Abstract

We fabricated 5 at.% Mn-added polycrystalline BiFeO3 films and investigated the annealing temperature effect on structural, ferroelectric and magnetic properties. In the x-ray diffraction patterns, only the diffraction peaks due to the BiFeO3 structure were observed and no secondary phase could be observed at annealing temperatures between 773 and 923 K. Adding Mn suppressed the leakage current density in the high electric field region when compared to pure BiFeO3 films. The conduction mechanism of the Mn-added BiFeO3 films was dominated by Ohmic conduction. Remanent polarization of the Mn-added polycrystalline BiFeO3 films for an applied electric field of approximately 1.5 mV/cm was 63 μC/cm2 for the specimen annealed at 773 K and 46 μC/cm2 for the specimen annealed at 923 K, although the remanent polarization still exhibited a tendency to increase with an increase in the electric field. Spontaneous magnetization was obtained at high annealing specimens. This study revealed that the annealing temperature strongly affected the ferroelectric and magnetic properties in Mn-added polycrystalline BiFeO3 films. In addition, by optimizing the annealing temperature, we realized multiferroics coexistent with spontaneous magnetization and spontaneous polarization at room temperature in the Mn-added polycrystalline BiFeO3 film.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Multiferroic BiFeO3 materials have attracted much interest because first-principle calculation predicted that the BiFeO3 films possess the extremely large spontaneous polarization of 90–100 μC/cm2 for a rhombohedral structure with space group R3c and 150 μC/cm2 for a tetragonal structure [1, 2]. In fact, in experiments, high remanent polarizations of 50–150 μC/cm2 were reported in the film from [3–7]. Although BiFeO3 films exhibited excellent ferroelectric properties, the leakage current density of these films was quite high at room temperature, and the almond-shaped of the ferroelectric hysteresis loops were observed. In our previous study [8], relatively high remanent polarization of 89 μC/cm2 was obtained at the low temperature of 93 K in polycrystalline BiFeO3 film annealed at 923 K. The leakage current density of the polycrystalline BiFeO3 film was reduced on the order of 10−1 A/cm2 to 10−8 A/cm2 at 150 kV/cm by decreasing the measuring temperature to 93 K. It is expected that the reducing the leakage current density and realize ferroelectric hysteresis loops of a well-saturated shape at room temperature. One way to reduce the leakage current density is to add La or Nb for the A-site or Mn, Cr or Ti for the B-site [9–17]. The Mn atom is the leading candidate for reducing the leakage current. The leakage current was reduced at an Mn concentration range between 3 and 5 at.% [11], although the reducing magnitude of the leakage current density from the addition of Mn atoms was differed in each report [10–12]. In contrast, in our previous study, spontaneous magnetization was obtained in non-doped polycrystalline BiFeO3 films by optimizing the annealing conditions by a chemical solution deposition (CSD) process, although the leakage current density was quite high and it was difficult to measure the ferroelectricity at room temperature. We expect to show the coexistence of the ferromagnetic and ferroelectric multiferroic properties in BiFeO3 films at room temperature by optimizing the annealing and adding Mn atoms to reduce the leakage current. The present study aims to fabricate the multiferroic films that exhibit ferromagnetic and ferroelectric properties at room temperature in a system of 5 at.% Mn-doped BiFeO3 films using the CSD method by optimizing the annealing temperature.

