Abstract

It was demonstrated that brookite-type titanium oxide can be directly synthesized by the hydrothermal treatment of novel water-soluble titanium complexes under basic conditions in the presence of an additive. In particular, single-phase brookite was synthesized from the titanium–glycolate complex at a pH of about 10 in the presence of excess NH3 aqueous solution or ethylenediamine, and powder thus obtained consisted of rod-like nanosized particles. It was suggested that the structures of titanium complexes are important for the formation of brookite.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Titanium dioxide (TiO2), which is chemically stable and non-toxic, has been used in a wide variety of applications such as in white pigments, cosmetics, and protective coatings, because of its high photo-refractive index. Recently, TiO2 has become attractive as a photocatalyst since harmful organic compounds and NO can be decomposed by titania under ultraviolet radiation [1–4]. It is known that three polymorphs of titania exist: anatase, rutile, and brookite. Among the three, anatase and rutile can be easily synthesized using various methods [4–7]. On the other hand, only a few research groups have reported the preparation of brookite, but even the best samples usually contained other TiO2 phases as well [8–11].

It is believed that brookite can be directly obtained from the precursor solution under the special solvothermal conditions of high pressure and high temperature but not by conventional calcination under ambient atmosphere. In fact, brookite has been obtained using the solvothermal method in several studies [1, 12–16]. It is typically prepared by the solvothermal method utilizing toxic organic solvents. In principle, other polymorphs of titania can be obtained by the hydrothermal treatment of strongly acidic solutions, containing titanium. In this case, however, the range of pH is rather restricted for the synthesis, and handling of the solution itself is quite inconvenient due to equipment corrosion. Therefore, novel water-soluble titanium complexes, stable over a wide pH range and environmentally benign, are very attractive precursors for the synthesis of titania by the hydrothermal method [17–19].

In the present study, we have examined the synthesis conditions of brookite-type titanium oxide using hydrothermal treatment of novel water-soluble titanium complexes, and we discuss the brookite formation.

Experimental

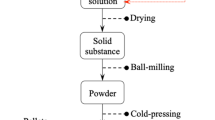

Titanium metal powder (5 mmol) was dissolved in a cold aqueous solution consisting of 30% H2O2 (20 mL) and 30% NH3 aqueous solution (5 mL). Citric acid (5 mmol), malic acid (5 mmol), tartaric acid (5 mmol), lactic acid (15 mmol), or glycolic acid (7.5 mmol) was added to the solution as a complexant [17–19]. The solution was heated to 80 °C to remove excess H2O2 and NH3, and it subsequently turned into a dry gel-like substance. This gel was dissolved in water yielding a transparent aqueous solution. The pH of the as-prepared titanium aqueous solution was about six. The total volume of this solution was adjusted to 20 mL by adding distilled water, and then it was sealed in a Teflon-lined stainless steel autoclave. The autoclave was maintained at 200 °C for 24 h and then cooled down to room temperature. The same procedure was applied for the solution with excess amount of complexant (pH 3) or NH3 aqueous solution (pH 10). After the vessel had been cooled, the resulting precipitate was separated by filtration and/or centrifuging and washed with distilled water until the pH of the filtrate became seven. The precipitate thus obtained was dried at room temperature. These samples were examined using powder X-ray diffraction (XRD, CuKα: wavelength λ = 1.5406 Å, scanning speed 4° min−1, scanning step 0.02°), Micro-Raman spectroscopy (green laser: λ = 532.2 nm, laser power 0.1 W, resolution 1 cm−1, exposure time 5.0 s) and transmission electron microscopy (TEM, Cu microgrid coated with holey carbon film, accelerating voltage 200 kV).

