Abstract

A novel method by combining NAC-FAS (NAnometer-sized Crystal Formation in Alcoholic Solutions) method and mechanical milling treatment was successfully applied for dispersing perovskite type oxide LaMnO3 finely on carbon support. Microscopic observation revealed that nano-sized oxide particles were dispersed fairly well in the carbon support. The gas diffusion-type electrode prepared by means of reducing number and quantity of chemicals exhibited more excellent oxygen reduction activity than the electrodes containing LaMnO3 prepared by RHP (Reverse Homogeneous Precipitation) method. It allowed current density as high as 300 mA cm−2 at −80 mV (vs. Hg/HgO) in 8 M KOH at 60 °C under air flow.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Gas-diffusion type electrodes seem to be an emerging solution for the construction of efficient metal-air batteries, brine electrolysis, or fuel cells. The corresponding research activity has been often focused on the search for new catalysts [1–3] for the reduction of atmospheric oxygen. Noble metals such as Pt and Pt alloys [1, 4, 5] are electroactive but expensive. Less expensive electrocatalysts have been explored, these include organometallic compounds [6], metal nitrides [3], single metal oxides [7], and mixed metal oxides such as spinel-type oxides [8], pyrochlore-type oxides [9], and perovskite-type oxides [10, 11]. Among different materials the carbon-supported perovskite type oxides revealed fairly encouraging catalytic properties [12–15]. Recently it is reported that an important factor controlling electrode performance, i.e., the degree of dispersion of the oxide catalyst on the carbon support, has been recognized. For example, the carbon-supported LaMnO3 prepared by the reverse micelle (RM) method [12] could maintain high current density of 300 mA/cm−2 at −70 mV versus Hg/HgO electrode in 8 M solution of KOH at 60 °C under air flow [12]. However, this method has its own problems as well, e.g., use of organic solvents (oil phase) and surfactants, rather tedious synthetic procedure and poor productivity (the amount of product obtained per batch is very small). On the other hand, a reverse homogeneous precipitation (RHP) method proved to give a colloidal dispersion of mixed hydroxide of metal (precursor) by putting an aqueous mixed solution of metal salts into a strong alkaline solution [16–18]. Obviously this method can mitigate the problem of the RM method above. The carbon-supported LaMnO3 thus prepared showed fairly good oxygen reduction activity [18].

Despite the mentioned progress in preparation of gas-diffusion type electrode we performed an approach targeting at new way of catalyst preparation of similar electrode properties. Since the RM and RHP methods might be considered as still complex preparation, we decided to look for more simply and shorter ways of catalyst preparation. If the carbon-supported LaMnO3 catalyst could find an application in practice, it would be essential to reduce quantities of reagents particularly organic solvents that are harmful for environment like cyclohexane and propanol. It would be also important to eliminate expensive chemicals like tetramethylammonium hydroxide (TMAH). These targets, if achieved, would additionally reduce cost of commercial manufacturing of gas-diffusion electrodes for oxygen reduction.

In our former works, we have assumed that the uniform distribution of LaMnO3 on carbon particles is an inevitable factor affecting electrode properties of the carbon-supported LaMnO3 catalyst, because it may be achieved by uniform dispersion of mixed hydroxide particles in the carbon-hydroxides mixture prior to calcination. Such dispersed hydroxide particles ensure a uniform distribution of LaMnO3 crystals in the catalyst since, as stated above, particles of mixed hydroxides transform into the perovskite type oxide upon calcination. In this study, we carried out new way by applying mechanical milling treatment for the above target. This paper reports the formation and characterization of the precursors and oxide, neat and carbon-supported, as well as the oxygen reduction activity of the carbon-supported oxide.