2 Experimental procedure

Mn-added polycrystalline BiFeO3 films were fabricated by the CSD method. As mentioned above, the leakage current density of the BiFeO3 films were decreased in a Mn concentration range between 3 and 5 at.% [11], and our preliminary experimental results showed the same tendency. Addition of only a few atomic percentage of the Mn was effective in reducing the leakage current density. Therefore, we examined the precursor solution of atomic ratio of Bi(Fe0.95Mn0.05)O3 prepared by mixing appropriate quantities of both precursor solutions BiFeO3 and BiMnO3. The mixed precursor solutions were spin-coated on the Pt(150 nm)/Ti(5 nm)/SiO2/Si(001) substrates at a rotational speed of 4,000–6,000 rpm for 50 s. The bottom Pt electrode and buffer Ti layers were prepared by rf magnetron sputtering. The bottom Pt layer was oriented along the <111> surface perpendicular to the substrate surface. The coated substrates were dried on a hotplate at 423 K for 1 min and calcined at 623 K for 5 min in air. These processes were repeated five times to obtain a film thickness of 200 nm. The annealing temperature was changed to the range between 673 and 1073 K using a rapid thermal annealing (RTA; ULVAC MILA-3000) apparatus. The heating rate was set to be around 10 K/s. After holding the target temperature for 10 min, the specimens were naturally cooled; therefore, the drop rate of the temperature was not constant. To make the capacitor configuration, the top Pt electrode with a thickness of 150 nm was deposited by rf magnetron sputtering using a metal mask. The top Pt electrode was 100 μm in diameter.

The crystal structure was identified by conventional x-ray diffraction (XRD: 2θ/θ, Cu-Kα; PANalytical X'Pert MRD) patterns. The surface morphology of the films was observed by atomic force microscopy (AFM) and scanning electron microscopy (SEM; JEOL JSM-6380). The ferroelectric hysteresis loops were measured at room temperature by making use of a high driving frequency of 100 kHz produced by TOYO Corporation (FCE-1A type ferroelectric test system). Leakage current density was measured using HP 4140B. A driving voltage was applied to the bottom electrodes. The magnetic properties were measured by a vibrating sample magnetometer (VSM: Tamakawa Corporation) at room temperature. The magnetic field was applied along the film plane.

3 Results and discussion

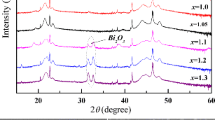

Figure 1 shows the x-ray diffraction patterns for the 5 at.% Mn-added BiFeO3 films with various annealing temperatures. At 673 K, only one diffraction peak was observed at approximately 2θ = 46°, which has two candidate structure—the reflection of (024) BiFeO3 or (200) Pt. Because the diffraction peak of (012) BiFeO3 was not observed, the diffraction peak located at 2θ = 46° should be identified as the reflection of the (200) Pt of the bottom electrode layer. Therefore, it could be considered that the apparent crystallized phases did not form at an annealing temperature of 673 K. The x-ray diffraction measurement of the Pt(150 nm)/Ti(5 nm)/SiO2/Si(001) substrates without BiFeO3 layers (not shown in this study) also supported this analysis. Between the annealing temperatures of 773 and 923 K, many diffraction peaks attributed to the BiFeO3 structure were observed and no secondary phase was formed, which indicated that the Mn-added polycrystalline BiFeO3 films were formed. In our previous study [18, 19], the crystal structure of the pure polycrystalline BiFeO3 films prepared by the same technique employed in this study was confirmed as a rhombohedral structure with the space group of R3c. Therefore, in this study, we used the index of the rhombohedral structure in the x-ray diffraction patterns, although the separated peaks were not observed. For example, reflections of (104) and (110) BiFeO3 were not split. At the annealing temperature of 973 K, Bi2O3 of a secondary phase was formed together with the BiFeO3 phase. Many unidentified diffraction peaks appeared and the diffraction peaks due to the BiFeO3 disappeared at an annealing temperature of 1073 K.

Figure 2 shows the AFM images for the 5 at.% Mn-added polycrystalline BiFeO3 films with various annealing temperatures. The film surface was flat at an annealing temperature of 673 K and crystal grains were not observed, which is consistent with the results of XRD measurement. Crystal grains with relatively homogeneous sizes approximately 2 μ were obtained at 773 and 873 K. A few dozen nano-meter sized of the projections appeared at the surface of the grains at 973 K and squared grains were formed at 1073 K, which could be attributed to the unknown phase as shown in Fig. 1. Figure 2(f) shows the temperature dependence of the root mean square (RMS) roughness value. The surface roughness slightly increased until 973 K and increased drastically at an annealing temperature of 1073 K. The RMS value was almost same to that of the thickness of the film for the sample annealed at 1073 K.

