Abstract

Polycrystalline magnesium of 99.8 wt.% purity was subjected to high-pressure torsion (HPT) at room temperature. A special technique was developed in order to enable HPT of Mg up to very high shear strains of 115 and hydrostatic pressures of 4 GPa. The texture development during HPT was investigated by systematic X-ray texture measurements. It can be described by a stationary oblique B fibre characteristic of hexagonal metals subjected to simple shear. From the measured shear strain and pressure dependences of the B fibre and from microstructure investigations by TEM, it is concluded that also mechanisms of both dynamic and of static recrystallization contribute to the texture evolution.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Magnesium and its alloys have been extensively studied in recent years, not only because of potential applications as light-weight engineering materials, but also due to their ability of hydrogen storage. Enhancing the strength with simultaneously keeping sufficient ductility can be obtained by methods of Severe Plastic Deformation (SPD) [1]. Among them, high-pressure torsion (HPT) allows to achieve very high plastic strains due to enhanced hydrostatic pressure which prevents the deformed material from cracking critical for deformation of pure Mg at room temperature. Moreover, HPT allows precise controlling of process parameters like shear strain, temperature and hydrostatic pressure [2]. Considering the hitherto published literature, the texture evolution of pure Mg in torsion has been studied in detail, but only to shear strains of 0.9 [3].

The present work aims at systematically investigating the texture of pure Mg subjected to HPT, i.e. up to very high shear strains and to study the influence of hydrostatic pressure. Microstructural investigations by Transmission Electron Microscopy (TEM) were undertaken in order to substantiate the findings resulting from texture analysis.

Experimental

Materials

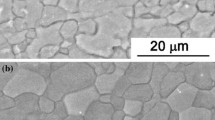

Polycrystalline magnesium samples of 99.8 wt.% purity were investigated after deformation by HPT. The starting material for HPT was Mg extruded at 350 °C having an average grain size of ~20 μm and a strong 〈0001〉 fibre texture in extrusion direction. Disc shaped samples suitable for HPT were cut by spark erosion from the extruded rod normal to the extrusion direction. The diameters of the torsion samples were 8 and 10 mm, their heights were 0.9 and 2 mm, respectively. In addition a 1-mm wide Cu ring was attached to the torsion sample to prevent unstable deformation caused by the excessive flow of the material across the HPT plungers [2].

High-pressure torsion

The HPT experiments were carried out at the Erich Schmid Institute for Material Science in Leoben (Austria). In situ flow curves of HPT were recorded during the deformation process by means of continuous torque—twist measurements. The Mg samples were deformed at hydrostatic pressures of 1, 2 and 4 GPa up to a maximum shear strain of about 115. The rotation of the plungers was at a rotation speed of 0.2 rot/min yielding a constant maximum shear strain rate of 5.3 × 10−1 s−1. Sample thickness reduction (due to compression) during HPT experiments amounted to less than 12%, e.g. the initial sample thickness of 0.89 mm was reduced to 0.77 mm after 1 rotation at 2 GPa. All samples were deformed at ambient temperature.

Texture measurements

The textures were measured on sections normal to the radial direction of the torsion samples at distances of 1.5 and 3.5 mm from the torsion axis (Fig. 1).

For X-ray diffraction the Cu Kα line (λ = 0.1542 nm) and a beam collimator of 0.3 mm in diameter was used. Pole figures \( \left( {0002} \right) \), \( (10\bar 10) \), \( (10\bar 11) \) and \( (10\bar 12) \) were registered using a GADDS area detector being part of the Bruker AXS D-8 wide angle diffraction system. The Orientation Distribution Function (ODF) was calculated by means of the ADC method using monoclinic symmetrization within the LABOTEX texture analysis software. The pole figures shown are recalculated from the ODFs. The fibre intensities in terms of volume fractions are calculated from the ODFs using a half width (FWHM) of 10°.

TEM investigations

For TEM specimen preparation, the HPT samples were mechanically ground to a thickness of about 0.15 mm. Then, discs with a diameter of 2.3 mm were punched and double-jet electropolished to perforation using an electrolyte consisting of 1% perchloric acid and 99% ethanol. TEM investigations were carried out with a Philips CM200 electron microscope at an acceleration voltage of 200 kV. Since the microstructure in all TEM foils consisted of a mixture of areas with large, recrystallized grains and smaller as-deformed ones, it was tried to select representative sites in all samples and to image them in bright- and dark-field mode.

Results and discussion

During torsion of Mg the c axis initially aligned in the shear plane (Fig. 2) mainly rotate towards the torsion axis forming the so-called B fibre (Figs. 3–5). Details of the experimental texture evolution will be given elsewhere. Such a rotation has been described recently by Beausir et al. [3] who investigated the texture evolution during free-end torsion of pure Mg up to shear strains of 0.9. Simultaneous texture simulations with the Taylor viscoplastic crystal plasticity model using basal, prismatic and pyramidal slip with relative critical resolved shear stress values of 1, 8 and 6, respectively, confirmed this rotation.

