Abstract

Secondary recycling is an alternative to solve at least part of the worldwide pollution problem caused by persistence of petrochemical plastic materials in the environment. In this work we report the secondary recycling of disposable polystyrene (PS) using cassava starch (Manihot esculenta Crantz) and a natural plasticizer extracted from a palm tree of the Amazon: Buriti (Mauritia flexuosa L.) oil. 13C-NMR spectroscopy reveals incorporation of the oil in the polymer matrix. Although phase separation had occurred, SEM depicts a very good dispersion of the thermoplastic starch (TPS) in the PS matrix with distinct domains. Thermal analyses indicate smaller thermal stability of the PS/TPS blends compared to PS and that possess intermediate characteristics between the pure PS and TPS, confirmed by DRX. Kinetic study shows a lowering of the activation energy for the thermal degradation of the blends.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

The persistence of petrochemical plastic materials in the environment beyond their functional life has resulted in a broad range of pollution, litter and waste disposal problems for the society [1]. One of the strategies to solve the problematic issues related to fossil resources and global environment is through recycling wasted polymers.

Tertiary recycling, which returns plastics to their constituent monomers or to their higher value hydrocarbon feed stock and fuel oil, is gaining momentum as an important technique of recycling [2]. Catalytic degradation [3–5] as well as supercritical degradation [6] and degradation through solvents [7] has been used as methods of tertiary recycling.

Another option of recycling is secondary or mechanical recycling, which is the reprocessing of plastic waste into new plastic products with a lower quality level. The introduction of natural polymers such as starch (which is biodegradable) into blends with petrochemical plastics such as polystyrene (PS) constitutes a form of secondary recycling. This approach has already been studied with recycled low density polyethylene/corn starch blends [8, 9].

PS, a versatile thermoplastic material used in a wide range of durable and single use applications, is among the most dominant packaging materials in today’s society and is not capable of self-decomposition [10, 11]. Therefore blending PS with different starches such as cassava (Manihot esculenta Crantz) turns out to be a means of recycling and has been promoted as a technique to achieve biodegradability [11].

These starch polymer blends are considered to be biodegradable because the removal of starch can cause severe reduction in the mechanical strength of the remaining non-biodegradable portions, so that it disintegrates into smaller pieces [1]. Breakdown of the polymer weakens the materials by reducing the molecular weight (chain length) eventually to a level that can then be metabolized by microorganisms.

A plasticizer agent is necessary to convert the starch into thermoplastic starch (TPS) and allow its proper blending to PS. The addition of a plasticizer agent to polymers containing a carbon–carbon backbone is required to overcome film brittleness, caused by high intermolecular forces. Plasticizers reduce these forces and increase the mobility of polymer chains, thereby improving flexibility and extensibility of the film [12].

The Buriti (Mauritia flexuosa L.), an abundant palm tree of the Amazonian Region of Brazil, supplies raw material for a variety of applications such as roots for medical use, trunks to produce wine, liqueur and canoe manufacture, proving itself as an important resource for workers. Among all these raw materials, the oil extracted from the Buriti fruit stands out as it is of great interest because of its composition and physical and chemical characteristics [13–18]. The Buriti oil, extracted with supercritical CO2 from the shell and the pulp of ripe Buriti fruits, shows in its chemical composition high concentrations of oleic acid, tocopherols and carotenoids (Table 1), especially β-carotene which is responsible for the oil’s red-orange color [14]. Studies related to the interesting optical properties of the oil and their blends with PMMA and PS were reported previously [17, 19, 20].

In this work we report a secondary recycling of disposable PS using abundant natural resources from Brazil: cassava starch and Buriti oil as the plasticizer agent. Since secondary recycling uses these reclaimed post-consumer elements as a source of material for new products these PS/TPS blends could be used in packaging and other applications. The resulting PS/TPS blends were characterized through thermal analyses, 13C nuclear magnetic resonance (NMR) spectroscopy and scanning electron microscopy (SEM) to provide a first insight into their properties.

