Abstract

Cell immobilization is one of the techniques used to improve H2 productivity in cyanobacteria. In this study, H2 production by immobilized cells of unicellular halotolerant cyanobacterium Aphanothece halophytica was investigated and optimized. The results showed that immobilized cells of A. halophytica had higher H2 production than free cells under nitrogen-deprived condition. Among various support material types used, agar-immobilized cells showed the highest H2 production rate. Under nitrogen deprivation, the optimal conditions of cell immobilization for H2 production were 3% (w/v) agar concentration, 0.2 mg dry cell weight per mL of gel solution, and 0.125 cm3 of agar cube. The optimum pH of medium and incubation temperature for H2 production by agar-immobilized cells were pH 7.4 and 40 °C, respectively. Using a large glass vial and headspace volume resulted in enhancement of H2 production by agar-immobilized cells. Finally, H2 production by agar-immobilized cells was analyzed for three consecutive cycles. H2 production could be maintained at the highest level after two cycles when half of immobilized cells were replaced with fresh immobilized cells. These findings indicate that the enhanced H2 production of the unicellular halotolerant cyanobacterium A. halophytica can be achieved by immobilization method, thus providing the possibility to improve H2 production by cyanobacteria in the future.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Hydrogen gas (H2) is considered as a clean and efficient energy carrier that can be used instead of current fossil fuels. H2 combustion provides a high heating value of 141.6 MJ kg−1 (Perry 1963) and generates mainly non-carbon-based products which do not affect the environmental pollution and the ozone layer (Kotay and Das 2008). H2 is mainly produced by the steam reforming and thermochemical processes; however, these processes require raw materials from diminished fossil fuel reserves. Besides, H2 can also be produced by biological processes from various kinds of microorganisms depending on the typical metabolic pathways. In cyanobacteria, H2 is mostly produced by electrons obtained from the degradation of storage carbohydrates under darkness rather than electrons from a water oxidation of a direct photolysis (Tamagnini et al. 2007; Ananyev et al. 2008). In some N2-fixing cyanobacteria, H2 is produced as a by-product from N2 fixation process (Reddy et al. 1996; Chen et al. 2008).

The unicellular halotolerant cyanobacterium Aphanothece halophytica is a model organism for studying salt tolerance mechanism in cyanobacteria because it could tolerate a high salinity up to 3 M NaCl (Takabe et al. 1988). Aphanothece halophytica has previously been shown as one of high potential H2-producing cyanobacteria (Taikhao et al. 2013, 2015). It produces H2 mainly by electrons obtained from a dark fermentation of storage glycogen under anaerobic condition (Taikhao et al. 2013). H2 production of A. halophytica is catalyzed by bidirectional hydrogenase encoded by five structural genes, hoxE, hoxF, hoxU, hoxY, and hoxH (Phunpruch et al. 2016). H2 production and in vivo bidirectional hydrogenase activity of A. halophytica are significantly increased under nitrogen-deprived condition (Taikhao et al. 2013; Phunpruch et al. 2016). In addition, A. halophytica can grow in natural seawater supplemented with 1.76 mM NaNO3, one-tenth of NaNO3 concentration in BG11, and can provide long-term H2 production when incubated in natural seawater (Taikhao et al. 2015).

The immobilization of cells on a suitable support material can be used to enhance H2 production efficiency of microorganisms. Cell immobilization can protect enzyme activity and/or cells from an external hostile environment by separating cells from a liquid phase (Bickerstaff 1995). Moreover, immobilization can prevent cells from forming clumps which lead to a breakage of the filaments (Anjana and Kaushik 2014). Cell entrapment in porous gels has been shown as the most popular technique for whole cell immobilization (Freeman 1984). H2 production by immobilized cells has been investigated in some strains of cyanobacteria. In the filamentous cyanobacterium Calothrix sp. 336/3, sodium alginate–immobilized cells showed an increase of H2 production efficiency and a prolonged H2 production over several cycles (Leino et al. 2009). Immobilized cells of cyanobacterium Microcystis aeruginosa with agar allowed the maintenance of stable H2 production (Rashid et al. 2009). H2 production by immobilized cells of the filamentous cyanobacterium Lyngbya perelegans with agar and alginate has been more sustained than that by free cells (Anjana and Kaushik 2014).

