Abstract

This paper addresses the multi-scale modeling aspects of damage in composite materials. The multiplicity of the scales of the operating mechanisms is discussed and clarified by taking examples of damage in a unidirectional ceramic matrix composite and in a cross ply polymer matrix composite laminate. Two multi-scale modeling strategies––the hierarchical and the synergistic––are reviewed in the context of deformational response. Finally, the “big picture” as it relates to the cost-effective manufacturing of composite structures intended for long-term performance is outlined and desired future direction in multi-scale modeling is discussed.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Composite materials can be viewed as material systems with a wide range of possibilities for engineering design. As engineered materials, composites can be made “advanced”, e.g. by using constituents that have high (advanced) properties, or by use of fiber architecture to create combinations and anisotropy of properties not possible in single (monolithic) materials, or both. Composites can also be engineered by “enrichment”, e.g. by adding elements that modify, alter or impart properties to meet specific needs. Examples of enrichment range from optical property modification by mixing curing agents to molecular-level morphological changes with nano-scale elements (clay particles, nanotubes, etc.). In all cases, effective engineering necessitates mathematical modeling of mechanisms and the consequent responses. From the early days of the rule of mixture type estimates to today’s multi-scale modeling, composite mechanics has been concerned with continuous refinement of methods to accomplish this goal. The computational tools available today have motivated a renewed emphasis on multi-scale modeling.

This article will focus on the multi-scale modeling aspects of damage in composites. In order to specify the scope of the treatment, we shall first define the key terms––fracture, damage and failure. The context of the treatment will be structural integrity and durability of composites under mechanical loading. The role of damage mechanics in the “big picture” of cost effective manufacturing will be discussed at the end, where directions for further development of modeling for this purpose will be outlined.

Fracture, damage and failure––Definitions

Fracture is conventionally understood to be “breakage” of material, or at a more fundamental level, breakage of atomic bonds, which manifests itself in formation of internal surfaces. Examples of fracture in composites are fiber fragmentation, cracks in matrix, fiber/matrix debonding and separation of bonded plies (delamination). The field of fracture mechanics concerns itself with conditions for enlargement of the surfaces of material separation.

Damage is a collective reference to irreversible changes brought about by energy dissipating mechanisms, of which atomic bond breakage is an example. Unless specified differently, damage is understood to refer to distributed changes. Examples of damage are multiple fiber-bridged matrix cracking in a unidirectional composite, multiple intralaminar cracking in a laminate, local delamination distributed in an interlaminar plane, and fiber/matrix interfacial slip associated with multiple matrix cracking. The field of damage mechanics is concerned with conditions for initiation and progression of distributed changes as well as consequences of those changes on the response of a material (and by implication, a structure) to external loading.

Failure is defined as the inability of a given material system (and consequently, a structure made from it) to perform its design function. Fracture is one example of a possible failure, but generally, a material could fracture (locally) and still perform its design function. On suffering damage (e.g. in the form of multiple cracking) a composite material could continue to carry loads, and thereby meet its load-bearing requirement, but fail to deform in a manner needed for its other design requirements such as vibration characteristics and deflection limits.

The multi-scale nature of damage

In a purist view, the first (basic) scale at which dissipative mechanisms occur is the lowest possible material size-scale. In reality, however, identifying this scale is limited by our ability to observe as well as to model and analyze the mechanisms at the observed scale. The so-called “micro” scale is a reference to the scale at which entities or features within a material are observable by a certain type of microscope. Thus, for example, the micro scale can be a few micrometers, if an electron microscope is used to observe entities such as cracks or crystalline slip within grains or at grain boundaries. The scale reduces by an order of magnitude if one focuses on dislocations observed by a transmission electron microscope. Today, the use of nano-scale elements (particles, fibers, tubes, etc.) has moved the basic scale further down where it is necessary to revisit the fundamentals of continuum mechanics and to develop modeling tools that can bridge the discrete-level descriptions (quantum mechanics) to continuum type (smeared-out) descriptions.

In an engineering approach, the purpose at hand should guide the choice of the basic scale. Thus if the overall (effective) characteristics of inelastic response are of interest, it would suffice to incorporate the energy dissipating mechanisms in a model, directly or indirectly, in an appropriate average sense, while if, for instance, a particular material failure characteristic is aimed, the analysis may need to be conducted at the local physical scale of the relevant details of the mechanisms. On the other hand, if the purpose is to design a material, i.e. to engineer its response or to provide it with certain functionalities, then it would be necessary to address scales where the material (micro) structure can be modified, manipulated or intruded.

