Abstract

Viscosity and electrical conductivity of liquid Sn–Ti and Sn–Zr alloys on the Sn-rich side were investigated in a wide temperature range above the melting temperature. It was shown that admixtures of Ti and Zr considerably increased the viscosity of liquid Sn. The electrical conductivity of the melts decreased with an increase of the Ti and Zr content. The conductivity results are interpreted in the context of the s–d hybridization model.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Typical filler metals for diamond brazing are based on ternary or quaternary Cu-based systems like Cu–Sn–Ti–Zr which contain active elements such as Ti or Zr in order to wet the diamond or other ceramic materials. Brazing processes need accurate information on thermodynamic data and phase diagrams of the binary and ternary subsystems. Although thermodynamic properties of binary Sn–Ti and Sn–Zr systems are comparatively fully studied [1–3], discrepancies between the published assessments still remain and some aspects are undetermined. Especially the intervals of solubility at higher temperatures, the structure of intermetallic compounds and their thermal expansion, in particular near the liquidus line on the Sn rich side of these systems. The components of the Sn–Ti and Sn–Zr systems show a substantial difference in melting temperatures. Therefore, the addition of a refractory element effects a drastic increase of the liquidus line, and even a negligible error in the alloy composition can provoke a serious error in determination of the solidification onset. Because of this peculiarity and the experimental difficulties the data on structure-sensitive properties of these systems in the liquid state are scarce in the literature. Nevertheless, the knowledge of the physical properties of the molten alloys prior to solidification is very important for the development of materials with predetermined characteristics.

In this work we present results for the viscosity and electrical conductivity of liquid Sn–Ti and Sn–Zr alloys on the Sn-rich side (up to 25 at.% Ti, Zr) measured over а wide temperature interval above the liquidus. We believe that these measurements are the first to be reported.

Experimental

The measurements of the dynamic viscosity were carried out using a computer-controlled oscillating-cup viscometer. Cylindrical boron nitride crucibles were used. The temperature was measured with a WRe-5/20 thermocouple arranged just below the crucible. The experiments were performed in an atmosphere of Ar + H2 after initially pumping out the working volume of the furnace to ∼10 Pa. A homogeneous temperature field up to values of 1600 K was created inside a furnace. The samples were initially heated and held at high temperatures well above the liquidus. After the oscillation period did not change any more with time indicating that the sample became homogeneous, the viscosity was measured during cooling the sample. Using the modified Roscoe equation, the viscosity has been calculated from the logarithmic decrement and the period of oscillations. The viscosity values were obtained with an accuracy of about 5%.

The electrical conductivity was measured by a contact method in accordance with the 4-point scheme as described elsewhere [4]. The samples were contained in the measuring cells manufactured of BN ceramics in the form of vertical cylinders with an operating cavity height of 60 mm. Six graphite electrodes, two for the current and four for the potential measurements, were inserted into the wall of the container along its vertical axis. The potential electrodes were provided with WRe-5/20 thermocouples. The experiments were performed under Ar gas pressures up to 10 MPa. The resultant error of the electrical conductivity did not exceed 2%.

Results and discussion

Viscosity

Four samples of both Sn–Ti and Sn–Zr identical in composition were chosen for the investigation: Sn98Ti2, Sn95Ti5, Sn85Ti15, Sn75Ti25 and Sn98Zr2, Sn95Zr5, Sn85Zr15, Sn75Zr25 (at.%). The measured values of the dynamic viscosity of the alloys, η(T), are presented in Figs. 1 and 2 together with that of pure Sn for comparison. The experimental data for pure Sn are in a good agreement with those reported earlier [5, 6]. The viscosity increases exponentially with cooling and the temperature dependence η(T) can be rather well described by the Arrhenius equation:

where η 0 is a constant (mPa s), R is the gas constant (J mol−1 K−1), T is the absolute temperature (K), E A is the flow activation energy (J mol−1). The η(T) curves calculated by the Arrhenius equation are denoted in Figs. 1 and 2 by solid lines. The values of η 0 and E A for the studied alloys are given in Table 1.

It is seen from Figs 1 and 2 that the admixtures of Ti and Zr increase the viscosity of liquid Sn. Literature viscosity data for pure liquid Ti and Zr are rare, very approximate and contradictory [7–11]. At the melting temperature, the viscosity of Ti obtained by levitation technology [9] is about a factor of two larger than that reported in [8] where the capillary technique was used. Similar discrepancies were also revealed for liquid Zr [9–11].

Both Sn–Ti and Sn–Zr binary systems are composed of components with substantial difference in melting temperatures. Because of this difference, the application of simple models, like the regular solution model is somewhat questionable. Another attempt with the Moelwyn–Hughes equation [7] and regular solution parameter taken from [12] for Sn–Ti and [13] for Sn–Zr found that the calculated viscosity values for both systems are systematically higher than the experimental ones, and the divergence increases with cooling. A positive deviation of viscosity is in agreement with a negative enthalpy of mixing for the both compound forming systems [12, 13], as pointed out in the recent viscosity review [14 and references therein].

