Abstract

Bismuth potassium titanate, (Bi1/2K1/2)TiO3 (BKT), ceramics were prepared by the hot-pressing (HP) method without dopant and with dopants of Bi2O3, La2O3 and MnCO3. The relative density of BKT ceramics hot-pressed at 1,060 and 1,080 °C (hereafter abbreviated to BKT-HP1060°C and BKT-HP1080°C) and x mass% Bi2O3, La2O3 and MnCO3 doped BKT ceramics hot-pressed at 1,060 °C (hereafter abbreviated as BKTBix; x = 0.1–0.6, BKTLax; x = 0.1–0.6 and BKTMnx; x = 0.1–0.3) were all higher than 97%. In this study, the ferroelectric properties of BKT ceramics were successfully obtained, and the remanent polarization P r and coercive field E c of BKT-HP1080°C were 22.2 μC/cm2 and 52.5 kV/cm, respectively. A small amount of La tends to increase P r, and the P r of BKTLa0.1 was 19.2 μC/cm2. The piezoelectricities were improved to optimize poling conditions, and the electromechanical coupling factor k 33 and piezoelectric constant d 33 of BKT-HP1080°C were 0.34 and 82.8 pC/N, respectively.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Environmental destruction has been a serious problem worldwide. Such a problem includes the release of harmful materials (e.g., Pb, Hg, Cd, Cr6+) from electrical industries, and some regulations to prevent the release of harmful waste materials such as WEEE, RoHS and ELV have already been implemented. Piezoelectric ceramics are widely used in various applications such as ceramic filters, actuators and sensors. However, PbZrO3–PbTiO3 (PZT)-based three-component systems that include with a large amount of Pb have been mainly used in piezoelectric applications because of their excellent properties [1, 2]. Therefore, lead-free piezoelectric materials have recently been extensively studied [3]. In lead-free piezoelectric materials, single crystals of the langasite series and ferroelectric ceramics with a tungsten bronze structure and a bismuth layer structure are piezoelectrics whose frequency constant is stably temperature-dependent. These materials have a good thermal stability, but small electromechanical coupling factors. For this reason, various lead-free piezoelectric solid solutions with a perovskite structure, such as BaTiO3, (Bi1/2Na1/2)TiO3 and KNbO3, have been actively studied [4–6].

Bismuth potassium titanate, (Bi1/2K1/2)TiO3 (BKT), is a typical ferroelectric material with a perovskite structure of tetragonal symmetry at room temperature and a relatively high Curie temperature, T c, of 380 °C [7]. Ivanova et al. investigated the crystal structure of BKT ceramics by X-ray diffraction analysis, and they reported that the lattice constants of BKT ceramics are a = 0.3913 nm, c = 0.3993 nm [8]. They also reported that the second-phase transition temperature T 2, that is, from tetragonal to pseudocubic, existed at about 270 °C. BKT ceramics seem to be a candidate for lead-free piezoelectrics with a high T c; however, a few electrical properties have been reported, because it is difficult to prepare a dense ceramic body by a conventional ceramic fabrication process. Recently, some chemical processes have been studied [9, 10] to improve the sinterability of BKT ceramics.

In this paper, we prepared the dense (Bi1/2K1/2)TiO3 (BKT) ceramics by the hot-pressing method without dopant [11] and with dopants of Bi2O3, La2O3 and MnCO3.

Experimental procedure

BKT powder was prepared using a conventional ceramic fabrication process. 3–4N metal oxide or carbonate powders of Bi2O3, TiO2 and K2CO3, La2O3 and MnCO3 were used as starting materials. These oxide or carbonate powders were mixed for 10 h in ethanol with zirconia balls by ball milling, followed by calcination at 800 °C for 4 h and 950 °C for 2 h in an alumina crucible. After calcination, the ground powder was ball-milled for 20 h and then pressed into discs of 20 mm diameter and 5 mm thickness.

Non-doped BKT ceramics were prepared at 1060 and 1080 °C for 3 h by hot pressing (HP) method (abbreviated to BKT-HP1060°C and BKT-HP1080°C), and a small amount of x mass% of Bi2O3, La2O3 and MnCO3 added BKT ceramics were prepared at 1060 °C for 3 h by HP method (abbreviated to BKTBix; x = 0.1–0.6, BKTLax; x = 0.1–0.6, BKTMnx; x = 0.1–0.3). A pressure of 150 kg/cm2 was applied for 2 h at the maximum sintering temperature. During hot pressing, bulk samples were tightly covered with alumina powders under poor-oxygen conditions; therefore, the resulting samples were annealed at 900 °C in air after hot pressing for reoxidization and reduction in inner stress.

