Abstract

BaTiO3 (BT) based X9R ceramics with high permittivity about 1700 were prepared by doping and pre-sintering technique. Pure Bi0.5Na0.5TiO3 (BNT) dopant was synthesized by the conventional solid state reaction first. Using this new approach, high performance BTBNT (BT doped with BNT) materials, owning high Curie temperature (139 °C), flat ferroelectric transition region and large permittivity at room temperature, were obtained. The effects of several dopants on dielectric properties of BTBNT ceramics were measured by the LCR meter. The suppression effect for the peaks in the dielectric constant at Curie temperature of these dopants have been ranked as follows: BiNbO4 > CaZrO3 > Nb2O5 > BNT.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

More and more multilayer ceramic capacitors (MLCs) have been used in harsh circumstances, such as engine electronic control unit (ECU), crank angle sensor (CAS) and antilock brake system (ABS) module which are mounted in an engine room of an automobile[1, 2]. In order to use fewer long power cables, the next generation of these electronic devices must be located very close to the electric actuator, for example directly on the engine, into the transmission, and near the brake disk[3, 4], which require components with the ability to work at temperature of 175°C[5]. It is clearly recognized that electronic equipments which can work at ambient temperature higher than 150°C without external cooling are beneficial for a variety of important applications, especially in the automotive, oil & gas, aerospace and energy production industries[4, 6–8]. High temperature chip capacitor has been applied in drilling devices and engines at high temperature. However, to our knowledge, BaTiO3 based X9R (−55 to 175°C, △C/C25°C = ±15%) ceramics with high permittivity have not been reported.

Tetragonal barium titanate (BaTiO3, BT) is a kind of ferroelectric perovskite which exhibits high permittivity at room temperature, making it a desirable material for MLCs applications. However, BaTiO3 displays three dielectric anomalies associating with phase transitions at −90°C, 0°C and 125°C. These anomalies cause large changes in dielectric constant near the transition temperature, particularly near Curie temperature (Tc). The dielectric constant drops down strongly above Curie temperature and consequently one major work is to raise Curie temperature up to 175°C for researching and developing high temperature capacitors. The doping effect on Curie temperature of BaTiO3 has been extensively researched. It is well known that the Curie point can be raised rapidly to a higher temperature by doping Pb ion which replaces Ba ion. However, the use of lead-based ceramics has been limited as the toxicity of lead oxide and its high vapor pressure during sintering caused serious environmental problems. Recently, Qi et al. [9] found one feasible method to increase the Tc from 128°C to 130°C by boron oxide vapor doping, but the raise of Tc was not obvious and it was not convenient for practical application. In this case, it is necessary to develop a high efficiency and simple technique to obtain high Curie temperature BaTiO3 raw materials. This paper focused on the preparation of BaTiO3 materials with high Curie point of 139 °C by a simple method known as the doping and pre-sintering approach. In addition, these techniques offer the possibility of realizing high dielectric constant at room temperature.

Bismuth sodium titanate (Bi0.5Na0.5TiO3, BNT) is an lead-free A-site complex perovskite ferroelectric relaxor material, which is regarded as an alternative to replace the widely used lead contained ceramics[10]. Its crystal structure is a perovskite type with rhombohedral symmetry at room temperature. Comparing with other dopants used to shift the Curie point, BNT does not contain lead, its Curie temperature is around 320°C and its dielectric constant is between 240 ∼ 340. Therefore, BNT dopant shows great prospect for preparing high temperature chip capacitor with high permittivity. According to our previous work[11], the Curie temperature of the ceramics system BaTiO3-Nb2O5-ZnO was raised by 6°C compared with pure BT ceramics by doping with 10 wt% BNT and the BT-based ceramics meeting EIA X8R (−55 to 150°C, ∆C/C25°C = ±15%) specification were obtained. Although doping BNT could raise the Curie point, it was inefficient and the prepared powder couldn’t meet X9R specification. In this paper, pre-sintering approach was used, through which the Curie temperature of BT was raised by 12°C by doping only 1 wt% BNT, therefore BT based X9R ceramics with high Curie temperature were successfully prepared.

