Abstract

The effect of the NaOH content and the presence of sodium silicate activators on the formation of crystalline phases from metakaolinite-based geopolymers were studied by X-ray powder diffraction (XRD), Rietveld quantitative XRD, solid-state MAS NMR and SEM in samples synthesized with varying NaOH contents and different curing times at 40 °C. Geopolymers activated with NaOH alone with Si/Na ratios of 4/4 or less formed the crystalline zeolite Na–A (Na96Al96Si96O384·216H2O), but at ratios >4/4 nanosized crystals of another zeolite (Na6[AlSiO4]6·4H2O) were formed. The Si/Na ratio of 4/4 produces a product of greatest crystallinity. The addition of sodium silicate in addition to NaOH significantly reduces crystallite formation. The network units of all the materials containing NaOH and sodium silicate are essentially the same, namely, tetrahedral [SiO4] units coordinated through four bridging oxygens to four aluminium atoms [denoted as Q4 Si(4Al) units]. A templating function of the various silicate units of the sodium silicate molecules is suggested to occur in geopolymerization, which differs from the reaction route operating when NaOH alone is used as the activator. This templating function is responsible for the suppression of crystallization and the increase in strength of the geopolymers activated with sodium silicate.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Metakaolinite, obtained by thermal dehydroxylation of kaolinite, is a common starting material used for the synthesis of zeolites and geopolymers. The reaction mechanism, network structure and crystallization behaviour of zeolites hydrothermally synthesized from metakaolinite activated with alkali (e.g. NaOH solution) at >80 °C, with solids contents of about 10 wt% have been extensively studied and are well understood [1–3]. The results of these studies can briefly be summarized as follows:

-

(1)

The reaction products are mainly crystalline Na–A zeolite with some hydroxysodalite [2, 3].

-

(2)

When metakaolinite reacts with NaOH, the transformation of aluminate from the hexa, penta and tetra-coordination of the starting material into tetrahedral units is faster than the transformation of the silicate species [1].

-

(3)

The silicate species after dissolution from metakaolinite is solely the monomer Si(OH)4 [1].

-

(4)

The reactive Si–OH part of the Si(OH)4 reacts immediately with the tetrahedral aluminate groups to form an amorphous aluminosilicate gel [1].

-

(5)

This amorphous gel, once formed, converts to the crystalline zeolite Na–A by a structural rearrangement without further change in composition [1, 4].

-

(6)

The network structure of the amorphous gel and the crystalline zeolite (Na–A) are essentially the same, i.e. Si is Q4(4Al), Al is Q4(4Si) and the Si/Al ratio is 1:1. The crystalline Na–A zeolite has a double four-membered ring structure [1, 5, 6].

-

(7)

29Si MAS NMR spectroscopy shows a high-field shift in going from the amorphous gel (δSi = −85 ppm) to crystalline zeolite (δSi = −89.3 ppm), and the 27Al spectra show a slight change in the tetrahedral resonance position from δAl = 60 ppm in the amorphous gel to δAl = 59 ppm in the crystalline zeolite phase [1, 4, 7].

In contrast with crystalline zeolites, metakaolinite-based geopolymers, which are generally produced by the reaction of metakaolinite with sodium hydroxide and sodium silicate solutions at <50 °C and solids contents ~50 wt%, are mainly X-ray powder diffraction (XRD)-amorphous. The possible existence of a crystalline component has largely been overlooked, though the network structure of the amorphous aluminosilicate gel has been examined intensively, especially by MAS NMR [8–12]. It is known that, depending on the activator content and type, the geopolymer can contain various silicate units (Q1, Q2, Q3 and Q4) substituted by varying numbers of aluminium atoms, but the typical peak in 29Si NMR spectrum at −87 ppm is usually assigned as Q4(4Al) [12], or, where the amount of Al substitution is less than 4, the position of this peak can move to −92 ppm [8, 10]. Aluminium is always in a fourfold coordination (the 27Al resonance is at 58 ppm in completely reacted materials [8, 10]). It has also been reported [12, 13] that the dissolution of aluminium from metakaolinite is faster than silicon, and condensation between aluminate and silicate species is faster than that of between the silicate species themselves. Van Deventer and co-authors [14] have suggested that XRD-amorphous geopolymers are actually composed of nanometre-sized crystalline zeolite structures, the crystallinity of which affects the mechanical properties.

