Abstract

Calcium sulphoaluminate (CSA) cement is considered the third series cement besides ordinary Portland cement (OPC) and calcium aluminate (CA) cement. It is produced from gypsum, bauxite and limestone at 1,300 °C and consists of yeelimite, belite and anhydrite as main mineral phases. In the last years, many attempts have been made in applying Raman spectroscopy for the characterization of cement, clinker minerals and supplementary cementing materials (SCMs), revealing that this technique is a valuable tool for the identification of different phases in cements. In this work micro-Raman spectroscopy has been used, together with X-ray diffraction, for the characterization of CSA cement and its main minerals. In order to identify which mineral phase is responsible for the different bands, Raman spectra have been acquired from synthesized yeelimite and belite phases (whose purity degree was checked by X-ray diffraction) and from calcium sulphate di-hydrate and anhydrous (gypsum and anhydrite, respectively). On these bases, Raman spectra collected on CSA clinker and cement have been successfully assigned. Moreover, Raman spectroscopy, together with X-ray diffraction, proved useful to follow the hydration process of CSA cement up to 28 days.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Calcium sulphoaluminate (CSA) cement was developed in China in the 1980s. Industrial production requires essentially gypsum, bauxite and limestone as raw materials, which are burnt at 1,300 °C in a conventional rotary kiln. These starting materials lead to a final clinker based on the quinary system CaO–SiO2–Al2O3–Fe2O3–SO3 and formed by three main minerals: tetracalcium trialuminate sulphate or yeelimite \( ({\text{C}}_{4} {\text{A}}_{3} \overline{{\text{S}}} ), \) dicalcium silicate or belite (C2S) and calcium sulphate or anhydrite \( {\text{(C}}\overline{{\text{S}}} {\text{)}}{\text{.}} \) Minor phases such as tricalcium aluminate (C3A), tetracalcium aluminoferrate or brownmillerite (C4AF), dodecalcium heptaaluminate or mayenite (C12A7) and dicalcium aluminum silicate or gehlenite (C2AS) can also be present.Footnote 1

Yeelimite (chemical formula Ca4Al6SO16) has a tetragonal crystalline structure with a 0 = b 0 = 13.03 Å and c 0 = 9.16 Å, space group \( {\text{P}}\overline{4} {\text{C}}2 \) [1]. The lattice is made up of [AlO4]5− tetrahedra sharing all oxygen atoms with other tetrahedra, giving rise to channels parallel to [001] directions: in these paths nesotetrahedra [SO4]2− and Ca2+ ions in cubic coordination are located.

Belite (Ca2SiO4) exists in at least four different polymorphs: α and α′ are trigonal polymorphs only stable at high temperatures (>1,400 °C); the β polymorph is monoclinic and the γ is orthorhombic. In cement clinker, the most stable phase is the β polymorph (a 0 = 5.51 Å; b 0 = 6.75 Å; c 0 = 9.32 Å; β = 94°38′; SG = P21/n) [2]. The structure is built up by columns of alternating [SiO4]4− tetrahedra and Ca2+ atoms, linked together by other Ca2+ ions placed in the holes between the tetrahedra.

Anhydrite (CaSO4) is orthorhombic, with a 0 = 6.99 Å, b 0 = 7.00 Å, c 0 = 6.24 Å, SG = Amma [3]. The structure is formed by [SO4]2− tetrahedra and [CaO8]14− distorted dodecahedra linked together to form alternating edge-sharing chains parallel to the z-axis.

Calcium sulphoaluminate cements are characterized by many advantageous properties [4–6] in particular for specific applications, like high early compression strength (i.e. 35–50 MPa at 12–24 h, up to 100 MPa after 5–10 years), tunable time of workability depending on the addition of different additives, high frost and corrosion resistance and limited shrinkage and expansion if set in presence or absence of free lime, respectively. Moreover, their production requires a lower clinker burning temperature and gives rise to lower emissions of CO2 compared to ordinary Portland cements (OPCs): these cements are therefore favored concerning their environmental impact.