Experimental

Materials

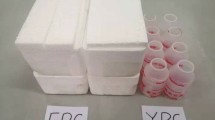

PS was obtained from PS cups (CopocentroTM Brazil). Dried cassava (Manihot esculenta Crantz) starch with 74.70 ± 1.76 % of amylopectin (determined by colorimetric analyses [21]) was used. Buriti oil (ρ = 0.86 g mL−1) extracted with supercritical CO2 from the shell and the pulp of ripe Buriti fruits was courteously supplied by Dr. S. G. C. Moreira from Universidade Federal do Pará (UFPA). Analytical reagent grade chloroform was also used.

Preparation of thermoplastic starch

Thermoplastic starch (TPS) was obtained by simply mixing starch powder, water and Buriti oil in the composition 50:15:35 (wt/vol/vol), respectively according to Godbole et al. [22], with some modification: the contents were mixed for 15–30 min. to obtain a paste. The paste was transformed into TPS by heating at 100 °C in water bath with continuous stirring for 15 min. This product so obtained was mixed with PS in different ratios and solvent cast films were obtained from chloroform.

Blending of PS with thermoplastic starch

PS and TPS were mixed in different ratios (wt/wt) of 0.9:0.1, 0.7:0.3, 0.5:0.5 and 0.3:0.7. The mixtures were then stirred at 50 °C with hot chloroform and blends were prepared by conventional-casting technique from the chloroform solutions of PS and starch using TeflonTM dishes as casting surfaces.

13C nuclear magnetic resonance (NMR) cross-polarization/magic angle spinning (CP/MAS) measurements

Solid-state 13C-NMR CP/MAS experiments were performed on a Varian model Mercury Plus 300 MHz spectrometer, equipped with a Varian double-tuned 7 mm probe, with resonance frequency of 75.459 MHz for 13C nuclei. 13C CP/MAS NMR spectra were recorded with a CP contact time of 1 ms, a repetition time of 4 s, and a spinning speed of 5 kHz. The 13C chemical shifts were externally referenced to hexamethylbenzene (HMB). Data manipulation was done using Mestre-C 2.3 software.

X-ray diffraction (XRD)

XRD analyses were obtained for the films at 1° min−1 and 2θ from 2 to 50°. The XRD patterns were collected using a RigakuD/Max-2A/C with Cu-Ka radiation at 40 kV and 20 mA.

Scanning electron microscopy (SEM)

Surface structures of the samples were studied through SEM (Zeiss, mod DSM 962). The samples were fractured in liquid nitrogen, fixed on aluminum supports using silver adhesive and covered with gold (Sputter Coater Balzers SCD050). The SEM images were obtained using 15 KV and 60 μA electric current.

Thermal analyses and evaluation of kinetic parameters

Thermogravimetry (TG) was carried out in a TGA-50/Shimadzu thermogravimetric analyzer. The mass of each sample was 5–10 mg and the reaction environment was flowing helium (50 mL min−1). Ongoing in the kinetic parameters acquisition the samples were heated in a platinum crucible, at heating rates of 5, 20 and 35 °C min−1. The thermogravimetric curves were recorded in the course of heating from room temperature to 550 °C where the pyrolytic decomposition of starch and its fractions sets in at temperatures higher than 303 °C. The TG technique was also used to determine the percentage weight loss and decomposition temperature (Td) of the composite by derivative thermogravimetry (DTG). The kinetic analysis used data obtained by the non-isothermical OZAWA method using the TGA Kinetic Analysis Program version 1.0 of Shimadzu Corp [23].

The differential scanning calorimetry (DSC) data of film samples (5–10 mg) were recorded in the temperature range of −100 to 200 °C, under a helium flow of 50 mL min−1 on a DSC-50/Shimadzu instrument. The samples were placed in sealed aluminium pans and heated at a rate of 10 °C min−1. Two scans were obtained for each sample and for the analyses the second scan’s resulting curve was used. The temperature at the midpoint of the change in slope of the DSC heat-capacity change was taken as the glass transition temperatures (Tg).