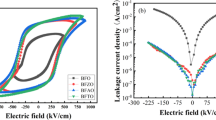

Figure 3(a) shows the leakage current density (J) vs electric field (E) characteristic at room temperature for the 5 at.% Mn-added polycrystalline BiFeO3 films with various annealing temperatures. The leakage current density has a tendency to increase with increasing the annealing temperature. The lowest leakage current density at 673 K was attributed to the low crystallinity and/or the amorphous structure. The leakage current density had magnitudes in the range between 10−3 and 10−4 A/cm2 order at an electric field of 100 kV/cm, which was more than one order of magnitude lower than for polycrystalline pure BiFeO3 film [20]. Note that the leakage current density of the Mn-added polycrystalline BiFeO3 films was suppressed in the high electric field region when compared to pure polycrystalline BiFeO3 film. This tendency is consistent with the previous report [11]. It could be concluded that the leakage current density was effectively reduced by adding small amounts of Mn and by annealing at low temperature. Figure 3(b) shows the double logarithmic plots of the leakage current curve for the 5 at.% Mn-added polycrystalline BiFeO3 films. In all specimens, the leakage current density was in proportion to the electric field. Figure 3(c) shows the inclination of each fitting line as shown in Fig. 3(b). The inclination of the Mn-added polycrystalline BiFeO3 films annealed at temperatures between 673 and 923 K was approximately 1, which indicated that the leakage current was predominantly due to Ohmic conduction. The inclination increased at high annealing temperatures, which implied that the leakage was not Ohmic conduction.

(a) Leakage current density (J) vs electric field (E) characteristic at room temperature for the 5 at.% Mn-added polycrystalline BiFeO3 films with various annealing temperatures. (b) Double logarithmic plots of the leakage current curve for the 5 at.% Mn-added polycrystalline BiFeO3 films. (c) Inclination of each fitting line as shown in (b)

Figure 4 shows the ferroelectric hysteresis loops for the 5 at.% Mn-added polycrystalline BiFeO3 films with various annealing temperatures. The driving frequency was 100 kHz maintained in order to suppress influence of the leakage current components. We measured the time delay of the response waveform to the driving voltage using a standard 1 nF capacitor and discovered that a compensation of 500 ns was necessary. We discuss the details of the compensating the phase delay elsewhere (Naganuma and Okamura, submitted for publication). Ferroelectricity could not be observed in the noncrystalline specimen annealed at 673 K. Ferroelectric hysteresis loops were obtained in the specimens annealed at temperatures from 773 to 923 K, and these specimens were confirmed unformed of secondary phases. The ferroelectricity disappeared above the annealing temperature of 973 K due to the formation of the secondary phase. Figure 4(g) shows the electric field dependence of the remanent polarization for the Mn-added polycrystalline BiFeO3 films. The remanent polarization of 773 K annealed specimen was relatively high compared with the specimens annealed at 873 and 923 K. The remanent polarization at the applied electric field of around 1.4 mV/cm was 63 μC/cm2 for 773 K annealing specimen and 46 μC/cm2 for 923 K annealing specimen. However, the remanent polarizations still had a tendency to increase when the electric field increased again as shown in Fig. 4(g), which indicated that Mn-added polycrystalline BiFeO3 films have a potential of showing much higher remanent polarization that we expected. Our other study (Naganuma and Okamura, submitted for publication), it was revealed that the influence of the leakage current component was well suppressed due to the high frequency of 100 kHz. Therefore, we considered that continuous increase of the remanent polarization by increasing the electric field was not dominated by the leakage current.

