Abstract

The influence of dibenzylidene sorbitol (DBS) on the optical clarity, crystallization behaviour and morphology of polyethylene has been studied by UV/visible spectroscopy, differential scanning calorimetry (DSC) and scanning electron microscopy (SEM). By combining crystal growth rates with Avrami parameters derived from DSC crystallization exotherms, nucleation densities were determined as a function of crystallization temperature. In the blend without DBS, the nucleation density decreased progressively with increasing crystallization temperature whereas, in the system containing DBS, the nucleating efficiency was found to remain constant and then decrease dramatically above 120 °C. Throughout the crystallization range studied, the DBS increased the nucleation density substantially, often to a value comparable with that seen in a commercial sorbitol-clarified propylene/ethylene copolymer system. SEM revealed a change from a continuous lamellar texture at low temperatures to one based upon isolated sheaf-like objects at 124 °C. At high crystallization temperatures, both the DSC and the SEM also provided evidence of a significant rejected linear fraction, which appeared to decorate the sorbitol network on quenching. Possible explanations for these effects are discussed.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Many different additives are used to modify the behaviour of engineering polymers. In the case of polypropylene, nucleating agents [1, 2] are often used and, in applications where optical clarity is important, the family of compounds based upon dibenzylidene sorbitol (DBS) [3, 4] has proved particularly effective. DBS is an amphiphile derived from the sugar alcohol d-glucitol which, because of its butterfly-like shape and constituent benzene rings, acetal oxygen moeties and hydroxyl groups, can self-assemble through a variety of intermolecular interactions [5, 6]. Many sorbitol derivatives constitute physical molecular organogelators; that is, they are capable of self-assembly at low concentrations into extended gel structures within a wide range of different liquids, including polymer melts, with consequent changes in the physical properties of the system [7, 8]. The precise structure adopted by DBS within polymeric melts depends upon the polarity of the matrix [9–11] and the concentration of the DBS; a complete phase diagram for the isotactic polypropylene/1,3:2,4-bis(3,4-dimethyldibenzylidene)sorbitol (DMDBS) system has been reported by Kristiansen et al. [12]. At concentrations of the order of 0.3%, DBS self-assembles to form an open, random network of twisted filaments, of the order of 10 nm in diameter [13]. As the concentration of DBS increases (∼1%), so these aggregate to form highly organized fibrillar bundles [14] until, at concentrations above 1.5–3%, depending upon the matrix system under investigation, spherultic arrangements of optically-visible sorbitol fibrils are reported [12, 15, 16].

Nevertheless, when incorporated into propylene-based systems at concentrations of less than 1%, the above disperse gels [13, 14] result in a massive increase in nucleation, which contributes to reduced optical scattering and improved mechanical properties [14]. Although effects have been reported in other polyolefins, the use of DBS has not been adopted widely elsewhere. Li et al. [17] introduced a sorbitol into low density polyethylene (LDPE) and observed modified charge transport behaviour. Changes have also been reported in the light scattering and non-isothermal crystallization behaviour of LDPE, although no detailed morphological analysis was attempted [18]. Manaure and Müller [19] examined the non-isothermal crystallization of a range of ethylene-based copolymers in the presence of DBS, noting that in general, the nucleating effect of the sorbitol appears complex. Finally, Nogales et al. [20] examined the effect of DBS on the crystallization behaviour of a number of sheared polymers, and demonstrated the existence of highly extended and oriented crystalline DBS within the melt and showed how this could give rise to oriented polymer crystallization. Evidently, sorbitols can modify the crystallization behaviour and morphology of a range of polyolefins, with potential property benefits. The study described here was therefore undertaken to investigate the effect of DBS on morphological evolution in polyethylene and to compare its effect with that seen in propylene-based systems.

Experimental

This study primarily concerns a polyethylene blend containing 20% linear (LPE) and 80% branched polyethylene (BPE). The linear polyethylene was the conventional Ziegler Natta high density polymer Rigidex 160-25 (BP), while the branched polyethylene was the low density material LD100BW (Exxon). This latter material was synthesised using a free radical high pressure process and, as such, would contain a range of branch lengths and of the order of 30 branches per 1,000 carbon atoms [21]. Molar mass data for both systems are given in Table 1. These polymers were blended in the melt and pelletized to give a material, which here and elsewhere [22] is referred to as BPK T/20M. In this, T indicates the crystallization conditions (crystallization temperature, T c, or quenched, Q) and 20, the percentage of LPE present. DBS was then added through a solution process, in which the required mass of polymer plus 0.3% of DBS were dissolved in xylene and precipitated in cold hexane. This system will be referred to as BPK T/20S. For comparison, data obtained from a commercial clarified propylene/ethylene copolymer (Novolen 3200MC, BASF) are also included.