In composite materials, the scales of inhomogeneities (reinforcements, additives, second phases, etc.) embedded in the baseline material (matrix) determine the characteristic scales of operation of the mechanisms of energy dissipation. Although energy dissipation may also be occurring at other (smaller) scales, e.g. the scale of the matrix material’s microstructure, the dissipative mechanisms associated with the inhomogeneities has usually an overriding influence on the composite behavior. For instance in short-fiber polymer matrix composites, the size of fiber diameter manifests the scale at which matrix cracks form, although energy dissipation may also occur at the matrix polymer’s molecular scale. The complexity introduced by inhomogeneities in composite damage is in the form of multiple scales of dissipative mechanisms depending on the geometrical features of the inhomogeneities. For the case of short fibers, for instance, the matrix cracking from the fiber ends and the fiber/matrix debonding occur at two length scales, determined by the fiber diameter and fiber length, respectively. For composite laminates, the thickness of identically oriented plies sets the scale for development of intralaminar cracking, while for formation of these cracks the appropriate scale is given by the fiber diameter. Thus in modeling of a composite material’s behavior one faces a complex situation concerning the length scales, and taking a hierarchical approach may not be the most efficient way, as we shall discuss later.

In the following the multi-scale nature of damage in composite materials will be illustrated and elaborated further by examining two particular cases.

Unidirectional ceramic fiber reinforced ceramic matrix composites (CMCs)

The first case for consideration is a unidirectionally reinforced CMC subjected to uniform, monotonically increasing tension in the fiber direction. The set of four micrographs from Sørensen and Talreja [7] shown in Fig. 1 illustrate the progressive matrix cracking in a SiC fiber reinforced glass-ceramic matrix. The axial strains at which these pictures are taken by a surface replication technique are indicated in each picture. The first picture at 0.15% strain shows an early stage of the matrix cracks lying normal to the (horizontal) fiber axis and not fully spanning the specimen cross-section. Progressively at higher strain levels the cracks are fully fiber-bridged, increasing in number and reaching a saturation density (maximum number of cracks per unit axial length). A schematic overview of the stages of damage corresponding to the stress-strain response is depicted in Fig. 2. In the first stage of no cracking the response is linearly elastic, followed by Stage II where the multiple matrix cracking renders the stress-strain response inelastic. The unloading moduli (axial Young’s modulus and Poisson’s ratio) show steady degradation with increasing crack number density in Stage II, which initiates at 0.13% strain and extends to 0.5% strain. Beyond this strain Stage III occurs where the frictional sliding at the fiber/matrix interface becomes significant. At a later part of this stage, beyond 0.7% strain, progressive fiber breakage takes place leading to localization of damage and subsequent failure.

Surface micrographs of a SiC fiber reinforced glass-ceramic composite at different axial strains. Tensile loading was in the (horizontal) fiber direction. From Sørensen and Talreja [7]

A schematic overview of the three stages of stress–strain response in a SiC fiber reinforced glass-ceramic composite. Based on Sørensen and Talreja [7]

The Stage II progressive cracking can be treated with damage mechanics, a field that concerns itself with characterization of damage, evolution of damage and relating damage to material response. Talreja [9] presented characterization of damage modes in ceramic matrix composites (matrix cracking, fiber/matrix debonding and fiber/matrix sliding) and derived for each mode expressions for the changes in moduli as functions of damage. Sørensen and Talreja [7] used that modeling approach for the Stage II matrix cracking described above. In the following we shall use this example to illustrate the multi-scale nature of damage and discuss how the scales can be incorporated in a damage mechanics framework.

Figure 3 shows schematically a fiber-bridged matrix crack typical of the Stage II damage in CMCs described above. This type of crack can be viewed as having three components, each causing dissipation of energy by a separate mechanism. One component is the crack surface formed by breakage of atomic bonds in the matrix. The second component consists of the fiber/matrix disbonds, which occur by breakage of atomic bonds at the interface. Finally, the third energy-dissipating component is the frictional sliding at the fiber/matrix interface that follows debonding. Each component has a characteristic geometry and an associated “influence” to signify its presence. In Talreja [9] the three mechanisms––matrix cracking, debonding and sliding––were treated as individual damage modes and were characterized by symmetric second order tensors, incorporating appropriate measures of influence for each mode. We shall discuss those damage modes here with a view to bringing out the multi-scale features.

Matrix cracking

A matrix crack can be viewed as a pair of internal surfaces in a composite that are able to perturb the stress state in a region around the surfaces by conducting displacement (i.e. separation of surfaces) from the undeformed configuration. The surface separation per unit of applied external load depends on the size and shape of the surfaces as well as on the constraint, if any, imposed by the surroundings. For a matrix crack in a unidirectional CMC the constraint comes from the bridging fibers as well as from the stiffening effect of fibers in the matrix surrounding the crack. As described in Talreja [9] a single crack can be characterized by a “damage entity tensor”, given by

where a i are components of an “influence vector” placed on a crack of surface area S at a point with outward unit normal vector of components n j . The influence vector can be resolved along the crack surface normal and tangential directions. For the type of crack considered here it is reasonable to assume that only the normal (crack opening) displacement matters, allowing a i to be expressed as

where the quantity a now represents a measure of the crack influence. From dimensional analysis, with d ij taken to be dimensionless, a has dimensions of length. Drawing upon fracture mechanics this length is in proportion to the crack length. For a fiber-bridged matrix crack the crack length l can be expressed in multiples of the average inter-fiber spacing. Thus,

where k is a constant, d is fiber diameter and v f is the fiber volume fraction. The expression in Eq. (3) is based on a hexagonal fiber arrangement. Similar expression will result from other assumption of fiber distribution in the cross-section. We can now infer that the microstructural length scale for matrix microcracking is the fiber diameter. Note that for an irregularly shaped crack surface the inter-fiber spacing, and therefore the fiber diameter, will still be the length scale.

