Abstract

La-doped 0.25Pb(Zn1/3Nb2/3)O3-0.75Pb(ZrxTi1-x)O3 (x = 0.51–0.57) ceramics were prepared by a conventional mixed oxide method. The piezoelectric and dielectric properties of various compositions near the morphotropic phase boundary (MPB) were investigated. The MPB was determined by X-ray diffraction (XRD) patterns. The optimal properties were obtained in the specimen with Zr/Ti = 53/47: d33 = 570 pC/N, kp = 0.60, εr = 3900, tgδ = 1.9%, Tc = 204°C, Pr = 35.21 μC/cm2, Ec = 11.62 kV/cm, which means it is a good candidate for applications.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

A relaxor ferroelectric, lead zinc niobate, Pb(Zn1/3Nb1/3)O3 (PZN) shows excellent dielectric, high piezoelectric and good electrostrictive properties [1]. However, pure perovskite PZN is so difficult to synthesize by conventional solid-state-reaction that some other perovskite materials such as PbTiO3 (PT), BaTiO3 (BT), Pb(Zr,Ti)O3 (PZT) have to be added to stabilize PZN [2–4].

PZN-PZT ceramics have been investigated widely for many years. The researches have mainly focused on two systems 0.2PZN-0.8PZT and 0.3PZN-0.7PZT. Due to its lower dielectric loss and higher Curie temperature, 0.2PZN-0.8PZT system is usually modified as “hard” piezoelectric ceramics, such as CuO-doped, MnO2-doped, Fe2O3-doped 0.2PZN-0.8PZT by Yudong Hou, Mankang Zhu et al. [5–7]. Low dielectric loss (tgδ = 0.2%) and high mechanical quality factor (Qm = 1041) were achieved through MnO2 addition [6]. On the contrary, 0.3PZN-0.7PZT system is modified as “soft” piezoelectric ceramics just because of its higher piezoelectric properties, just like La-doped 0.3PZN-0.7PZT by Guochu Deng , Xia Zeng et al. [8–10]. Though very high piezoelectric coefficient (d33 = 845 pC/N) and electromechanical coupling factor (kp = 0.7) were attained through a two-step hot-pressing route , dielectric loss is still high (tgδ > 2.0%) and the cost is huge [8]. The good piezoelectric properties (d33 = 580 ± 10 pC/N) was obtained by a conventional oxide mixing oxide technique and excess ZnO addition , but dielectric loss is higher (tgδ = 3.85%) [10]. So 0.25PZN-0.75PZT may be a good attempt to get optimal piezoelectric properties and low dielectric loss by La doping, though it was modified by MnO2 doping [11] as “hard” piezoelectric ceramics.

In this paper, La-doped 0.25PZN-0.75PZT was investigated by a conventional mixed oxide method. The MPB of the system was observed through XRD patterns. The effect of Zr/Ti ratio on the properties was also discussed here. The most important is that the good piezoelectric properties , low dielectric loss and high coercive field were attained at the same time by a low-cost conventional method.

2 Experimental procedure

The La-doped 0.25PZN-0.75PZT ceramics were prepared through a conventional oxides mixing method. The basal formula was 0.25Pb(Zn1/3Nb2/3)O3-0.75Pb0.95La0.05(ZrxTi1-x)0.988O3 in which the value of x is 0.51,0.52,0.525,0.53,0.535,0.54,0.55 , and 0.57 . The raw materials were Pb3O4, TiO2, ZrO2, ZnO, Nb2O5, and La2O3 (>99%). The mixtures were ball-milled for 4 h, then dried.The dried powders were calcined at 900°C for 2 h.After remilling for 4 h, the powders were dried and pressed into pellets of 12 mm diameter under a pressure of 400 MPa and sintered at 1270°C for 2 h in PbO-rich atmosphere using PZN-PZT powder .The PbO volatilizes first from the “bed” powder (PZN-PZT) outside of the pellets, thus the partial pressure of PbO increases with the volatilization of PbO ,even to be saturated, which creates the PbO-rich atmosphere.