The above materials were characterized by UV/visible spectroscopy, differential scanning calorimetry (DSC) and scanning electron microscopy (SEM). To estimate optical clarity, transmission through samples 70 μm in thickness was measured over the wavelength range 300–1,100 nm [16], using a Perkin Elmer Lambda 35 spectrometer. The samples were immersed in silicone oil and a cuvette filled with silicone oil was used as a reference. Thermal analysis was carried out using a Perkin–Elmer DSC 7, calibrated with high purity indium. For SEM, internal surfaces were cut using an RMC CR21/MT7 cryo-ultramicrotome and then etched using a 1% w/v solution of potassium permanganate in an acid mix containing five parts concentrated sulphuric acid, two parts orthophosphoric acid and one part water. Etching and sample recovery were performed according to standard procedures [23, 24].

Results

Optical clarity

Figure 1 shows plots of optical transmission as a function of crystallization temperature for both polyethylene blend systems and the commercial clarified propylene/ethylene copolymer. These data relate to a wavelength of 550 nm, but equivalent behaviour was observed at other wavelengths [16]. In the case of the Novolen 3200MC, rapid quenching produces samples that exhibit maximum optical transmission (∼95%) while, for isothermal specimens, increasing the crystallization temperature results in a progressive reduction in clarity. From Fig. 1, the transmitted intensity falls from ∼93% for samples crystallized at 110 °C to ∼85% for samples crystallized at 135 °C. We have previously shown that in Novolen 3200MC there is no marked reduction in the nucleating efficiency of DBS between 119 and 136 °C [25] whereas, within this temperature window, there is a significant reduction in the extent to which the ethylene-rich molecular fraction is able to crystallize [26]. The above reduction in optical clarity is therefore largely a morphological effect, relating to molecular fractionation and segregation effects [26] and changes in the relative proportions of the α and γ crystal forms [27, 28].

Plot of optical transmission at a wavelength of 550 nm against crystallization temperature for the polyethylene blend systems BPK T/20M (△: without DBS) and BPK T20/S (▴: with DBS). Equivalent data derived from the commercial clarified propylene/ethylene copolymer Novolen 3200MC (♦) are shown for comparison

The behaviour of the two polyethylene systems is, quantitatively, rather different from that described above. The BPK T/20M system without DBS exhibits greatly reduced optical transmission throughout the accessible isothermal crystallization range; up to 120 °C, the transmission drops progressively, before falling dramatically. In blends of this type, 120 °C corresponds to the typical temperature at which a continuous banded spherulitic texture is replaced by one in which the LPE crystallizes to form relatively compact lamellar aggregates, separated from one another by BPE [29]. At high crystallization temperatures, T c > 120 °C, the behaviour of BPK T/20M (without DBS) and BPK T/20S (with DBS) are indistinguishable whereas, below 120 °C, the clarity of the system containing DBS is greatly improved and approaches that of the Novolen 3200MC. These results indicate that DBS can have a marked effect on the optical properties of polyethylene but, unlike the propylene/ethylene copolymer, this appears to be very temperature dependent.

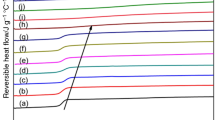

Melting behaviour

Typical DSC melting traces for the two polyethylene systems are shown in Figs. 2, 3. In the absence of DBS (Fig. 2), the behaviour of the system is in line with published data [29–32] in that all traces are dominated by two transitions. The high temperature peak in the range 125–130 °C characterizes the LPE-rich lamellae that form isothermally, while the broad transition around 108 °C corresponds to quenched, BPE-rich material. In the system containing DBS (Fig. 3), an additional, intermediate feature (arrowed) develops progressively between the two principal transitions as the crystallization temperature is increased. In BPK 122/20S, for example, this is located at about 118 °C and, consequently, must be associated with quenched material. This feature is always located below T c.

Morphology

The morphologies seen in BPK T/20M (i.e., in the absence of DBS) are typical of such a blend, ranging from relatively open banded spherulites below about 120 °C, to compact LPE-rich axialites separated from one another by BPE at higher temperatures [29, 30]. Consequently, for the sake of brevity, no micrographs of this material are shown here. In the case of the blend containing DBS, four representative temperatures were chosen to illustrate the range of morphologies seen in this system.