The consequence of the presence of a matrix crack is generally in changing the composite’s deformational response, which is defined and measured at a larger length scale, e.g. the characteristic length of a volume containing a representative sample of the cracks. This volume is called a representative volume element (RVE). For the Stage II stress–strain response [7] used the model proposed in Talreja [9]. Accordingly, assuming the influence vector magnitude a to be proportional to the crack length,

where α is a constant representing the constraint to the crack surface displacement. This constant equals zero when the constraint allows no crack separation, while it increases as the constraint reduces.

From Eqs. (1), (2) and (4), the damage entity tensor for matrix cracking is

where t is the specimen thickness (or the through-thickness characteristic dimension of the crack).

The macro-level deformational response is derived from a strain energy density function that depends on the strain and damage states. The matrix-cracking damage state is characterized by [9],

where V is the RVE volume of a representative volume element (RVE) over which the summation is conducted. Substituting Eq. (5) in Eq. (6), one obtains

where \( D^{{\text{mc}}} = D_{11}^{{\text{mc}}} \), the only surviving component of the damage mode tensor, f is the fraction of RVE width spanned by a crack and η is the crack number density, i.e. the number of cracks per unit volume, and A is the cross-sectional area. The quantity within the brackets < > is averaged over the RVE volume.

The matrix crack length, Eq. (3), thus appears in the damage descriptor, Eq. (7). Also, as shown in [9], the crack length also governs the elastic constants at a given crack density η. For instance, the axial Young’s modulus can be written as

where c is a constant and the superscript 0 is for the initial value.

In characterizing matrix cracks as a damage mode, Eq. (7), no specific account is made of the associated fiber/matrix debonding and sliding mechanisms. These can be considered separately and then accounted for by their interactions with the matrix cracks [9]. Discussions of these mechanisms follow.

Interfacial debonding

The fiber/matrix interface can debond due to several causes. Essentially, a stress normal to fibers or a shear stress along fibers, or a combination of the two, must exist for the bond to fail. These stresses can be generated by a fiber break or brought into play by an approaching matrix crack. Alternatively, a preexisting flaw at the fiber surface or an imperfect fiber, or its misalignment, can produce those stresses. If debonds are produced without interaction with matrix cracks, then they can be characterized in a manner similar to matrix cracks. A characterization of such distributed debonding is given in Talreja [9] based on certain simplifying assumptions. The only surviving damage mode tensor component for this case is D 22 and its form is the same as that of D mc in Eq. (7). Thus the debond length and the debond number density enter into the damage mode description. The debond length will depend on the characteristic flaw length, which in turn depends on the manufacturing process. Unless the ability of the manufacturing process to produce interfacial flaws somehow depends on the composite microstructure, no microstructural length scale can be identified for the debonding mechanism.

For the case of a matrix crack initiating debonding and then merging with the debond crack, further driving force to the advancement of the debond crack comes from the opening displacement of the matrix crack. The damage configuration of interest then is not the debond crack by itself but a combined matrix-debond crack. The latter can be viewed as a fiber-bridged matrix crack, discussed above, with the constraint to its surface displacement now modified by the presence of debonding. Then the constant α in Eqs. (4), (5) and (7) may be changed to another value, resulting in a change of the constant c in Eq. (8).

Thus for debonding that occurs in conjunction with matrix cracking the determining length associated with the damage mode is still the matrix crack length l, although with a modified influence. This length can still be expressed by Eq. (3), giving the fiber diameter as the microstructural length scale.

Specific treatments of debonding by itself and of debonding in conjunction with matrix cracking are given in Talreja [9]. Based on that work the axial modulus for the latter case can be modified from Eq. (8) to be

where

where d l is the ratio of the debond length to the crack length and k l is a constant. Here a fixed ratio of the number of debonds per unit of matrix crack length has been assumed.

From Eqs. (9) and (10) it can be seen that the debond length does not enter into the RVE response directly but via its ratio to the crack length, suggesting that the governing length for this response is the crack length.

Interfacial sliding

Interfacial sliding occurs when fibers and matrix remain in contact after debonding of the interface and undergo unequal displacements. Talreja [9] defined a measure of the slip at the interface as the area swept off by the relative displacement of one constituent over the other and expressed this measure in terms of a slippage vector. A slippage tensor was then constructed as a dyadic product of the slippage vector with itself to account for the insensitivity of the material response to the direction of slip. As in the case of debonding discussed above, when sliding occurs in conjunction with matrix cracking, the slip damage tensor, which represents this damage mode averaged over the RVE, turns out to depend on the average matrix crack length. In fact it depends explicitly on the average crack opening displacement, which in turn depends on the average crack length. The only surviving component of the slip damage tensor can be written as [9]

where d is the fiber diameter, v f is the fiber volume fraction and c d is the crack opening displacement and the quantity within the brackets < > is averaged over the RVE volume.

