss tangent (tan δ) curves of the poly(SA-co-AM) hydrogels with F = 0.2, 0.3, and 0.5 are shown in Figs. 5 and 6, respectively. It can be easily observed that the hydrogel with F = 0.2 exhibits the best performance among all samples. In Fig. 5, the storage modulus of the F = 0.2 hydrogel decreases abruptly from 10.4 to 0.8 MPa at the temperature from 20 to 50 °C. The peak temperature of the loss tangent of the F = 0.2 hydrogel is about 34 °C, as showed in Fig. 6.

The temperature at which the storage modulus decrease abruptly coincides with the peak temperature of the tan δ curves, and also corresponds to the crystal melting temperature (T m) of the hydrogels obtained by DSC measurement. This phenomenon indicates that the poly(SA-co-AM) hydrogels have large storage modulus at T < T m because of the crystal structure. However, the crystals of the hydrogels melt and the copolymers become amorphous at T > T m, resulting in the storage modulus decrease abruptly.

The thermoresponsive shape-memory effects of the poly(SA-co-AM) hydrogels with different F were examined by the bending test, and the shape recovery ratios are showed in Fig. 2 (open circle). It can be found that the hydrogel with F = 0.2, of which the shape recovery ratio can reach 97%, exhibits excellent shape-memory effect. The thermoresponsive shape-memory function of the poly(SA-co-AM) hydrogels is presumably due to two components, the SA and the crosslinked network structure. The crosslinked structure in the poly(SA-co-AM) hydrogels can determine the permanent shape, while SA which can form lamellar crystal in the hydrogels is the switching segments. The hydrogels cannot observe favorable shape recovery ratio when F < 0.2 because the lower content of SA in the copolymer. However, the recovery ratio of the hydrogels decrease with the increase in F value when F > 0.2. The more content of SA maybe make the copolymer hydrogels cannot form fine crosslinked network structure, therefore the hydrogels with F > 0.2 also could not show excellent shape recovery performance.

In Fig. 7, an interesting picture demonstrates the performance of shape-memory poly(SA-co-AM) hydrogel with F = 0.2. The hydrogel was stiffness at room temperature and the permanent shape of the sample was a rod. When it was heated up to 60 °C, the hydrogel became soft and could easily be deformed to the alphabet of ‘S’, then the deformed sample was cool down to room temperature and the temporary shape was fixed without loading. However, if the temperature was raised to 60 °C again, the hydrogel quickly returned to the initial shape in 20 s. This phenomenon is reversible and the recovery ratio can maintain more than 85% after 20 times.

Conclusion

A series of copolymer hydrogels poly(SA-co-AM) with various SA–AM composition were successfully synthesized through radical copolymerization of SA with AM. The swelling ratio of the poly(SA-co-AM) hydrogels gradually decreased with increase in the content of SA. The SA can form lamellar crystal in the copolymer hydrogels, and the T m of the hydrogels is about 35 °C which is lower than that of PSA. The prepared poly(SA-co-AM) hydrogels are satisfactorily thermoresponsive shape-memory materials base on the abruptly change in storage modulus with the temperature below and above the T m. The poly(SA-co-AM) hydrogel with F = 0.2, which can form fine crosslinked network structure, exhibits the highest shape recovery ratio as it has the optimum content of SA.

References

Feninat FE, Laroche G, Fiset M, Mantovani D (2002) Adv Eng Mater 4:91

Lendlein A, Kelch S (2002) Angew Chem Int Ed 41:2034

Zhu G, Liang G, Xu Q (2003) J Appl Polym Sci 90:1589

Mitsumata T, Gong JP, Osada Y (2001) Polym Adv Technol 12:136

Liu GQ, Ding XB, Cao YP (2005) Macromol Rapid Commun 26:649

Chang YW, Mishra JK, Cheong JH, Kim DK (2007) Polym Int 56:694

Auad ML, Contos VS, Nutt S (2008) Polym Int 57:651

Hornbogen E (2006) Adv Eng Mater 8:101

Lendlein A, Langer R (2002) Science 296:1673

Annette MS (2006) Macromol Rapid Commun 27:1168

Debdatta R, Karger-Kocsis J (2008) J Mater Sci 43:254. doi:10.1007/s10853-007-2176-7

Liu GQ, Ding XB, Cao YP (2006) Macromol Rapid Commun 27:1100

Matsuda A, Sato JI, Osada Y (1994) Macromolecules 27:6485

Osada Y, Matsuda A (1995) Nature 376:219

Tanaka Y, Kagami Y, Matsuda A, Osada Y (1995) Macromolecules 28:2574

Kagami Y, Gong JP, Osada Y (1996) Macromol Rapid Commun 17:539

Reyntjens WG, Duprez FE, Goethals EJ (1999) Macromol Rapid Commun 20:251

Plate NA, Shibaev VP, Petrukhin BS (1971) J Polym Sci 9:2291

Plate NA, Shibaev VP (1974) Macromol Rev 8:117

Acknowledgements

This work was financially supported by the National Natural Science Foundation of China (Grant Nos. 20574051 and 20774064), the Project of Science and Technical Development of China (Grant No. 2007AA03Z533), and the Specialized Research Fund for the Doctoral Program of Higher Education (Grant No. 20050058001).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Lin, X.K., Chen, L., Zhao, Y.P. et al. Synthesis and characterization of thermoresponsive shape-memory poly(stearyl acrylate-co-acrylamide) hydrogels. J Mater Sci 45, 2703–2707 (2010). https://doi.org/10.1007/s10853-010-4255-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-010-4255-4