Abstract

Potentiodynamic polarization and electrochemical impedance spectroscopy were employed to test carbonitrided CP-Ti, treated by a relatively new method called pulsed-plasma electrolytic carbonitriding. The results show excellent corrosion resistance for modified CP-Ti. The effect of frequency and duty cycle of pulsed current were investigated. It was found that pulse frequency and duty cycle affect the size and porosity of nanocrystalline carbonitrides and by controlling these effective parameters surface modification can render the CP-Ti material extremely corrosion resistant.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Titanium possess low density, high strength-to-weight ratio, high stiffness and strength [1, 2]. Commercially pure titanium (CP-Ti) is being investigated and recommended for elevated temperature applications, where weight reduction is a prime concern. The resistance of CP-Ti to corrosion at room temperatures has been investigated and there are some reports of electrochemical studies to this end in service environments [3–6]. For implant applications it is necessary to consider both biological and corrosion aspects. Other Ti-based alloys are also being investigated for implant applications. Also CP-Ti is extensively used as raw material in biomedical implants [6].

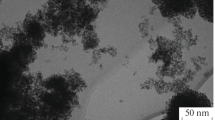

Some surface modification techniques have been developed for protection of Titanium [7, 8]. The plasma electrolytic carbonitriding (PEC/N) [9–12], a new and effective surface treatment technique developed, has been applied for surface modification of Ti alloys and some significant results have been reported [13, 14]. PEC/N process provides titanium thick, hard, high corrosion resistant ceramic-like nitride, and carbide films composed of a porous nanocrystalline layer [10, 11].

In this particular work, the corrosion behavior of CP-Ti in Ringer’s solution, used to simulate human body fluids, is investigated for carbonitrided samples at different conditions. Two electrochemical techniques were used for this purpose: potentiodynamic polarization and electrochemical impedance spectroscopy (EIS). Standard corrosion parameters, such as corrosion current density (i corr), corrosion potential (E corr), polarization resistance (R p) and corrosion rate (C R) were calculated from these experiments.

Effect of coating parameters on the properties of PEC/N films on CP-Ti have not been well studied; and the relationship between electronic characteristics and corrosion properties of PEC/N film is also seldom concerned. In this investigation, effects of two different effective parameters (frequency and duty cycle of pulse current) in Triethanolamine base electrolyte on the structure, composition and corrosion resistance of CP-Ti with PEC/N film were studied. Based on the results, corrosion resistance of the PEC/N films was analyzed.

Experimental procedure

CP-Ti was received in the form of rod with a diameter of 25 mm. Disc-shaped specimens with thickness of 5 mm and a diameter of 20 mm were obtained from the center of these rods using usual machining. Prior to the surface treatment, each specimen was ground with 240–3,000 grit SiC paper and ultrasonically cleaned with alcohol. The corrosion measurements for each experimental condition were carried out using a potentiostat/galvanostat (EG&G 273A, Princeton Applied Research), a standard cell and electrode holders. Saturated calomel electrode was used as the reference electrode and the counter electrode consisted of platinum plate. The surface area exposed to the electrolyte was 0.785 cm2. The corrosion behavior of the treated CP-Ti was evaluated at room temperature using Ringer’s solution which was not deaerated, with an approximate pH between 5 and 6.

The potentiodynamic polarization curves for the samples were recorded for a potential scan from −0.4 V versus open circuit potential to 2 V versus saturated calomel electrode at a scan rate of 0.5 mV/s. The polarization curves were analyzed to determine E corr (corrosion potential) and i corr (corrosion current). The corrosion rate, C R (rate of metal dissolution), in millimeters per year, was determined with the following standard equation:

where A W, z and ρ are characteristic properties of each sample (atomic weight, valence, and density respectively) and F is the Faraday constant (96,500 As/mol). Equivalent weights based on standard equations were obtained to calculate the corrosion rate.

Electrochemical impedance spectroscopy was also used to evaluate the samples. This method was conducted according to the ASTM G-106 standard practice. Samples were left in contact with Ringer’s solution at open circuit conditions for 1 h prior to carrying out the EIS tests. The alternating current (AC) impedance spectra for CP-Ti were obtained at the open circuit potential, with a scan frequency range of 100 KHz to 10 mHz with amplitude of 10 mV to obtain 30 experimental points. Nyquist plots were obtained by curve fitting these data points using a commercial software package called Electrochemistry Power Suite. These plots were analyzed to determine the solution resistance (R Ω), polarization resistance at the electrode/solution interface (R p), and the double layer capacitance at this interface (C DL). Bode plots were also plotted from the same data to better analyze and understand the corrosion phenomena occurring during the impedance tests.