Results and discussions

Synthesis of single-phase brookite-type TiO2

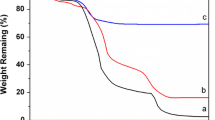

The XRD and Raman spectroscopy measurements indicated that the obtained samples were either anatase, rutile, or brookite-type TiO2. The results of identification of titania polymorphs are summarized in Table 1. Under all conditions used, single-phase anatase was obtained from the titanium complex solutions with citric acid, tartaric acid, or malic acid as a ligand. On the other hand, various titania polymorphs formed from the titanium–lactate complex or the titanium–glycolate complex solutions at different values of pH. From these two complexes, rutile was obtained at pH 6 without additives. At pH 3, in the presence of excess amount of a complexant, anatase particles tended to form. Brookite-type TiO2, which is extremely difficult to obtain from conventional Ti compounds, was obtained at pH 10 using excess amount of NH3(aq). In general, it is difficult to confirm whether the powders contain single-phase brookite or a mixture of brookite and anatase from only XRD data, since most of the diffraction peaks of brookite overlap with those of anatase. Therefore we used Raman spectroscopy as an additional characterization method. Figure 1 shows the Raman spectra for the samples synthesized by hydrothermal treatment of titanium–lactate complex or titanium–glycolate complex aqueous solution at pH 10 adjusted by excess amount of NH3(aq). It is known that single-phase anatase has characteristic bands at 144 cm−1 and 516 cm−1, which are absent for brookite [20]. These peaks were observed for the sample obtained from the titanium–lactate complex, but there were no such peaks in the spectrum of TiO2 synthesized from the titanium–glycolate complex. This result indicates that single-phase brookite can be synthesized by hydrothermal treatment of titanium–glycolate complex at pH 10 in the presence of excess amount of NH3 aqueous solution.

Among the five water-soluble titanium complexes, the structures of the titanium–citrate complex, the titanium–lactate complex, and the titanium–glycolate complex have been determined [17–19]. Among these complexes, only the architecture of Ti–O–Ti bonds in the titanium–glycolate complex resembles the atomic arrangement in brookite and this is the reason why single-phase brookite can be selectively synthesized from the titanium–glycolate complex [19]. The titanium–lactate complex contains only one Ti atom in the molecule [18] and it does not provide any “built-in” structure of titanium polymorphs. Therefore lactate complex acts most likely only as a source of titanium ions and formation of anatase, rutile, and anatase–brookite mixture follows well-known pH dependence. The reasons for the exclusive anatase formation from the citrate, tartrate, and malate complexes are not clear yet.

Effects of amount of NH +4 , pH and reaction time

Figure 2 shows the XRD patterns for the particles synthesized by the hydrothermal treatment of the titanium glycolic acid complex by adding various amounts of 30% NH3 aqueous solution. This original solution of the complex had a pH 6; pH values of 9.1 and 9.3 were obtained by adding 0.2 mL and 0.5 mL of the ammonium solution, respectively (total volume was 20 mL). Adding more than 1.0 mL NH3(aq) yielded a pH 10. The formation of the brookite phase can be confirmed by the characteristic diffraction peak at 2θ ≈ 30.8° in the XRD patterns. According to the XRD patterns (Fig. 2), brookite phase was obtained under basic conditions, even if the excess amount of NH3 aqueous solution was very small. The more NH3(aq) was added, the weaker was the characteristic rutile peak at around 2θ = 27.4° and the sharper was the characteristic peak of brookite observed at around 2θ = 30.8°. The Raman spectra show that single-phase brookite was obtained in the presence of over 0.5 mL ammonium solution. Figure 3 shows TEM images of brookite particles obtained by the hydrothermal treatment of the titanium–glycolate complex with various amounts of NH3(aq). All the samples were composed of rod-like nanosized particles. For larger amounts of aqueous NH3, larger particles of TiO2 were obtained. These results are consistent with the XRD patterns.

To check the effect of NH +4 ions on the formation of brookite, the concentration of NH +4 equal to that after addition of 1.0 mL of 30% NH3 aqueous solution was adjusted by adding ammonium sulfate (NH4)2SO4. The pH of this solution was 5.1. After hydrothermal treatment of the prepared solution at 200 °C for 24 h, rutile was obtained as the only phase. This result demonstrated that a basic solution (pH about 10) is important to obtain single-phase brookite, while ammonium ions do not seem to play an important role.

The hydrothermal reaction time was also varied between 1 and 100 h when 1.0 mL NH3 (aq) was added to the titanium–glycolate complex solution. An amorphous phase was obtained after 1 h treatment. However, after 2 h brookite started to form as the single phase. This observation indicates that brookite does not form through intermediate phases, rather the brookite nuclei are directly formed from the complex and continue to grow in the solution.

