Abstract

In 2003 Nature Materials article, Keckes et al. presented deformation properties of a variety of woods in relation to deformation of their individual wood cells. Their point is “The remarkable mechanical properties of biological materials reside in their complex hierarchical structure…”. This holds for mineral-based biological materials such as bone as well as for wood. Indeed, one of us (J.L.K.) introduced the concept that to explain the material properties of cortical bone, it was necessary to treat it as a complex material/structural hierarchical composite. Calculations to determine anisotropic properties of bone measured using ultrasonic wave propagation techniques, were extended to similar measurements on both soft and hard woods. These anisotropic properties calculations have been extended to include data based on mechanical measurements of orthotropic elastic constants of both soft and hard woods for comparison with both earlier ultrasonic measurements and mechanical testing on other woods. This work illustrates the fact that understanding and modeling the properties of wood is a complex task as the symmetry changes with scale. For example, lignin is isotropic, hemicellulose and cellulose are transversely isotropic, while the cells and microstructure have orthotropic symmetry.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Wood has been an important structural material for millennia. Its properties have intrigued engineers and forestry scientists to the point that a considerable literature on structure–property relationships developed post-World War 2. This includes, among others: The Elasticity of Wood and Plywood [1]; chapter 20 in The Testing of Engineering Materials (4th edition) [2]; the 4 volume EMMSE/MEC set: vol. I, Wood: Its Structure and Properties [3]; vol. II, Wood as a Structural Material [4]; vol. III, Adhesive Bonding of Wood and Other Structural Materials [5]; and vol. IV, Wood: Engineering Design Concepts [6]. Also in this category are: chapter 4 in Wood Handbook: Wood as an Engineering Material [7] and Acoustics of Wood [8].

Keckes et al. in 2003 study presented the deformation properties of a variety of woods in relation to the deformation of their individual wood cells [9]. They make the point that “The remarkable mechanical properties of biological materials reside in their complex hierarchical structure…”. This holds for mineral-based biological materials such as bone as well as for wood. Indeed, one of us (J.L.K.) introduced the concept that in order to explain the material properties of compact haversian cortical bone, it was necessary to treat it as a complex material/structural hierarchical composite [10, 11]. The insight that led Katz to put forth this concept for modeling bone’s material properties evolved from a series of ultrasonic wave propagation (UWP) studies of the anisotropic elastic properties of cortical bone [12–15] following a similar ultrasonic study of the anisotropic properties of fluoroapatite [16] and the modeling of the anisotropic elastic constants of hydroxyapatite [17], the inorganic (“mineral”) component of bone.

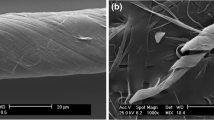

Kretschmann [18] following on the Keckes et al. work [9], describes the “complicated hierarchical structure” of wood including an illustration of wood’s anatomy (Fig. 1) [18]. A comparison of this illustration with one of several often used as descriptive of the hierarchical structure of bone (Fig. 2) [19] shows the remarkable similarity of the micro- and ultra-structural aspects between both, except that on the microstructural level, haversian bone is based on circular cross sections (transverse isotropy) while on the cellular level that for wood is based on rectangular cross sections (orthotropy).

Kretschmann: Wood Cells Hierarchical Anatomy ([18] with permission of Nature Materials)

Lakes: Bone Hierarchical Anatomy ([19] with permission of Nature)

The Keckes et al. [9] and Kretschmann [18] articles symbolize what appears to be a most recent resurgence of interest in the properties of woods, see for example, in 2003, Fracture and Fatigue in Wood [20]; additionally in 2004: chapters 1, 2 (in part), 3, 4, and 8 (in part) in Optimization Mechanics in Nature [21]; a paper in May 2004 MRS Bulletin [22]; an article in July 2004 Mechanical Engineering [23]; a paper in the 2004 European Journal of Physics [24]; and continuing into 2005 with a Paper just accepted by the European Journal of Mechanics A: Solids [25].