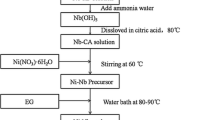

The BNT composition used in our experiment was prepared by conventional solid state reaction technique. Reagent-grade oxides and salts (TiO2, Bi2O3, and Na2CO3) were used as raw materials. The mixtures were mixed in a roll ball-mill filled with alcohol and with zirconia balls as ball-milling media for 6 h. After torrefaction, the mixtures were calcined at 800°C for 2 h. Phase analysis of the powders was conducted using a Philips X'Pert diffractometer with Cu Kα radiation. From the XRD patterns of BNT powders as shown in Fig. 1, the pure Bi0.5Na0.5TiO3 phase was observed.

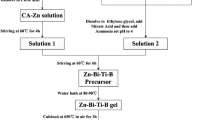

Commercial BT powders with submicrometer size were prepared by hydrothermal method. Next, BT powders with 1 wt% BNT were mixed in ball mills filled with deionized water for 24 h and with zirconia balls as ball-milling media. After further torrefaction, the mixtures were pre-sintered at 1100°C for 24 h to form new raw materials with high Tc, and the resulting powders were then denoted as BTBNT. The powders were also analyzed by XRD to identify possible phases formed after pre-sintering treatment. XRD measurements shown in Fig. 2 demonstrate that the new raw materials of BTBNT powders are single phase perovskite BaTiO3.

The prepared ceramic powders were pressed into disk form (10 mm in diameter and 1 mm in thickness) by mixing ceramic powders with 3 wt% of poly(vinyl alcohol) (PVA) binder, and finally, the disks were sintered at 1200 °C in air for 3 h. After the samples sintered at 800 °C with Ag electrodes on both surfaces, the dielectric properties of the samples were measured from −55 °C to 175 °C with an impedance analyzer LCR (HP4284A) at 1 kHz and 1 V.

XRD diffraction patterns of the BT and BTBNT specimens sintered at 1200 °C showed peaks indexed to single phase BaTiO3, and their structure was tetragonal, because the (002) and (200) diffraction peaks at about 45 °C separated from each other. XRD patterns in the range of 2θ = 43.5–47° of the BT and BTBNT specimens are shown in Fig. 3, which showed that the diffraction patterns near 45 °C were affected by doping BNT. The values (Table 1) of 2θ for (002) and (200) diffraction peaks could be calculated using peak fitting software. We selected (002) and (200) diffraction peaks of the BaTiO3 solid solution to determine the lattice parameters as shown in Fig. 3. In tetragonal crystal system, the crystal lattice plane spacing (d), the Miller index (HKL) and lattice parameters (a,c) meet the following equation:

According to the Bragg equation λ=2dsinθ and the above formula, lattice parameters (a,c) were calculated using the values of 2θ for (002) and (200) diffraction peaks, and the degree of tetragonality (c/a) and unit cell volume (a2c) were also determined. As shown in Table 1, BTBNT ceramics had a low degree of tetragonality and unit cell volume.

Figure 4 shows the temperature dependence of dielectric constants of pure BT ceramics and BTBNT ceramics. Compared with pure BT ceramics, BTBNT ceramics did not only possess the advantages of high Curie temperature (139 °C) and flat ferroelectric transition region, but also maintained a large permittivity at room temperature.