To enhance the efficiency of H2 production in A. halophytica, we investigated H2 production by cells immobilized with various support materials. H2 production of immobilized cells was optimized under various physiological conditions such as concentration and size of support materials, cell concentration, nutrient and mineral concentrations, pH of medium, incubation temperature, size of container, and headspace volumes. Finally, H2 production of immobilized cells for three cycles was also investigated.

Materials and methods

Cyanobacterial strain and growth condition

The halotolerant unicellular cyanobacterium Aphanothece halophytica was cultivated in a 250-mL Erlenmeyer flask containing 100 mL of BG11 medium (pH 7.4) (Rippka et al. 1979) supplemented with Turk Island salt solution (Garlick et al. 1997). The initial cell concentration was adjusted to OD730 of approximately 0.1. The cyanobacterial cells were cultivated in an incubator shaker at a speed of 120 rpm at 30 °C under the light intensity of 30 μmol photons m−2 s−1 for 7 days.

Cell immobilization with various support materials

Aphanothece halophytica cells grown in BG11 supplemented with Turk Island salt solution for 7 days were harvested by centrifugation at 8000×g at 4 °C for 10 min, washed twice and resuspended in NaNO3-deprived BG11 medium (BG110) supplemented with Turk Island salt solution. The cyanobacterial cells were immobilized with three different types of support materials: agar (Difco, USA), agarose (Bio Whittaker Molecular Application, USA), and κ-carrageenan (Marcel Carrageenan, Philippines). The cell suspension was added to the autoclave-sterilized agar, agarose, and κ-carrageenan solutions in water bath at 50 °C and mixed by vortexing. A final cell concentration was adjusted to 1 mg dry cell weight per mL of gel solution whereas the final concentration of agar, agarose, and κ-carrageenan solutions was 1.5% (w/v) in BG110 supplemented with Turk Island salt solution. The mixture was cooled to solidify the gel before cutting into square cubes of 0.5 × 0.5 × 0.5 (w × l × h) cm3.

Optimization of cell immobilization for H2 production

Aphanothece halophytica cells were immobilized with the selected support material. In this study, concentrations of support material (1–3% (w/v)) and cyanobacterial cells (0.2–5 mg dry cell weight mL−1) including volumetric sizes of cubes with immobilized cells (0.0156–1 cm3) were optimized. The immobilized cells of A. halophytica were transferred into a 20-mL glass vial and incubated in BG110 supplemented with Turk Island salt solution for 24 h under the light before measuring H2 production using a gas chromatograph.

Effect of nutrient and mineral concentrations on H2 production rate by immobilized cells

Aphanothece halophytica cells immobilized with the selected support materials were soaked in BG110 (pH 7.4) supplemented with Turk Island salt solution containing various independent concentrations of nutrients and minerals, 0–176 mM NaNO3, 0.25–1 M NaCl, 0–150 mM MgSO4·7H2O, 0–400 μM Fe3+, or 0–100 μM Ni2+. The immobilized cells were transferred into a 20-mL glass vial containing 9 mL of indicated media and subsequently incubated at 30 °C under light intensity of 30 μmol photons m−2 s−1 for 24 h. After incubation, immobilized cells were purged with argon gas to enter anaerobiosis and incubated in the dark for 24 h. H2 production measurement of cells was determined from the headspace in vials. In addition, the effects of pH of medium (pH 6–10) and incubation temperature (20–45 °C) on H2 production by immobilized cells were also investigated.

Effect of volumetric size of glass vial, immobilized cells, and headspace on H2 production rate by immobilized cells

The immobilized cells of A. halophytica were transferred into two volumetric sizes of glass vial (20 and 120 mL) and incubated in BG110 supplemented with Turk Island salt solution for 24 h under the light before measuring H2 production using a gas chromatograph. The effects of different volumetric sizes of immobilized cells and headspace on H2 production rate were also investigated.