Thermal mechanical analyses (TMA) were performed in a TMA-50/Shimadzu at a rate of 10 °C min−1 from ambient temperature to 100 °C under atmosphere of air. The analyses were performed in the penetration mode with load 100 mN. The softening temperature (Ts) was obtained from the tangent of the first decay of the curve.

Results and discussion

The blends had a yellow color due to the presence of β-carotene from Buriti oil. The greater the content of TPS in the blends the more brittle they became as shown by LORCKS [24].

In order to evaluate the incorporation of TPS in the polymer matrix, 13C-NMR spectra in the solid-state were acquired for PS, starch and all the blends (Fig. 1). Four characteristic resonance lines were detected in the PS spectra: 146.486 ppm (non-protonated aromatic carbon); 128.204 ppm (protonated aromatic carbons); 46.583 ppm (methynic carbon) and 40.678 ppm (methylenic carbon), which are similar to experimental data obtained by Wu et al. [25]. 13C-NMR spectra of PS/TPS blends show characteristic starch resonance lines that are in accordance with experimental data obtained by Jayasekara et al. [26] (Table 2) and characteristic PS resonance lines. The spectrum for the PS/TPS blends reveal the incorporation of starch in the blends as the characteristic peaks of starch (73 ppm among others) are still present in all blends in spite of the starch content in the blends. It is also noticeable that the intensity of the peak referring to carbons C-2, C-3 and C-5 (CH–OH) is directly proportional to the starch content in the blends. It is also worth mentioning that the materials with starch content superior to 30% show the four resonance lines demonstrating that the prepared compounds have characteristics of both PS and TPS.

The X-ray patterns of PS, TPS and all blends are shown in Fig. 2. XRD results for the PS/TPS blends show intermediate characteristics between the PS matrix and TPS with changes in their crystalline and amorphous domains. As there are no shifts of the blends’ peaks compared to PS and TPS and no appearance of different peaks than those of PS and TPS making it clear that there is no strong chemical reactions between the components of the blends.

The morphological analysis of PS, starch and the PS/TPS blends was accomplished also by SEM micrographs (Fig. 3). Spherical/lenticular forms with unimodal distribution characteristic of cassava starch [27] with sizes from 5 μm to 35 μm are depicted (Fig. 3a). PS’s micrograph (Fig. 3f) reveals layers spread irregularly. The PS/TPS blend 0.9:0.1 (Fig. 3e) shows apparent absence of starch micro domains but reveals presence of characteristic cavities from Buriti oil. In the 0.7:0.3 PS/TPS blend (Fig. 3d) there are defined PS and starch regions (lenticular form preserved). The blend with starch content 70% (Fig. 3b) shows a lack of PS micro domains and a strong presence of starch with different forms from the original spherical one. In all blends it is possible to see a good dispersion of starch, as there are no smooth areas or large agglomerates indicating compatibility between the polymers.

The thermograms for the PS, TPS and the blends are shown in Fig. 4. The PS/TPS blends showed two stages of decomposition. The first stage (Td1) refers to the decomposition of TPS [28] and the second (Td2) to PS’s depolymerization [29]. Pyrolytic decomposition of starch and its fractions sets in at temperatures higher than 303 °C [30]; the decomposition products include carbon monoxide, water, volatile organic compounds and a carbonaceous residue. In the first stage of decomposition the weight loss increases with the increase of TPS in the matrix. However, in the second stage of degradation, the increase in TPS content seems to lead to a smaller weight loss. The degradation of PS occurs at lower temperatures in the blends because of the modifications in the PS matrix structure due to its interaction with the TPS.

The kinetic study of the thermal degradation was done by the Ozawa method [23, 31]. Ozawa [23, 34] derived the non-isothermal kinetics of the process; the conversion C(T) at temperature T and cooling/heating rate is given by:

where Z(T) is the cooling or heating function of the process and m is the Ozawa exponent.

