Abstract

A new organic–inorganic hybrid sorbent was prepared by a double-imprinting approach for the selective separation of Cu(II) from aqueous solution. In the prepared hierarchically imprinted sorbent, both Cu(II) and surfactant micelles (cetyltrimethylammonium bromide) were used as templates. The sorbent was prepared through self-hydrolysis, self-condensation, and co-condensation of the crosslinking agent (tetraethoxysilane) and the functional precursor (3-aminopropyltrimethoxysilane) in an alkaline media followed by gelation. The adsorption property and selective recognition ability of the sorbents were studied by equilibrium-adsorption method. Results showed that in the presence of Zn(II) the biggest selectivity coefficient of the imprinted sorbents for Cu(II) was over 500, which is much higher than those of non-imprinted sorbents. The largest relative selectivity coefficient (k′) of the ion-imprinted functionalized sorbent between Cu(II) and Zn(II) was over 500. The uptake capacities and the selectivity coefficients of the hierarchically imprinted sorbent were much higher than those of the sorbent prepared without CTAB template. Furthermore, the new imprinted sorbent possessed a fast kinetics for the removal of Cu(II) from aqueous solution with the saturation time less than 10 min, and could be used repeatedly. This sorbent has been successfully applied to the separation and determination of the trace Cu(II) in real water samples and those spiked with standards. This new sorbent can be used as an effective solid-phase extraction material for the highly selective preconcentration and separation of Cu(II) in environmental samples.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Molecular imprinting is an emerging technique for preparing polymeric materials possessing highly selective and affinitive properties. The method involves complexation in solution of a target compound (template) with functional monomers, through either covalent or non-covalent bonds followed by a polymerization reaction with an excess of crosslinking agent. Removal of the template molecule from the polymer by extracting with solvents leaves specific recognition sites, which are complementary to the template in terms of its shape, size, and functionality in the polymer network. Therefore, molecularly imprinted polymers (MIPs) show higher selectivities and affinities in rebinding the template than its analogues and other structurally unrelated compounds [1–4]. Ion-imprinted polymers (IIPs) are similar to MIPs, but they recognize given ions after imprinting [5]. There are three steps involved in ion-imprinting process: (i) complexation of metal ion (template) to polymerizable ligand; (ii) polymerization of this complex; and (iii) removal of metal ion after co-polymerization. After removal of target ion, the prepared polymer is put into a solution containing metal ions from which the imprinted ion should thus be preferentially extracted. In ion-imprinting process, the selectivity of a polymeric adsorbent is based on the specificity of the ligand, on the coordination geometry and coordination number of the ions, on their charges and sizes [6, 7].

Due to biological and environmental impact of copper ion, the development of new methods for selective separation, purification, and determination of Cu(II) is of continuing interest. There are a number of previously published papers dealing with the preparation of ion selective imprinted polymers for Cu(II) [8–15]. Very recently, Shamsipur et al. [8] have reported the preparation of copper(II) ion-imprinted polymer material for separation of Cu(II) in aqueous solutions by using 5,6,14,15-dibenzo-1,4-dioxa-8,12-diazacyclopentadecane-5,14-diene and 2-vinylpyridine as a non-vinylated chelating agent and a functional vinyl monomer, respectively. Dakova et al. [9] reported the synthesis of microspheric Cu(II) IIPs using methacrylic acid as a monomer, trimethylolpropane trimethacrylate as a crosslinking agent and 4-(2-pyridylazo)resorcinol as a specific Cu(II) ligand. Dai et al. [10] have reported a design for copper(II)-selective sites on mesoporous sorbent through hierarchical double imprinting. Say et al. [11] have developed IIPs based on poly(EGDMA/methacryloylamidohitidine/Cu(II)) microparticles through dispersion polymerization and reported higher selectivity coefficients compared to non-imprinted polymers for Cu(II) over Zn(II), Co(II), and Ni(II) ions. Birlik et al. [12] have synthesized ion-imprinted polymers for solid phase extraction of copper using chitosan-succinate as a metal complexing polymer. A Cu(II)-imprinted interpenetrating polymer network gel was synthesized by the ionic imprint polymer technique [13]. Baghel et al. [14] have also synthesized IIPs for Cu(II) using a simple acrylamide both as a monomer and a complexing ligand without using an additional complexing agent. ESR method has been used for the investigation of the complex formation processes within the sorbents imprinted with Cu(II) [15].