When crystallized at 118 °C, BPK 118/20S forms open sheaf-like objects (see Fig. 4) that are composed of a radiating array of thick, isothermally crystallized lamellae separated from one another by quenched, branched polymer. These objects fill space. The nucleation density in this system is, however, extremely high and, consequently, these axialites are rather immature [33]. At 120 °C, isolated axialites can be seen in the region of the sample shown in Fig. 5, indicating that the nucleation density is somewhat lower. Increasing the crystallization temperature further results in a marked reduction in nucleation density and the formation of objects of increasing internal complexity, as shown in Figs. 6, 7. Figure 7 shows a sample crystallized isothermally to completion at 124 °C, where the constituent axialites are composed of a densely packed array of isothermal lamellae. In such objects, the subsidiary lamellae appear entirely to fill the interstices between the first-formed dominant crystals [34].

In addition to changes in the form of the objects that develop isothermally, the structure of the quenched matrix also varies systematically with isothermal crystallization temperature. After crystallization at 118 °C, the quenched matrix appears rather featureless at SEM resolutions, in common with similar blends without DBS [29]. However, as the crystallization temperature increases, so the presence of structural features within the matrix becomes increasingly evident; Fig. 8 shows structural features that appear linear in form and resemble the shish-kebab textures reported for polyethylene systems crystallized following melt shear [35, 36]. Previous studies of blend systems based upon Rigidex 160-25 [37] have revealed growth-halos [38] around spherulites grown isothermally at 125 °C, which form as a result of the rapid crystallization, during quenching, of the low molar mass linear fraction that is evident in Table 1 [39]. We propose that the extended structures shown in Fig. 8 have a similar origin, but that here, these result from the decoration of DBS fibrils by crystals formed from low molar mass LPE. It is this lamellar population that, on melting, gives rise to the intermediate DSC peak arrowed in Fig. 3.

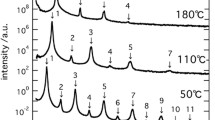

Avrami analysis

Avrami theory [40–43] provides a direct means of calculating absolute nucleation densities, provided the kinetics of crystal growth are known. Consequently, Fig. 9 was generated from DSC measurements of isothermal crystallization behaviour using appropriate kinetic data for BPK T/20M [44]. In the case of BPK T/20M, the nucleation density drops progressively as T c increases whereas, in the presence of the DBS, the nucleation density remains approximately constant at ∼5 × 1010 cm−3 up to about 120 °C, and then falls dramatically. Estimates from SEM micrographs of nucleation densities in BPK T/20S lead to figures of ∼2 × 1010 cm−3 at 120 °C and ∼3 × 108 cm−3 at 124 °C, which are in line with the data presented in Fig. 9. Thus, we can conclude that, throughout the temperature range studied, the addition of DBS increases the nucleation density by between 2 and 3 orders of magnitude, indicating that DBS is a highly effective nucleant for polyethylene. For comparison, Fig. 9 also includes nucleation data previously reported for Novolen 3200MC [25], which are typical of such a system [3, 45]. Evidently, DBS can induce nucleation densities in polyethylene that are at least as high as those in the clarified propylene-based system.

Discussion

Although the control of physical properties has been the major driver associated with the technological application of sorbitols, the most intriguing element to emerge from this study is the temperature dependence of the nucleating behaviour of DBS. In particular, we feel that the abrupt decrease in the nucleating efficiency of DBS above 120 °C may provide important clues concerning the fundamental nature of polymer/sorbitol interactions. A number of explanations can be proposed for this effect.

The sharp change in behaviour we see between 120 and 124 °C could be a solubility effect; that is, the DBS exists as a disperse gel below 120 °C but progressively dissolves in the polyethylene as the melt temperature increases over this small range [12]. However, the above hypothesis does not agree well with a considerable body of experimental evidence. First, from Fig. 9, it is evident that the nucleation density falls by two orders of magnitude between 120 and 123 °C and therefore, if this were solely a result of dissolution of the DBS, it would suggest that 99% of the gel dissolved within this narrow temperature range. Shepard et al. [14] examined the rheological behaviour of a number of polyolefin systems containing DMDBS and showed that, in fact, gels form progressively over a wide temperature range. Nogales et al. [20] performed X-ray scattering studies on polypropylene containing 1% DBS and concluded that the DBS exists as anisotropic crystalline structures at 170 °C, in good agreement with the rheological data described above. These workers also reported that DBS is similarly present as anisotropic solid structures at the same temperature when polyethylene is used in place of polypropylene [20], so suggesting that DBS does not behave in a radically different manner in these two host polymers. Indeed, sorbitol gel formation processes have been explored in a range of different solvents and have been shown to depend critically on the polarity of the matrix [9–11]; polyethylene and polypropylene are both non-polar molecules. Thus, if one assumes that the DBS gel formation process is not radically different in these two polymers, for a non-polar polyolefin system containing 0.3% of sorbitol, the sol/gel transition should occur progressively between about 175 and 150 °C [12, 20]. Second, the morphology shown in Fig. 8 shows extended structures decorated by polyethylene lamellae, which we believe are best interpreted in terms of a low molar mass linear polyethylene fraction that has crystallized rapidly upon fibrils of DBS during quenching. If the DBS were largely dissolved at 124 °C then, for this to have occurred, the fibrils of DBS must have rapidly self-assembled during quenching, before the low molar mass LPE fraction was able to crystallize. This is inconsistent with the kinetics of sorbitol gel formation [36]. Thus, although we cannot entirely dismiss the possibility that the rapid decrease in nucleation density we see above 120 °C is caused by the abrupt dissolution of the DBS in the polyethylene matrix, we do not believe that this is the most likely explanation for this effect.