Cycle of H2 production by immobilized cells

The immobilized cells and free cells of A. halophytica were transferred into a 120-mL glass vial and incubated in BG110 supplemented with Turk Island salt solution at 30 °C under light intensity of 30 μmol photons m−2 s−1 for 24 h. Cells were purged with argon gas and incubated at 40 °C under darkness. H2 production of cells was determined for three cycles (36 h for each cycle). After finishing H2 production measurement in each cycle, the medium in glass vial was removed and replaced with the fresh medium. In some cases, different volumes (30, 50, and 100%) of immobilized cells after the first cycle were removed and replaced with the same respective volume of fresh immobilized cells for the analysis of H2 production in the second and third cycles. For free cell experiments, the culture after each cycle was centrifuged to harvest the cells before suspension with the new fresh medium for the next cycle. Similarly, the different volumes (30, 50, and 100%) of free cell culture after the first cycle were removed and replaced with the same respective volume of fresh free cells from 7-day culture before analyzing H2 production in the second and third cycles. Then, cells were purged with argon gas to remove O2. H2 production was analyzed for three cycles.

Measurement of H2 production

A total of 6 cm3 cubes containing immobilized cells with 6 mg dry cell weight (equivalent to 1 mg dry cell weight per mL of gel solution) were transferred into a 20-mL glass vial containing 9 mL of BG110 (pH 7.4) supplemented with Turk Island salt solution. Glass vials were sealed with a rubber stopper with an aluminum rim. The cubes with immobilized cells were incubated in BG110 supplemented with Turk Island salt solution at 30 °C under light intensity of 30 μmol photons m−2 s−1 for 24 h. Then, O2 in the glass vial was removed by purging argon gas for 10 min. Immobilized cells were then incubated under darkness at 30 °C for 24 h. H2 evolution of immobilized cells was determined by analyzing the headspace gas phase using a gas chromatograph (Hewlett-Packard HP5890A, Japan) with a molecular sieve 5 Å 60/80 mesh packed column and thermal conductivity detector as previously described (Taikhao et al. 2013). H2 production was expressed as μmol H2 per g dry weight per hour. Each H2 production determination was performed with triplicate measurements.

Dry cell weight determination

Dry cell weight of A. halophytica was measured by filtration of 10 mL cell suspension through a GF/C glass microfiber filter (47 mm diameter) (Whatman, UK). The filter containing cells was washed twice with distilled water and dried at 70 °C in an oven before weighing using a four-digit balance. This drying step was repeatedly performed until a constant weight was obtained. The dry cell weight was calculated from the difference between the weight of filter with and without cells.

Statistical data analysis

The values of H2 production by immobilized cells were statistically compared using a one-way analysis of variance (ANOVA) with Duncan’s multiple range test. Differences between treatment are considered significant at a level of 0.05 (p < 0.05). Data were analyzed using IBM SPSS statistics 23 (IBM Corp, USA).

Results

Effect of support material types on H2 production by immobilized cells

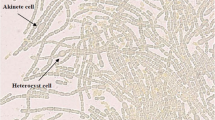

H2 production by A. halophytica immobilized cells with three support materials (agar, agarose, and κ-carrageenan) was investigated. The square cubes containing cells immobilized with agar, agarose, and κ-carrageenan were prepared and used for the study. H2 production of immobilized cells and free cells incubated in BG110 under darkness was monitored up to 7 days as shown in Fig. 1. For A. halophytica cells immobilized with 1.5% (w/v) agar, maximum accumulated H2 at 164.08 ± 4.76 μmol H2 g−1 dry weight was observed after anaerobic dark incubation for 2 days, followed by cells immobilized with 1.5% (w/v) κ-carrageenan and 1.5% (w/v) agarose, respectively. The results indicated that agar had the highest potential as the support material for H2 production by immobilized cells of A. halophytica. At day 2 of anaerobic dark incubation, H2 production by agar-immobilized cells was approximately fivefold higher than that by free cells (Fig. 1). It should be noted that agar-immobilized cells had the highest rate of H2 production at 6.16 ± 0.08 μmol H2 g−1 dry weight h−1 after 1 day of anaerobic dark incubation. Agar-immobilized cells were used for optimization of H2 production in further experiments.