Figure 5 shows the normalized magnetization curves measured at room temperature for the 5 at.% Mn-added polycrystalline BiFeO3 films with various annealing temperatures. The magnetic field was applied in the film plane direction. For the specimen annealed at 673 K (not shown here), the magnetization linearly increased with increasing the magnetic field such as paramagnetic material. This specimen did not show any diffraction peaks in XRD, and the surface morphology was flat (no crystal grains) as mentioned earlier. According to the bulk amorphous Bi–Fe–O [21], bulk amorphous Bi–Fe–O shows the spin glass behavior at low temperature (below 220 K) and paramagnetism at room temperature. In amorphous Bi–Fe–O, magnetization linearly increased as the magnetic field increased [21]. Therefore, it could be assumed that after annealing at 673 K, the specimen had an amorphous structure: however the details of the structural analysis using transmission electron microscopy (TEM) are necessary to confirm. The specimen annealed at the temperatures between 773 and 873 K showed the M–H curve of typical weak ferromagnetism that did not exhibit magnetic coercivity. The magnetic susceptibility of these weak ferromagnetic Mn-added polycrystalline BiFeO3 films had a tendency to increase as the annealing temperature increased, which indicated that the magnetic properties were influenced by the crystallinity and/or grain size. A relatively high M S/M r of approximately 0.4 together with a magnetic coercive field of around 1 kOe was obtained at annealing temperatures of 923 and 973 K. As mentioned above, ferroelectric properties were obtained at annealing temperatures between 773 and 923 K, which meant that the Mn-added polycrystalline BiFeO3 film annealed at 923 K realized the room temperature ferroelectric and ferromagnetic type of multiferroic. The key techniques for obtaining the multiferroic film were to optimize the annealing temperature to obtain the spontaneous magnetization, and adding small amounts of Mn atoms to suppress the leakage current.

4 Conclusion

We fabricated the 5 at.% Mn-added polycrystalline BiFeO3 films using CSD method followed by post deposition annealing at a temperature range between 673 and 1073 K, and discussed the effect of the annealing temperature on the film structural, magnetic properties and ferroelectric properties, which includes the leakage current. The following results were obtained: films were crystallized above the annealing temperature of 773 K, and the polycrystalline single phase of 5 at.% Mn-added BiFeO3 films with grains around 2 μm in diameter were obtained at annealing temperatures between 773 and 923 K. The Bi2O3 of secondary phase was formed together with the BiFeO3 phase at 973 K. At an annealing temperature of 1073 K, the BiFeO3 phase almost disappeared and many unknown phases appeared. The leakage current was suppressed in the high electric field region by adding 5 at.% of Mn. From the double logarithm plots, it was revealed that the leakage current mechanism of the 5 at.% Mn-added polycrystalline BiFeO3 films without secondary phases was Ohmic conduction. Ferroelectric hysteresis measurements using a high frequency of 100 kHz revealed that the ferroelectricity was only observed at the annealing temperatures of 773 and 923 K. The specimens showed the linear increment of remanent polarization as the electric field increased, which suggested the presence of rather high remanent polarization in these films. We will discuss the potential of high remanent polarization of more than 100 μC/cm2 in the near future. A spontaneous magnetization together with the relatively high magnetic coercivity of 1 kOe was obtained at annealing temperatures of 873 and 923 K. Therefore, we successfully obtained multiferroic films having both ferroelectric and ferromagnetic at room temperature in the system of Mn-added polycrystalline BiFeO3 film with annealed at 923 K. The key techniques for obtaining the multiferroic film are by optimizing the annealing temperature to obtain spontaneous magnetization and adding the small amounts of Mn atoms to suppress the leakage current. The present study it was revealed that the process window of the double ferroic-film is narrow.