Elastic anisotropy

Both the Keckes et al. [9] and Kretschmann [18] discourses are based on quasi-static mechanical testing of the uniaxial tensile stress–strain behavior. Enhancement of the understanding of the deformation properties of wood necessitates a description of its anisotropic properties as well. Clearly, both wood and bone must have considerable transverse elastic properties as well as those along the longitudinal direction, i.e., along the species’ principal axis. Obtaining the full set of orthotropic elastic stiffness coefficients for both bovine plexiform cortical bone [26] and soft and hard woods [27, 28] also allows calculation of their directional traditional elastic properties, Young’s, bulk and shear moduli and Poisson’s ratio, as well as their Voigt and Reuss moduli and the shear and compressive scalar anisotropy factors [29]. The Voigt modulus is obtained by averaging the stiffness coefficients over all possible crystal (or equivalent texture) orientations in the material; the Reuss modulus is obtained by averaging the compliance coefficients over all possible crystal (or equivalent texture) orientations in the material. Therefore, the Voigt modulus represents the upper bound on the elastic properties, where a uniform strain distribution is assumed, and the Reuss modulus represents the lower bound on the elastic properties, where a uniform stress distribution is assumed. Such sets of orthotropic elastic constants for bovine plexiform cortical bone and soft and hard woods are given in Tables 1 and 4, respectively, in Katz and Meunier [30]. The formulae to calculate the Voight and Reuss values are provided in the appendix of that paper [30].

The Voigt and Reuss moduli are important in this case because they are the bases for the Chung and Buessem calculation [30] adapted for the present analyses. As Chung and Buessem point out “…for an aggregate containing anisotropic crystals, a difference between the limiting values is expected from the Voigt and Reuss assumptions. The concept underlying the present theory of the Percent Elastic Anisotropy is that the magnitude of this difference is a function only of the degree of elastic anisotropy possessed by the crystal under consideration.”

In order to compare these disparate ultrasonic wave propagation (UWP) measurements of anisotropic elastic constants as well as those done by mechanical testing, Katz and Meunier [29, 30] adopted the calculation by Chung and Buessem [31] for single crystals of various inorganic materials with either cubic or hexagonal (transverse isotropic) symmetry. Chung and Buessem provided the rationale for the Percent Elastic Anisotropy calculation in the opening two sentences of their Abstract, “The elastic anisotropy of a crystal is the orientation-dependence of the elastic moduli or sound velocities. Essentially, all the known crystals are elastically anisotropic.” They go on to say that their “…paper presents a convenient method of describing the degree of elastic anisotropy in a given cubic, hexagonal, trigonal, and tetragonal crystal…”. The calculation yields two scalar anisotropy factors, one for shear anisotropy, As* (%), and one for compressive anisotropy Ac* (%), based on algebraic relationships between the full set of elastic constants, five C ij for transverse isotropy (hexagonal symmetry in crystal physics):

where G is the shear modulus and K is the bulk modulus.

This calculation was adapted by Katz and Meunier for compact haversian cortical bone exhibiting transverse isotropic symmetry [30] (hexagonal symmetry in crystal physics) based on earlier modeling [11] and ultrasonic measurements [13, 14] that showed that selected volumes of compact bone could be treated as pseudo-crystals on the microstructural level. They then extended the calculation to cover the full set of nine C ij for orthotropic symmetry [29] (orthobombic symmetry in crystal physics). Thus, only one has to compare pairs of single scalar values between experiments on samples of the same anisotropic material from different sources, or on different samples from the same piece of anisotropic material.