Effects of a different of additives

Figure 4 shows XRD patterns of the particles obtained from the titanium–glycolate complex in the presence of various compounds. Single-phase brookite was obtained from the complex solution at a pH of about 10 after the addition of 99.0% ethylenediamine, whereas a mixture of brookite and rutile was obtained from solutions containing NaOH or KOH. We believe that the complexes in the presence of a strong base such as NaOH or KOH were substantially hydrolyzed and the original structure was destroyed or at least altered. The resulting structures of the complexes were not favorable for building the brookite nuclei. It had been reported that the presence of alkaline or alkaline earth metals is important for the formation of brookite [16], however we demonstrated that in the presence of sodium chloride at neutral pH rutile formed as the only phase (see Fig. 4f). Our experience indicates that it is the weakly basic environment that is important for the formation of brookite.

Conclusions

Brookite was obtained by the hydrothermal treatment of the titanium–glycolate or the titanium–lactate complex solutions under basic conditions. In particular, single-phase brookite was prepared from the titanium–glycolate complex solution in the presence of excess amount of NH3 aqueous solution or ethylenediamine. When the solution was almost neutral or acidic, brookite was not obtained even in the presence of excess amount of ammonium ions. Also brookite could not be obtained from the solutions with citric acid, malic acid, or tartaric acid as ligands under any conditions. These results indicated that the structure of the titanium complexes is important to build up brookite. In addition, we revealed that brookite is formed directly from solution rather than through the intermediate titania polymorphs.

References

Kominami H, Ishi Y, Kohno M, Honishi S, Kera Y, Ohtani B (2003) Catal Lett 91(1–2):41

Yin S, Fujishiro Y, Wu J, Aki M, Sato T (2003) J Mater Pro Tech 137:45

Yin S, Sato T (2004) J Photochem Photobio A Chem 163:1

Yamoto T, Wada Y, Yin H, Sakata T, Mori H, Yanagida S (2002) Chem Lett 31(10):96

Yin S, Li R, He Q, Sato T (2002) Mater Chem Phys 75:76

Cheng H, Zhenguo JM, Qi L (1995) Chem Mater 7:663

Li X, Xiong Y, Li Z, Xie Y (2006) Inorg Chem 45(9):3493

Music S, Gotic M, Ivanda M, Popovic S, Turkovic A, Trojko R, Sukulic A, Furic K (1997) Mater Sci Eng B 47:33

Zhang YH, Chan CK, Porter J, Guo W (1998) J Mater Res 13:2602

Potter A, Chnèac C, Trone E, Mazerolles L, Jolivet J-P (2001) J Mater Chem 11:1116

Ye X, Sha J, Jiao Z, Zhang L (1997) Nano Struct Mater 8(7):919

Nagase T, Ebina T, Iwasaki T, Hayashi H, Onodera Y, Chatterjee M (1999) Chem Lett 28(9):911

Zheng Y, Shi E, Cui S, Li W, Hu X (2000) J Am Ceram Soc 83(10):2634

Zheng Y, Shi E, Cui S, Li W, Hu X (2000) J Mater Sci Lett 19:1445

Mitsuhashi T, Watanabe M (1978) Mineral J 9:236

Kominami H, Kohno M, Kera Y (2000) J Mater Chem 10:1151

Kakihana M, Tada M, Shiro M, Petrykin V, Osada M, Nakamura Y (2001) Inorg Chem 40:891

Kakihana M, Tomita K, Petrykin V, Tada M, Sasaki S, Nakamura Y (2004) Inorg Chem 43:4546

Tomita K, Petrykin V, Kobayashi M, Shiro M, Yoshimura M, Kakihana M (2006) Angew Chem Int Ed 45:2378

Tompsett GA, Bowmaker GA, Cooney RP, Metson JB, Rodgers KA, Seakins JM (1995) J Raman Spectrosc 26:57

Acknowledgements

We are grateful for support by a CREST/JST grant. Part of this work was also supported by a Grant in Aid for Science Research, No. 18206069 from the Ministry of Education, Science and Culture, Japan.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Kobayashi, M., Tomita, K., Petrykin, V. et al. Direct synthesis of brookite-type titanium oxide by hydrothermal method using water-soluble titanium complexes. J Mater Sci 43, 2158–2162 (2008). https://doi.org/10.1007/s10853-007-1912-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-007-1912-3