In this study, a type of new Cu(II) ion-imprinted sorbent was prepared, for the first time, by a hierarchically double-imprinting method with both copper ions and surfactant micelles (cetyltrimethylammonium bromide, CTAB) as templates, 3-aminopropyltrimethoxysilane (APTS) as functional monomer, and tetraethoxysilane (TEOS) as crosslinking agent. The characteristic of these sorbents was evaluated by infrared (IR) spectra. The acidity of the solution on their adsorption capacities was studied by the static-adsorption method. In addition, their adsorption kinetics, selective adsorption abilities, and reutilization were also investigated. Finally, the new sorbents were successfully applied to the separation and determination of the trace Cu(II) in real water samples and those spiked with standards.

Experimental

Chemicals

APTS was bought from Acros Orgnics (Fair Lawn, NJ). CTAB was acquired from Tianjin Jinke Fine Chemical Research Institute (Tianjin, China). Tetraethoxysilicate (TEOS) was purchased from Wuhan University Silicone New Material Co., Ltd. (Wuhan, China). CuSO4 · 5H2O, ZnCl2, sodium acetate, nitric acid, and acetic acid were purchased from Sinopharm Chemical Reagent Co., Ltd (Shanghai, China). The pH of the solutions was adjusted using the following buffers: sodium acetate/hydrochloric acid for pH 2–3.5, sodium acetate/acetic acid for pH 4–6.5, and KH2PO4/NaOH for 7–8. All reagents used were of the highest available purity and of at least analytical grade. Doubly deionized water (DDW) was used throughout this work.

Apparatus

FT-IR spectra (4000–400 cm−1) in KBr were recorded using an Avatar-360 spectrometer (Nicolet, Waltham, USA). A TAS-990 atomic absorption spectrophotometer (Pgeneral, Beijing, China) was used for determining the unextracted Cu(II) and Zn(II). The instrumental parameters were those recommended by the manufacturer. Hollow cathode lamps were used as the radiation sources at 324.7 (Cu), 213.9 nm (Zn), respectively, with a current of 3.0 mA (Cu and Zn) and a 0.4 nm slit width (Cu and Zn).

Preparation of ion-imprinted sorbent

To prepare the Cu(II) ion-imprinted sorbent, the typical procedure involves mixing CTAB, CuSO4 · 5H2O, APTS, DDW, and base (1 M NaOH) in relative molar ratios of 0.2:0.12:0.5:106:0.38. The mixture was stirred for 48 h and then refluxed at 90 °C for 12 h. The solid blue product was recovered by filtration and then refluxed in ethanol/HNO3 to extract the surfactant templates with ethanol and to strip the copper ion templates by HNO3. The final material was washed with large amounts of 1 M HNO3 to ensure the complete removal of the copper ion templates. The resulting gels were washed with 1 M NaOH till the pH of filtrate to 7.0, then washed with copious amount of DDW, and dried under vacuum at 60 °C for 24 h. The non-imprinted sorbent was prepared using an identical procedure without the addition of the Cu(II) template. The imprinted sorbent without CTAB was also prepared using an identical procedure without the addition of the CTAB.

Static adsorption test

In the competitive adsorption of Zn(II)/Cu(II), a 0.1 g portion of sorbent was equilibrated with 10 mL of the buffered solutions (pH 5.5 acetic acid/sodium acetate buffer) containing 2 mM of Cu(II). The mixtures were mechanically shaken for 20 min at room temperature, and then filtrated. The filtrate was measured for unextracted Cu(II) and Zn(II) by a TAS-990 atomic absorption spectrophotometer.