Hydration of calcium sulphoaluminate cement essentially results in the rapid formation of ettringite \( ({\text{C}}_{6} {\text{A}}\overline{{\text{S}}} _{3} {\text{H}}_{{32}} ) \) from yeelimite and gypsum, according to the following reaction scheme:

Ettringite is the main crystalline phase formed during the hydration of CSA cement: it is a calcium trisulphoaluminate hydrate, characterized by a hexagonal structure with a 0 = 11.24 Å and c 0 = 21.45 Å (SG = P31c) [7]. The structure is built up of hexagonal columns of Ca6[Al2(OH)12 · 24H2O]6+ oriented along the z-axis; channels rise in the inter-column space, filled with sulphate groups and crystallization water. In commercial CSA cement, calcium sulphate (gypsum or hemihydrate) is added and ground with the clinker in order to control the growth of ettringite [8]: in fact, depending on its micro-structural characteristics, ettringite can influence the setting time of the cement and can be responsible for very high early strength, high sulphate resistance and low shrinkage [9].

Raman spectroscopy has been reported in a limited number of papers for the investigation of OPCs. Raman spectra of different OPCs, clinker minerals, SCMs and hydration products, have been reported by many authors using excitation sources with different wavelengths and Fourier Transform or dispersive instruments, as can be found in the literature from 1976 up to now [10–16]. Although FT-systems are not suitable for cement analyses due to the dominant effect of photoluminescence in their frequency range [17], a recent review [18] has pointed out that Raman spectroscopy offers several advantages in investigating and characterizing cementitious materials. In fact, it is easy to perform either on powders and manufactured products, it requires only small sample amounts, no sample preparation and allows low detection limits. Three important works [19–21] report hydration studies on pure clinker minerals—C3S, C3A and C4AF—using Raman spectroscopy: all of them conclude that this technique is very useful in following the hydration of pure clinker phases.

Comparing Raman spectroscopy with other instrumental techniques classically used in solid state studies, further advantages are highlighted.

X-ray Powder Diffraction (XRPD), for instance, gives information only about crystalline phases and requires accurate sample grinding and X-Ray safety management.

Infra-Red (IR) spectroscopy shows intense absorptions for water vibrations and this constitutes a great limit for hydration studies where in situ crystalline structure changes should be followed. Moreover, IR-active molecular modes are characterized by extended dipolar–dipolar coupling making very difficult the assignment on the basis of crystal vibrational analysis. Raman spectra, on the contrary, show generally a much simpler vibrational pattern, being coupling phenomena between quadrupole moments much less frequent: this suggests that the solid-state effects are often minimized and vibrations of ions or molecules in the lattice may be treated as if they were isolated.

Thermal analyses can be very useful to get information related to burning behavior of raw admixtures. Moreover these techniques can be used for quantification of water amount in hydrated pastes and, subsequently, for valuation of content of hydrated phases as ettringite or aluminum hydroxide, especially when these phases are difficult to quantify by XRD because of their low crystallinity or amorphous phases. Nevertheless it cannot be performed in situ but requires sampling of specimens.

Nuclear Magnetic Resonance (NMR) spectroscopy is a very powerful technique: it allows to obtain specific and detailed information such as coordination state of aluminum, silicon or even sulphur, to perform micro-pore size analyses of porous materials and to study hydration and/or hardening kinetics on the basis of H-1 relaxation activity of cement pastes. On the other hand, this technique still remains mainly academic, as it is difficult to perform, requires qualified operator, results are of hard interpretations and moreover it is very expensive.

In this paper we present the results of the application of Raman spectroscopy for the characterization of CSA cement and its clinker minerals (yeelimite, belite and anhydrite). Moreover, a qualitative study of CSA cement hydration by Raman spectroscopy, compared with XRD data, is reported.

The application of Raman spectroscopy dovetails possible technological implementations in the cement industrial field since, in this context, fast, economical and reliable tools for the monitoring of the production processes are often advisable.

Materials and methods

CSA clinker (specific surface = 0.50 m2/g) and gypsum (specific surface = 0.12 m2/g) samples were supplied by Buzzi Unicem S.p.A., whilst anhydrite was obtained by dehydrating gypsum at 400 °C for 2 h in a oven.

Yeelimite was prepared burning stoichiometric amounts of CaO, Al2O3 and CaSO4 · 2H2O at 1,400 °C in a Carbolite tubular furnace: successive burning were performed and at each step the growth of yeelimite was verified by XRD analysis. CaO was obtained burning limestone used as raw meal for cement production at 900 °C. Al2O3 was a pure reagent grade supplied by Carlo Erba (Italy).

Belite was prepared burning stoichiometric quantities of CaO and SiO2 (Merck, Germany) at 1,200 °C; 0.5% in weight of B2O3 (Merck, Germany) was added in order to stabilize the β polymorph of belite [22].