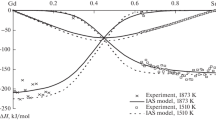

Electrical conductivity

The experimental temperature dependence of the electrical conductivity of liquid Sn–Ti and Sn–Zr alloys and pure Sn, σ(T), is presented in Figs. 3 and 4. The data for pure Sn are in agreement with those reported earlier [15]. In all alloys the electrical conductivity decreases gradually with heating and with the increase of the Ti or Zr additions. The later also leads to a decrease of the temperature coefficient dσ/dT in the high-temperature region corresponding to liquid phase. A drastic increase of the electrical conductivity, specific for each composition, corresponds to the solidification onset. Contrary to the stepwise conductivity changes in pure metals during the liquid–solid transition, the extended conductivity increase during solidification is explained by a gradual precipitation of the solid phases between liquidus and solidus temperature. The later is peculiar to the systems with substantial difference in melting temperatures of the components.

The electrical conductivity of simple liquid metals is well described by the Ziman equation [16] which makes use of pseudopotentials and structure factors. Serious difficulties are encountered in the case of 3d transition metals. The point is that d-electrons heavily distort the density of states and the free electron approximation in its classic form is not quite correct.

The interpretation in terms of phase shifts, proposed by Friedel [17], provides only semiquantitative agreement with experiment [18]. The Ti and Zr dopants belong to transition metals with partially filled d shells. The d states in such solutes can be described using the Friedel–Anderson scheme, central to which is the concept of virtual bound states. This picture is substantiated by experimental data for transition metal impurities in liquid Al [19] and Sn [20].

The electrical conductivity of a liquid alloy is expressed as [21]:

where \( {\hbar } \) is the Planck constant, n e is the electron density, e is the electron charge, L 0 is the mean free path of conduction electrons, k f is the Fermi wave number.

It is clear that the change of conductivity in Sn–Ti and Sn–Zr alloys can be attributed to the changes in the parameters n e and L 0. The later is due to the structure changes, which may include the altering of the nearest neighbour distance, the first coordination number, as well as the relaxation time of s–d resonance scattering. The contribution of these parameters to the total conductivity can be very different. n e can lead either to an increase or to a decrease of conductivity, whereas a decrease of L 0 due to the s–d resonance scattering always results in a decrease of conductivity as it occurs if Ti or Zr are added to liquid Sn.

Summary

Viscosity and electrical conductivity of liquid Sn–Ti and Sn–Zr alloys were studied by the oscillating-cup and the four-probe method, respectively. The temperature dependence of the viscosity can be well described by the Arrhenius equation. The admixtures of 3d metal to liquid tin lead to a substantial increase of the viscosity in the liquid Sn–Ti and Sn–Zr alloys as predicted for the compound forming systems. Admixtures also reduce the electrical conductivity of the liquid Sn. The conductivity results are interpreted in terms of s–d hybridization.

References

Dupin N, Ansara I, Servant C et al. (1999) J Nuclear Mater 275:287

Subasic N (1998) Calphad 22(2):157

Liu C, Klotz UE, Uggowitzer PJ, Löffler JF (2005) Monatshefte für Chemie-Chemical Monthly 136(11):1921

Plevachuk Yu, Sklyarchuk V (2001) Meas Sci Technol 12(1):23

Herwig F, Wobst M (1991) Z Metallkd 82:913

Gebhardt E, Köstlin K (1958) Z Metallkd 48:636

Battezzati L, Greer AL (1989) Acta Metall 37(7):1791

Agaev AD, Kostikov VI and Bobkovski VN (1980) Izv Akad Nauk SSSR Metall 43(3)

Paradis P-F, Ishikawa T, Yoda S (2002) Int J Thermophys 23(3):825

Elyutin VP, Maurakh MA, Turov VD (1965) Izv Vyssh Ucheb Zaved Chern Met 8:110

Ishikawa T, Paradis P-F, Itami T, Yoda S (2005) Meas Sci Technol 16:443

Heuzy M-C, Pelton AD (1996) Metall Trans 27B:810

Sudavtsova VS, Podarevskaya OV (2001) In: Gelchinski B (eds) in Proceedings of the 10th Russian Conference on Structure and Properties of Metallic and Slag Alloys, Ekaterinburg, November 2001. YUrGU edition, Ekaterinburg, p 10

Terzieff P (2006) J. Alloys Compd., doi:10.1016/j.jallcom.2006.11.074

Bestandji M (2000) Ph. D. Thesis, University of Metz, France

Ziman J (1972) Principles of the theory of solids. Cambridge Univ. Press, London

Friedel J (1969) In: Ziman JM (ed.) Transition metals: electronic structure of the d band and its role in “Crystalline and Magnetic Structures, The Physics of Metals, vol. 1: Electrons”. Cambridge Univ., London

Makradi A, Gasser JG, Hugel J et al. (1999) J Phys: Condens Matter 11:671

Terzieff P, Auchet J (1998) J Phys: Condens Matter 10:4139

Tamaki S (1968) J Phys Soc Jpn 25(6):1596

Faber TE (1972) An introduction to the theory of liquid metals. Cambridge Univ., London

Acknowledgments

This work was financially supported by SNSF in the framework of the SCOPES research project No. IB7320-111101/1.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Plevachuk, Y., Mudry, S., Sklyarchuk, V. et al. Viscosity and electrical conductivity of liquid Sn–Ti and Sn–Zr alloys. J Mater Sci 42, 8618–8621 (2007). https://doi.org/10.1007/s10853-007-1821-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-007-1821-5