Abstract

Several β-cyclodextrin polymers (βCDP) have been obtained by cross-linking β-cyclodextrin (βCD) with the reagent epichlorohydrin (EP). It is expected that these polymers are capable of retaining different organic molecules by adsorbing them on its network and also by forming inclusion complexes with βCDs. In this work, two soluble polymers containing 39% and 48% βCD and other insoluble ones with 65% and 74% βCD have been studied. The total amount of CD in the polymers could not be available for complexation. This parameter has been calculated by means of the decrease of colour intensity of phenolphthalein solutions when different amounts of βCDP were added. The insoluble polymer with 74% βCD appears to possess less CD available than that with 65% βCD, probably due to the higher cross-linking degree of the former. On the other hand, a higher availability of CD is found for the soluble polymer which contains 48% βCD. Moreover, the amount of glycerol monoether groups formed as a side effect during the cross-linking process has been determined and related to the epichlorohydrin content, structure and swelling properties of the polymers. It is concluded that, varying the synthesis conditions, it is possible to induce structural modifications in the hydrogel networks which can improve their practical applications.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

β-Cyclodextrins can be cross-linked with bi- or multi-functional reagents in order to obtain different soluble or insoluble polymers. The most employed cross-linking agent is epichlorohydrin (EP). Although it is considered to be toxic for animals, humans and a potential pollutant for the environment, EP is widely used in the chemical industry. The polymers are purified before use, and the presence of free EP is improbable [1]. Soluble polymers can be obtained employing shorter times of reaction or smaller initial CD concentrations than those for insoluble polymers [2]. These resins have several applications. Soluble βCDP show the advantage to be much more soluble in water than the native βCD, and they could be used for modulating the solubility of drugs, such as naproxen [3]. Insoluble polymers are capable of sorbing a large amount of water and swelling without dissolving (hydrogels), so they can be used as sorbents of pollutants and dyes from wastewaters [4–6]. The high sorption capacities of different organic molecules reported for these polymers are related to a mechanism of sorption involving both physical adsorption in their network and the formation of inclusion complexes with βCDs. On the other hand, swellable, hydrophilic polymers are useful as drug carrier systems and for drug controlled release [7–9]. In all these applications, both the swelling capacity and the mechanical properties play important roles [10].

Depending on the amount of the different reagents used in the synthesis and on the reaction temperature, the polymers yield different βCD percentages and structures. In this work, two soluble polymers containing 39% and 48% βCD and other insoluble ones with 65% and 74% βCD have been studied. Taking into account that the total amount of CD in the polymers could not be available for complexation, this parameter has been calculated in this work. Moreover, the amount of glycerol monoether groups formed as a side effect during the cross-linking process have been determined and related to the epichlorohydrin content, structure and swelling properties of the polymers.

Experimental

Materials

One of the insoluble βCDP studied was purchased from Cyclolab (Budapest, Hungary) and the other soluble and insoluble ones were synthesised in our laboratory by polycondensation under alkaline conditions, as described previously [11–13]. βCD used for the synthesis of polymers was obtained from Roquette Laisa España S.A. (Tarragona, Spain); EP and NaOH were from Sigma-Aldrich (Barcelona, Spain). The commercial insoluble polymer was in the shape of spherical beads ranging between 160 and 250 μm. The insoluble polymers 2 and 3 obtained were ground with a stainless steel electric mill first and then with agate mortar, and sieved between 160 and 250 μm. The molecular sizes of the polymers 4 and 5 were 15.52 and 13.12 nm, respectively (taken from Ref. [12], corresponding to CDP-15 and CDP-6, respectively).

Phenolphtalein, Na2CO3, formaldehyde solution (36% in water) and other reagents analytical grade were supplied from Prolabo (Paris, France). Disodium 4,5-dihydroxy-2,7-naphtalenedisulfonate, sodium arsenite (NaAsO2) and sodium metaperiodate (NaIO4) were from Sigma (St Quentin-Fallavier, France).

Methods

βCD content in polymers

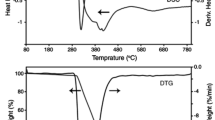

The βCD content in the insoluble polymers was determined by elemental analysis using a LECO CHN-2000 analyser. The results were corrected taking into account the humidity of the samples, obtained by thermogravimetry (Mettler Toledo TGA-SDTA 851e).

