Abstract

Solid dispersions of valdecoxib were prepared with the objective of dissolution enhancement by melt granulation technique using polyvinyl pyrollidone (PVP K 30) and polyethylene glycol (PEG 4000) alone (1:1) and in combination (1:0.5:0.5). Phase solubility studies showed a linear increase in valdecoxib solubility with increase in polymer concentration in both the cases. The FTIR spectroscopic studies showed the stability of valdecoxib and absence of well defined valdecoxib—PVP K 30–PEG 4000 interaction. Powder X-ray diffraction (XRD) and differential scanning calorimeter (DSC) were used to characterize the solid state of the dispersion, indicated a complete transformation of drug from crystalline to amorphous form. In vitro dissolution studies performed in 0.1 N HCl showed a significant enhance in dissolution rate when PEG 4000 and PVP K 30 were used in combination. Improved drug dissolution by both the carriers may be attributed to the improved wettability, reduction in drug crystallinity and solubilizing effects from solid dispersions of valdecoxib. Accelerated stability studies of solid dispersion with PVP K 30 and PEG 4000 does not show any significant change in the drug content and dissolution profile in 6 months study period. This study concluded that the dissolution rate of valdecoxib can be modulated by appropriate levels of hydrophilic carriers.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Water insoluble drugs are usually characterized by a low bioavailability due to less absorption which is a major concern of pharmaceutical industries worldwide. Attempts to improve the solubility of these drugs have been performed by various approaches. Solid dispersion technique using proper carrier, reduces the drug particle size and changes micro-environment of the drug particle, increases dissolution rate and thus changes the biopharmaceutical properties [1]. This technique has been used to increase the solubility and improve the dissolution of many poorly soluble drugs [2–6]. However, solid dispersion without using solvent is devoid of toxicity and is popular among the researchers. Hydrophilic synthetic polymers have been widely investigated as carrier substances for solid dispersions. Polyethylene glycol (PEG) and polyvinylpyrrolidone (PVP) are amongst the most frequently investigated hydrophilic polymeric carriers [7–15].

Valdecoxib, 4-(5-methyl-3-phenyl-4-isoxazolyl) benzene sulfonamide, a non-steroidal anti-inflammatory drug (NSAID) which is a highly specific, cyclooxygenase-2 (COX-2) inhibitor for a variety of acute and chronic inflammatory diseases [16]. Valdecoxib offers the unique therapeutic prospect of alternative pain and inflammation without untoward effects to the gastric tract, renal and platelet as associated with conventional NSAIDs. Valdecoxib acts by inhibiting the conversion of arachidonic acid to the prostaglandins that mediate pain and inflammation, while having no effect on the formation of prostaglandins that mediate normal homeostasis in the GI tract, kidney and platelets and that are formed under the control of cyclooxygenase-I [17, 18]. The major problem with valdecoxib therapy is its poor aqueous solubility and dissolution in gastric fluid due to its poor wettability and/or agglomeration of particles [19]. Attempts were already made to enhance the solubility of this drug by solid dispersion techniques using different carriers like PEG, PVP and chitosan [20–24]. The attempts were made earlier only by using single carrier like in case of PVP K 30:valdecoxib (1:1) solid dispersion, the use of PVP alone could not convert valdecoxib in amorphous form; conversion of crystal to amorphous is required to improve dissolution [24]. In PEG 4000:valdecoxib (10:1) solid dispersion, only effective concentration as per criteria defined (100% drug release in 20 min) but ratio shown that the amount of PEG is very high compared to that of valdecoxib [22]. Hence, the present work is an attempt to enhance the aqueous solubility and dissolution rate of valdecoxib using two different carriers i.e. PVP K 30 and PEG 4000 together in combination with drug (0.5:0.5:1) and to study their physico-chemical properties.

Experimental

Materials

Valdecoxib, sodium starch glycolate, Aerosil® 200 (BPRL Pvt. Ltd., Bangalore, India), PEG 4000, Tween 80 (S.D. Fine Chem. Lab., Mumbai, India) and PVP K 30 (Zydus Recon, Bangalore, India) were received as gratis sample. All other reagents and chemicals used were of analytical grade. Distilled water was used throughout the study.