The Shimadzu software (see Experimental part) used provided the following kinetic parameters: activation energy (E a ), order (n) and frequency factor (A). The values of these parameters for all blends are shown in Table 3. From the presented data it can be inferred that the reaction mechanism for the decomposition of the blends is similar as the same order of reaction (1.1) is obtained for all blends. As the content of TPS increases in the blends the frequency factor decreases. A decrease in the activation energy of the total thermal decomposition of the blends is also observed when there is an increase in the starch content. Table 4 presents the Td values for the two stages of degradation of the blends in the different heating rates (β). It can be observed that the greater the value of β the greater Td is obtained. This is due to the fact that the sample requires smaller amount of time to reach a certain temperature with greater heating rates [32].

Figure 5 shows the DSC curves obtained for PS, TPS, pure starch and Buriti oil. Figure 6 depicts the DSC curves obtained for PS/TPS blends. PS’s DSC curve shows only the vitreous transition of the polymer around 97 °C. TPS’s DSC curve shows a small exothermic peak around −25 °C related probably with the crystallization of starch, due to the fast cooling of the sample. Besides, the curve presents two endothermic peaks which to according with Garcia-Quiroz et al. [15] are characteristics of Buriti oil: the first occurs in the solid-phase, between −12 °C and −2 °C and the second corresponds to the melting process from −2 °C to 10 °C. Also in the starch’s DSC curve it can be observed a exothermic peak between −23 °C and −5 °C associated with the formation of small crystals of starch, due to the fast cooling of the sample and a large endothermic peak from 15 °C to 145 °C \((\Updelta\hbox{H}=113\,\hbox{J}\,\hbox{g}^{-1})\) related to the starch gelatinization due to environmental moisture. This phenomenon described in literature [33, 34] corresponds basically to the swelling of granules with later loss of crystallinity, an endothermic phenomenon. DSC data (Fig. 6) shows that the PS/TPS blends display intermediate characteristics between pure PS and TPS as was already indicated by the spectroscopic analyses, revealing immiscible materials. The blends with TPS content up to 30% depict DSC curves more similar to PS because the shown glass transition temperatures are closer to PS and only a small endothermic peak near −9 °C, related to the Buriti oil is registered. The greater the TPS content in the blends the greater the peaks’ size (Fig. 6) related to the transition attributed to Buriti oil present in TPS. It is also noticeable in the DSC curves that a lowering of the glass transition temperature occurs as the TPS content increase in the blends with widening of the peak until its complete disappearance what reveals starch incorporation in the films and greater easiness of thermal degradation. These data showed agreement with results obtained by thermogravimetry.

TMA plots (Fig. 7) indicate that the increase in the TPS content of the blends decreases the Ts of the polymeric matrix. This is in concordance with DSC experiments. This result shows that the addition of TPS to PS does not offer advantages in terms of maintaining or increasing thermal mechanical properties. In spite of this, the blending leads to materials with smaller Ts than PS, which indicates that TPS probably altered PS’s structure.

Conclusions

This study provided a first insight in the synthesis and characterization of polymer blends from polystyrene waste and natural resources. Cassava starch and Buriti oil’s importance are that they are renewable sources, environmentally friendly and natural products and therefore aid in the decomposition of PS. 13C-NMR and XRD results reveled that the PS/TPS blends possess intermediate characteristics between the pure PS and TPS. The SEM micrographs showed a very good dispersion of TPS in the PS matrix. The results of TG experiments indicated that the degradation of the blends happens in two stages and the degradation stage related to PS occurs at lower temperatures in the blends due the modifications in its structure which is important to recycling. DSC results confirm the obtained data through 13C-NMR and XRD in the sense of revealing the intermediate characteristics of PS/TPS blends. As the content of TPS in the blends increases a lowering in Tg and Ts is noticed, compared to that of pure PS. These results indicate the formation of new materials with characteristics of PS, cassava starch and Buriti oil.

The lower activation energy and smaller thermal stability make this kind of blend an interesting approach to produce low cost semi-biodegradable material in order to increase the use of environmentally friendly material in packaging.