Experimental

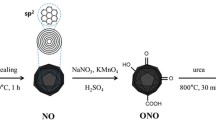

It is known well that the growth of inorganic particles in deposit may be suppressed by application of non-aqueous conditions like alcoholic ones in the NAC-FAS method (NAnometer-sized Crystal Formation in Alcoholic Solutions). Synthesis of carbon supported perovskite oxide (LaMnO3) by combining NAC-FAS method and mechanical milling treatment was shown in Fig. 1, as compared with RHP method. Following that statement, an appropriate quantity of 2 M water solution of La3+ and Mn2+ mixed ions was added to 10 cm3 of ethanol and shaken vigorously. Subsequently one added alkalizing reagent; TMAH (28wt.% water solution) or KOH (8 M water solution) in an excess of 1.5 factors over stoichiometric quantity. The fine particle deposit of mixed hydroxides was additionally treated in ultrasonic bath for 5 min. Then powdered carbon (EC600JD, Katjen Black Int. Co.) was added in the amount suitable for a desired catalyst composition. This mixture was subjected to a long treatment for 60 min in ultrasonic bath. That transformed the mixture into a smeary substance. It was then filtrated and washed with distilled water. The still wet residue was milled in an alumina mortar until it became dry (ca. 20–30 min). The dry deposit was calcinated in nitrogen at 650 °C for 5 h. The carbon-supported LaMnO3 catalysts thus obtained were used to prepare gas-diffusion type electrodes, which were composed of a gas supply layer [about 0.2 mm thick, carbon black (AB-7, Denki Kagaku Kogyo Co.):PTFE (Daikin Kogyo Co.) = 7:3 in weight ratio] and a reaction layer (about 0.2 mm thick, carbon-supported oxide:PTFE = 8.5:1.5 in weight ratio) on a Ni mesh current collector, as described in detail elsewhere [12]. The electrical resistances for all of electrodes fabricated were confirmed to be less than 10 mΩ by using IR compensation instrument combined with a potentiostat. The electrochemical efficiency of each gas-diffusion type electrode towards reduction of oxygen of was tested from the cathodic polarization in 8 M solution of KOH at 60 °C under air flow versus Hg/HgO electrode by means of a potentiostat (Hokuto Denko Co., HA 305) without IR compensation. XRD spectra were recorded (Rigaku Denki, Co., RINT 2100) to confirm the formation of LaMnO3. Morphology and uniformity of the carbon-supported catalysts and electrodes were evaluated on a field emission type scanning electron microscope (JEOL Field Emission Scanning Microscope JSM 6340F).

Results and discussion

XRD investigations

As mentioned earlier, the main aim of the research was to simplify preparation and reduce the number and quantity of reagents. Example XRD spectra (Fig. 2) confirm that LaMnO3 crystals grow from so obtained mixed hydroxides after calcination. The spectra are characteristic for nano-crystal of cubic perovskite type oxide (LaMnO3.00, JCPDS 35–1353). The performed mechanical elaboration of carbon-hydroxide mixtures provides a satisfactory uniformity of mixed hydroxides. Both, lanthanum and manganese hydroxides are accessible in stoichiometric proportions to produce LaMnO3 in reaction centres, i.e., particles of mixed hydroxides. Crystalline LaMnO3 may be obtained also if an inorganic alkalizing reagent (KOH) was used. Other phase including K ion could not be found in XRD pattern obtained. It is to remember that KOH excess is easier to utilise than a similar quantity of TMAH being an expensive organic substance. As it is presented later, catalyst obtained by means of KOH showed almost same performance of cathodic polarization as that obtained by means of TMAH. The currently presented method is also applicable to the preparation of samples containing more than 50 mass % of LaMnO3.

By means of the Scherrer’s method, the crystal size of LaMnO3 was estimated in Table 1 for two series of samples. It is visible that in most cases the crystal size of the TMAH-precipitated LaMnO3 is smaller than those noticed for the KOH-precipitated perovskite type oxide. For the first ones, the crystal size seems to grow upon increasing LaMnO3 content in a sample, while that for KOH-precipitated perovskite type oxide is rather constant.

In the same pathway, we also prepared samples of carbon-free LaMnO3 (TMAH- and KOH-precipitated) as shown in Table 1, that is, no carbon was added during preparation. The estimated crystal size of KOH-precipitated LaMnO3 is 1.5 times bigger than that of the KOH-precipitated samples supported on carbon. This indicates that carbon particles, usually of 30–40 nm diameter, play a supporting role in diminishing and separating of lanthanum and manganese hydroxide particles and their calcination product LaMnO3, finally. The application of TMAH confirmed the earlier result that this reagent helps to obtain smaller crystals of LaMnO3. The crystallite size of TMAH-precipitated samples of carbon-free LaMnO3 is smaller than that of KOH-precipitated sample of carbon-free LaMnO3 but slightly bigger than that of the carbon-supported samples. That seems to be usually ascribed to a difficult agglomeration of mixed-hydroxide sols prepared in the presence of N(CH3) +4 cation. The last statement confirms the foregoing remarks that carbon particles help to reduce the size of hydroxide particles.