While NMR analysis provides information about the local chemical environments of the atoms, XRD gives information about the nature and structure of any crystalline phases present. In this study, we have synthesized geopolymers from metakaolinite with various amounts of NaOH, cured for varying periods, to produce materials ranging from amorphous to crystalline. XRD and MAS NMR techniques were used to monitor the evolution of the crystalline phases and the structural changes occurring during the reaction. Sodium silicate was also added as an activator to some samples, and the results compared with those of sodium hydroxide alone.

Experimental procedure

Material preparation

The metakaolinite (MetaMax, Engelhard Corp., USA, particle diameter D50 = 6.1 μm, BET specific area 10.2 m2/g) had the composition (wt%) taken from supplier’s specification, of 52% SiO2, 43.8% Al2O3, 1.63% TiO2, 0.7% Fe2O3, traces of Na2O and K2O and a LOI of 0.107%. NaOH pellets (>99% purity) were from Applichem (Germany). The batch compositions are listed in Table 1 (S1–4). The NaOH was dissolved in distilled water and cooled to ~20 °C before mixing with the metakaolinite and mechanically stirred to a uniform paste. This paste was sealed in a plastic bag and cured at 40 °C for varying lengths of time from 2 h to 10 days, then finely ground for analysis. For comparison, other samples (S5–7 in Table 1) were prepared with the addition of sodium silicate solution (Orica, NZ, grade D, molar ratio SiO2/Na2O ≈ 2:1, solids content 44 wt%). In these samples, the sodium silicate solution was mixed with the NaOH prior to the addition of the metakaolinite powder.

Analysis techniques

XRD patterns were obtained with a Philips PW1700 series computer-controlled diffractometer with a graphite monochromator using Co-Kα radiation, from 10 to 100° (2θ) at 0.025° step intervals, counting for 5 s per point. Quantitative XRD phase analysis was carried out by the Rietveld method using SiroQuant (version 2.5) software and data determined at step intervals of 0.04° with counting times of 16 s per point. The internal standard was ~20 wt% crystalline alumina (676) supplied by the US National Institute of Standards and Technology.

Multinuclear MAS NMR spectra were acquired at 11.7 T using a Bruker Avance 500 spectrometer. 29Si spectra were recorded at a spectrometer frequency of 99.924 MHz with a 5-mm Doty MAS probe spun at 4 kHz, using a 6-μs (π/10) pulse, a 30-s delay and 20–60 scans, the spectra being referenced to tetramethylsilane. 27Al spectra were acquired at a spectrometer frequency of 130.24 MHz, with a 4-mm Doty MAS probe spun at 10–12 kHz using a 1-μs (π/10) pulse and a 1-s delay, the spectra referenced to Al[(H2O)6]3+ in 1 M aqueous AlCl3 solution. A 29Si liquid NMR spectrum of sodium silicate solution was acquired from the same spectrometer with slow sample spinning (15 Hz), a 90° pulse, a 3-s delay and 3,200 scans.

Samples for SEM were fractured and carbon coated. The SEM images were obtained using a LEO440 microscope (LEO Electron Microscopy Ltd., Oberkochen, Germany) from the internal pore surfaces or fracture surfaces, to determine the size and shape of the crystals.