Hennings et al. [12] pointed out that incorporation of the Bi increased the Curie point of BT ceramics due to the Bi-layered perovskites formation (Bi4Ti3O12, Tc = 675°C). The radii of Bi3+ (1.02 Å) and Na+ (0.99 Å) are close to Ba2+ (1.43 Å), so Bi3+ and Na+ occupied A site. Because Bi3+ and Na+ have a smaller radii, the occupation caused unit cell volume reduction, which lead to that the movement of Ti4+ became difficult in oxygen-octahedral and no spontaneous polarization occurred. Therefore, BT ceramics doped with BNT presented with a suppressed ferroelectric transition region and smooth dielectric temperature characteristics, indicating that substitution of Bi and Na for Ba could tend to suppress spontaneous polarization and the permittivity maximum which characterized the ferroelectric transition. As shown in Fig. 4, the Curie peak for BTBNT broadened obviously, and on the other hand, doping a little BNT (εr=240 ∼ 340) didn’t cause sharp drops in dielectric constant of BT ceramics. These features of high Curie temperature, flat ferroelectric transition region and large permittivity at room temperature are very propitious for further development of the high temperature chip capacitors.

In our previous study[13], a series of novel BaTiO3-based X8R (−55 to 150 °C, ∆C/C25°C = ±15%) ceramics in the BaTiO3-Nb2O5-Zn0.2Mg0.8TiO3 (ZMT) system have been reported. They presented a broad region of permittivity, excellent temperature characteristics, low dissipation factor and high resistivity. Calcium borosilicate glass (CBS) and rare earth oxide CeO2 were used as effective dopants in searching for middle temperature sintering and environmental friendly X8R compositions[14]. The preparation of ZMT and CBS dopants were documented in our previous studies[13–15]. Following up on our earlier investigations on the X8R ceramics, this work emphasizes on the BTBNT-Nb2O5-ZMT-CeO2-CBS composition to prepare X9R ceramics.

The dielectric properties of various BT-based and BTBNT-based ceramics are shown in Table 2. No. 1 (BT-C) and No. 3 (BTBNT-C) show basic formulas of BT-Nb2O5-ZMT-CeO2-CBS and BTBNT-Nb2O5-ZMT-CeO2-CBS respectively. In No. 2 (BT-C-BNT), 1 wt% BNT was doped into No. 1 (BT-C). The Curie temperature of BT-C ceramics was 129 °C (higher than 127 °C for pure BT ceramics), which could be attributed to change of the degree of tetragonality (c/a) and unit cell volume (a2c) cased by doping Nb2O5-ZMT[13]. Comparing No.2 and No. 3, the Tc was raised by 1 °C and 10 °C from 129 °C respectively. It can be explained by the fact that for No. 3, the pre-sintering of BTBNT had BNT (Tc = 320 °C) solidly dissolve into BT, which raised Tc strongly (12 °C/1 wt%) and improved temperature characteristics. But for No. 2, there were reactions between BNT and other dopants during the sintering process, for example, BNT promoted crystallization of CBS[13]. Therefore, the technique without pre-sintering process show a inconspicuous effect on the Curie temperature (1 °C/1 wt%).

In the case of the initial BTBNT-C composition, the proposed ceramics showed a high dielectric constant near 2000 and Curie point of 139 °C. However, its temperature coefficient of capacitance (TCC) was still out of the range of the X9R specification due to the strong and sharp Curie peak.

Several dopants (Nb2O5, CaZrO3, BNT and BiNbO4) were added with the amount of 2 wt% to improve the temperature characteristics of the initial BTBNT-C composition to meet X9R specification, namely to depress and broaden the dielectric peak at Curie temperature. The results are summarized in Table 2 No. 4–7. The data listed in Table 2 No. 3–7 show that all the materials exhibited a high permittivity (>1500). Figure 5 shows the temperature dependence of dielectric constant and capacitance change of all samples over a wide temperature range from −55 to 175 °C. The ferroelectric peak intensity was depressed by all the dopants as shown in Table 2 and Fig. 5. Moreover, Nb2O5 and CaZrO3 raised the Curie point to higher temperatures. This indicated that the ferroelectric phase became stable at high temperature[16] and it was considered to be beneficial for improving the stability of temperature of the dielectrics at high temperature.