SEM investigations

SEM investigations were performed to evaluate the dispersion of LaMnO3 on carbon support and the influence of milling on the homogeneity of carbon-supported LaMnO3. Figures 3 and 4 show SEM micrographs of non-milled and milled samples respectively. Each secondary electron image (SEI) is accompanied by a reflected electron image figuring the distribution of perovskite type oxide particles (bright spots on micrograph marked as COMPO) among carbon grains. In the non-milled samples (Fig. 3b), bright spots corresponding to LaMnO3 are non-uniformly scattered in the image showing that the particles of LaMnO3 are agglomerated in packs of ca. 10 μm size. In milled samples (Fig. 4), in contrast, the COMPO image is practically identical with the SEI image, indicating that LaMnO3 particles are dispersed far more sorely. This proves higher uniformity of the milled samples.

Single particles of LaMnO3 are visible provided one applies an appropriate magnification (Fig. 5). Such estimated size of LaMnO3 particles (20–30 nm) is close to the crystal size calculated by means of Scherrer’s method (ca. 22 nm). This was noticed not only for this particular sample but for other investigated samples, as well. It was also found that many LaMnO3 crystals, if grouped in packs (Fig. 6), are durably bonded. Each group of crystals grew probably from a larger particle of mixed hydroxides that was unsatisfactory dispersed in non-milled samples. Pulverization of large agglomerates of hydroxides by natural phenomena occurring in RHP method but also by ultrasonic treatment and milling (and possibly by other methods) seems to be an essential point for each synthesis aiming at homogenous carbon-supported perovskite type oxide catalyst.

Electrode performance

The carbon-supported LaMnO3 samples were obtained because of their possible application to the preparation of gas diffusion electrodes. Cathodic polarization test was a basic experiment for the evaluation of electrode performance towards oxygen reduction. Figure 7 shows cathodic polarization curves recorded for the electrodes made of carbon-supported catalysts containing different amounts of TMAH-precipitated LaMnO3. The potential of a polarized electrode always depends on current passing by the electrochemical set up. It is noticed that the polarized potential for some tested samples was as high as −85 mV (vs. Hg/HgO electrode) for 300 mA cm−2. This result is practically identical with the previously reported data for catalysts obtained by more sophisticated methods [12, 18].

The polarization curves in Fig. 7 indicate that the electrode performance does not change monotonically with the increasing in LaMnO3 content. Figure 8 contains the values of polarization potential recorded at current density of 300 mA cm−2 plotted versus LaMnO3 content (mass %) in the carbon-supported catalyst, as compared with RHP method. The electrode performance approaches its maximum, i.e., potential of the electrode is high for the electrodes prepared form carbon-supported catalyst containing 25–35% of LaMnO3. For lower and higher quantities of LaMnO3, the corresponding electrodes are more polarized. This meaning of this behavior is not yet fully understood. The gradual increase in the intermediate loading range seems to be natural because it reflects that the current density at fixed E (e.g., −100 mV) is roughly proportional to the loadings (Fig. 7). On the other hand, the drop of potential at high loading may suggest that the oxide could not be dispersed well under the preparation condition adopted, as such coagulation of oxides for RHP method was reported previously [18]. The curves in Fig. 8 represent two types of catalyst, TMAH-precipitated and KOH-precipitated. The best-performing electrode of KOH series behaves similarly to the most efficient one from TMAH series also in the same range of LaMnO3 content. This result means that the use of KOH is useful for inexpensive process of catalyst preparation. It is considered that the particles by KOH-precipitated are easy to be dispersed on carbon support by mechanical milling treatment, although the reason is not clear yet. In addition, both electrodes were seen to be far inferior to the RHP-based electrode. Figure 8 contains also an additional curve, which may serve as a reference curve, for some electrodes prepared from non-milled catalyst containing the large agglomerates of LaMnO3 crystals as presented in Fig. 3. These electrodes are evidently less efficient in oxygen reduction than those made of milled carbon-supported perovskite type oxide catalyst containing KOH- and TMAH-precipitated LaMnO3.