The crystal structures of the sintered specimens were examined by X-ray diffractometer (D/max 2500 v/pc, Rigaku, Japan). The surfaces of specimens were polished and printed silver electrodes, and the specimens were poled in silicone oil at 120°C by applying a DC field of 3.3 kV/mm for 20 min. The piezoelectric coefficient(d33) was measured by a quasi-static piezoelectric d33 meter (ZJ-2, Institute of Acoustics Academic Sinica, Beijing, China), and the electromechanical coupling facror (kp) was determined by the impedance analyzer with the resonance and antiresonance technique, according the following relationship [Eq. (1)]:

Where fr and fa are the resonance and antiresonance frequencies,respectively [12]. The dielectric constant (εr) and dielectric loss (tgδ) were measured at room temperature on an LCR automatic meter(XC2810A, Tianjin Xince Electronics Appartaus Technology Co., Ltd., Tianjin, China).The Curie temperature (Tc) was determined through the peak of the ε-T curve which was measured by the same LCR automatic meter in a temperature-controlled furnace. The P-E curve and S33-E curve of specimen were measured by a standard ferroelectric tester (WS-2000, RADIANT) at a frequency of 1 Hz and at room temperature.

3 Results and discussion

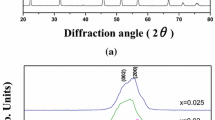

3.1 XRD analysis

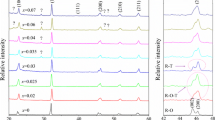

The XRD patterns of La-doped 0.25PZN-0.75PZT (Zr/Ti = 51/49-57/43) are shown in Fig. 1. In these patterns, no second phase (pyrochlore phase) can be found.All the patterns show the characteristics of pure perovskite phase, but as the Zr/Ti ratio increases from 51/49 to 57/43, the differences happen at the peaks of {200} reflection near 44° , where the {200} reflection shows a single peak for the rhombohedral phase, while it splits into two peaks for the tetragonal phase [13]. The differences imply the relationship between the phase structure of PZN-PLZT and the Zr/Ti ratio. In order to analyze the differences and determine the relationship, the peaks of {200} reflection are shown in Fig. 2. For the first four compostions (Zr/Ti = 51/49, 52/48, 52.5/47.5, 53/47) , the {200} reflection clearly splits into two peaks and can be well fitted with three Gaussian peaks (dash lines), which correspond to (002)T , (200)R , and (200)T from left to right, respectively [8, 13]. Though the following three specimens (Zr/Ti = 53.5/46.5, 54/46, 55/45) don’t clearly splits into two peaks , the peak can also be well fitted with three Gaussian peaks. This means the tetragonal and rhombohedral phases coexist in these compostions. The last specimen (Zr/Ti = 57/43) shows a single peak, which corresponds to (200)R . That means this compostion only contains the rhombohedral phase. As can be seen from the trend of these XRD patterns, a transition from the tetragonal phase to the rhombohedral phase happens as the Zr/Ti ratio increases.

According to three Gaussian peaks fitting of the curves of {200} peaks, the relative phase contents of the tetragonal and rhombohedral phases were estimated. The fractions of the rhombohedral (Rh) and the tetragonal (Tet) phases were determined by the formulas [Eq. (2), Eq. (3)] [13]

The I(002)T, I(200)R, I(200)T are the integrated intensities of the (002)T, (200)R, (200)T peaks, respectively. As expected, the rhombohedral phase fraction increases notably with the increase of Zr/Ti ratio, as shown in Fig. 3. Almost equal contents of tetragonal and rhombohedral phases were found in the specimen with Zr/Ti = 53/47. According to Huiqing Fan et al. [13], the MPB of 0.25PZN-0.75PLZT (La = 5 mol%) system can be determined in the region of Zr/Ti = 52.5/47.5–53.5/46.5.

3.2 Piezoelectric properties

Figure 4 showes the piezoelectric properties of 0.25PZN-0.75PLZT with various Zr/Ti. As we can see, the piezoelectric coefficient (d33) and electromechanical coupling factor (kp) increase dramatically with Zr/Ti from 51/49 to 53/47 ,and then decrease sharply from 53/47 to 57/43. The d33 and kp reach their peak values (570 pC/N and 0.60) at Zr/Ti = 53/47. The evolving trends of d33 and kp with Zr/Ti are accordant and just similar to the trend of corresponding properties of PZT near MPB. The piezoelectric ceramics near MPB are easy to pole because the crystal structure has good mobility near MPB, and thus domains turn more easily. So the peaks of piezoelectric properties appear in MPB. The effect of La doping on the piezoelectric properties is always explained as La doping substitutes for Lead, resulting in the formation of lead vacancies, so domains turn more easily, and piezoelectric properties improve [9].