Assuming the crack opening displacement to be proportional to the crack length we may rewrite Eq. (11) as

where ξ is a constant depending on the fiber volume fraction and fiber stiffness. The fiber diameter is placed within the brackets to allow for its variation. Equation (12) indicates that this damage mode depends directly and strongly on the fiber diameter in addition to depending on the matrix crack length, which in turn is expressible in terms of the fiber diameter, as in Eq. (3). Thus the microstructural length scale also in this case is the fiber diameter. Note that the fiber length over which sliding occurs is not a characteristic dimension of the mechanism when it occurs in conjunction with matrix cracking.

Ply cracking in laminates

Figure 4 shows an X-ray radiograph of a carbon-epoxy cross-ply laminate after being subjected to tension-tension cycling. In this two-dimensional view the horizontal lines are images of cracks in the 90-plies, while the vertical lines indicate cracks (also called axial splits) that lie in the 0-plies [3]. The shaded areas are sites of interlaminar cracks (delaminations), which are depicted in Fig. 5. For the sake of our discussion on length scales of damage we shall primarily focus on ply cracking.

An X-ray radiograph showing transverse cracks, axial cracks and delaminations in a cross ply laminate after fatigue [3]

Figure 6 illustrates multiple matrix cracking in a ply of an arbitrary orientation θ with respect to the 90-direction. The cracks are shown at a mutual spacing s, which represents the average crack spacing in a RVE. Using a second order tensor characterization for this mode of damage [8] gives

where the superscript pc stands for ply cracking, κ is a ply constraint parameter, t c is the thickness of the cracked ply and t is the laminate thickness. The components n i of the unit vector normal on a crack surface are given by

where θ as shown in Fig. 6 is the crack inclination.

The laminate stiffness matrix in the presence of a fixed state of ply cracking is given by [8]

where the indices p and q take values from 1 to 6 in accordance with the Voigt notation. The superscript 0 on the stiffness matrix indicates initial value while D indicates the contribution due to damage.

The stiffness matrix reduction due to damage can be expressed in a first approximation as

where κ′ is a modified ply constraint parameter, which depends on the ply constraint, the crack orientation and ply properties.

The length scale variable entering the damage descriptor, Eq. (13), and consequently, the elastic response change, Eq. (16), is the crack dimension, which for fully developed ply cracks, as assumed here, is the ply thickness t c . The other crack dimension along the fiber axis in the ply extends as far as the imposed stress acts and is therefore not the characteristic length scale of the cracking mechanism. Expressed differently, the crack surface displacement, which is the cause of stress perturbations and thereby the elastic response changes, depends on the crack dimension through the ply thickness.

Although the ply cracks are assumed for simplicity to be sharp-tipped, as illustrated in Fig. 6, in reality they must get blunted by merging with the local delamination, i.e. the separation of plies at the interface, caused by the intense stress field carried by the approaching ply crack fronts. The extent of the delamination cracks along the ply interfaces must depend on the interfacial bond strength as well as on the ply crack length t c . In fact this situation is analogous to the fiber/matrix debonding in conjunction with matrix cracking in unidirectional CMCs, discussed in the section “Interfacial Debonding” above. Drawing upon that analogy we deduce that the delamination length enters the analysis not directly but via its ratio to the ply crack length t c . Thus, once again the relevant length scale variable is the total cracking ply thickness t c .

When cracking occurs in more than one ply orientation, multiple length scales result with each length scale variable equaling to the combined thickness of the set of consecutive cracking plies of the corresponding orientation. Also, the delamination associated with each ply cracking contributes to the effect on the elastic response via the ratio of the associated delamination length to the ply crack length. Figure 7 illustrates the ply (matrix) cracking and delamination in an angle ply laminate.

Finally, let us return to the delamination mode observed in fatigue of cross ply laminates depicted in Figs. 4 and 5. As illustrated in Fig. 5 this delamination occurs locally at the intersection of cracks in the two orthogonal orientations in adjacent plies. The cause of this delamination and the effect of its presence have not been adequately analyzed. Therefore, any inference regarding its characteristic length scale is speculative at present. It appears, however, that the growth of the delamination is mainly along the two orthogonal ply crack directions, suggesting thereby two length scales. These length scales may be described as the two principal directions of an ellipse, which may be taken to approximate the delamination geometry.

Multi-scale modeling of damage for elastic response

Damage entity size and microstructural length scales

In the Section “The Multi-scale Nature of Damage” we have examined the governing dimensions of the damage entities from the viewpoint of elastic response in the presence of damage. We have looked at two specific cases of damage in unidirectional CMCs and in PMC laminates. The framework within which we have analyzed the issue of characteristic lengths is the continuum damage mechanics using characterization of damage with second order tensors. This particular representation of damage, in the form used here, provides a consistent characterization of the basic damage entity involved in each case, e.g., a matrix crack in a CMC and a ply crack in a PMC laminate. The crux of the characterization is the “influence” vector, which provides a relevant measure of the action induced by the presence of the damage entity. By expressing the magnitude of this vector in terms of the characteristic and governing dimension of the damage entity the “essence” of the damage entity is carried into the damage entity tensor. This dimension, when properly identified and related to the microstructural entities, provides the length scale associated with the damage mechanism considered. The relevance of the length scale to determining the elastic response affected by that damage mode becomes clear when we examine the response measured over the RVE. For this a damage mode tensor, which acts as an internal state variable in a continuum damage framework, is considered. We have examined the damage mode tensor in a simple form, such as that in Eq. (6), which is the volume average of the damage entity tensor over the RVE. This does not account for the damage entity distribution and can therefore be used only for the RVE-averaged, i.e. the meso-scale, response, and not for describing damage evolution. Thus, we have examined the length scales of damage within the context of the elastic response.