Fortunately, what eventually came to the attention of Katz and Meunier was a series of papers by Bucur describing UWP measurements on a number of different soft and hard wood samples, treating each as having orthotropic symmetry [27, 28] comparable to the same symmetry found in young mammalian plexiform bone [26, 32]. Katz and Meunier then applied the same idea that selected volumes of wood could be treated as pseudo-crystals on the microstructural level. Thus, Bucur’s data enabled Katz and Meunier to calculate both the shear and compressive, anisotropy factors for her wood samples, Table 4 in Katz and Meunier [30], and compare them with those they calculated for both plexiform and haversian bone, Table 1 in Katz and Meunier [30]. We have performed similar calculations for mechanical testing data performed under quasi-static conditions on woods [7] other than those used by Bucur in her MHz ultrasonic measurements [27, 28]. This additional calculation made it apparent that rather than just tabulating, as was done for Bucur’s data [30], a plot of As* (%) versus Ac* (%) would highlight the correlations that indicate that both hard and soft woods exhibit the same type of material symmetry. Figure 3 shows the comparison in graphic form. This figure indeed shows that a “master curve” relating shear and compressive properties exists for living materials with similar microstructural symmetry, such as bone and wood. This “master curve” can be applied over a widerange of material properties whether obtained by ultrasonic wave propagation at MHz frequencies or mechanical testing techniques performed under quasi-static conditions. It is interesting to see that there is a clear separation between hard and soft woods that have the same material symmetry. The only exception is Balsa; the explanation may hinge on the fact that the anisotropic elastic properties of Balsa are much lower than either the hard or soft woods. If Ac* (%) and As* (%) are higher, then the degree of elastic anisotropy is higher. Our “master curve” shows the same type of quadratic behavior as shown in the curves for both cubic and hexagonal single crystals in Chung and Buessem paper [31].

The order of magnitude difference between the wood and the bone anisotropy, wood > bone, is clearly seen in these figures as well as the systematic differences in anisotropy between the hard and soft woods, i.e., soft wood > hard wood anisotropy. This again, yields insight into structure/property/function (SPF) relationships as the deformation response to load required for trees is significantly different than that required for bones as well as for soft woods relative to hard woods.

Results

In order to provide additional insight into the respective elastic properties of both hard and soft woods measured by UWP with the tensile measurements of wood by Keckes et al. [9], we have calculated the anisotropic technical moduli for both soft and hard woods derived from the technical moduli measured by traditional mechanical testing, i.e., quasi-static stress–strain measurements. The full set of nine technical moduli for 11 kinds of woods measured by quasi-static techniques (elastic ratios for various species (Forest Products Laboratory, Wood Handbook, Chpt. 4: p 4–6, Wood Handbook 1999. U.S.D.A., Washington, DC) [33], is reproduced in Table 1 (E, Young’s modulus; G, shear modulus; v, Poisson’s ratio)).

The full matrix for technical moduli follows, Eq. 2:

For an orthotropic material such as bone or wood, only 9 of the 12 nonzero terms in Eq. 2 are independent based on the symmetry of the S ij tensor:

This further reduces for transverse isotropy to only five of the nonzero terms:

The full C ij matrix for an orthotropic material follows, Eq. 5:

The full set of nine C ij for 11 kinds of woods, listed in Table 2, has been calculated, from Table 1 above. As the E 1 value of Mahogany–Honduras was unavailable, the value of 10.3 GPa given for Mahogany was used in the calculation.

Finally the C ij in Table 2 have been used to calculate the Voigt (symbolized by a superscript V) and Reuss (symbolized by a subscript R) moduli and thence the values of As* (%) and Ac* (%), Table 3. In order to compare the relative anisotropies measured by mechanical testing [33], the values of As* (%) versus Ac* (%) from Table 3 have been added to Fig. 3 with those measured by UWP [27, 28].

Discussion

It is clear that measurement of the elastic properties of living tissues such as bone and wood are not identical from sample to sample or when made by different techniques. Thus, it is not unexpected to find differences between the moduli measured by quasi-static mechanical testing with the high strain rate, high-frequency UWP techniques. Even so, one would expect that the elastic anisotropy measured in such tissues would be comparable as the differences are of scale and not of kind, even though the individual C ij element may not have the same frequency dependency. An example of this is given for UWP measurements in bovine bone in Table 4, where extensional (bar) wave measurements (low MHz frequency) from Lipson and Katz [32] are compared with dilatational longitudinal wave measurements (high MHz frequency) of Katz et al. [26].