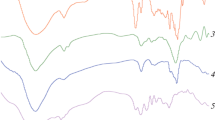

For soluble polymers, this determination was made by means of magnetic nuclear proton resonance (1H-NMR), using a simple method described by different authors [2, 11]. A solution of 5 × 10−4 mol/L concentration was prepared, and measured in a Bruker Advance 400 Ultrashield (9.36T) spectrometer (100 accumulations) after a presaturation to eliminate the solvent signal. The amount of βCD in the polymer has been quantified considering that the spectrum presents two types of signals: a wide peak at ∼5 ppm assigned to the anomeric proton of the glucose C1 carbon of βCD, and two other peaks between 3 and 4 ppm corresponding to hydrogen atoms of both the glucopiranose ring and EP (i.e., to the hydroxypropyl ether fragment resulting from the condensation reaction), as explained previously by Romo et al. [12].

Apparent swelling capacity

The apparent swelling capacity of the polymers was obtained by an apparent volume increase method [13] and expressed as the ratio between the swelling volume and the amount of dry polymer.

βCD available for complexation

The βCD available for complexation has been determined by means of the decrease of colour intensity of phenolphthalein solutions when different amounts of βCDP were added [14]. Previously, a calibration curve was obtained being the phenolphthalein concentration of 3 × 10−5 M and [βCD] ranging from 0 to 5.0 × 10−3 M at pH 10.5, supported by 4 × 10−3 M Na2CO3. Solutions were spectrophotometrically measured at 550 nm and 25 °C within 10 min. The polymer amounts for the assays were between 3.1 and 5.8 mg, depending on the βCD content. βCDP samples were placed in capped amber bottles and stirred at 400 rpm during 90 min. Several experiments were performed in the same conditions with 2.7 mg of pure βCD as a standard.

Determination of glycerol monoether groups

In order to quantify the amount of glycerol monoether groups (GME) formed as a side effect during the cross-linking process, periodate oxidation of the polymers has been carried out. The formaldehyde produced during the oxidation of the diol end groups has been quantified by a chromotropic method described by Hamdi and Ponchel [15]. The experiments were carried out with 15 mg of polymer, 10 mg βCD were also oxidised for comparison. After reaction, aliquots mixed with the chromotropic acid reagent were spectrophotometrically measured at 570 nm. Each assay was performed at least three times, three aliquots per experiment.

Results and discussion

Table 1 shows the βCD content, particle size and apparent swelling capacity of the insoluble polymers studied. Polymer 1 was a commercial sample and polymer 2 and 3 were synthesised at 50 and 25 °C, respectively. Soluble polymers, named 4 and 5, were obtained at 50 and 35 °C, respectively.

The swelling capacity depends on the amount of cross-linking agent used, the temperature and the polymerisation method. The water sorption capacity increases when the polymerization temperature is increased [13]. It can be seen that the βCDP 1 and 2, synthesised at 50 °C, show a higher swelling capacity, as expected. At higher temperatures, the cross-linking agent EP shows higher reactivity and it is possible that two or more molecules of EP react forming longer polyhydroxypropyl ether chains between two βCDs, so the resulting expanded network is capable of absorbing a larger amount of water molecules. This fact can explain that polymers with a similar chemical composition show different structural characteristics and, for instance, a different swelling equilibrium.

Referring to the βCD amount available for complexation, results are also shown in Table 1. It has been found that the insoluble polymer with 74% βCD appears to possess less CD available than those with 65% βCD, probably due to the higher cross-linking degree of the former. On the other hand, a higher availability of CD is found for the soluble polymer which contains 48% βCD. Smaller particles have a higher surface/volume ratio, so there will be fewer βCD cavities obstructed by the cross-linker bridges.

It is known that during the polymerization reaction, as a side effect, glycerol monoether ending groups are formed (Fig. 1) [2]. In some cases di- or tri-glycerol diethers can be also formed [16]. Periodate oxidation of GME results in formaldehyde groups, which can be determined by the chromotropic method mentioned above. Results are compiled in Table 2.

Scheme of the reactions of βCD with EP [2]

The amount of GME is nearly the same for polymers 1, 2 and 3, nevertheless, taking into account the parameters collected in Table 1, differences in their network structure could be inferred. Both polymers 1 and 2, containing similar %βCD, show similar quantity of GME, it suggests that both polymer networks are similar and they could have been synthesised under similar experimental conditions. On the other hand, polymer 3, which was obtained at 25 °C, possesses different structural characteristics, according to the results shown in Table 1.