The curves of BTBNT ceramics doped with Nb2O5 or CaZrO3 satisfied X9R specification perfectly. Meanwhile those samples doped with BNT or BiNbO4 did not meet the X9R specification, which is surrounded by a bold line of rectangular shape as shown in Fig. 5(b). Fortunately, it was very likely to get BaTiO3 based X9R materials if the initial compositions were doped with more than 2 wt% of BNT or less than 2 wt% of BiNbO4. According to the TCC measurement (Fig. 5(b)) and capacitance variation data at Curie temperature (Table 2), the suppression effect for dielectric peak of the above dopants could be ranked as follows: BiNbO4 > CaZrO3 > Nb2O5 > BNT.

In conclusion, the dielectric properties of BTBNT ceramics, which were synthesized by doping and pre-sintering approach, have been discussed in terms of different dopants to depress the ferroelectric peaks. The initial BTBNT-Nb2O5-ZMT-CeO2-CBS ceramics exhibited a temperature dependence that failed to reach the X9R specification with the temperature variation of capacitance 22.8% at Curie point and −16.7% at 175 °C. Adding 2 wt% Nb2O5, CaZrO3, BNT or BiNbO4 to the initial composition resulted in a suppression of the ferroelectric transition. The Nb2O5 or CaZrO3 doped samples achieved the X9R specification perfectly and both of these dopants raised the Curie point towards higher temperature. By using this improved approach, BaTiO3 based X9R ceramics with high dielectric constant of about 1700 were developed successfully.

References

S. Sato, T. Nomura, and A. Sato. Dielectric ceramic composition and electronic device. United States Patent: 6226172, 1999

Y.S. Jung, E.S. Na, U. Paik, J. Lee, J. Kim, Mater. Res. Bull. 37(9), 1633 (2002)

I. Kazushige, and S. Akira. Dielectric ceramic composition and electronic device. United States Patent: 7262146, 2007

D. Flandre, A.N. Nazarov, and P.L.F. Hemment, Science and technology of semiconductor-on-insulator structures and devices operating in a harsh environment. 2005, London: Kluwer Academic Publisher. 1

T. Zednicek, S. Pala, and Z (AVX Technical Publication, Sita, 2004)

P.G. Neudeck, R.S. Okojie, L.-Y. Chen, P. Ieee. 90(6), 1065 (2002)

J.L. Evans, P. Jacobsen, R. Thompson, and R. Wayne Johnson. High temperature automotive electronics. 2002. Reno, NV, United States: The International Society for Optical Engineering

R.W. Johnson, J.L. Evans, P. Jacobsen, J.R. Thompson, M. Christopher, IEEE Transactions on Electronics Packaging Manufacturing 27(3), 164 (2004)

J.Q. Qi, W.P. Chen, Y. Wang, H.L.W. Chan, L.T. Li, J. Appl. Phys. 96(11), 6937 (2004)

X. Jing, Y. Li, Q. Yin, Mat. Sci. Eng. B. 99(1–3), 506 (2003)

M. Du, Y. Yuan, S.-R. Zhang, B. Tang, Y.-R. Li, J. Inorg. Mater. 23(2), 267 (2008)

D. Hennings, G. Rosenstein, J. Am. Ceram. Soc. 67(4), 249 (1984)

B. Tang, S. Zhang, X. Zhou, D. Wang, Y. Yuan, J. Electron. Mater. 36(10), 1383 (2007)

B. Tang, S.R. Zhang, X.H. Zhou, Y. Yuan, J. Mater. Sci-mater. El. 18(5), 541 (2007)

M. Du, Y. Li, Y. Yuan, S. Zhang, B. Tang, J. Electron. Mater. 36(10), 1389 (2007)

H. Kishi, N. Kohzu, Y. Mizuno, Y. Iguchi, J. Sugino, H. Ohsato, T. Okuda, Jpn. J. Appl. Phys 38(9B), 5452 (1999)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Tang, B., Zhang, SR., Zhou, XH. et al. Preparation and modification of high Curie point BaTiO3-based X9R ceramics. J Electroceram 25, 93–97 (2010). https://doi.org/10.1007/s10832-009-9594-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10832-009-9594-7