Results and discussion

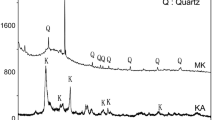

Crystallinity

The metakaolinite is predominantly amorphous (Fig. 1) with small amounts of anatase (TiO2) and quartz (SiO2) impurities (97% amorphous phases, 2.4% anatase, 0.6% quartz, according to the Rietveld XRD analysis). When metakaolinite was mixed with NaOH only (S1–4), the nature and quantity of the crystalline phases formed and their crystallization rate is significantly affected by the NaOH content. The quantity of the crystalline phases in samples cured at varying times, determined by the Rietveld method, is summarized in Table 2 and plotted in Fig. 2. The typical XRD patterns of samples S2–4 cured for various times are shown in Fig. 3. The crystallization onset times, estimated from the XRD results for samples S1–4, are summarized in Table 3, which includes samples S5–7 for comparison.

Tables 2 and 3 indicate that the crystallization of zeolite phases from metakaolinite activated with NaOH alone depends critically on the Si/Na ratio. Sample S3 (Si/Na = 4/4) begins to form significant quantities of zeolite Na–A (Na96Al96Si96O384·216H2O) after about 1.5 days. The amount of this phase increases steadily at longer curing times, reaching 90% after 10 days (Fig. 2). In contrast, sample S2 with a lower Na content (Si/Na = 4/3) begins to form small amounts of zeolite Na–A more slowly after 3 days. Reducing the Na level still further to Si/Na = 4/2 (sample S1) produces only 1.2% zeolite Na–A in 10 days. The molar composition of sample S3 (Si/Na = 4/4) facilitates the formation of zeolite Na–A by accurately satisfying both the composition requirement of this zeolite and the structural requirements of its Q4 Si(4Al) units, in which the substitution of one Al atom for one Si requires one Na+ for charge balance.

When the NaOH level is greater than 4/4 (as in sample S4 where Si/Na = 4/6), rapid crystallization occurs in about 2.5 h, but the product is an unnamed hydrosodalite-type zeolite, Na6[AlSiO4]6·4H2O. The quantity of this crystalline phase reaches ~50% after curing for 2.5 h, and remains at this level thereafter. The crystal size of this zeolite, determined using SiroQuant XRD software, is ~21 nm, and is independent of the curing time, from 3 h to 10 days. This small crystallite size is also consistent with the broadness of the XRD peaks of this phase (Fig. 3, S4). Thus, excess NaOH significantly reduces the quantity of the crystalline phase and alters its composition, as well as shortening the time to onset of crystallization and reducing the crystallite size. The reduction in crystallinity at high NaOH contents (Si/Na > 4/4, as in S4) is due to the rapid formation of large numbers of nuclei (“burst” nucleation) which hinders their growth into crystals.

Crystallization is also drastically suppressed by the addition of sodium silicate. Samples S5 and S6 contain the same NaOH concentrations as samples S2 and S3, respectively, but also contain sodium silicate. In these samples, the Si source is both the metakaolinite and the sodium silicate, and the Na source is both the NaOH and the sodium silicate, but the Si/Na ratios are only slightly different in samples S5 (Si/Na = 4/3.22) and S6 (Si/Na = 4/3.97), compared with samples S3 (Si/Na = 4/3) and S4 (Si/Na = 4/4). However, the XRD patterns show that both S5 and S6 are nearly 100% amorphous (the amount of zeolite Na–A in sample S6 is <0.5%), ignoring the anatase and quartz impurities. Where sodium silicate in the same concentration is the sole activator, as in sample S7, very little reaction occurs, as evidenced by the 29Si and 27Al NMR spectra (a slight increase in the 57.7 ppm 27Al NMR peak) and the position of the XRD-amorphous bump (Fig. 4). Despite the lack of reaction with sodium silicate alone, its presence in even a small amount in combination with NaOH is effective in altering the mechanism of crystallization, as discussed in the section “Differences in the reaction mechanisms of metakaolinite with NaOH and sodium silicate”.