X-Ray diffraction studies were performed using a Bruker AXS D4 Endeavor diffractometer working in Bragg-Brentano geometry, equipped with a ceramic X-ray tube KFF (CuKα radiation) and a SOL-X energy dispersive detector. All measurements were performed with the following operative conditions: X-ray radiation: 40 kV and 40 mA; scan range: 5–55°; scan rate: 1.2° min−1; step size: 0.02°.

Refinement was conducted by Rietveld method using the Topas 2.0 package (commercially supplied by Bruker AXS): structural models for all the phases were taken from the software database. For some crystalline phases preferred orientations have been refined based on the March-Dollase algorithm; for ettringite spherical harmonic of second order was used to optimize the structure. ICDD catalog numbers, crystal data, preferred orientations and crystal size of the main four phases detected on all samples at different hydration times are supplied as supporting information.

Micro-Raman spectrometer was a Jobin-Yvon HR800 LabRAM instrument equipped with an Olympus BX41 microscope, a HeNe 20 mW laser working at 632.8 nm and a Peltier cooled CCD detector. Correct calibration of the instrument was verified by measuring the Stokes and anti-Stokes bands and checking the position of the Si band at ±520.6 cm−1. Each spectrum was acquired using a 10× objective, resulting in a laser beam size at the sample of the order of 50 μm: in these conditions the spot size was such that the analyzed area was statistically representative of the bulk composition. Furthermore, checks either by collection on different sample portions and by averaging several measurements on different points always gave similar results. The 1,200–300 cm−1 spectral region, where lattice vibrational modes lie, was considered; each spectrum was collected performing 5 scans of 60 s. Data elaboration was performed using the Microcal Origin 6.0 software: all spectra were subjected to a default FFT filter smoothing (5 points); only for spectrum of yeelimite an automatic background subtraction was necessary.

For hydration studies, a series of samples was prepared adding 10% in weight of gypsum to CSA clinker and water in a water:cement ratio (w/c) of 0.5. Hydration of each sample was stopped at different fixed times by grinding them under acetone to remove non-bonded water away and then drying at 40 °C. In this way hydrated powdered samples at different hydration steps were analyzed with both XRPD and Raman spectroscopy.

Results and discussion

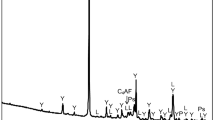

Purity of synthesized clinker minerals (yeelimite and belite) and of anhydrite were checked by X-ray diffraction: corresponding patterns, compared to X-Ray diffraction pattern of powdered CSA clinker, are shown in Fig. 1.

Raman spectra of three main mineral phases of calcium sulphoaluminate cement and gypsum are reported in Fig. 2.

Yeelimite has a strong band at 991 cm−1 and minor bands at 616 and 521 cm−1. The first two are due to vibrational modes of sulphate [SO4]2− groups [23]. The third band lies in the region 650–500 cm−1, where vibrational modes of [AlO4]5− tetrahedra in silicates can be found [24]; it is therefore supposed to be due to vibrations of [AlO4]5− tetrahedra.

Monoclinic polymorph of belite shows a more structured spectrum: the main bands, due to ν1 modes of tetrahedra [SiO4]4−, lie at 861 and 846 cm−1 and are typical for belite mineral [11]; similarly, the characteristic triplet of bands at 557, 537 and 515 cm−1, due to a ν4 [SiO4]4−, can be detected. Some other bands are visible in the Raman spectrum of belite: the band at 980 is assigned to ν3 [SiO4]4−, while the band at 899 is assigned to ν1 [SiO4]4− [10]. In the low frequency region two weak bands are found at 425 and 396 cm−1, as reported also in literature without a clear assignment [11, 18]. However, on the basis of the vibrational behavior of silicate materials [24] the two signals can be assigned to bending modes of [SiO4]4− tetrahedra (ν2).

Anhydrite shows a very strong band at 1,018 cm−1 (ν1 [SO4]2−) and minor signals at 1,161 and 1,130 cm−1 (ν3 [SO4]2−), at 676, 627 and 609 cm−1 (ν4 [SO4]2−) and at 499 and 417 cm−1 (ν2 [SO4]2−) [10].

Finally, gypsum has a very intense band at 1,007 cm−1 (ν1 [SO4]2−) and minor peaks at 1,135 and 1,096 cm−1 (ν3 [SO4]2−), at 671 and 618 cm−1 (ν4 [SO4]2−) and at 493 and 414 cm−1 (ν2 [SO4]2−) [10].