Desorption procedure

A 0.1 g portion of imprinted sorbent was equilibrated with 10 mL of the buffered solutions (pH 5.5 acetic acid/sodium acetate buffer) containing Cu(II). The mixtures were mechanically shaken for 20 min at room temperature, and then filtered. After that, the imprinted sorbent with loaded Cu(II) was eluted with DDW, 1 M HNO3, DDW in sequence, and the desorbed Cu(II) was subsequently measured by the atomic absorption spectrophotometer.

Recycling test

A 0.1 g portion of Cu(II)-imprinted sorbent was packed into an empty SPE polypropylene tube (6.5 × 1.0 cm i.d.) and compressed to a volume of approximately 0.2 mL. Polypropylene frits were located above and below the sorbent bed for avoiding the leakage of absorbent. Then, 10 mL of buffer (pH 5.5 acetic acid/sodium acetate buffer) containing 2 mM of Cu(II) and 10 mL DDW was allowed to pass through the bed via gravity in sequence. The unextracted Cu(II) was measured by atomic adsorption spectrophotometer. The sorbents were washed in sequence with 1 M HNO3 and DDW, and then dried under vacuum at 60 °C for 12 h before next recycling.

Sample preparation and analysis

Tap water samples were filtered through a P10 glass filter prior to use. The usual general precautions were taken to avoid contamination [16]. The lake water samples were collected in polyethylene bottles from Linghu Lake (Anqing, China) in July 2008. The surface river water samples were collected in polyethylene bottles from a dirty region of Changjiang River (Anqing, China) in July 2008. The polyethylene bottles were cleaned with detergent, DDW, dilute nitric acid and DDW in sequence. To oxidize organic matter, such as humic acid, the lake water and river water samples were digested by an oxidizing UV-photolysis in the presence of 1% H2O2 using a low pressure Hg-lamp which was integrated into a closed quartz vessel [17, 18].

An amount of 10 mL of the above samples was mixed with 0.1 g of Cu(II) ion-imprinted sorbent, and the adsorbed metal ions were eluted and analyzed according to the desorption procedure.

Results and discussion

Synthesis and characterization of sorbent

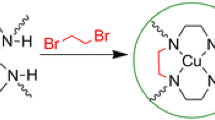

Synthesis of sorbent

The schematic representation of the synthesis route and ion-recognition are shown in Fig. 1. the complexes were first formed between metal ions and functional ligands (–NH2) of APTS in the synthesis process, then the imprinted silica gels were formed via the hydrolysis, co-condensation and gelation of the complexes and TEOS in surfactant micelle solution in the presence of NaOH. Finally, the copper ion and the surfactant incorporated in the sorbent were removed by acid leaching and ethanol extraction, respectively.

IR spectra of sorbent

To confirm the presence of APTS in the imprinted sorbents, the IR spectra of blank silica obtained from the gelation of TEOS, the non-imprinted sorbent, and the Cu(II) ion-imprinted sorbent were measured as shown in Fig. 2. In the three spectra, the observed peaks around 1057 and 961 cm−1 are attributed to Si–O–Si and Si–O–H stretching vibrations, respectively, and the bands around 794 and 458 cm−1 also resulted from Si–O vibrations, indicating the occurrence of silica matrices in the three materials. On the other hand, when compared with the IR spectrum of blank silica as shown in Fig. 2, there are broad –NH2 stretching at 3250–3450 cm−1, aliphatic C–H around 2925 cm−1 and the –CH2 bend bands about 1472 cm−1 in the IR spectrum of the Cu(II) ion-imprinted sorbent, showing the presence of APTS in the sorbent. Furthermore, the IR features of the Cu(II) ion-imprinted sorbent and the non-imprinted sorbent have the very similar appearances of the major bands, showing that –NH2 was successfully grafted onto the surface of blank silica.