The next question to address is: What is the significance of the length scales of damage? The basic concept behind length scales appears to be the intuitive idea that effects seen at a given observation “window” (e.g. RVE size) must be determined by events occurring at dimensions smaller than the window size. Implicit is the assumption that those events are associated with certain discrete entities such as grains in a polycrystalline material, and that the action of those entities and interactions between them when averaged over the window size provides the “response” variables applicable at that scale. Carrying this logic one step “behind” would suggest that the response at the scale of the discrete entities in a RVE could be given by the sub-entities lying within those entities. Thus, if a grain is viewed as an entity, then the dislocations within the grain could be the sub-entities. This move to smaller and smaller size-scales could in principle have no end other than the limit set by the tools of observation and analysis available at a given time. In engineering science, in contrast to “pure” sciences, one takes a pragmatic approach driven by the application or need at hand. From this point of view, one must consider the purpose first and go as far down in scales as needed. Thus if the purpose is to determine the elastic response changes induced by damage in a composite material, then one must go as much down in length scales as necessary to determine the reversible deformation (or stress) related effects, but no further.

The next question is whether a hierarchy of length scales can be identified. What we have illustrated by the discussion of the two cases of composites with damage is that a simple hierarchy of length scales does not exist. Instead, a complex damage mode may involve more than one governing length, e.g., the matrix-crack length and the interfacial sliding length for a fiber-bridged crack. Also, multiple damage modes may operate simultaneously, and interactively, leading to multiple length scales, e.g., in the case of multiple off-axis plies in a laminate. These considerations suggest that an alternative is needed to the strategy of starting at the smallest length scale and working up the scale hierarchy. Talreja [10] proposed one such strategy, the so-called “synergistic” damage mechanics. The following discussion will address the two strategies.

Hierarchical vs. Synergistic multi-scale approach

It would be fair to say at the outset that the hierarchical multi-scale approach is intuitively logical. For a complex composite architecture, which is quite often the case in practical applications, one can think of starting with the smallest basic unit––a discrete fiber embedded in matrix––and proceed to the level of a representative unit of collective fiber arrangement. The basic unit can be analyzed as a piecewise homogeneous continuum, with two regions, if fiber and matrix are considered, or three, if an interfacial layer is added. The result (stress, strain, temperature, etc.) can then be averaged in some sense over a representative unit to get a description for the homogenized medium. Several models for doing this exist, e.g., the Mori-Tanaka method. These models aim at bridging the two scales––the scale of the basic unit and the RVE scale. Generally, the issue of uniqueness remains unresolved in the sense of representation of the collective fiber effect. There is as yet no precise and rigorous definition of a representative unit for a general case, which is the source of lack of uniqueness. A logical extension of the discrete-to-collective bridging of the fiber–matrix case to higher scales produces the hierarchical approach in multi-scale modeling. One can argue if this approach is efficient, in spite of its logic. Historically, the hierarchical approach has not preceded other approaches. A structural analyst has worked with macro-level descriptions of material behavior, e.g., the classical laminate plate theory, and has looked for micro-level information as needed. A materials developer, on the other hand, has focused on effects of constituents and their microstructural arrangements on properties. In recent years the seemingly abundant computer power has motivated the hierarchical approach with the hope of integrating materials design and structural analysis.

Our objective here is to examine approaches for multi-scale analysis of damage in composites. A first thought would be to conduct damage initiation and progression analysis as a part of the hierarchical multi-scale approach. It turns out not to be that straightforward. The issues confronting this approach will be discussed below, along with the merits of an alternative approach.

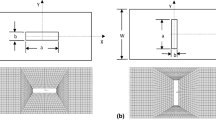

Let us first take an overall view of the multi-scale approach. Figure 8 illustrates, from left, an object of structural integrity assessment within which a region of potential criticality (failure) exists. This region (a substructure) is analyzed to determine the loading on its boundary. Next step is to examine how this loading induces damage. This step requires analyzing heterogeneities (microstructure, generally), which govern initiation of damage. Simple examples are debonding of fibers from matrix and matrix cracking from broken fiber ends. The analysis of local stress/strain fields to determine such micro-failures is commonly referred to as micromechanics. The micromechanics itself could be conducted at multiple scales. An example is fiber/matrix debonding at the fiber diameter scale and coalescence of the debond cracks at the scale of a representative number of fibers.