An example of CSA cement Raman spectrum is reported in Fig. 3.

Most intense bands are located at 1,016 and 991 cm−1, in the region where stretching vibrations of [SO4]2− groups lie. On the basis of their frequencies they can be assigned to anhydrite and yeelimite, respectively.

A broadened signal appears between 900 and 800 cm−1, centered at 857 cm−1. This feature is strongly asymmetrical: this is probably the result of the convolution of the two bands of C2S, that appear unresolved or as a consequence of lower crystal perfection caused by the presence of foreign ions in the lattice or because of the small particle size of minerals of CSA clinker [11]. This signal is the only fingerprint of the presence of belite in CSA sample: the triplet of bands at 557, 537 and 515 cm−1 (ν4 [SiO4]4−) are only present in well crystallized samples and are often undetectable in Raman spectra of C2S from clinker.

The large band ranging from 750 to 550 cm−1, because of the shape and the broadness, can be due to a fluorescence phenomenon occurring in presence of transition metals in the sample [11]: in particular iron, present as impurity in bauxite, can be found in substitution of aluminum in yeelimite structure. Nevertheless, in the same region, it is possible to highlight the presence of the three anhydrite bands at 676, 627 and 609 cm−1, respectively.

In the lower region of the spectrum a narrow and intense band appears at 418 cm−1, together with a minor band at 500 cm−1 and a broad band centered at 457 cm−1: all of them arise from anhydrite.

Band positions of CSA clinker, of its main phases and relative assignation are summarized in Table 1. On the whole, many acquisitions performed on powdered CSA samples gave all very similar spectra. Raman spectra of CSA span the fingerprints of all the contained phases: bands at 1,016 and 991 cm−1 are attributed to anhydrite and yeelimite and the band at 857 cm−1 to belite. The only difference concerns the relative intensities of the two bands at 1,016 and 991 cm−1. In most cases these two bands are similar in intensity, but small differences in local composition caused the increase in intensity of one or another.

In Fig. 3 a Raman spectrum of a CSA cement added with 10% gypsum is also shown, revealing the fingerprint of gypsum at 1,007 cm−1 (ν1 [SO4]2−).

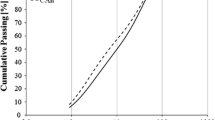

For hydration studies, samples cured between 90 min and 28 days have been investigated. Mineralogical composition of each sample has been determined by XRD quantitative analysis with Rietveld method and is reported in Table 2: along the curing time, yeelimite, belite, anhydrite and gypsum are stepwise replaced by ettringite; minor phases as C3A, C4AF, C2AS and \( {\text{C}}_{5} {\text{S}}_{2} \overline{{\text{S}}} \) (sulpho-spurrite) were detected. Aluminum hydroxide which forms in the reaction between gypsum and yeelimite cannot be quantified by XRD analysis as it is amorphous.

Quantitative data reported in Table 2 disagree from expected results based on stoichiometrical considerations. To explain this gap, the variation of the medium during hydration and the presence of amorphous or micro-crystalline phases have to be taken into account.

In Fig. 4 selected Raman spectra of hydrated CSA samples at different hydration times are shown. Most significant changes occurred in the region between 1,050 and 950 cm−1 (showed for clarity in extended scale in Fig. 4b) and are indicative of modifications in the sulphate-based minerals, in good correlation with XRD analyses. On the contrary, the band at 857 cm−1, corresponding to belite, never disappear, showing that the amount of this phase remains almost constant: this evidence suggests and confirms that hydration of C2S in CSA cements takes place only after very long times. Two hypothesis can be done to explain this behavior: on the one hand, the rapid precipitation of ettringite causes the generation of a barrier that prevents water from reaching C2S; on the other hand belite in CSA clinker has been produced by a lower burning temperature with respect to Portland clinker and is therefore less reactive.