Absorption behaviors of sorbent

Effect of pH on the absorption behaviors

The effect of the solution acidity on the static adsorption capacity was also studied as shown in Fig. 3. The percentage of Cu(II) extracted increased obviously as the pH of the aqueous solution increased from 2 to 8, while it varied little with further increase in pH. When the pH was below 3.5, only less than 40% of Cu(II) was extracted onto the imprinted sorbent. This might be due to the protonation of the amine in the binding site, which reduced the binding ability of the monoamine group involved in chelating formation with the Cu(II) in aqueous solution [19], and when pH larger than 8, precipitation of the metal hydroxide is expected. As shown in Fig. 3, the optimum pH for extraction of Cu(II) from aqueous solution ranged from 5.5 to 7.5. Within this pH range, neither precipitation of the metal hydroxide nor the protonation of the amine as the active chelating groups occurred obviously. Therefore, the acetic acid/sodium acetate buffer solution of pH 5.5 was selected for the adsorption test in this work.

Binding selectivity of the sorbent

To investigate the adsorption selectivity of the imprinted sorbent, the competitive ion recognition studies were performed here. Compared with Cu(II), Zn(II) ion has the same charge, similar size, and additionally Zn(II) ion also binds well with the amine ligand [20], so it was chosen as the competitive species. Table 1 summarizes the percentage of the adsorbed metal ions, uptake capacity, distribution coefficient (K d), selectivity coefficient (k) of the sorbent toward Cu(II), and the relative selectivity coefficient (k′) obtained in these competitive ion-binding experiments between Zn(II) and Cu(II) ions. A comparison of the k values for the imprinted sorbent prepared with the addition of CTAB with the other sorbents shows a significant increase in k for Cu(II) through imprinting, with the largest k and k′ values over 500 in Zn(II)/Cu(II) competitive adsorption. And this imprinted sorbent also shows high uptake capacity and high selectivity for Cu(II) in river water samples spiked with standard Zn(II) (or Ca(II), Mg(II), Na(I)) and Cu(II) ions. On the other hand, the imprinted sorbent prepared without addition of CTAB has lower uptake capacity and lower relative selectivity coefficient (k′) below 5, while the non-imprinted sorbent has lower selectivity coefficient k. This could be attributed to the flexibility of the cavity and the specific binding sites containing functional groups in a predetermined orientation [20]. Although Zn(II) ion has the same charge, similar size, and also binds well with the amine ligand in comparison with Cu(II), the Cu(II) ion-imprinted sorbents exhibit much higher selectivity for Cu(II) than Zn(II) due to the imprinting effect, in which the coordination geometry selectivity might play a important role, because the Cu(II)-imprinted sorbent can provide the ligand groups arranged in a suitable way required for coordination of Cu(II).

Moreover, kinetic experiments of Cu(II) sorption on the imprinted sorbent were carried out. In total, 0.1 g of the imprinted sorbent was added to 10 mL of 2 mM Cu(II) aqueous solution buffered to pH 5.5. The mixture was mechanically shaken for 2–30 min at room temperature. Then, the sorbent was filtered off rapidly and washed with DDW. The excess unextracted Cu(II) in the filtrate was determined by atomic absorption spectrophotometer. Figure 4 shows the uptake kinetics of copper ions. It is clear that the velocity of adsorption is fairly rapid. Within 5 min, about 95% of Cu(II) was adsorbed onto the imprinted sorbent.

Recycling of the sorbent

To test the recyclability of the sorbent, 0.1 g of Cu(II) ion-imprinted sorbent was used to extracted Cu(II) through extraction/striping cycles. The stripping agent used in this experiment was 1 M HNO3. The results of the recyclability studies are shown in Table 2. The imprinted sorbent was found to be able to remove 98 ± 2% of the Cu(II) from solution through six extraction cycles. The capacity of the sorbent in these five recycles was 98 ± 2% of the fresh sorbent. Therefore, the Cu(II) ion-imprinted sorbent showed excellent reusability and stability towards Cu(II).

Sample analysis

Calibration curve

The calibration was performed by using six Cu(II) standards at different concentrations in the range of 0–1 mg L−1. The obtained linear regression equations and correlation coefficients (r) for Cu(II) were A = 0.18726 c Cu – 0.00315 and r = 0.99977, correspondingly, where A was the absorbance of the Cu(II) standards and c Cu was the concentrations of Cu(II) added with the unit of mg L−1. Results showed that the linear range was relatively wide for the determination of Cu(II) in environmental water samples.