The alternative interpretation of Fig. 9 concerns the interactions that occur between the DBS and the crystallizing polymer. The mechanism by which a solid additive acts to promote nucleation can be termed epitaxy and classical epitaxy occurs under conditions where crystallographic disregister is less than 10–15% [46–48]. However, Mitchell and co-workers have shown that DBS can influence the crystallization behaviour of polymers ranging from polyethylene [20] to poly(ε-caprolactone) [49], suggesting that neither chemical interactions nor precise lattice dimensions are the route cause of the nucleating ability of DBS. Rather, these workers have suggested that DBS may “direct the polymer crystallization through a graphoepitaxy-type mechanism” [49]; that is, through nucleation on topographical features a few nanometres in height [50]. A similar explanation has also been proposed to account for variations in the nucleating ability of chalk [43]. Thus, the ability of a substrate to induce nucleation will depend not only on lattice matching, local interactions etc, but also on its available dimensions—a phenomenon Gresco and Phillips have termed the “Template Mechanism” [46]. If such a process were to occur in DBS, then the decrease in the nucleating effectiveness of the DBS that is seen at ∼120 °C may be associated with the scale of the features exhibited by the DBS fibrils relative to the polyethylene stem length required to initiate crystal growth. Shepard et al. [14] have shown that, in polyolefin melts, individual fibrils of DMDBS can aggregate to form structures that range in size from 10 to 100 nm, whereas the initial critical stem lengths measured in polyethylene range from 12 nm at 110 °C to 22 nm at 128 °C [51]. Thus, as the crystallization temperature increases, so the size of the critical nucleus increases, such that a reduced fraction of the DBS fibril size distribution would be able to act as nucleation sites and the nucleation density would drop, as is seen experimentally.

Conclusions

The addition of DBS to polyethylene results in greatly enhanced nucleation. Nucleation densities were found to be increased by between 2 and 3 orders of magnitude, to values than exceed those seen in a commercial clarified propylene/ethylene copolymer. However, above ∼120 °C, the nucleating efficiency of DBS for polyethylene decreases dramatically such that a continuous space-filling lamellar texture is replaced by discrete axialites surrounded by quenched matrix. At the highest temperatures, there is clear evidence of structure within the matrix, which we interpret as decorated DBS fibrils. Although this pronounced decrease in the nucleating effectiveness of DBS above 120 °C could be explained in terms of a progressive dissolution of the DBS or through a change in the nature of the polymer/sorbitol interactions, in view of reports of the direct detection of DBS fibrils in polyethylene melts at temperatures as high as 170 °C [20], the rheological behaviour of polyolefin/sorbitol systems [12, 14] and our observation of shish-kebab structures within the quenched matrix after high temperature isothermal crystallization, we believe that the relative size of the DBS fibrils and the critical polymer nuclei is a key factor in determining the nucleating ability of sorbitol systems.