Analytical method

The amount of valdecoxib in samples was quantified by high performance liquid chromatography (HPLC) system (Shimadzu, LC-10ATVP, Japan) consisting of a Phenomenex C18 analytical column (4.6 × 250 mm, Luna, 5.0 μm). The column was maintained at ambient temperature and the compounds were eluted at a flow rate of 1.0 mL/min. Potassium dihydrogen phosphate buffer (pH = 3), acetonitrile, methanol and tetrahydrofuran (400:250:350:2.5) was used as mobile phase. The injection volume was 20 μL and the column effluent was monitored at 240 nm.

Preparation of solid dispersions and physical mixtures

Weighed quantity (400 mg) of carrier (PEG 4000 or PVP K 30) was taken in a porcelain dish and heated (70–80 °C) in a water bath. Valdecoxib (400 mg) was added with continuous heating and stirring for 2 min to obtain uniform mixing. This mixture was triturated with blend of lactose (4 g) and microcrystalline cellulose (1 g). Tween 80, 3% w/w sodium starch glycolate and Aerosil® 200 (1%) were added and mixed. Water was added drop by drop with triturating till suitable wet mass was obtained. The wet mass was then passed through sieve No. 44 (355 μm) and dried at 60 °C for 1 h. While preparing a solid dispersion containing the combination of PEG 4000 and PVP K 30, 200 mg of each polymer was used and prepared similarly.

The physical mixtures of valdecoxib with PEG 4000, PVP K 30 and their combination were also prepared by mixing drug and carriers in a mortar for 10 min. Granules were prepared similar to the solid dispersion. The dried granules obtained were stored in screw cap vial at room temperature.

Phase solubility studies

Solubility measurements were carried out by the method described by Higuchi and Lach [25]. An excess amount of valdecoxib (20 mg) was added to 0.1 M HCl containing various concentrations of PEG 4000 and PVP K 30 and their combination (up to 0.005 Moles) in a glass vial. The system was stirred for 24 h at 37 °C and kept at rest for 24 h to attain equilibrium. The solution was then filtered through a membrane filter (pore size 0.45 μm) and after dilution; the solubility was determined by HPLC. The amount of drug dissolved against moles of carrier was plotted and the stability constant was calculated by the equation.

where So is the solubility of drug in absence of carrier.

Evaluation of drug content

The drug content in granules were determined by weighing a quantity equivalent to 20 mg of valdecoxib and dissolved in 0.1 M HCl, diluted to suitable concentration and analyzed by HPLC.

Dissolution studies

In vitro dissolution tests were performed for both solid dispersion and physical mixtures with drug equivalent of 20 mg using the dissolution test apparatus USPXXIV Type II (paddle type) (Electro Lab, Mumbai, India). The dissolution medium (900 mL) used was 0.1 M hydrochloric acid maintained at 37 ± 0.5 °C with paddle rotation maintained at 100 rpm (n = 3). The release of valdecoxib was measured by withdrawing samples at regular intervals and filtered through a membrane filter (pore size 0.70 μm). The samples withdrawn were replaced with fresh medium maintained at the same temperature and the drug was assayed by HPLC. Dissolution characteristics of physical mixtures and solid dispersions were compared.

Dissolution efficiency studies

The dissolution efficiency of the batches was calculated by the method mentioned by Khan [26, 27]. It is defined as the area under the dissolution curve between time points t 1 and t 2 expressed as a percentage of the curve at maximum dissolution, y100, over the same time period or the area under the dissolution curve up to a certain time, t, expressed as a percentage of the area of the rectangle described by 100% dissolution in the same time.

Differential scanning calorimetry

Differential scanning calorimetry (DSC) analysis was performed with DSC-60 instrument (Schimadzu, Japan). Sample equivalent to 2 mg of valdecoxib was sealed in an aluminium pan and heated at a temperature range of 0–300 °C at the rate of 10°/min.

Powder X-ray diffraction studies

The powder X-ray diffraction (XRD) of the pure drug, physical mixtures and solid dispersions were recorded using an X-ray diffractometer (Siemens D5005, Munich, Germany). The scanning rate was 5°/min and diffraction angle (2θ) was 0–60°.

Fourier transform infrared spectroscopy (FTIR)

Valdecoxib, carriers, physical mixture and solid dispersion in carriers were characterized by FTIR. Samples prepared in potassium bromide discs were subjected to FTIR recording on FTIR-8400S, (Shimadzu, Japan) instrument. Data were analyzed over a spectral range of 4000–400 cm−1.