The observed densities of the obtained ceramics were measured using the Archimedes method. The crystal structures and lattice constants of the sintered ceramics were determined by X-ray diffraction analysis with CuKα radiation through a Ni filter using an X-ray diffractometer (Rigaku; RINT2000). The temperature dependences of the dielectric constants ɛ s and loss tangent tanδ were measured at 10 kHz, 100 kHz and 1 MHz using an automated dielectric measurement system with a multifrequency LCR meter (YHP 4275A). D–E hysteresis loops at 50 Hz of the prepared specimens were observed using a ferroelectric testing system (Toyo Corporation; Model 6252 Rev. C). The piezoelectric properties were measured by a resonance–antiresonance method based on EMAS-6002 standards using an impedance analyzer (HP 4294A).

Results and discussion

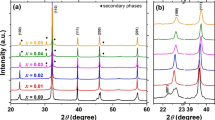

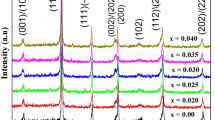

The results of X-ray diffraction patterns showed BKT-HP1060°C, BKTBix, BKTLax and BKTMnx were single-phase perovskite structures; however, the phase of BKT-HP1080°C included a few impurity peaks, because hot-pressing temperature of 1080 °C is higher temperature of proper sintering temperature. The lattice parameters of BKT-HP1060°C were a = 0.3925 nm and c = 0.3993 nm, which agree well with (a = 0.3913 nm, c = 0.3993 nm) reported values [7]. The theoretical densities of the obtained ceramics were all higher than 97%; however, BKT-HP1060°C had some micro-cracks in the ceramic bodies. Those micro-cracks decreased with increasing the amount of additives. The resistivities of both samples were fairly high of the order of 1013 Ω·cm at RT.

The temperature dependences of dielectric constants, ɛ s, and dielectric loss tangents, tanδ, in the temperature range from room temperature to 600 °C, and at frequencies from 10 kHz to 1 MHz were measured. Figure 1 shows the temperature dependence of ɛ s and tanδ from 10 kHz to 1 MHz for BKT-HP1060°C and BKT-HP1080°C. Figure 1 displays the tanδ curves show two peaks. High-temperature peaks have a frequency dispersion; therefore, it is thought that these peaks are related to T c. On the other hand, low-temperature peaks are almost independent of frequencies; therefore, it is considered to indicate second phase transition, T 2, between tetragonal and pseudo-cubic, and the temperatures of BKT-HP1060°C and BKT-HP1080°C are about 340 and 317 °C, respectively. T c of Bi2O3, La2O3 and MnCO3 doped BKT ceramics had a tendency to decrease with increasing x.

D–E hysteresis loops were measured by virtual ground circuit at 50 Hz. D–E hysteresis loops of BKT-HP1060°C and BKT-HP1080°C are shown in Fig. 2. Well-shaped D–E hysteresis loops with low leakage current were obtained for all specimens at RT. Figure 3 shows the saturation properties of remanent polarization P r for (a) BKT-HP1060°C and BKT-HP1080°C, (b) BKT-Bix (c) BKT-Lax and (d) BKT-Mnx. The P r and coercive fields E c values were 22.2 μC/cm2 and 52.5 kV/cm for BKT-HP1080°C, and 14.2 μC/cm2 and 47.3 kV/cm for BKT-HP1060°C, respectively. It is thought to be the difference in grain size between these samples, that of 0.2 μm for BKT-HP1060°C and 0.4 μm for BKT-HP1080°C. Figure 2(b, c and d) display the maximum applied fields increased with increasing the amount of dopants. These results were caused by suppression of micro-cracks. Compared with BKT-HP1060°C, the P r of BKTLax increased and the rising applied field shift lower, and this result imply BKT ceramics become soft such as La-doped PZT ceramics. On the other hand, the P r of BKTBix and BKTMnx were almost same as BKT-HP1060°C. The temperature dependence of D–E hysteresis loops for BKT-HP1080°C was observed in the temperature range from room temperature to 260 °C as shown in Fig. 4. The P r and the E c gradually decreased with increasing sample temperature, and a well-saturated D–E hysteresis loop was observed even at 260 °C.