In Fig. 8 the direction of the arrows indicates moving from structural (macro) scale downwards to decreasing length scales. Until the microstructural entities are explicitly included in an analysis, the regime of analysis is characterized as “continuum”, beyond which it is known as micromechanics. In the context of damage the continuum regime is called Continuum Damage Mechanics (CDM), while the micromechanics is typically not given an additional characterization (except, perhaps, occasionally as micro-damage mechanics, see [2]). Historically, the fields of CDM and micromechanics have developed independently, CDM going back to Kachanov [4], while micromechanics originated in various works, but its characterization as a coherent field may be credited to Budiansky [1], who defined it as “the mechanics of very small things”. In recent years the upsurge of computational mechanics has also boosted micromechanics, adding the aspects of numerical simulation and length-scale based characterizations such as “nanomechanics”. The increasing confidence in the power of computation has led to the notion of the hierarchical approach, with the implicit assumption that “basic” laws, when placed into a simulation scheme, will lead to physically correct results. Thus, once the microstructure, at any chosen level of length scale, has been codified in a simulation scheme, the results of computation will describe the behavior at the next higher level, the assumption goes. In the context of damage mechanics this may raise a few issues that we shall discuss below.

The first issue in a hierarchical approach is the choice of length scales. As discussed in Section “The Multi-Scale Nature of Damage” above, the microstructural length scales are relatively straightforward, and consequently setting up a hierarchy of scales and procedures for bridging between them can be accomplished relatively easily. However, the microstructural configuration and driving forces for damage initiation and progression determine the length scales of damage. Thus, length scales of damage and their hierarchy are not fixed but are subject to evolution. To illustrate this, consider ply cracking in a laminate. In the early stage, individual ply cracks initiate from debonding of fibers, giving the damage length scale in terms of the fiber diameter. When the ply cracks are fully-grown through the ply thickness, the mechanism of interest is the multiplication of cracks. At this stage, the damage length scale is crack spacing, which in turn depends on the ply thickness as well as the constraint to surface displacement of the ply cracks. The two-stage behavior and the evolving nature of damage complicate any hierarchical scheme for prediction of response.

Another issue in a hierarchical approach is the multiplicity of damage modes. If more than one damage mode operates at a time, and there is interaction between the modes, then a hierarchy of length scales becomes questionable. Consider ply cracking in a commonly used, quasi-isotropic [0/±45/90] s laminate in axial tension. Multiple matrix cracking occurs in 90-plies, followed by the same in plies of −45 and 45 orientations. The three ply cracking modes progress interactively and at some stage concurrently. The length scales associated with the three damage modes do not show hierarchy. Consequently, bridging the scales by some averaging scheme becomes irrelevant. Further complication to the hierarchical scale arrangement is given by the interlaminar cracking that results from the cracking in individual off-axis plies.

An alternative to the hierarchical approach is the synergistic damage mechanics (SDM) approach proposed by this author [10]. Conceptually the approach combines the strengths of CDM and micro-damage mechanics (MDM). In CDM the material microstructure (e.g., distributed fibers) and the distributed damage, which may be called micro-damage structure, are treated as smeared-out fields. This homogenization is illustrated in Fig. 9 as a two-step process, where the material microstructure is viewed as consisting of “stationary” entities (e.g., fibers and plies) and the micro-damage structure is considered as a family of evolving entities (e.g., cracks and voids). A set of response functions are expressed in terms of the field variables (stress, strain, temperature) and internal variables, which represent the smeared-out field of evolving damage entities. The internal variables, although being field quantities, actually have an RVE associated with them at each material point. Strictly speaking, there is another RVE associated with the stationary microstructure, but it is customary in continuum treatments to bypass it by requiring that the quantities such as the elastic moduli of virgin material be measured at a scale much larger than the scale of the individual stationary microstructure entities. There is a tendency to do that for the RVE associated with damage as well, as evidenced in finite element based analyses where reduced (damage induced) properties are assigned at nodal points. The reduced properties are meaningful only at the RVE scale, which depends on the length scales of damage discussed above.

To illustrate the structure of SDM let us consider the Helmholz free energy function for isothermal, mechanical response, as

where the strain tensor ε and damage variable D, generally also a tensor, are independent variables representing the material state. The variable D is viewed as an internal variable, representing some measure of the collective presence of damage entities in an RVE at the considered point where the material response is sought. In Fig. 9 the RVE at a point is shown as a finite-sized cube of material containing a representative sample of damage entities.