Stability studies

Stability studies were carried out by keeping the samples in screw cap vials in stability chambers (Analytical technology, Bangalore, India) at 25 ± 2 °C and 60 ± 5% RH. Samples were drawn regularly and analyzed for active drug content and dissolution studies till 6 months.

Statistical analysis

All the data obtained for dissolution and drug content were evaluated statistically. The data were tested by one-way analysis of variance (ANOVA) and t-test to test the effects of various treatments.

Results and discussion

Effects of PEG 4000 and PVP K 30 on the solubility of valdecoxib when used alone and in combination at various concentrations were studied. The solubility of valdecoxib in 0.1 M HCl at 37 °C was found to be 0.025 M, which is generally considered as practically insoluble. Phase solubility studies showed that the solubility of valdecoxib increased linearly (slope 0.0045, 0.0056, and 0.006 for PEG 4000, PVP K 30 and its combination respectively) as a function of concentration of polymers. Increase in solubility was recorded when the polymers were used in combination than individually. Among PEG and PVP, the latter had shown higher solubility, though statistically insignificant (p > 0.05). The solubility curves obtained highly resembled to the Type A L curve described by Higuchi and Connors [28]. This linear correlation, with a slope of <1, suggests the formation of a 1:1 (mol/mol) drug:carrier solid dispersion.

The stability constant (K c) of valdecoxib with PEG 4000, PVP K 30 and when combined were found to be 144, 160 and 150 M−1 respectively indicating that the valdecoxib & carriers dispersion (1:1 molar ratio) are sufficiently stable. In fact, values of obtained stability constants are always within the range of 100–1,000 M−1, which is believed to indicate an ideal value. Actually, smaller values of K c indicate a too weak interaction between drug and carrier, while larger values are symptomatic of an incomplete drug release from the inclusion complex [29]. So Values we got are considered as ideal and is expected to be stable.

The low stability constant suggests that high concentration of both the carriers is required for complex formation. As the complex has low stability constant, it dissociates in solution readily and releases the drug as individual molecules to facilitate absorption when administered. The data obtained in the present study clearly indicated the stability of valdecoxib in both the carriers. We did not see any instability with the carriers studied.

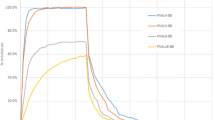

The percentage of drug content was determined for the physical mixture and solid dispersions. The values ranged from 94.39 ± 0.025 to 99.22 ± 0.016 for physical mixtures and solid dispersion. Dissolution data were evaluated on the basis of cumulative percentage drug release, dissolution efficiency and correlation coefficient (r) [30]. Figure 1 compares the dissolution profile of valdecoxib, physical mixtures and solid dispersions in 0.1 M HCl (pH = 1.2). It is evident from Fig. 1 that the release of pure drug was only 53% after 60 min. However, slight enhancement in the dissolution rate with physical mixture was observed in comparison to pure drug. The valdecoxib–PVP dispersions have a higher percentage of drug release compared to valdecoxib–PEG dispersions. This may be due to the more solubilizing and wetting effect of PVP compared to PEG. In earlier studies done by Modi and Tayade concluded that in PVP K 30:valdecoxib (1:1) solid dispersion, the usage of PVP alone could not convert valdecoxib in amorphous form, conversion of crystal to amorphous is required to improve dissolution & studies done by Liu, Liu, & Desai concluded that in PEG 4000:valdecoxib (10:1) solid dispersion, only effective solid dispersion which as per criteria defined (100% drug release in 20 min) but in this study proportion of PEG is very high compared of valdecoxib. Hence, combinations of PVP & PEG were used in the experimental design in our study. Combining the carriers (PEG 4000 and PVP K 30) had shown improved dissolution rate when compared to individual physical mixtures. However, significant enhancement (p < 0.001)) was recorded with the solid dispersions containing PEG 4000 and PVP K 30 alone and its combination in the ratio of 1:1 (drug:carrier). Analysis of the dissolution data at various time intervals like Q10, Q30 and Q50 (i.e., percentage of drug dissolved in 10, 30 and 50 min respectively) reveals that rate increased in the following pattern, pure drug < physical mixture < solid dispersion. It was also noticed that more than 90% of drug released from PEG–PVP combination in 20 min, as desired. When the dissolution efficiency was evaluated, a maximum value was observed with solid dispersion than physical mixtures. Interestingly, the correlation coefficient also had the similar results (Table 1).