3.3 Dielectric properties

Figure 5 demonstrates the dielectric constants (εr) of depoled and poled 0.25PZN-0.75PLZT ceramics. The εr after poling increases at first and reaches the highest value (3900) at Zr/Ti = 53/47, then decrease.The εr before poling shows similar change trend, but it reaches the peak value (2531) at Zr/Ti = 52/48. Both of peaks occur near MPB where the microstructure is of good mobility just as shown by many past reports. Two curves intersect at less than Zr/Ti = 57/43, which locates in the rhombohedral phase region (right side of the MPB) , while they usually intersect in the tetragonal phase region [14] (left side of the MPB) or in the MPB [15]. When Zr/Ti ratio is less than 57/43, the dielectric constants of the poled specimens are greater than those of the depoled specimens, whereas it is the opposite at Zr/Ti = 57/43. According to Fesenko [16], Z.Xinhua [17] et al. , in the tetragonal phase, polarization will relieve the clamping effect of the 180° domains, and thus the dielectric constant increases, While in the rhombohedral phase, the dielectric constant decreases due to the reorientation of the 90° domains after poling and the obvious dielectric anisotropy of monodomain crystal. That means that the reversal of 180° domains will increase the permittivity , whereas the turn of 90° domains will reduce the permittivity. The reversal of 180° domains dominates with Zr/Ti < 57/43, so the poled dielectric constants are higher than the depoled ones. And when Zr/Ti ratio is 57/43 where the rhombohedral phase exist only, the turn of 90° domains begins to dominate, so the opposite result happens. These results coincide with 0.3PZN-0.7PLZT by Guochu Deng et al. [8].

As can be seen in Figure 6, The poled dielectric losses are less than the depoled ones, which means that polarization reduces the dielectric losses. This result agrees with many reports [8, 16, 18, 19] and was explained as polarization causes domain reorientation along one direction. And as observed in some researches [18, 19], the dielectric losses show an increase tendency with the increase of the Zr/Ti ratio. Weston et al. [19] considered that the tetragonal phase has lower dielectric loss than the rhombohedral phase because of a decrease in the mobility of the domain walls. It is noteworthy that the dielectric losses of 0.25PZN-0.75PLZT ceramics are relative low compared with 0.3PZN-0.7PLZT ceramics reported [8, 10, 20]. That implies some 0.25PZN-0.75PLZT ceramics which have good piezoelectric properties may be good candidates for device applications.

Figure 7 shows the Curie temperatures (Tc) of 0.25PZN-0.75PLZT (La = 5 mol%)specimens with different Zr/Ti ratios. As we can see, The Tc values of all compostions are in the range of 192–207°C, which are much lower than the Tc values (230–495°C, 360°C typical) of PZT [21]. The Tc of PZN-PLZT will decrease with the increase of La doping and PZN composition according to reports [9, 13], so the Tc values of 0.25PZN-0.75PLZT are relative low compared with PZT. In addition, the Tc presents a reduce trend as Zr/Ti ratio increases, which is due to the decrease of amount of PbTiO3 that has the relative high Tc of 490°C [22].

Figure 8 shows the P-E curve and S33-E curve of the optimal formula. It can be seen that the higher remnant polarization ( Pr = 35.21 μC/cm2) and coercive field ( Ec = 11.62 kV/cm) were attained at the same time. That means this material will have good piezoelectric properties and aging property, which is of superiority for applications. Under a field of 20 kV/cm, the strain S33 is up to 2.01 × 10−3 . In other words, the d33 under a field of 20 kV/cm is 1010 pm/V.