References

J.B. Neaton, C. Ederer, U.V. Waghmare, N.A. Spaidin, K.M. Rabe, Phys. Rev. B 71, 014113 (2005)

C. Ederer, N.A. Spaldin, Phys. Rev. Lett 95, 257601 (2005)

J. Wang, J.B. Neaton, H. Zheng, V. Nagarajan, S.B. Ogale, B. Liu, D. Viehland, V. Vaithyanathan, D.G. Schlom, U.V. Waghmare, N.A. Spaldin, K.M. Rabe, M. Wuttig, R. Ramesh, Science 299, 1719 (2003)

J. Li, J. Wang, M. Wuttig, R. Ramesh, N. Wang, B. Ruette, A.P. Pyatakov, A.K. Zvezdin, D. Viehland, Appl. Phys. Lett 84, 5261 (2004)

J. Li, J. Wang, M. Wuttig, R. Ramesh, N. Wang, B. Ruette, A.P. Pyatakov, A.K. Zvezdin, D. Viehland, Appl. Phys. Lett 84, 5216 (2004)

K.Y. Yun, D. Ricinschi, T. Kanashima, M. Noda, M. Okuyama, Jpn. J. Appl. Phys 43, L647 (2004)

D. Lebeugle, D. Colson, A. Forget, M. Viret, P. Bonville, J.F. Marucco, S. Fusil, Phys. Rev. Lett 76, 024116 (2007)

H. Naganuma, Y. Inoue, S. Okamura, IEEE Trans. Ultrason. Ferroelectr. Freq. Control. In press (2007)

X. Qi, J. Dho, R.Tomov, M.G. Blamire, J.L.M. Driscoll, Appl. Phys. Lett 86, 062903 (2005)

C.-F. Chung, J.-P. Lin, J.-M. Wu, Appl. Phys. Lett 88, 242909 (2006)

S.K. Singh, H. Ishiwara, K. Maruyama, Appl. Phys. Lett 88, 262908 (2006)

K. Takahashi, M. Tonouchi, Jpn. J. Appl. Phys 45, L755 (2006)

J.K. Kim, S.S. Kim, W.-J. Kim, A.S. Bhalla, R. Guo, Appl. Phys. Lett 88, 132901 (2006)

Y. Wang, C.-W. Nan, Appl. Phys. Lett 89, 052903 (2006)

S.R. Shannigrahi, A. Huang, N. Chandrasekhar, D. Tripathy, A.O. Adeyeye, Appl. Phys. Lett 90, 022901 (2007)

H. Uchida, R. Ueno, H. Nakai, H. Funakubo, S. Koda, Jpn. J. Appl. Phys 44, L 561 (2005)

D. Lee, M.G. Kim, S. Ryu, H.M. Jang, S.G. Lee, Appl. Phys. Lett 86, 222903 (2005)

H. Naganuma, A. Kovacs, Y. Hirotsu, Y. Inoue, S. Okamura, Trans. Mat. Res. Soc. Jpn 32, 39 (2007)

H. Naganuma, A. Kovacs, A. Hirata, Y. Hirotsu, S. Okamura, Mater. Trans 48, 2370 (2007)

H. Naganuma, S. Okamura, J. Appl. Phys 101, 09M103 (2007)

S. Nakamura, S. Soeya, N. Ikeda, M. Tanaka, J. Appl. Phys 74, 5652 (1993)

Acknowledgments

We wish to express gratitude to Prof. Hiroshi Funakubo, Tokyo Institute of Technology for the ferroelectric measurements using the FCE-1A type ferroelectric tester produced by TOYO Corporation. We also express gratitude to Prof. Nobuyuki Hiratsuka, Saitama University for the magnetic measurements using the vibrating sample magnetometer. This study was partly funded by the Grant-in-Aid for Young Scientist [Start up program] (Grant No. 18860070) from the Ministry of Education, Culture, Sports, Science and Technology of Japan, and by the Sasakawa Scientific Research Grant from The Japan Society (Grant No. 19-216).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Naganuma, H., Miura, J. & Okamura, S. Annealing temperature effect on ferroelectric and magnetic properties in Mn-added polycrystalline BiFeO3 films. J Electroceram 22, 203–208 (2009). https://doi.org/10.1007/s10832-007-9400-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10832-007-9400-3