The internal state (damage) in a general case may contain multiple modes, such as the ply cracking modes in a [0/±45/90] s laminate. In the conventional CDM approach the response function R, and any function derived from it, is expressed in terms of D, which is formulated to represent a measure of the intensity of damage. Examples of such measures are void volume fraction and crack number density. Such “passive” measures end the CDM at the RVE level, i.e., the role of CDM gets limited to generating constitutive relationships at the RVE (meso) level that are then used for analyzing structural (macro) response. In the SDM approach we proceed down from the RVE level to one or more micro-levels as warranted by the situation at hand. This is accomplished by developing a characterization of damage entities that is “active” in the sense that the presence of damage entities is accounted for by including the “influence” of damage entities. In contrast, the passive characterization is limited to only accounting for the “presence” of damage entities by measures such as crack number density, as noted above. The characterization of influence is accomplished by assigning a two-vector representation to a damage entity, as illustrated in Fig. 9. The vector a carries the influence through its magnitude and direction. The magnitude of the vector represents a measure of how much the damage entity is able to affect its surroundings, while the direction of the vector indicates the orientation in which this effect acts. For instance, if we are concerned about deformational response of a composite, then clearly the surface of a given damage entity must conduct a displacement in order to affect this response. Imagine for instance a transverse crack in 90-plies of a [0/±45/90] s laminate. The degree to which this crack opens under an imposed axial load increment will determine how much the axial elastic modulus of the composite will reduce. If the axial stiffness of the sublaminate [0/±45] is high, then the crack opening displacement will be low, and consequently, the modulus reduction will be small. In a passive damage characterization, where only the crack number density enters, no distinction can be made between the presence of cracks in different constraining environments. In the SDM approach the constraint to the damage entity influence is represented in a constraint parameter, such as α in Eq. (4) for a fiber-bridged matrix crack. The determination of the constraint parameter, and generally any influence function, is accomplished by a micromechanics analysis at levels warranted by the length scales of damage.

The SDM approach has been illustrated in Varna et al. [11] for the elastic response of [±θ/904] s laminates and in Varna et al. [12] for the linear viscoelastic response of cross ply laminates of different 0/90 ply mix. In each case the transverse cracking in 90-plies was considered as the damage mode subjected to different constraints. Thus in the [±θ/904]s laminates θ is varied to vary the constraint, while no cracking is considered in the ±θ plies. The objective in both the works just cited was to demonstrate SDM for the case of one damage mode with varying constraint and varying meso scale (RVE size). This addresses the first of the two issues in hierarchical multi-scale modeling discussed above. This author and his associates in ongoing work are treating the other issue of multiple damage modes. The main ideas in dealing with the first issue are discussed next.

Let us consider the elastic response of [±θ/904] s laminates. At a damage state where multiple transverse cracks of average spacing s exist, an elasticity response function (modulus), derived from the free energy function, Eq. (17), can be expressed as Talreja [8]

where R 0 is the initial (undamaged) value of the response, t c is the thickness of the cracked plies, κ is the constraint parameter and f 1 and f 2 are normalized functions of the laminate geometry (ratio of cracked to uncracked plies) and ply properties, respectively. The expression in Eq. (18) results from a linearized theory; more terms of higher order in \( \frac{{t_c }} {{^s }} \) will appear in a higher order theory. In Varna et al. [11] it was shown based on MDM analysis that the constraint parameter κ could be approximated as a function of θ by a polynomial function of ply properties and ratio of thicknesses of cracked and uncracked (constraining) plies. Thus with input from MDM the CDM framework could be applied to the class of [±θ/904] s laminates. Note that in the conventional CDM framework the response function R must be calculated separately for each θ value.

In the case of linear viscoelastic response, R, κ, f 1 and f 2, are all functions of time. In Varna et al. [12] it was shown that the functions f 1 and f 2 are normalized functions of laminate geometry and relaxation moduli of undamaged plies, respectively, while the time variation of κ was found by parametric studies of [0/90n] s to be given by a polynomial function of the ratio of axial relaxation moduli of the cracked plies to that of the uncracked plies. Once again, an MDM analysis allowed predicting viscoelastic response (for a fixed crack density) for a class of composites with a CDM framework without experimentally determining material constants for each laminate configuration.

Although at this point no results are available for the case of multi-mode damage using SDM (work is ongoing) it is fair to state that a purely MDM approach or a conventional CDM framework will not provide results without excessive computation (for MDM) or tedious experiments (for CDM).

The “Big Picture”

In composites damage modeling, and in engineering research generally, it is important to have the ultimate goal in mind to develop the right strategy and to be clear about the context. For us the goal is to assess integrity and durability of composite structures. This goal is not new; it has been in sight for most of us involved in materials modeling. Figure 10 shows the “big picture” in which structural integrity and durability assessment is embedded. The starting place in the iterative process illustrated in the figure is manufacturing. One selects a process, e.g., liquid compression molding and quantifies its process parameters, which along with other manufacturing details involved, such as machining and assembly, determine the material state in the component manufactured. The material state is characterized by a set of properties (e.g., elastic moduli, strength and fracture toughness). These properties undergo evolution in the service environment due to phenomena such as fatigue, creep/viscoelasticity and aging. The performance evaluation for the expected component life involves assessment of structural integrity and durability. Finally, a trade-off study of cost against performance is conducted to assess the cost-effectiveness. Most cost drivers lie in the manufacturing process, whose parameter variation allows moving toward the optimal design.