As expected from XRD analyses, gypsum is gradually consumed within the first 8 h, decreasing up to undetectable amount. The Raman spectra show its presence in non-hydrated samples, but already after 4 h of hydration, the 1,007 cm−1 band only appears as a weak shoulder broadening the anhydrite peak at 1,016 cm−1. Within the first 4 h, in fact, the 1,016 cm−1 peak appeared indeed broader and afterwards its intensity starts decreasing with the aging of the material. This process is paralleled by a gradual broadening of the Raman band at 991 cm−1 revealing that yeelimite is going through structural modifications. This becomes still more evident from 4 to 8 h, when XRD data (Table 2) show that yeelimite has been reduced to 22%; at the same time, ettringite forms up to constitute the 33% of the total composition. Shape modification of 991 cm−1 Raman band can be therefore attributed to the formation of ettringite at expenses of yeelimite and gypsum that is totally consumed.

Between 8 and 24 h a significant decrease in intensity of the anhydrite band at 1,016 cm−1 can be detected and at the same time bands at 676, 627, 609, 418 cm−1 completely disappear. This suggests that, after all gypsum has reacted, anhydrite begins to react with yeelimite to form ettringite: this observation is confirmed by X-ray quantitative analysis, revealing that anhydrite amount decreases from 6 to 2% between 8 and 24 h. Decreasing of the 1,016 cm−1 Raman band is almost completed after 48 h.

After 48 h the Raman spectrum shows a broad band centered at 988 cm−1, that is characteristic of the ν1 sulphate vibration of the ettringite structure [25]. The broad shape of this band is due to an extremely variable neighborhood that surrounds ettringite crystals: non-crystalline water, dipolar interactions and physisorbed water can influence vibrational behavior of ettringite and therefore cause the observed width of its ν1 [SO4]2− band. Moreover, between 24 and 48 h also the appearance of another weak band characteristic of ettringite around 550 cm−1, due to Al–OH vibrations [25], can be observed. After 48 h ettringite accounts for more than 50% of the sample; the presence of a residual amount of anhydrite (2% from XRD, see Table 2) is revealed by the shoulder at 1,016 cm−1.

No significant differences can be detected in Raman spectra recorded on samples from 7 up to 28 hydration days: this means that the main hydration phase, ettringite, is almost completely formed after 48 h, as also suggested by XRD.

On the whole, hydration of CSA can be easily followed by Raman investigation, observing in particular modifications of the bands lying in the region of sulphate stretching vibration (1,050–950 cm−1) shown in Fig. 4b. The spectral features in CSA cement can allow the determination of the disappearance in time of gypsum, anhydrite and yeelimite and the formation of ettringite phases.

Conclusions

Many clear advantages make Raman spectroscopy a suitable technique for the study of CSA cement: first of all, the lack of ferrous phases, or its presence in limited amount, reduce the possible interference of fluorescence emissions; moreover, it has to be highlighted that the main phases of CSA clinker are based on sulphate minerals, characterized by a good Raman activity.

Raman micro-spectroscopy has been thus applied successfully for the characterization of the main minerals present in calcium sulphoaluminate cement clinker, yeelimite, anhydrite and belite, giving clear and not overlapping spectral features. Raman spectrum of calcium sulphoaluminate cement results in a combination of the spectra of its main constituents: yeelimite and anhydrite are well separated because of the different position of the band corresponding to ν1 [SO4]2− vibrations, lying at 991 cm−1 and 1,016 cm−1, respectively; belite is detected because of its main band around 860 cm−1. Moreover, when gypsum is added to CSA cement, its presence is detected due to its band at 1,007 cm−1.

It is worth nothing that even if the main vibrational mode (ν1 band of [SO4]2−) is common to all phases, it lies at different frequencies in different chemical structures: 1,016 cm−1 in anhydrite; 1,007 cm−1 in gypsum; 991 cm−1 in yeelimite; 988 cm−1 in ettringite.

On these bases, the hydration study revealed that Raman spectroscopy is useful in order to follow the structural changes occurring in CSA cement pastes when hydrated in presence of gypsum: comparing the informations obtained from Raman spectra with those supplied by XRD, the following considerations can be drawn:

-

1.

gypsum reacts first, while anhydrite starts reacting only when most of the gypsum has been consumed;

-

2.

formation of ettringite is proved by the gradual shift of the main band of yeelimite from 991 cm−1 to 988 cm−1 and its broadening;

-

3.

the hydration can be considered almost complete after 2 days and only minor changes occur after this period in Raman spectra.

On the basis of these results Raman spectroscopy seems to be a very suitable tool for monitoring either the composition of CSA clinker and the hydration of CSA cement. This is particularly important considering that, due to the advances in instrumental configuration, portable instruments are available with good spectral resolution and collection efficiency, that can be used to make a monitoring of the production process without any sample preparation and also to better understand the hydration progress directly in situ as on manufactured products, an operation that would be impossible to carry out with X-ray powder diffraction analysis.