Application to water samples

The proposed method was then applied for the separation and determination of Cu(II) in tap water, lake water, and river water samples. The standard addition method was applied to check the selectivity of the ion-imprinted sorbent for Cu(II) against matrix elements, and to determine the accuracy and precision of the new extraction method. The results are listed in Tables 3 and 4. When the water samples spiked with Cu(II) standards of different concentrations (10, 15, 20, and 50 μg L−1) were treated by the imprinted sorbents and then desorbed by 1 M HNO3, the recoveries were all in the range of 93–104% with RSD of 1.1–3.6%, demonstrating that the interference species in the matrix were eliminated satisfactorily after extraction and preconcentration procedure. The results also indicate the suitability of the present Cu(II) imprinted sorbent for the quantitative adsorption and preconcentration of Cu(II) from natural water samples.

Conclusions

A new type of Cu(II) ion-imprinted sorbent was successfully synthesized by a double-imprinting method. Thus, prepared imprinted sorbent showed several unique characteristics, such as obvious fast adsorption and desorption kinetics, mild imprinting reactive condition, low price, and proper selectivity for Cu(II). This sorbent can be potentially used as the solid-phase extraction material for the selective preconcentration and separation, and determination, when coupled with other instrumental methods, of trace Cu(II) in environmental samples.

References

Martin P, Wilson ID, Jones GR (2000) J Chromatogr A 889:143

Haginaka J (2004) Anal Bioanal Chem 379:332

Suedee R, Srichana T, Saelim J, Thavornpibulbut T (1999) Analyst 124:1003

Vlatakis G, Andersson LI, Müller R, Mosbach K (1993) Nature 361:645

Rao TP, Kala R, Daniel S (2006) Anal Chim Acta 578:105

Izatt RM, Bradshaw JS, Bruening RL, Bruening ML (1994) Am Lab 28C-28M

Sreenivasan K (2007) J Mater Sci 42:7575. doi:https://doi.org/10.1007/s10853-007-1625-7

Shamsipur M, Fasihi J, Khanchi A, Hassani R, Alizadeh K, Shamsipur H (2007) Anal Chim Acta 599:294

Dakova I, Karadjova I, Ivanov I, Georgieva V, Evtimova B, Georgiev G (2007) Anal Chim Acta 584:196

Dai S, Burleigh MC, Ju YH, Gao HJ, Lin JS, Pennycook SJ, Barnes CE, Xue ZL (2000) J Am Chem Soc 122:992

Say R, Birlik E, Eröz A, Yilmaz F, Gedikbey T, Denizli A (2003) Anal Chim Acta 480:251

Birlik E, Eröz A, Denizli A, Say R (2006) Anal Chim Acta 565:145

Wang S, Zhang R (2006) Microchim Acta 154:73

Baghel A, Boopathi M, Singh B, Pandey P, Mahato TH, Gutch PK, Sekhar K (2007) Biosens Bioelectron 22:3326

Molochnikov LS, Kovalyova EG, Zagorodni AA, Muhammed M, Sultanov YM, Efendiev AA (2003) Polymer 44:4805

Guo Y, Din B, Liu Y, Chang X, Meng S, Tian M (2004) Anal Chim Acta 504:319

Burba P, Willmer PG (1992) Fresenius J Anal Chem 342:167

Guéguen C, Belin C, Thomas BA, Monna F, Favarger PY, Dominik J (1999) Anal Chim Acta 386:155

Fang GZ, Tan J, Yan XP (2005) Anal Chem 77:1734

Lu YK, Yan XP (2004) Anal Chem 76:453

Acknowledgement

This work was supported by the National Natural Science Foundation of China (No. 20775003).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wang, Z., Wu, G., Wang, M. et al. An imprinted organic–inorganic hybrid sorbent for selective separation of copper ion from aqueous solution. J Mater Sci 44, 2694–2699 (2009). https://doi.org/10.1007/s10853-009-3353-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-009-3353-7