Electrode performances as a function of LaMnO3 supporting on carbon black (lower) or per geometric surface area of electrode (upper abscissa). (TMAH-originated milled, KOH-originated milled, TMAH-originated non-milled, RHP method[18])

From the above results, it is found that synthesis of carbon-supported perovskite oxide (LaMnO3) by combining the NAC-FAS method based on KOH-precipitated and the mechanical milling treatment is useful for simplifying preparation, reducing the cost of reagents as well as obtaining high activity of oxygen reduction, originating from good dispersion of oxide particles. It may be introduced to the so far established pathways like RHP method as an intermediate step towards lanthanum and manganese hydroxides being well dispersed among carbon grains. It is known that the partial substitution of alkaline earth metal for A-site is also effective for improving the activity. It is interesting to see in the future how the method can be applied to such substituted perovskite type oxides on carbon support.

Conclusions

The following conclusion can be drawn from the present study.

-

1.

An efficient carbon-supported LaMnO3 catalyst was obtained in a rather simple way by combining NAC-FAS (NAnometer-sized Crystal Formation in Alcoholic Solutions) method and mechanical milling treatment for small quantities of essential reagents only.

-

2.

Particles of LaMnO3 prepared by new method were uniformly distributed among carbon particles. Mechanical milling treatment of hydroxide-carbon mixture seems to be an important step for the preparation of homogenous carbon-supported LaMnO3 catalyst.

-

3.

Carbon particles play an important role in the reduction of the size of LaMnO3 crystals. They probably act as an abrasive material that diminishes the size of mixed hydroxide particles and later separate growing LaMnO3 crystals.

-

4.

Organic reactant THAH may be replaced by KOH and such precipitated catalysts lead to electrodes that undergo cathodic polarization as almost same as those obtained by means of THAH.

-

5.

Electrode properties of the carbon-supported catalysts towards oxygen reduction depended not only on the percentage of LaMnO3 but were very sensitive to its uniform distribution among carbon particles. The electrodes obtained by the new pathway exhibit more excellent oxygen reduction activity in 8 M KOH at 60 °C under air flow than the electrodes containing LaMnO3 prepared by RHP method.

References

Motoo S, Watanabe M, Furuya N (1984) J Electroanal Chem 160:351

Sugawara M, Ohno M, Matsuki K (1991) Chem Lett 1465

Miura N, Horiuchi H, Shimizu Y, Yamazoe N (1987) Nippon Kagaku Kaish 1987:617

Watanabe M, Tomikawa M, Motoo S (1985) J Electroanal Chem 195:81

Aikawa H (1996) Soda & Chorine 93

Zhang HM, Teraoka Y, Yamazoe N (1987) Chem Lett 4:665

Matsuda Y, Yamashita K, Takatsu Y (1983) Denki Kagaku 51:925

King WJ, Tseung ACC (1974) Electrochem Acta 19:485

Zen JM, Goodenough JB, Manoharam R (1992) J Appl Electrochem 22:140

Shimizu Y, Uemura K, Matsuda H, Miura N, Yamazoev N (1990) J Electrochem Soc 137:3430

Hyodo T, Shimizu Y, Miura N, Yamazoe N (1994) Denki Kagaku 62:158

Hayashi M, Uemura H, Shimanoe K, Miura N, Yamazoev (1998) Electrochem Solid-State Lett 1:268

Miura N, Hayashi M, Hyodo T, Yamazoe N (1999) Mat Sci Forum 315–317:562

Hyodo T, Hayashi M, Mitsutake S, Miura N, Yamazoe N (1997) J Appl Electrochem 27:745

Hyodo T, Hayashi M, Miura N, Yamazoe N (1996) J Electrochem Soc 143:L266

Teraoka Y, Nanri S, Moriguchi I, Kagawa S, Shimanoe K, Yamazoe N (2000) Chem Lett 1202

Teraoka Y, Taura Y, Moriguchi I, Kagawa S (1995) Kagaku Kagaku Ronbunshu 21:1032

Imaizumi S, Shimanoe K, Teraoka Y, Miura N, Yamazoe N (2004) J Electrochem Soc 151:A1559

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Lukaszewicz, J.P., Imaizumi, S., Yuasa, M. et al. New approach towards preparation of efficient gas diffusion-type oxygen reduction electrode. J Mater Sci 41, 6215–6220 (2006). https://doi.org/10.1007/s10853-006-0723-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-006-0723-2