DSC studies were performed for the pure drug, physical mixture and solid dispersion with PVP K 30 and PEG 4000. Figure 2 shows the results of DSC thermograms. An endothermic peak was observed at 175.53 °C corresponding to valdecoxib melting, indicating its crystalline nature, when the pure drug was analyzed. Incase of physical mixtures, three different peaks were observed, at 163.53 °C, 53 °C and 230 °C of valdecoxib, PEG 4000 and PVP K 30 respectively. The drug peak was slightly broadened, shifted to a lower temperature with reduced intensity in the thermogram of physical mixture. The melting peak of valdecoxib was totally disappeared in thermogram of solid dispersion, indicating the absence of crystalline drug in solid dispersion samples. This could be attributed to uniform distribution of drug in crust of polymer. Moreover, the data also indicate there seems to be no interaction between the components of binary system. Further this also proves the state of drug has been changed from crystalline to amorphous. Amorphous form is the highest energy form of a compound which produces faster dissolution [31, 32]. It is reported that the deviation in peak height indicate the formation of solid dispersion [33]. It might be hypothesized that polymer inhibited crystallization of drug during solid dispersion process. Further, when the thermograms were compared, it was found that drug and polymers are compatible and the glass transition temperature was not influenced by the preparation procedure. This suggest that valdecoxib in the solid dispersion was in amorphous state (Fig. 2).

A powder X-ray diffraction pattern of the pure drug, physical mixture and solid dispersions are shown in Fig. 3. The X-ray diffractogram of valdecoxib has sharp peaks at diffraction angles (2θ) 12.26°, 15.88°, 19.88°, 22.08°, and 23.92° showed a well defined crystalline X-ray pattern in comparison to others. Patterns of the physical mixture demonstrated a simple superposition of each component, while that of solid dispersion sample were clearly different, complete absence of any diffraction peaks, showing the new solid phase has been formed. The solid dispersions showed significant decline in the peaks suggesting that it is more amorphous than the physical mixture. Moreover, no other peaks than those that could be assigned to the mixture of PVP K 30 and PEG 4000 were detected in solid dispersions, indicating absence of chemical interaction in the solid state between the three entities. The positions of PVP and PEG 4000 patterns in the solid dispersions were the same and superimposable, which again ruled out the possibility of chemical interaction and compound formation between valdecoxib, PVP K 30 and PEG 4000. Result of this study implies that valdecoxib is present in an amorphous form in solid dispersion.

FTIR spectra of valdecoxib and its binary systems with PVP K 30 and PEG 4000 are presented in Fig. 4. Pure valdecoxib spectra showed sharp characteristic peaks at 3377.6, 3250.3, 1332.9, and 1149.68 cm−1. The spectra of physical mixtures were equivalent to the spectra obtained by the addition of polymers and the crystalline drug spectrum. This indicated that no interaction occurred with simple physical mixing of drug and hydrophilic polymers. The FTIR spectrum of solid dispersion of valdecoxib with PEG and PVP showed a significant broadening O–H stretching vibration peak characteristic of PEG (large band between 3,483 cm−1 and 3,119 cm−1) and a C-N stretching vibration peak characteristic of PVP (1,238 cm−1) and S=O stretching vibration characteristic of valdecoxib (1,149 cm−1). This indicated that no interaction has occurred in solid dispersion of valdecoxib with PEG and PVP.

The stability studies were carried out for a period of 6 months for the solid dispersion with PEG 4000 and PVP K 30 and their combination. No significant differences in the dissolution profile were observed throughout the study period. The DSC studies were also performed to identify any changes in state of the prepared solid dispersions. DSC thermograms obtained were similar, as that one obtained initially, indicating no change in the state of the solid dispersion during the study period.

Conclusion

Phase solubility studies showed a higher solubility of valdecoxib when PEG 4000 and PVP K 30 were used in combination, with stability constant (K c = 150 M−1). Analysis of dissolution data showed a significant enhancement in dissolution rate with solid dispersion preparation using PEG and PVP in combination. DSC and XRD studies suggest the conversion of valdecoxib from crystalline to amorphous form. FTIR studies concluded that there was no well defined interaction between drug and polymers, since no new peaks or shift of peaks could be observed. Stability studies carried out has also shown that the solid dispersion using PEG and PVP is stable through out the period of study. In general, these results showed that using PEG and PVP in combination would significantly enhance the aqueous solubility of valdecoxib.