For additional discussions of the hierarchical structure/property relationships in bone see Currey [34] and the two chapters, # 12 & 13, by Lucchinetti [35, 36] in Cowin [37]; chapter 13 [36] in Cowin [37] is especially relevant to the studies of Keckes et al. [9] and Kretschmnann [18] as it analyzes dense bone tissue as a molecular composite.

This expectation, stated above, that the elastic anisotropy measured in viscoelastic tissues would be comparable over a wide range of measurement frequencies should also be true for both soft and hard wood tissues with orthotropic symmetry, as dispersion of moduli with frequency in wood can be expected to be less than that in bone. Figure 3, the plot of As* (%) versus Ac* (%) for bone, and both the UWP (at low MHz) and MT (quasi-static, i.e., at very low Hz) measurements of both soft and hard woods clearly illustrates this. The MT data fall into separate domains between the soft and hard woods almost exactly as do the UWP data. Balsa wood provides an interesting deviation as the lone outlier on the graph shown in Fig. 3. Clearly, this must be due to the unusual softness of the tissue, affecting its structure/property relationship relative to those of both the soft and hard woods measured either by MT and/or UWP techniques.

The question of scale raised above is most important in developing any understanding of the material properties of complex hierarchical living materials such as wood and bone. This is evinced by a number of experiments directed at structure/property relationships in various woods at different scales, e.g., Hofstetter et al. [25], Kretschmann et al. [38], Cramer et al. [39]. Thus, this is also the reason for the experiment of Keckes et al. [9] and the associated comments by Kretschmann [18].

It is interesting to note that in the 1960s and 1970s there were a number of mechanical testing experiments to obtain the elastic symmetry of the lower size scale constituents of wood, e.g., lignin (isotropic) [40], hemicellulose, and cellulose (transverse isotropy, modeled on lignin) [41], effect of fiber orientation in the cell wall [42], and cell wall anisotropy [43].

The same calculations for the woods described above have been done for both the set of isotropic C ij for lignin [40], and for the transverse isotropic C ij for hemicellulose and cellulose [41]Footnote 1; these data are listed below in Table 5.

The values of As* (%) and Ac* (%) are plotted in Fig. 3. There is one concern with these C ij for both hemicellulose and cellulose, as both C 44 and C 55 are given the same value as C 66 based on scaling the lignin values. The values of C 66 = ½(C 11 − C 12) for both hemicellulose and cellulose is consistent with elasticity theory. However, there is no a priori reason why both C 44 and C 55 should equal C 66. Clearly these values should be determined by direct experiments. It appears likely that these present values of C 44 and C 55 will not impact seriously on the values of As* (%) and Ac* (%). Therefore, we include them in Fig. 3 as they provide a picture of the effects of scale on the hierarchical anisotropic properties of wood. It points to the fact that understanding and modeling the properties of wood is a complex task as the symmetry changes with scale. Lignin is isotropic, hemicellulose and cellulose are transversely isotropic, while the cells and microstructure have orthotropic symmetry. It is only by using these two scalar anisotropy factors that we can place in perspective the full hierarchical effect of wood’s constituent structures and its properties.

It is important to note that the C ij are functions of frequency, and the functional dependence of each element need not be the same. Since dry wood has a lower tan delta than bone over most of the frequency range, the dispersion of moduli with frequency in wood can be expected to be less than that in bone.

References

Hearmon RFS (1948) The elasticity of wood and plywood. His Majesty’s Stationary Office, London, UK

DAVIS HE, Troxell GE, Hauck GFW (1982) The testing of engineering materials, 4th edn. McGraw-Hill, New York

Wangaard FF (ed) (1982) Wood: its structure and properties. Pennsylvania State University, University Park, PA

Dietz AGH, Schaffer EL, Gromala DS (eds) (1982) Wood as a Structural Material, vol II. Pennsylvania State University, University Park, PA

Blomquist RF, Christiansen AW, Gillespie RH, Meyers GE (eds) (1983) Adhesive bonding of wood and other structural materials. Pennsylvania State University, University Park, PA