Notes

Note that standard cement nomenclature is followed here, whereby C = CaO, S = SiO2, A = Al2O3, F = Fe2O3, \( \overline{{\text{S}}} \) = SO3 and H = H2O.

References

Peixing Z, Yimin C, Liping S, Guanying Z, Wenmei H, Jianguo W (1992) 9th international congress on the chemistry of cement, New Delhi, p 201

Yannaquis N (1955) Rev des Matériaux de Construct 480:213

Deer WA, Howie RA, Zussman J (1992) An introduction to the rock-forming minerals. Longman, Harlow, p 617

Sharp JH, Lawrence CD, Yang R (1999) Adv Cem Res 11:3

Yanmou W, Muzhen S (1994) World Cement 8:7

Pera J, Ambroise J (2004) Cement Concrete Res 34:671

Moore AE, Taylor HFW (1970) Acta Cryst B 26:386

Wang Y, Su M, Yang R, Lui B (1992) 9th international congress on the chemistry of cement, New Delhi, p 454

Adams LD (1997) 19th international conference on cement microscopy, Cincinnati, p 1

Bensted J (1976) J Am Ceram Soc 59:140

Conjeaud M, Boyer H (1980) Cement Concrete Res 10:61

Dyer CD, Hendra PJ, Forsling W (1993) Spectrochim Acta A 49:715

Bonen D, Johnson TJ, Sarkar SL (1994) Cement Concrete Res 24:959

Kirkpatrick RJ, Yarger JL, McMillan PF, Yu P, Cong X (1997) Adv Cem Bas Mat 5:93

Newman SP, Clifford SJ, Coveney PV, Gupta V, Blanchard JD, Serafin F, Ben-Amotz D, Diamond S (2005) Cement Concrete Res 35:1620

Potgieter-Vermaak SS, Potgieter JH, Belleil M, De Weerdt F, Van Grieken R (2006) Cement Concrete Res 36:663

Dyer C, Smith BJE (2005) J Raman Spectrosc 26:777

Potgieter-Vermaak SS, Potgieter JH, Van Grieken R (2006) Cement Concrete Res 36:656

Tarrida M, Madon M, Le Rolland B, Colombet P (1995) Adv Cem Bas Mat 2:15

Black L, Breen C, Yarwood J, Deng CS, Phipps J, Maitland G (2006) J Mater Chem 16:1263

Black L, Breen C, Yarwood J, Phipps J, Maitland G (2006) Adv Appl Ceram 105(4):209

Midgley CM (1952) Acta Cryst 5:307

Socrates G (2001) Infrared and Raman characteristic group frequencies. Wiley, Chichester, 347 pp

Lazarev AN (1972) Vibrational spectra and structure of silicates. Consultant Bureau, New York, 302 pp

Deb SK, Manghnani MH, Ross K, Livingston RA, Monteiro PJ (2003) Phys Chem Miner 30:31

Acknowledgments

This work was supported by ASP (Associazione per lo Sviluppo Scientifico e Tecnologico del Piemonte) by means of a grant to DG, and Buzzi Unicem S.p.A. The authors gratefully acknowledge Ing. Massimo Paris, Buzzi Unicem S.p.A. (Guidonia, Italy), Ing. Luigi Buzzi, Buzzi Unicem S.p.A. (Casale Monferrato, Italy), Dr. Marcus Paul, Dyckeroff AG (Wiesbaden, Germany) and Prof. Gian Lorenzo Valenti, Università degli Studi della Basilicata (Potenza, Italy) for their critical reading. Authors are also grate to the referee that revised the manuscript, for the competence and the accuracy of the comments and the precious suggestions.

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

Below is the link to the electronic supplementary material.

10853_2007_1790_MOESM1_ESM.doc

Tables of crystal data, preferred orientations and crystal size of the main phases detected in the hydrated samples by XRD analyses – Rietveld method refinement are available free as electronic supplementary materials (DOC 43 kb)

Rights and permissions

About this article

Cite this article

Gastaldi, D., Boccaleri, E., Canonico, F. et al. The use of Raman spectroscopy as a versatile characterization tool for calcium sulphoaluminate cements: a compositional and hydration study. J Mater Sci 42, 8426–8432 (2007). https://doi.org/10.1007/s10853-007-1790-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-007-1790-8