The mixture of PEG and PVP in dispersion systems rendered the drug more hydrophilic and more wettable in the dissolution medium. This is the prime reason for rapid and complete drug dissolution from solid dispersion systems. Decreased crystallinity and increased wetting of the particles may be considered as major contributors to the enhanced valdecoxib dissolution from a solid dispersion system containing PEG and PVP.

Solid dispersions prepared from hydrophilic polymers using the melt granulation technique were effective in improving drug dissolution. The dispersion containing PEG and PVP shows acceptable dissolution compared to the PEG or PVP dispersion or pure drug. The study revealed that optimum levels of hydrophilic carriers ensure a prompt and complete dissolution of valdecoxib from solid dispersions that are used in oral pharmaceutical formulations.

References

Craig, D.Q.M.: The mechanisms of drug release from solid dispersions in water-soluble polymers. Int. J. Pharm. 231, 131–144 (2002). doi:10.1016/S0378-5173(01)00891-2

Leuner, C., Dressman, J.: Improving drug solubility for oral delivery using solid dispersions. Eur. J. Pharm. Biopharm. 50, 47–60 (2000). doi:10.1016/S0939-6411(00)00076-X

Swarbrick, J., Boylan, J.C.: Encyclopedia of Pharmaceutical Technology. Marcel Dekker, New York (2001)

Saha, R.N., Sajeev, C., Priya, P.K., Sreekhar, C., Shashikanth, G.: Solubility enhancement of nimesulide and ibuprofen by solid dispersion technique. Indian J. Pharm. Sci. 64, 529–534 (2002)

Patel, D.M., Shah, R.R., Jogani, P.D.: Studies to enhance dissolution of piroxicam. Indian J. Pharm. Sci. 65, 264–267 (2003)

Rawat, S., Asgar, L.F., Jain, S.K.: Formulation development studies of rofecoxib. Indian J. Pharm. Sci. 65, 367–370 (2003)

Kaur, R., Grant, D.J.W., Eves, T.: Comparison of PEG and polyoxyethylene stearate as excipients for solid dispersion systems of griseofulvin & tolbutamide I, II: phase equilibria. J. Pharm. Sci. 69, 1317–1326 (1980). doi:10.1002/jps.2600691121

Simonelli, A.P., Mehta, S.C., Higuchi, W.L.: Dissolution rates of high energy PVP-sulfathiazole coprecipitates. J. Pharm. Sci. 58, 538–549 (1969). doi:10.1002/jps.2600580503

Wade, A., Paul, J.W.: Handbook of Pharmaceutical Excipients. Pharmaceutical Press, Washington (1994)

Tros De Ilarduya, M.C., Martin, C., Goni, M.M., Martinez-Oharriz, M.C.: Solubilization and interaction of sulindac with polyvinylpyrrolidone K30 in the solid state and in aqueous solution. Drug Dev. Ind. Pharm. 24, 295–300 (1998). doi:10.3109/03639049809085623

Broman, E., Khoo, C., Taylor, L.S.: A comparison of alternative polymer excipients and processing methods for making solid dispersions of a poorly water soluble drug. Int. J. Pharm. 222, 139–151 (2001). doi:10.1016/S0378-5173(01)00709-8

Bates, T.R., Higuchi, W.L.: Dissolution characteristics of reserpine-PVP coprecipitates. J. Pharm. Sci. 21, 710–712 (1969)

Albertini, B., Cavallari, C., Passerini, N., Onzalez-Rodriguez, G.M.L., Rodriguez, L.: Evaluation of β-lactose, PVP K12 and PVP K90 as excipient to prepare piroxicam granules using two wet granulation techniques. Eur. J. Pharm. Biopharm. 56, 479–487 (2003). doi:10.1016/S0939-6411(03)00114-0

Pan, R.N., Chen, J.H., Chen, R.R.: Enhancement of dissolution and bioavailability of piroxicam in solid dispersion systems. Drug Dev. Ind. Pharm. 26, 989–994 (2000). doi:10.1081/DDC-100101327

Tantishaiyakul, V., Kaewnopparat, N., Ingkatawornwong, S.: Properties of solid dispersion of piroxicam in PVP. Int. J. Pharm. 181, 143–151 (1999). doi:10.1016/S0378-5173(99)00070-8