References

Aggarwal P (1999) Thermochim Acta 340–341:195

Ali MF, Siddiqui MN (2005) J Anal Appl Pyrolysis 74:282

Kim J, Lee W, Lee S, Kim S, Choi M (2003) Catal Today 87:59

Zhibo Z, Nishio S, Morioka Y, Ueno A, Ohkita H, Tochihara Y, Mizushima T, Kakuta N (1996) Catal Today 29:303

Williams PT, Bagri R (2004) Int J Energy Res 28:31

ke H, Li-hua T, Zi-Bin Z, Cheng-Fang Z (2005) Polym Degrad Stab 89:312

Karaduman A, Simsek EH, Cicek B, Bilgesu AY (2002) J Anal Appl Pyrolysis 62:273

Pedroso AG, Rosa DS (2005) Carbohydr Polym 59:1

Rodriguez-Gonzalez FJ, Ramsay BA, Favis BD (2003) Polymer 44:1517

Thomson DA (1995) Plast Rubber Paper Recycling ACS Symp Ser 609:89

Kiatkamjornwong S, Sonsuk M, Wittayapichet S, Prasassarakich P, Vejjanukroh P (1999) Polym Degrad Stab 66:323

Parra DF, Tadini CC, Ponce P, Lugao AB (2004) Carbohydr Polym 58:475

Fran ça LF, Reber G, Meireles MAA, Machado NT, Brunner G (1999) J Supercrit Fluids 14:247

Bernal-Alvarado J, Mansanares AM, da Silva EC, Moreira SGC (2003) Ver Sci Instrum 74:697

Garcia-Quiroz A, Moreira SGC, de Morais AV, Silva AS, Rocha GN, Alcântara P (2003) Instrum Sci Technol 31:93

Albuquerque MLS, Guedes I, Alcântara P, Moreira SGC (2003) Vib Spectrosc 33:127

Albuquerque MLS, Guedes I, Alcântara P, Moreira SGC, Neto NMB, Correa DS, Zílio SC (2005) J Braz Chem Soc 16:1113

Lognay G, Trebejo E, Jordan E, Marlier M, Severin M, Ortiz de Záate I (1987) Grasas y Aceites 38:303

Durães JA, Drummond AL, Pimentel TAPF, Murta MM, Moreira SGC, Bicalho FS, Sales MJS (2006) Eur Polym J (unpublished)

Durães JA, Drummond AL, Pimentel TAPF, Murta MM, Moreira SGC, Sales MJS (2004) Br PI 0403407-4

Chrastil J (1987) Carbohydr Res 159:154

Godbole S, Gote S, Latkar M, Chakrabarti T (2003) Bioresour Technol 86:33

Ozawa T (1965) Bull Chem Soc Jpn 38:1881

Lorcks J (1998) Polym Degrad Stab 59:245

Wu RR, Kao HM, Chaing JC, Woo EM (2002) Polymer 43:171

Jayasekara R, Harding I, Bowater I, Christie GBY, Lonergan GT (2004) Polym Test 23:17

Tester RF, Karkalas J, Qi X (2004) J Cereal Sci 39:151

Carvalho AJF, Curvelo AAS, Agnelli JAM (2001) Carbohydr Polym 45:189

Shalaby SW (1981) In: Turi EA (ed) Thermal characterization of polymeric materials. Academic Press Inc., Florida, p 287

Rudnik E, Matushek G, Milanov N, Kettrup A (2006) J Thermal Anal Calorimetr 85:267

Ozawa T (1971) Polymer 12:150

Chan JH, Balke ST (1997) Polym Degrad Stab 57:135

Leloup LM, Colonna P, Buleon A (1991) J Cereal Sci 13:1

Bastioli C (1995) In: Scott G, Gilead D (eds) Degradable polymers. Chapman & Hall, London, p 112

Acknowledgements

The authors are grateful for XRD measurements at the Instituto de Geociências – Laboratório de Difração de Raios-X and financial support from UnB-IQ, CNPq, FAP-DF, FINATEC, FINEP-CT INFRA No. 0970/01 and to Dr. J. A. Dias (IQ-UnB) for NMR spectra acquisition.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Pimentel, T.A.P.F., Durães, J.A., Drummond, A.L. et al. Preparation and characterization of blends of recycled polystyrene with cassava starch. J Mater Sci 42, 7530–7536 (2007). https://doi.org/10.1007/s10853-007-1622-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-007-1622-x