The electromechanical coupling factors of the longitudinal extensional mode, k 33, for BKT-HP1080°C were measured using a rectangular specimen of 2 × 2 × 5 mm3. BKT ceramics are difficult to pole at room temperature, because of high coercive field. Therefore, poling treatments were carried out in the temperature ranges from 100 to 200 °C and in the electrical fields range from 7 to 8 kV/mm. The highest electromechanical coupling factor k 33 and piezoelectric constant d 33 of BKT-HP1080°C were obtained at 150 °C, and these values were 0.28 and 69.8 pC/N. However, The maximum phase, θ max, in the frequency dependence of the impedance Z, was 49°; this means that this ceramic was not poled completely. To improve piezoelectric properties, a cooling poling treatment was carried out. Specimens were cooled from 250 to 100 °C in the electrical fields range from 6 to 7 kV/mm. The frequency dependences of the impedance |Z| and phase θ for BKT-HP1080°C are shown in Fig. 5. By this poling treatment, the θ max, k 33 and d 33 values of BKT-HP1080°C were improved up to 64°, 0.34 and 82.8 pC/N. This result indicates cooling poling treatment is very effective for BKT ceramics, and it is expected that the piezoelectricity improve to optimise poling conditions such as temperature and poling field.

The temperature dependence of f r and k 33 of BKT-HP1080°C was measured in the temperature range from room temperature to 400 °C as shown in Fig. 6. This result displays the f r curve has a peak at 310 °C, and piezoelectricity disappeared at this temperature. In Fig. 1, the peaks of tanδ, which are independent of measurement frequency, are observed at 317 °C, which almost agrees with temperature the peak of f r. These results show that the T 2 of BKT-HP1080 °C ceramics from tetragonal to pseudo-cubic was about 310 °C.

Conclusions

High relative densities of 97% have been fabricated using the HP method. Well-shaped D–E hysteresis loops with no leakage current of non-doped and Bi2O3, La2O3 and MnCO3 doped BKT ceramics were successfully obtained. The remanent polarization P r and coercive field E c of BKT-HP1080°C were 22.2 μC/cm2 and 52.5 kV/cm, respectively. The piezoelectric properties of BKT-HP1080°C were highly improved by electric cooling method. In this study, the second-phase transition temperature T 2 was determined from temperature dependences of f r and tanδ, and the T 2 of pure BKT ceramics was about 340 °C. This study indicates BKT ceramics is one of the superior candidates for lead-free piezoelectric ceramics with high T c.

References

E. Sawaguchi, J. Phys. Soc. Jpn. 8, 615 (1953)

T. Yamamoto, Jpn. J. Appl. Phys. 35, 5104 (1996)

T. Takenaka, H. Nagata, J. Eur. Ceram. Soc. 25(12), 2693 (2005)

H. Nagata, N. Koizumi, N. Kuroda, I. Iigarashi, T. Takenaka, Ferroelectrics 229, 237 (1999)

T. Takenaka, K. Maruyama, K. Sakata, Jpn. J. Appl. Phys. 30, 2236 (1991)

S. Tashiro, H. Nagamatsu, K. Nagata, Jpn. J. Appl. Phys. 41, 7113 (2002)

C.F. Buhrer, J. Chem. Soc. 36, 798 (1962)

V.V. Ivanova, A.G. Kapyshev, Y.N. Venevtsev, G.S. Zhdanov, Izv. Akad. Nauk. SSSR. 26, 354 (1962)

T. Wada, A. Fukui, Y. Matsuo, Jpn. J. Appl. Phys. 41, 7025 (2002)

Z.F. Li, C.L. Wang, W.L. Zhong, J.C. Li, M.L. Zhao, J. Appl. Phys. 94, 2548 (2003)

Y. Hiruma, R. Aoyagi, H. Nagata, T. Takenaka, Jpn. J. Appl. Phys. 44, 5040 (2005)

Acknowledgements

The authors would like to thank Toho Titanium Co., Ltd. for providing titanium oxide powder with high purity. This work was partially supported by a Grant-in-Aid for Scientific Research (B) (No. 17360327) from the Japan Society for the Promotion of Science.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Hiruma, Y., Marumo, K., Aoyagi, R. et al. Ferroelectric and piezoelectric properties of (Bi1/2K1/2)TiO3 ceramics fabricated by hot-pressing method. J Electroceram 21, 296–299 (2008). https://doi.org/10.1007/s10832-007-9146-y

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10832-007-9146-y