CP-Ti samples used in this study were modified by different conditions of pulsed-plasma electrolytic carbonitriding. All these samples were carbonitrided at 500 V by rectangular pulse shape method at different frequencies and duty cycles. The temperature of electrolyte remained constant at 30 °C, by circulating cold water around electrolyte bath. Electrolyte bath tank was made from stainless steel and acted as anode in electrochemical system of coating process. Other specifications can be found in Refs. [12, 15]. The carbonitrided layer formed as a result of the plasma electrolysis process has a thickness around 10 μm for all samples regarding to the kinetics of layer’s growth for each coating process’s conditions that achieved by pretests. The as-received samples were used as control for comparison purposes. All corrosion testing was carried out at 25 °C. Four samples were tested for each experimental condition and the average of these results is reported. Outlier data was not included in these calculations.

Micrographs of samples were obtained with electron backscattering using scanning electron microscopes (SEM) (Philips XL-30 and CamScan MV-2300).

Results and discussion

The modified surfaces were observed in SEM by mounting the samples in a polymeric resin. Figure 1 is an example of two different samples with different frequencies and shows the difference between the sizes of nanocrystalline carbonitrides.

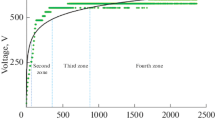

Standard techniques were used to extract E corr, i corr and C R values from the potentiodynamic polarization plots, samples of which are shown in Figs. 2 and 3. Table 1 shows the polarization data obtained for CP-Ti including Tafel slopes (β a and β c), E corr and i corr values.

From Table 1, it is possible to observe low values of corrosion rate for all of the samples treated with PEC/N. Also in all of the cases the corrosion current density has been reduced after coating process. The formation of carbonitride films on the CP-Ti samples, resulting from the surface treatment renders these samples passive and highly corrosion resistant in Ringer’s solution.

Figures 4 and 5 show Nyquist plots obtained experimentally for CP-Ti in Ringer’s solution, respectively. The impedance spectra shown in Fig. 4 for CP-Ti indicate that the best corrosion resistance that was exhibited for samples carbonitrided at high frequencies in comparison with other samples. This behavior can be attributed to the presence of a denser compound layer formed with this treatment by higher frequencies. The Nyquist plots obtained for CP-Ti at different duty cycles (Fig. 5) indicate that the best corrosion resistance is obtained for the carbonitrided samples at lower duty cycles in comparison with the samples by higher duty cycles, attributed to the presence of a well performed and lower sizes of nanocrystalline carbonitrides in compound layer on the CP-Ti surface and corroborated by the polarization data in Table 1. Although attempts were made with X-ray diffraction to determine the nature of the carbonitride layer formed on CP-Ti during the plasma electrolytic process, this layer has not been clearly identified yet. Figure 6 illustrates X-ray diffraction of a sample treated by 100 Hz (frequency) and 10% (duty cycle) at different glancing angles (3, 5 and 10°) which shows a complex compound layer. All of the samples treated by PEC/N were coated by this complex phase. Nevertheless, the presence of this continuous protective layer improves the corrosion resistance of this metal, manifested in the high values of R p obtained experimentally for the carbonitrided samples.

Table 2 shows the corrosion parameters obtained for CP-Ti with EIS. This table shows the values of solution resistance (R Ω), polarization resistance (R p) and capacitance of the double layer (C DL) obtained by curve fitting the EIS data using Electrochemistry Power Suite. The electrolyte resistance (R Ω) has consistent values that are noted for CP-Ti in the presence of Ringer’s solution.

The higher value of R Ω for the case of the CP-Ti sample carbonitrided at lower frequencies is possibly a manifestation of the porous complex titanium carbonitrided layer. Higher values of polarization resistance (R p) are also noted for all of the samples treated by PEC/N. A high R p value is an indication of the working electrode strongly resisting change from its equilibrium state and corresponds to a low rate of titanium ion release. This behavior is clearly noted and is in agreement with the results found with potentiodynamic polarization. From Table 2, it can also be seen that, in general, for all surface treatments that tested for corrosion properties in Ringer’s solution, high values of polarization resistance (R p) ranging from 176 to 51,242 MΩ Cm2 are measured, which implies an excellent corrosion resistance for this metal after surface modification. Also values of C DL in the range of 30–40 μF/Cm2 were determined. The R Coat values for the two samples treated at different duty cycles and frequencies (1,000 Hz—10%, 10 Hz—20%) reveal an interesting point. First sample (1,000 Hz—10%) has a lower value of CPECoat and its R Coat value formed during the EIS tests is larger than for other sample (10 Hz—20%) treated at duty cycle of 20%. This reflects the presence of a relatively coherent and stable carbonitride layer formed on first sample (1,000 Hz—10%) with this treatment, while the obtained layer formed on other sample (10 Hz—20%) is porous and possibly less stable. During impedance testing, this porous carbonitride is made denser by passivation, reflected in a larger value of CPECoat. Bode phase plot spectra from the EIS data were evaluated to observe changes in the sample surface during EIS testing. From this graph it is possible to deduce the presence of a compact film, if (a) the phase angle is close to 90° over a wide-frequency range, and (b) if the spectrum shows linear portions at intermediate frequencies. Figure 7 shows representative Bode plots for two samples treated at a very opposite frequencies and duty cycles (10 KHz—10%, 10 Hz—60%) in Ringer’s solution as examples. The impedance spectra found for the sample (10 KHz—10%) exhibited a near capacitive response illustrated by a phase angle close to 85°, while the sample (10 Hz—60%) showed a phase angle close to 80° over a wide frequency range. This response and the high values of R p obtained from the Nyquist plot corroborates the presence of a barrier layer formed on this metal after the surface treatment especially for sample (10 KHz—10%). Sample (10 KHz—10%) has the highest frequency and lowest duty cycle in this study which tends to receive the lowest size of nanocrystalline carbonitrides on its surface. It seems that compact layer with nanocrystalline carbonitrides with smaller dimensions, shows a better corrosion behavior. This fact is obviously clear for all samples treated in this study. So by increasing frequency and decreasing duty cycle of the pulse current, the corrosion behavior of samples will improve significantly.