References

Fillon B, Lotz B, Thierry A, Wittmann JC (1993) J Polym Sci: Part B: Polym Phys 31:1395

Gahleitner M, Wolfschwenger J, Bachner C, Bernreitner K, Neissl W (1996) J Appl Polym Sci 61:649

Fillon B, Thierry A, Lotz B, Wittmann JC (1994) J Thermal Anal 42:721

Sterzynski T, Lambla M, Crozier H, Thomas M (1994) Adv Polymer Tech 13:25

Watase M, Nakatani Y, Itagaki H (1999) J Phys Chem B 103:2366

Wilder EA, Spontak RJ, Hall CK (2003) Mol Phys 101:3017

Terech P, Weiss RG (1997) Chem Rev 97:3133

Terech P, Rossat C, Volino F (2000) J Colloid Interf Sci 227:363

Wilder EA, Hall CK, Khan SA, Spontak RJ (2003) Langmuir 19:6004

Yamasaki S, Tsutsumi H (1995) Bull Chem Soc Jpn 68:123

Ilzhoefer JR, Spontak RJ (1995) Langmuir 11:3288

Kristiansen M, Werner M, Tervoort T, Smith P, Blomenhofer M, Schmidt H-W (2003) Macromolecules 36:5150

Thierry A, Straupé C, Lotz B, Wittmann JC (1990) Polym Commun 31:299

Shepard TA, Delsorbo CR, Louth RM, Walborn JL, Norman DA, Harvey NG, Spontak RJ (1997) J Polym Sci: Part B: Polym Phys 35:2617

Smith JM, Katsoulis DE (1995) J Mater Chem 5:1899

Mercurio DJ, Spontak RJ (2001) J Chem Phys 105:2091

Li X, Cao Y, Du Q, Yin Y, Tu D (2001) J Appl Polym Sci 82:611

Ozawa T (1971) Polymer 12:150

Manaure AC, Müller AJ (2000) Macromol Chem Phys 201:958

Nogales A, Olley RH, Mitchell GR (2003) Macromol Rapid Commun 24:496

Brydson J (1999) Plastics materials. Butterworth Heinemann, Oxford, p 205

Dodd SJ, Champion JV, Zhao Y, Vaughan AS, Sutton SJ, Swingler SG (2003) IEE Proc – Sci Meas Technol 150:58

Olley RH, Hodge AM, Bassett DC (1979) J Polym Sci: Polym Phys Ed 17:627

Olley RH, Bassett DC (1982) Polymer 23:1707

Martin CP, Vaughan AS, Sutton SJ, Swingler SG (2002) J Polym Sci: Part B: Polym Phys 40:2178

Zhao Y, Vaughan AS, Sutton SJ, Swingler SG (2001) Polymer 42:6587

Laihonen S, Gedde UW, Werner P-E, Martinez-Salazar J (1997) Polymer 38:361

Foresta T, Piccarolo S, Goldbeck-Wood G (2001) Polymer 42:1167

Hosier IL, Vaughan AS, Swingler SG (1997) J Mater Sci 32:4523

Hosier IL, Vaughan AS, Swingler SG (2000) J Polym Sci: Part B: Polym Phys 38:2309

Barham PJ, Hill MJ, Keller A, Rosney CCA (1988) J Mater Sci Letts 7:1271

Puig CC (2001) Polymer 42:6579

Vaughan AS, Bassett DC (1988) Polymer 29:1397

Vaughan AS (1992) Sci Prog Oxf 76:1

Keller A, Machin MJ (1967) J Macromol Sci (Phys) B1:41

Pople JA, Mitchell GR, Sutton SJ, Vaughan AS, Chai CK (1999) Polymer 40:2769

Zhao Y (2000) PhD Thesis, The University of Reading

Patel D, Bassett DC (1994) Proc R Soc Lond A 445:577

Conde Braña MT, Iragorri Sainz JI, Terselius B, Gedde UW (1989) Polymer 30:410

Avrami M (1939) J Chem Phys 7:1103

Avrami M (1940) J Chem Phys 8:212

Avrami M (1941) J Chem Phys 9:177

Kowalewski T, Galeski A (1986) J Appl Polym Sci 32:2919

Gherbaz G, Vaughan AS, to be published

Kim CY, Kim YC, Kim SC (1993) Polymer Eng Sci 33:1445

Gresco AJ, Phillips PJ (1994) J Adv Mats 25:51

Gresco AJ, Phillips PJ (1994) Polymer 35:3373

Yan S, Petermann J, Yang D (1996) Polymer 37:2681

Siripitayananon J, Wangsoub S, Olley RH, Mitchell GR (2004) Macromol Rapid Commun 25:1365

Jandt KD, Buhk M, Petermann J (1996) J Mater Sci 31:1779

Barham PJ, Chivers RA, Keller A, Martinez-Salazar J, Organ SJ (1985) J Mater Sci 20:1625

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Vaughan, A.S., Hosier, I.L. The effect of dibenzylidene sorbitol on the crystallization behaviour of polyethylene. J Mater Sci 43, 2922–2928 (2008). https://doi.org/10.1007/s10853-007-1801-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-007-1801-9