Network structure deduced from NMR spectroscopy

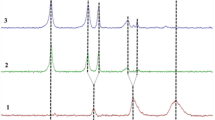

Figure 5 shows the 29Si and 27Al MAS NMR spectra of metakaolinite and the geopolymers S2–4 cured for two times corresponding to the amorphous and crystalline states, and sample S6 cured for 10 days, corresponding to amorphous state only. The peak at −103 ppm in the 29Si metakaolinite spectrum is due to Q3(1Al) [6, 9] or Q4(1Al) [7, 12], and the 27Al NMR spectrum contains resonances due to Al(VI) (4.1 ppm), Al(V) (29 ppm) and Al(IV) (58 ppm) [15].

The 29Si spectra (Fig. 5) show that the reaction products of the geopolymers all contain a resonance within the shift range for Q4(4Al) units, but their centre-of-gravity positions change from −84 ppm in the amorphous samples to −89 ppm upon crystallization. A downfield change occurs in the tetrahedral 27Al resonance position, from 60.4 ppm in the amorphous state to 58.5 ppm in the crystalline. This result suggests that the amorphous phase and the crystalline zeolite phases contain the same structural units irrespective of any difference in molecular formulae of the crystalline phase.

The crystallographic structure and network topology of zeolite Na–A, the crystalline phase formed in samples S2 and S3, is well known. The similarity of the 29Si and 27Al MAS NMR spectra of sample S4 (cured for 5 days) and samples S2 and S3 (cured for 5 days) suggests that the unnamed crystalline zeolite Na6[AlSiO4]6·4H2O [16] formed in sample S4 has the same network structure as crystalline zeolite Na–A.

Comparison of the 27Al and 29Si spectra of sample S1 (cured for 10 days), S2 (cured for 2 days), S2 (cured for 5 days) and S3 (cured for 1 day) with the spectra of metakaolinite shows that all the aluminate has been converted to the typical fourfold geopolymer coordination for the materials in the curing periods, but some of the Si species from the starting metakaolinite (the resonances from −100 to −108 ppm) remain. This suggests that the transformation of the Al from the metakaolinite to the geopolymer is faster than the transformation of Si. This observation also applies to sample S7 (Fig. 4) and is consistent with previously reported results for a metakaolinite-based zeolite [1] and metakaolinite-based geopolymer [12].

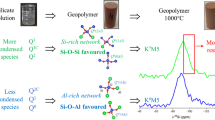

Differences in the reaction mechanisms of metakaolinite with NaOH and sodium silicate

The results of “Network structure deduced from NMR spectroscopy” section indicate that the silicate network units in samples S1–4 are Q4 (4Al), irrespective of their amorphous or crystalline content. This suggests that when NaOH is the activator, the Si and Al species dissolve from the metakaolinite reactant, forming the transient species Si(OH)4 [1, 12] and Al(OH)4 [1, 12, 17] which assemble into nuclei containing Q4(4Al) units. These Q4(4Al) nuclei can then grow in an orderly manner to form zeolite-type crystallites with no change in composition during the nucleation and growth stages of the process. This mechanism has previously been proposed for zeolite formation [1].