Texture of Mg before HPT (reference coordinate system as shown in Fig. 1)

However, the absolute value of the rotation was somewhat higher than that in experiment and for shear strains of about 8 even slightly exceeded 90°. In contrast, the textures in our work measured at shear strains larger than 10 exhibit a steady state behaviour with respect to rotation of the c-fibre axis as well as to texture intensity (Figs. 6, 7). The rotation of the fibre c-axis is only 80° or less (corresponding to a deviation from ideal position of 10° or more), depending on the hydrostatic pressure applied (Fig. 6). Following Skrotzki et al. [4], this indicates some process to occur which prevents the rotation of the c axes in reaching their ideal position. The limitation of rotation is suggested to arise from the onset of discontinuous dynamic recrystallization beyond a certain critical strain reached. Since the texture rotation found is the same for all strains investigated, this critical strain is thought to be smaller than the smallest deformations of samples being subjected to texture investigation. With increasing hydrostatic pressure, however, the deviation of the B fibre from the ideal position becomes larger (see Figs. 4, 5 and especially Fig. 6); at the same time, the texture intensity decreases (Fig. 7). Following the argumentation above, these findings indicate a lowering of the critical shear strain for recrystallization with increasing hydrostatic pressure. This conclusion is confirmed if one inspects the characteristics of in situ monitored stress–strain curves shown in Fig. 8. Here it is seen that the onset of steady-state being represented by constant or slowly decreasing stress indeed occurs at lower strains if the hydrostatic pressure is increased. These in situ stress–strain curves also give evidence for the dynamic nature of recovery/recrystallization since absolute softening occurs in almost all curves, irrespective of the hydrostatic pressure applied (Fig. 8).

Texture evolution of HPT deformed pure Mg as a function of shear strain at three hydrostatic pressures represented as (0002) pole figures (reference coordinate system as shown in Fig. 1)

Texture evolution of HPT deformed pure Mg as a function of shear strain at three hydrostatic pressures represented as \( (10\bar 10) \) pole figures (reference coordinate system as shown in Fig. 1)

In order to demonstrate that recrystallization has taken place, the microstructure was investigated by TEM. All samples investigated at shear strains greater than 10 showed a recrystallized bimodal grain structure with equiaxed grains of about 1 and 5 μm (Figs. 9, 10) which confirms the interpretation of texture investigations. However, with increasing hydrostatic pressure, the volume fraction as well as the size of the recrystallized grains is markedly increased (Fig. 10). This observation does not combine with the assumption that recrystallization occurs purely dynamically, because in this case the grain size of recrystallized grains should decrease with increasing steady state flow stress which has been found in the in situ flow curves shown in Fig. 8. Moreover, previous investigations on the effect of pressure on recovery and/or recrystallization processes [5–7] showed that an increase of the hydrostatic pressure increasingly suppresses the mechanisms of diffusion in the material and also those of dynamic recovery and/or recrystallization, but enhances those of the static one due to increased driving force given by a high density of accumulated vacancies. Thus, in the present case recrystallization or at least some abnormal grain growth may have taken place during unloading, that means during and after release of the pressure. Usually, grain growth does not change the texture drastically.

At this point of discussion we are left with the conclusion that both static and dynamic recrystallization processes might contribute to the texture effects found in HPT deformed Mg. For a quantitative determination of these contributions further investigations appear to be necessary.

Summary

The strain evolution of texture and microstructure in pure Mg deformed by HPT at different hydrostatic pressures can be described as follows:

-

Pure Mg subjected to HPT develops a steady state texture, the strength of which depends on the hydrostatic pressure.

-

The texture is mainly characterized by the so-called B fibre typical of simple shear deformation of hexagonal metals. However, the fibre axis deviates from its ideal position against the shear sense. The angular deviation increases and the texture strength decreases with the hydrostatic pressure applied.

-

TEM investigations show a recrystallized microstructure consisting of a bimodal grain size with the volume fraction and size of larger grains increasing with hydrostatic pressure.

-

In addition to the typical shear components, textures and microstructures can be described best in terms of discontinuous dynamic as well as of discontinuous static recrystallization mechanisms.

References

Valiev RZ (2004) Nature Mater 3:511. doi:https://doi.org/10.1038/nmat1180

Bonarski BJ, Schafler E, Holzleithner Ch, Mikułowski B, Zehetbauer MJ (2008) Arch Metall Mater 53:117

Beausir B, Tóth LS, Neale KW (2007) Acta Mater 55:2695. doi:https://doi.org/10.1016/j.actamat.2006.12.021

Skrotzki W, Scheerbaum N, Oertel C-G, Brokmeier H-G, Suwas S, Tóth LS (2007) Acta Mater 55:2211. doi:https://doi.org/10.1016/j.actamat.2006.08.018

Schafler E, Dubravina A, Mingler B, Karnthaler HP, Zehetbauer MJ (2006) Mater Sci Forum 503–504:51

Dubravina A, Zehetbauer MJ, Schafler E, Alexandrov I (2004) Mater Sci Eng A 387–389:817. doi:https://doi.org/10.1016/j.msea.2004.03.093

Zehetbauer M, Stüwe HP, Vorhauer A, Schafler E, Kohout J (2003) Adv Eng Mater 5:330. doi:https://doi.org/10.1002/adem.200310090

Acknowledgements

The authors are grateful for financial support from the Focus Project “Bulk Nanostructured Materials” of University of Vienna, and from the PhD Program “I022-N Experimental Materials Science-Nanostructured Materials” of University of Vienna. They kindly acknowledge support by Grant No. 11.11.180.255 provided by the Polish Ministry of Science and Higher Education. Parts of this work have been achieved within an Ernst Mach scholarship of the Austrian Exchange Services OEAD, and within a scholarship of the Central European Exchange Programme for University Studies (CEEPUS). The authors gratefully acknowledge the financial support of the Austrian Science Fund Project Nr. 17095N02.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Bonarski, B.J., Schafler, E., Mingler, B. et al. Texture evolution of Mg during high-pressure torsion. J Mater Sci 43, 7513–7518 (2008). https://doi.org/10.1007/s10853-008-2794-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-008-2794-8