Returning to the structural integrity and durability assessment, the role of materials modeling for composites is described in Fig. 11. Here the starting place is structural stress analysis of a given component, often by a finite element code. The input to this is the loading environment along with a deformational model, which is taken to be that of the initial material state (as produced by the manufacturing process). In most cases prior experience guides in identifying critical sites in the component that are prone to failure. The local stress states in those sites determine the initiation and evolution of damage, also called sub-critical failure. The mechanisms of damage depend additionally on the “microstructure”, i.e., the fiber architecture, ply configuration, fiber/matrix interface, etc. In the discussion above we have illustrated two cases of damage in two widely different microstructure scenarios. Along with this we have also discussed the damage mechanics approaches, CDM and MDM, as well as the hierarchical versus SDM strategies. The outputs of these modeling efforts are either deformational changes, expressed as stiffness-damage relationships, or strength (failure criticality), or both. The stiffness change result also provides incremental input to the stress analysis, updating the deformational model. The final goal of life prediction (durability) can be reached either by a stiffness criterion or a strength criterion, depending on the performance requirement.

The multi-scale modeling approach discussed here has been focused on the deformational response. Other considerations are needed for treating the local-to-global failure. The length scale issues are substantially different for failure than for deformational response. Discussion of these calls for a separate, focused treatment reserved for a future work.

Future direction

Referring to Fig. 10 again, the material state resulting from the manufacturing process depends on the defects inherent in the process, in addition to the constituents and their mix in the composite. Any practical manufacturing process produces a variety of defects, such as misaligned fibers, broken fibers, irregularly distributed fibers, resin rich areas, voids and interfacial disbonds. In most modeling efforts the composite microstructure is idealized to be defect free or at best assumed to have simplified defect geometry and distribution. The field known as “effects of defects” has been active since the 1970s when regularly distributed defects embedded in homogenized composites were studied. The more recent advances in morphological characterization based on stereological tools and stochastic methods have so far been only applied to properties of heterogeneous media [5, 6]. The future direction for advancement in damage mechanics lies in incorporation of as-manufactured defects in damage models. This is far from a straightforward proposition. Further discussion follows.

The hierarchical multi-scale modeling faces major difficulties in analysis of defects for damage initiation and growth, as well as for prediction of the consequent global structural response. Not only is the hierarchy of length scales of damage dubious, as discussed above, the microstructural length scales are rendered complex by the defect morphology. For instance in describing microstructure of a unidirectional composite, misalignment of fibers adds additional descriptors to the two parameters––fiber diameter and inter-fiber spacing––needed for the perfectly aligned case, assuming uniform distribution of fibers. The implication on damage initiation and growth makes the situation worse.

In an SDM approach not all microstructural details are necessary, only those motivated by the smeared-out higher scale. For instance the surface displacement capacity of damage entities within the RVE needed for describing the meso-scale response can be calculated by considering only those details of microstructure that are expected to influence that quantity. Thus with discrimination and judicious choices the modeling can be simplified without sacrificing essential physical effects. One may ask why starting at a lower scale and proceeding upwards could not achieve the same advantage. The problem with that would be not knowing which details of the microstructure would be important for the response until the analysis is done. Approaching from the structural level helps clarify the determining factors for the needed response.

Concluding remarks

Multi-scale modeling is of great interest today largely because of the availability of computational power as well as observation and imaging techniques. However, there is a risk of losing tractability of damage and conducting ineffective analyses if strategies and approaches are not sufficiently scrutinized. In this paper the length scale issues have been addressed by considering two widely different damage scenarios. The problems associated with identifying a hierarchy of length scales in the presence of damage suggest taking an approach where the continuum modeling of damage and micro-damage modeling are combined in a synergistic manner.

A methodology for assessing structural integrity and durability of components manufactured by practical methods needs incorporation of defects in a multi-scale damage analysis. Future work should move in this direction.

References

Budiansky B (1983) Comput Struct 16:3

Hashin Z (1990) In: Boehler JP (ed) Yielding, damage, and failure of anisotropic solids, Mechanical Engineering Publications, London, p 3

Jamison RD, Schulte K, Reifsnider KL, Stinchcomb WW (1984) Effects of defects in composite materials, ASTM STP 836. American Society for Testing and Materials, Philadelphia, p 21

Kachanov LM (1958) Izv. AN SSSR, Ofd. Tekhn. Nauk. 8:26 (in Russian)

Pyrz R (2000a) In: Chou T–W (Volume ed), Kelly A, Zweben C (eds-in-Chief), Comprehensive composite materials, vol 1. Elsevier, Oxford, p 465

Pyrz R (2000b) In: Talreja R, Månson J-AE (Volume eds), Kelly A, Zweben C (Eds-in-Chief), Comprehensive composite materials, vol 2. Elsevier, Oxford, p 553

Sørensen BF, Talreja R (1993) Int J Damage Mech 2:246

Talreja R (1990) In: Boehler JP (ed) Yielding, damage and failure of anisotropic solids. Mechanical engineering publications, London, p 509

Talreja R (1991) Mech Mat 12:165–180

Talreja R (1996) In: Cardon AH et al (eds) Progress in durability analysis of composite systems. A.A. Balkema, Rotterdam, p 117

Varna J, Joffe R, Talreja R (2001) Compos Sci Technol 61:657

Varna J, Krasnikovs A, Kumar RS, Talreja R (2004) Int J Damage Mech 13:301

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Talreja, R. Multi-scale modeling in damage mechanics of composite materials. J Mater Sci 41, 6800–6812 (2006). https://doi.org/10.1007/s10853-006-0210-9

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-006-0210-9