In contrast, when sodium silicate is the activator, a variety of Q0, Q1, Q2 and Q3 silicate units are present in the sodium silicate (Fig. 6) [9, 10] and act as templates for condensation with the Al–OH groups from the transient Al(OH)4 species dissolved from the metakaolinite. These aluminate species are characterized by a 27Al MAS NMR resonance at δ = 78 ppm [12, 17]. The Si–O bonds of sodium silicate oligomers with more than one silicon atom (i.e. Qn, where n > 0) can rupture to form further active Si–OH groups for attachment to the Al atoms. These Al-containing oligomers can retain their 29Si NMR spectral signature for long time (up to 21 h [8]) before slowly condensing to form larger oligomers and eventually geopolymers. Thus, the reaction of metakaolinite with sodium silicate involves (i) the dissolution of Si and Al from the metakaolinite, (ii) breakup of the large oligomeric units of the sodium silicate, (iii) attachment of Al species to the sodium silicate oligomers and (iv) the growth of geopolymers by condensation. The process involves changes in the composition, molecular size, bond strength, bond angle and so on. The nominal Si/Al ratio determines the final 29Si resonance position in the MAS NMR spectrum of the fully reacted material. The structural changes involved in this process are illustrated by the 29Si and 27Al MAS NMR spectra reported by Singh et al. [8]. The templating function of the soluble sodium silicate has been further confirmed by experiments using Na4SiO4 containing only Q0 monomeric orthosilicate units [9] which gave a geopolymer product containing only a 29Si MAS NMR resonance at −87 ppm, corresponding to Q4 Si(4Al) units. The long length and flexibility of soluble sodium silicate molecules hinders their condensation into units with long range ordering; consequently, materials synthesized from sodium silicate tend to be amorphous.

This suggested templating role of sodium silicate solution in geopolymer synthesis differs from previous concepts that the function of the sodium silicate is only to provide additional soluble silicate, hence influencing the Si/Al/Na ratio and thus crystallization [18]. The templating concept is also at variance with the previous view that the addition of soluble silicate solution does not fundamentally change the reaction mechanism [13, 19], although the alkaline function of the alkali silicate in the dissolution of the metakaolinite remains valid.

The eventual fate of the silicon dissolved from metakaolinite by the use of sodium silicate as the activator remains unclear. 29Si and 27Al MAS NMR spectroscopy [9] indicates that after 21 h the 29Si spectrum remains unchanged but the Al is fully converted to [AlO4]. This suggests that after their removal from the metakaolinite, the Si and Al species do not react to form a zeolitic material (which would have a 29Si NMR signature at about −85 ppm); thus, the reaction mechanism operating with NaOH activator is not occurring. It is possible that the Si species derived from the metakaolinite can link to the silicate oligomers from the soluble sodium silicate without altering the structural or 29Si NMR spectral features of the latter.

When NaOH and sodium silicate are used together as activators, their functions are complementary. However, it is evident from the present samples S5 and S6 that small amounts of sodium silicate can dominate the mechanism. Moreover, the dissolution of Al is accelerated by the presence of NaOH, as evidenced by the complete reaction occurring in samples S5 and S6 (see “Crystallinity”), in contrast with the incomplete reaction in sample S7.

SEM morphology

The SEM micrographs (Fig. 7) clearly show the presence of cubic crystals of zeolite Na–A, and the higher degree of crystallinity in sample S3 than in S2. No crystallites are visible in sample S4, reflecting the very small size (~21 nm) of the unnamed zeolite in this sample. The SEM micrographs of samples S5 and S6 (Fig. 8a, b), synthesized using a combination of NaOH and Na-silicate activators, show no crystal morphology, but appear to be of denser texture than the samples synthesized with NaOH only (Fig. 7a, b) and are hence more resistant to surface scratching. Neither the lath-like structures of Fig. 8a nor the flower-like features in Fig. 8b could be analysed by energy dispersive X-ray spectrometry because of their small size, but the flower-like crystals are probably Na2CO3 formed by atmospheric carbonation of the excess NaOH migrating from the interior to the surface of the specimen [17]. The unreacted relicts of metakaolinite visible in sample 7 (Fig. 8c) are evidence that geopolymerization has not fully occurred in this sample.