Physicians Desk Reference, Medical Economics Company Inc., New Jersey, 2577 (2003)

Jadhav, G.S., Vavia, P.R.: Development and pharmacodynamic evaluation of tablet containing inclusion complex of valdecoxib with β-cyclodextrin. Indian J. Pharm. Sci. 60, 525–526 (2004)

Talley, J.J.: A potent and selective inhibitor of COX-2. J. Med. Chem. 43, 775–777 (2000). doi:10.1021/jm990577v

Product Monograph, BextraTM, Pharmacia Canada Inc., Mississauga Ontario, Pfizer Canada Inc., Kirkland Quebec. http://www.pfizer.ca. Accessed on 19 November 2006

Ambike, A.A., Mahadik, K.R., Paradkar, A.: Stability study of amorphous valdecoxib. Int. J. Pharm. 282, 151–162 (2004). doi:10.1016/j.ijpharm.2004.06.009

Liu, C., Desai, K.G.H., Liu, C.: Solubility of valdecoxib in the presence of poly (ethylene glycol) 4000, poly (ethylene glycol) 6000, poly (ethylene glycol) 8000, and poly (ethylene glycol) 10 000 at (298.15, 303.15, and 308.15) K. J. Chem. Eng. Data 50, 278–282 (2005). doi:10.1021/je049667h

Liu, C., Liu, C., Desai, K.G.H.: Enhancement of dissolution rate of valdecoxib using solid dispersions with polyethylene glycol 4000. Drug Dev. Ind. Pharm. 31, 1–10 (2005)

Gurusamy, S., Kumar, V., Mishra, D.N.: Preparation, characterization and in vitro dissolution studies of solid systems of valdecoxib with chitosan. Chem. Pharm. Bull. 54, 1102–1106 (2006). doi:10.1248/cpb.54.1102. (Tokyo)

Modi, A., Tayade, P.: Enhancement of dissolution profile by solid dispersion (Kneading) technique. AAPS PharmSciTech 7(3), 68 (2006). doi:10.1208/pt070368

Higuchi, T., Lach, J.L.: Investigation of some complexes formed in solution by caffeine: IV. Interactions between caffiene and sulfathiazole, sulfadiazine, p-aminobenzoic acid, benzocaine, phenobarbital, and barbital [J]. J. Am. Pharm. Assoc. Sci. Ed. 43, 349–354 (1954)

Khan, K.A.: The concept of dissolution efficiency. J. Pharm. Pharmacol. 27, 48–49 (1975)

Anderson, N.H., Bauer, M., Boussac, N., Khan, Malek, R., Munden, P., Sardaro, M.: An evaluation of fit factors and dissolution efficiency for the comparison of in vitro dissolution profiles. J. Pharm. Biomed. Anal. 17, 811–822 (1998). doi:10.1016/S0731-7085(98)00011-9

Higuchi, T., Connors, K.: A phase solubility technique. Adv. Anal. Chem. Instrum. 4, 117–211 (1965)

Mukne, A.P., Nagarsenker, M.S.: Triamterene-β-cyclodextrin systems: preparation, characterization and in vivo evaluation. AAPS PharmSci Tech 5, E19 (2004). doi:10.1208/pt050119

Gareth, A.L., Didier, M., Roger, P.T.L.: Pharmaceutical Experimental Design. Marcel Dekker, New York (1999)

Rao, N.R., Chowdary, K.P.R.: Improvement of dissolution rate and bioavailability of piroxicam with pregelatinized starch. Indian J. Pharm. Sci. 63, 36–40 (2001)

Dabholkar, R.D., Redkar, M.R., Devrajan, P.V., Solusorb, P.V.: A novel technology for solubilization of poorly soluble drugs. Indian J. Pharm. Sci. 60, 517–518 (2004)

Rawat, S., Jain, S.K.: Solubility enhancement of celecoxib using β-cyclodextrin inclusion complexes. Eur. J. Pharm. Biopharm. 57, 263–267 (2004). doi:10.1016/j.ejpb.2003.10.020

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Shah, J., Vasanti, S., Anroop, B. et al. Enhancement of dissolution rate of valdecoxib by solid dispersions technique with PVP K 30 & PEG 4000: preparation and in vitro evaluation. J Incl Phenom Macrocycl Chem 63, 69–75 (2009). https://doi.org/10.1007/s10847-008-9490-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10847-008-9490-9