For all cases, a simple EEC model shown in Fig. 8 is sufficient to explain the observed EIS data.

The corrosion behavior of carbonitrided CP-Ti in Ringer’s solution was experimentally studied and it appears that this material has excellent corrosion resistance based on both direct current and alternating current techniques.

Although the main aim of this study was to investigate the resistance to corrosion of CP-Ti in a physiological environment, a number of points regarding the type and composition of carbonitride formed after plasma electrolysis and the oxide film growth in Ringer’s solution for the samples (10 KHz—10%, 10 Hz—60%) (different opposite frequencies and duty cycles) need to be further discussed.

Conclusions

The corrosion parameters (E corr, i corr) obtained by the potentiodynamic polarization technique indicate excellent corrosion resistance for pulsed-plasma electrolytic carbonitrided CP-Ti. Both electrochemical techniques show that these samples exhibit a corrosion behavior in Ringer’s solution better than raw CP-Ti and by increasing frequency and decreasing duty cycle of pulse current not only the size of nanocrystalline carbonitrides will decrease, but also the corrosion characteristics will improve significantly. Surface carbonitriding at 1,000 Hz significantly increases the corrosion resistance of CP-Ti, while carbonitriding at 10 Hz results in the formation of a porous carbonitrided layer. In general, the low values for corrosion rate, and the high values of polarization resistance (R p) obtained experimentally for carbonitrided CP-Ti in Ringer’s solution, imply that this material has the potential to be considered as a biomaterial.

References

Donachie MJ (2000) Titanium a technical guide, 2nd edn. ASM International, United States of America

Lutjering G, Albrecht J (2004) Ti-2003 science and technology. Wiley-VCH, Frankfurt

González JEG, Mirza-Rosca JC (1999) J Electroanal Chem 471(2):109

Kuphasuk C, Oshida Y, Andres CJ, Hovijitra ST, Barco MT, Brown DT (2001) J Prosthet Dent 85(2):195

Burstein GT, Liu C, Souto RM (2005) Biomaterials 26:245

Ratner BD, Hoffman AS, Schoen FJ, Lemons JE (2004) Biomaterials science. Academic Press

Vanzillotta PS, Sader MS, Bastos IN, de Almeida Soares G (2006) Dent Mater 22(3):275

Cai Z, Bunce N, Nunn ME, Okabe T (2001) Biomaterials 22(9):979

Yerokhin AL, Nie X, Leyland A, Matthews A, Dowey SJ (1999) Surf Coat Technol 122:73

Shen D, Wang Y, Nash P, Xing G (2007) Mater Sci Eng A 458(1–2):240

Li XM, Han Y, Li YS (2007) Surf Coat Technol 201(9–11):5326

Aliofkhazraei M, Taheri P, Sabour AR, Dehghanian Ch (2007) Mater Sci (in press, will appear on No. 3)

Nie X, Tsotsos C, Wilson A, Yerokhin AL, Leyland A, Matthews A (2001) Surf Coat Technol 139:135

Li XM, Han Y (2006) Electrochem Commun 8:267

Taheri P, Dehghanian Ch, Aliofkhazraei M, Sabour AR (2007) Plasma Process Polym 4(4):S711

Acknowledgement

The authors would like to express their gratitude to National Association of Nanoscience and Nanotechnology of Iran and Arvandan Oil and Gas Production Company (TMU 85-09-66) for financial support of this project.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Aliofkhazraei, M., Rouhaghdam, A.S. & Sabouri, M. Effect of frequency and duty cycle on corrosion behavior of pulsed nanocrystalline plasma electrolytic carbonitrided CP-Ti. J Mater Sci 43, 1624–1629 (2008). https://doi.org/10.1007/s10853-007-2323-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-007-2323-1