Conclusions

Four geopolymers were synthesized at 40 °C by the reaction of metakaolinite with varying amounts of NaOH activator, giving Si/Na molar ratios of 4/2, 4/3, 4/4 and 4/6. The formation of crystallites in the samples, studied by quantitative XRD, depended strongly on the NaOH content. At compositions corresponding to Si/Na ratios of 4/4 and less, zeolite Na–A crystallites (Na96Al96Si96O384·216H2O) were formed. The crystallization rate increased with increasing NaOH content, and the proportion of the crystalline phase gradually increased at longer curing times, reaching 90% after 10 days where Si/Na = 4/4. At higher NaOH contents (Si/Na = 4/6), crystallization occurred rapidly after about 2.5 h, forming a hydrosodalite with the formula Na6[AlSiO4]6·4H2O; however, the proportion of this crystalline phase remained at only about 50% even after very long curing times. The addition of even small amounts of sodium silicate to the NaOH activator drastically suppresses crystallization. The network units are essentially same in both the amorphous and crystalline materials produced by activation with NaOH or a combination of NaOH and sodium silicate, and were identified by solid-state 29Si and 27Al MAS NMR as Q4(4Al) units. The Si and Al dissolved from metakaolinite activated by NaOH form transient states of Al(OH) and Si(OH) which polymerize into zeolite Q4(4Al) crystallites. However, when sodium silicate is used as an activator, the variety of silicate units (Q0, Q1, Q2 and Q3) of sodium silicate act as templates for aluminate to assembly. The condensation between the Al–OH from metakaolinite and the Si–OH of sodium silicate is slow, and the reaction product is amorphous.

References

Rocha J, Klinowski J (1991) J Chem Soc Faraday Trans 87:3091

Benharrats N, Belbachir M, Legrand AP, D’espinose De La Caillerie J-B (2003) Clay Miner 38:49

Heller-Kallai L, Lapides I (2007) Appl Clay Sci 35:99

Engelhardt G, Fahlke B, Mägi M, Lippmaa E (1985) Zeolites 5:49

Lippmaa E, Mägi M, Samoson A, Tarmak M, Engelhardt G (1981) J Am Chem Soc 103:4992

Thomas JM, Fyfe CA, Ramdas S, Klinowski J, Gobbi GC (1982) J Phys Chem 86:3061

Engelhardt G, Fahlke B, Mägi M, Lippmaa E (1983) Zeolites 3:292

Singh PS, Bastow T, Trigg M (2005) J Mater Sci 40:3951. doi:https://doi.org/10.1007/s10853-005-1915-x

Singh PS, Trigg M, Brugar I, Bastow T (2005) Mater Sci Eng A 396:392

Barbosa VFF, MacKenzie KJD, Thaumaturgo C (2000) Int J Inorg Mater 2:309

Fletcher RA, MacKenzie KJD, Nicholson CL, Shimada S (2005) J Eur Ceram Soc 25:1471

Weng L, Sagoe-Crentsil K (2007) J Mater Sci 42:2997. doi:https://doi.org/10.1007/s10853-006-0820-2

Sagoe-Crentsil K, Weng L (2007) J Mater Sci 42:3007. doi:https://doi.org/10.1007/s10853-006-0818-9

Provis JL, Lukey GC, van Deventer JSJ (2005) Chem Mater 17:3075

MacKenzie KJD, Smith ME (2002) Multinuclear solid-state NMR of inorganic materials. Pergamon Materials Series, vol 6. Pergamon-Elsevier, Oxford

Felche J, Luger S, Baerlocher C (1986) Zeolites 6:367

Duxson P, Lukey GC, Separovic F, van Deventer JSJ (2005) Ind Eng Chem Res 44:832

Duxson P, Lukey GC, van Deventer JSJ (2007) J Non-Cryst Solids 353:2186

Duxson P, Fernández-Jiménez A, Provis JL, Lukey GC, Palomo A, van Deventer JSJ (2007) J Mater Sci 42:2917. doi:https://doi.org/10.1007/s10853-006-0637-z

Acknowledgement

We are indebted to Martin Ryan for his assistance with the XRD quantitative analysis.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zhang, B., MacKenzie, K.J.D. & Brown, I.W.M. Crystalline phase formation in metakaolinite geopolymers activated with NaOH and sodium silicate. J Mater Sci 44, 4668–4676 (2009). https://doi.org/10.1007/s10853-009-3715-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-009-3715-1