Moreover, the soluble polymers particles are much smaller than those of the insoluble ones, so a higher amount of GME is expected. In addition, polymer 4 possesses more GME than polymer 5, according to the higher content of EP in the polymer structure.

It is concluded that, varying the synthesis conditions, it is possible to induce structural modifications in the hydrogel networks which can improve their practical applications.

References

Crini, G., Peindy, H.N.: Adsorption of C.I. Basic Blue 9 on cyclodextrin-based material containing carboxylic groups. Dyes and Pigments 70, 204–211 (2006)

Renard, E., Deratani, A., Volet, G., Sebille, B.: Preparation and characterization of water soluble high molecular weight β-cyclodextrin-epichlorohydrin polymers. Eur. Polym. 33, 49–57 (1997)

Mura, P., Faucci, M.T., Maestrelli, F., Furlanetto, S., Pinzauti, S.: Characterization of physicochemical properties of naproxen systems with amorphous beta-cyclodextrinepichlorohydrin polymers. J. Pharm. Biomed. Anal. 29, 1015–1024 (2002)

Crini, G., Bertini, S., Torri, G., Naggi, A., Sforzini, D., Vecchi, C., Janus L., Lekchiri, Y., Morcellet, M.: Sorption of aromatic compounds in water using insoluble cyclodextrin polymers. J. Appl. Polym. Sci. 68, 1973–1978 (1998)

Yu, J.C., Jiang Z.-T., Liu H.-Y., Yu, J., Zhang, L.: β-Cyclodextrin epichlorohydrin copolymer as a solid-phase extraction adsorbent for aromatic compounds in waters samples. Anal. Chim. Acta 477, 93–101 (2003)

Romo, A., Peñas, F.J., Isasi, J.R.: Sorption of dibenzofuran derivatives from aqueous solutions by β-cyclodextrin polymers: an isosteric heat approach. J. Colloid Interf. Sci. 279(1), 55–60 (2004)

Li, J., Xiao, H., Li, J., Zhong, Y.: Drug carrier systems based on watersoluble cationic beta-cyclodextrin polymers. Int. J. Pharm. 278, 329–342 (2004)

Brazel, C.S., Peppas, N.A.: Mechanisms of solute and dry transport in relaxing, swellable hydrophilic glassy polymers. Polymer 40, 3383–3398 (1999)

Davis, M.E., Brewster, M.E.: Cyclodextrin-based pharmaceutics: past, present and future. Nat. Rev. Drug Discovery 3, 1023–1035 (2004)

Dumitriu S. (ed.): Polymeric Biomaterials. Marcel Dekker, New York (1994)

Crini, G., Consentino, C., Bertini, S., Naggi, A., Torri, G., Vecchi, C., Janus L., Morcellet M.: Solid state NMR spectroscopy study of molecular motion in cyclomaltoheptaose (β-cyclodextrin) crosslinked with epichlorohydrin. Carbohyd. Res. 308, 37–45 (1998)

Romo, A., Peñas, F.J., Sevillano, X., Isasi, J.R.: Application of factorial experimental design to the study of the suspension polymerization of β-cyclodextrin and epichlorohydrin. J. Appl. Polym. Sci. 100(4), 3393–3402 (2006)

García-Zubiri, I.X.: Ph.D. Thesis, University of Navarra at Pamplona, Spain (2005)

Vikmon, M.: Proc. I Int. Symp. Cyclodextrins, Budapest, Hungary, p. 69 (1981)

Hamdi, G., Ponchel, G.: Enzymatic degradation of epichlorohydrin crosslinked starch microspheres by α-amylase. Pharm. Res. 16(6), 867–875 (1999)

Fridman, R.B.: In: Duchêne, D. (ed.) New trends in cyclodextrin and derivatives, Edition de Santé, Paris, pp. 159–177 (1991)

Acknowledgements

Authors are grateful to the Comisión Interministerial de Ciencia y Tecnología (Project MAT2003-08390-C02-01) and PIUNA for financial support. Moreover, the authors acknowledge Dr. A. Romo and I.X. García-Zubiri for the synthesis of the polymers.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Vélaz, I., Isasi, J.R., Sánchez, M. et al. Structural characteristics of some soluble and insoluble β-cyclodextrin polymers. J Incl Phenom Macrocycl Chem 57, 65–68 (2007). https://doi.org/10.1007/s10847-006-9221-z

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10847-006-9221-z