Freas AD, Moody RC, Soltis LA (eds) (1986) Wood: engineering design concepts. Pennsylvania State University, University Park, PA

Wood handbook: wood as an engineering material. Agricultural handbook 72, U.S. Government Printing Office, Washington DC (1987)

Bucur V (1995) Acoustics of wood. CRC Press, Boca Raton, FL

Keckes J, Burgert I, et al. (2003) Nat Mater 2:810

Katz JL (1976) In: Mates RE, Smith CR (eds) Advances in bioengineering. American Society of Mechanical Engineers, New York, p 17

Katz JL (1980) Nature 283:106

Lang SB (1970) IEEE Trans Biomed Eng 17:101

Yoon HS, Katz JL (1976) J Biomech 9:407

Yoon HS, Katz JL (1976) J Biomech 9:459

Bonfield W, Grynpas MD (1977) Nature 270:453

Yoon HS, Newnham RE (1973) Am Mineral 54:1193

Katz JL, Ukraincik K (1971) J Biomech 4:221

Kretschmann D (2003) Nature Mater 2:775

Lakes R (1993) Nature 361:511

Smith I, Landis E, Gong M (2003) Fracture and fatigue in wood. John Wiley & Sons Inc., Somerset, NJ, p 39

Collins MW, Hunt DG, Atherton MA (eds) (2004) Optimization mechanics in nature. WIT Press, Great Britain

Navi P, Heger F (2004) In: MRS Bulletin Special Issue: Construction Materials: From Innovation to Conservation 29(5):332

Staff Writers and Contributors (2004) Mech Eng 126(7):40

Perkalskis BS, Freeman JR, Suhov A (2004) Eur J Phys 25:323

Hofstetter K, Hellmich C, Eberhardsteiner J (2005) Eur J Mech A/Solids 24:1030

Katz JL, Lipson S, Yoon HS, Maharidge R, Meunier A, Cristel P (1984) Calc Tissue Inter 36:S31

Bucur V (1980) Catgut Acoust Soc Newsletter 33:24

Bucur V, Archer RR (1984) Wood Sci Technol 18:255

Katz JL, Meunier A (1990) J Mater Sci: Mater Med 1:1

Katz JL, Meunier A (1987) J Biomech 20:1063

Chung DH, Buessem WR (1968) In: Vahldiek FW, Mersol SA (eds) Anisotropy in single crystal refractory compounds, vol 2. Plenum Press, New York, p 217

Lipson S, Katz JL (1984) J Biomech 17:231

Forest Products Laboratory, Wood Handbook, Chpt 4. U.S.D.A., Washington, DC, p 4 (1999)

Currey J (2002) Bone: structure and mechanics. Princeton University Press, Princeton, NJ

Lucchinetti E (2001) In: Cowin S (ed) Bone mechanics handbook, Chpt 12, 2nd edn. CRC Press, Boca Raton, FL, p 1

Lucchinetti E (2001) In: Cowin S (ed) Bone mechanics handbook, Chpt 13, 2nd edn. CRC Press, Boca Raton, FL, p 1

Cowin S (ed) (2001) Bone mechanics handbook, 2nd edn. CRC Press, Boca Raton, FL

Kretschmann DE, Cramer SM, Lakes RS, Schmidt TW (2006) In: Stokke DD, Groom LH (eds) Characterization of the cellulosic cell wall. Blackwell, Oxford, UK, p 147

Cramer SM, Kretschmann DE, Lakes RS, Schmidt TW (2005) Holzforschung 59:539

Cousins WJ (1976) Wood Sci Technol 10:9

Cave ID (1978) Wood Sci Technol 12:75

Cave ID (1969) Wood Sci Technol 3:40

Cave ID (1968) Wood Sci Technol 2:268

Acknowledgements

This work is a contribution from the UMKC Center for Research on Interfacial Structure & Properties (UMKC-CRISP).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Katz, J.L., Spencer, P., Wang, Y. et al. On the anisotropic elastic properties of woods. J Mater Sci 43, 139–145 (2008). https://doi.org/10.1007/s10853-007-2121-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-007-2121-9