4 Conclusions

0.25PZN-0.75PLZT ceramics of pure perovskite structure were prepared by a conventional mixed oxide method.. The MPB of 0.25PZN-0.75PLZT (La = 5 mol%) system was determined precisely in the range of Zr/Ti = 52.5/47.5–53.5/46.5 by XRD patterns. The optimal properties were attained in the specimen with Zr/Ti = 53/47 : d33 = 570 pC/N , kp = 0.60, εr = 3900, tgδ = 1.9%, Tc = 204°C, Pr = 35.21 μC/cm2, Ec = 11.62 kV/cm. As expected, the good piezoelectric properties, low dielectric loss and high coercive field were obtained at the same time by a low-cost conventional method. So it is believed that the 0.25PZN-0.75PLZT ceramics can be good candidates for device applications such as transducers and actuators.

References

L.E. Cross, Ferroelectrics 76, 241–247 (1987)

A. Halliyal, U. Kumar, R.E. Newnham, L.E. Cross, J. Am. Ceram. Soc. 70, 119–124 (1987)

A. Halliyal, U. Kumar, R.E. Newnham, L.E. Cross, Am. Ceram. Soc. Bull. 66, 671–676 (1987)

A. Halliyal, A. Safari, Ferroelectrics 158, 295–300 (1994)

Y.D. Hou, M.K. Zhu, H. Wang, B. Wang, H. Yan, C.S. Tian, Mater. Sci. Eng. B 110, 27–31 (2004)

Y.D. Hou, M.K. Zhu, F. Gao, H. Wang, B. Wang, H. Yan, C.S. Tian, J. Am. Ceram. Soc. 87, 847–850 (2004)

M.K. Zhu, P.X. Lu, Y.D. Hou, X.M. Song, H. Wang, H. Yan, J. Am. Ceram. Soc. 89, 3739–3744 (2006)

G.C. Deng, Q.R. Yin, A.L. Ding, X.S. Zheng, W.X. Cheng, P.S. Qiu, J. Am. Ceram. Soc. 88, 2310–2314 (2005)

X. Zeng, A.L. Ding, G.C. Deng, T. Liu, X.S. Zheng, Phys. Status Solidi A 202, 1854–1861 (2005)

X. Zeng, A.L. Ding, T. Liu, G.C. Deng, X.S. Zheng, W.X. Cheng, J. Am. Ceram. Soc. 89, 728–730 (2006)

H.Y. Park, C.H. Nam, I.T. Seo, J.H. Choi, S. Nahm, J. Am. Ceram. Soc. 93, 2537–2540 (2010)

S.H. Lee, C.B. Yoon, S.B. Seo, H.E. Kim, J. Mater. Res. 18, 1765–1770 (2003)

H. Fan, H.E. Kim, J. Appl. Phys. 91, 317–322 (2002)

D.A. Berlincourt, C. Cmolik, H. Jaffe, Proc. IRE 48, 220–229 (1960)

P.D. Gio, V.D. Dan, J. Alloys Compd. 449, 24–27 (2008)

E.G. Fesenko, A.Y. Dantsiger, L.A. Resnitohenko, M.F. Kupriyanov, Ferroelectrics 41, 137–142 (1982)

Z. Xinhua, J. Xu, Z. Meng, J. Mater. Sci. 32, 4275–4282 (1997)

C.H. Wang, Jpn. J. Appl. Phys. 42, 4455–4456 (2003)

T.B. Weston, A.H. Webster, V.M. McNamara, J. Can. Ceram. Soc. 36, 15 (1967)

X. Zeng, X.Y. He, W.X. Cheng, X.S. Zheng, P.S. Qiu, J. Alloys Compd. 485, 843–847 (2009)

B. Jaffe, W.R. Cook, H. Jaffe, Piezoelectric Ceramics (Academic, New York, 1971)

S. Kwon, E.M. Sabolsky, G.L. Messing, J. Am. Ceram. Soc. 84, 648–650 (2001)

Acknowledgements

This work is financially supported by the National ‘863’ (2010AA09Z102) program of China. The authors are grateful to Yubin Wang for his theoretical guidance and Analytical Center of Tianjin University for their technical assistance. The authors would also like to thank Liu Qiao, Xiangchao Meng et al. for their help during this work.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wang, N., Sun, Q., Ma, W. et al. Investigation of La-doped 0.25Pb(Zn1/3Nb2/3)O3-0.75Pb(ZrxTi1-x)O3 ceramics near morphotropic phase boundary. J Electroceram 28, 15–19 (2012). https://doi.org/10.1007/s10832-011-9672-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10832-011-9672-5