Effect of support material types on H2 accumulation by immobilized cells of A. halophytica under N deprivation. Harvested cells from 7-day culture suspended in N-deprived medium were immobilized with various support material types at 1.5% (w/v) concentration. The cell concentration was fixed at 1 mg dry cell weight per mL of gel solution. The cubes with immobilized cells were incubated at 30 °C in the light for 24 h before determination of H2 production by further incubating the cubes for another 24 h in the dark. Free cell experiments were done in the same manner but without a procedure of cell immobilization

Effect of agar concentration on H2 production by immobilized cells

Aphanothece halophytica cells were immobilized with either 1, 1.5, 2, 2.5, or 3% (w/v) agar concentration. The results showed that H2 production of agar-immobilized cells was increased with an increase of agar concentrations. Cells immobilized with 3% (w/v) agar produced the highest H2 production of 19.72 ± 0.76 μmol H2 g−1 dry weight h−1 after anaerobic dark incubation for 1 day (Fig. 2a). Agar concentration lower than 1% (w/v) was difficult to handle due to its soft gel texture. On the other hand, some obstacles such as a lot of bubbles, high viscosity, and too rapid solidification were encountered when agar concentrations higher than 3% (w/v) were used. Thus, the final 3% (w/v) agar concentration was used for further experiments.

Effect of agar concentration, cell concentration, and volumetric size of agar cubes with immobilized cells on H2 production by A. halophytica under N deprivation. The agar cubes at various concentrations (a) with immobilized cells at 1 mg dry cell weight per mL gel solution were incubated at 30 °C in the light for 24 h before determination of H2 production by further incubating the cubes for another 24 h in the dark. H2 production was also measured in 3% (w/v) agar-immobilized cells with various cell concentrations (b) and various volumetric sizes of cubes with immobilized cells (c). Data are means ± SD (n = 3). Different letters indicate the significant difference, and the same letter indicates no significant difference according to Duncan’s multiple range tests at p < 0.05

Effect of cell concentration on H2 production by agar-immobilized cells

H2 production rate by agar-immobilized cells with various final cell concentrations at 0.2, 0.5, 1, 2, 3, and 5 mg dry cell weight mL−1 was determined under dark anaerobic condition. The results showed that an increase in cell concentration resulted in a decrease of H2 production (Fig. 2b). Agar-immobilized cells containing 0.2 mg dry cell weight mL−1 gave the highest H2 production of 38.85 ± 1.91 μmol H2 g−1 dry weight h−1 after anaerobic dark incubation for 1 day (Fig. 2b). Thus, the final cell concentration of 0.2 mg dry cell weight mL−1 was used for further experiments.

Effect of volumetric size of cubes with agar-immobilized cells on H2 production

Agar gels cut into the square cubes with the same sizes of width, length, and height at 0.25, 0.50, 0.75, and 1 cm, corresponding to volumetric sizes of 0.0156, 0.125, 0.422, and 1 cm3, respectively, were used for H2 production experiments. The cubes of agar-immobilized cells with volumetric size of 0.125 cm3 showed the highest H2 production of 39.14 ± 1.51 μmol H2 g−1 dry weight h−1 after anaerobic dark incubation for 1 day (Fig. 2c). This volumetric size was used for further experiments.

Effect of nutrient and mineral concentrations on H2 production by immobilized cells

Aphanothece halophytica cells entrapped in 3% (w/v) agar gels with final cell concentration of 0.2 mg dry cell weight mL−1 were incubated in BG110 (pH 7.4) supplemented with Turk Island salt solution containing various concentrations of NaNO3, NaCl, MgSO4·7H2O, Fe3+, and Ni2+. Under various NaNO3 concentrations, agar-immobilized cells incubated in BG11 without NaNO3 gave the highest H2 production of 39.26 ± 0.38 μmol H2 g−1 dry weight h−1 (Table 1). When NaNO3 concentration was increased, H2 production by agar-immobilized cells was markedly decreased (Table 1). Under various NaCl concentrations, the highest H2 production of 39.09 ± 4.29 μmol H2 g−1 dry weight h−1 was obtained in immobilized cells incubated in BG110 containing 0.5 M NaCl (Table 1). H2 production by immobilized cells was severely suppressed in cells incubated in BG110 containing 1 M NaCl (Table 1). Under various concentrations of MgSO4·7H2O, Fe3+, and Ni2+, H2 production was highest in immobilized cells incubated in BG110 containing 30 mM MgSO4·7H2O, 4 μM Fe3+, or without Ni2+. Too high concentration of these chemicals decreased H2 production of immobilized cells (Table 1).

Effect of pH of medium and temperature on H2 production by immobilized cells

The 3% (w/v) agar cubes containing 0.2 mg dry cell weight mL−1 were incubated in BG110 supplemented with Turk Island salt solution whose pH was varied from 6 to 10 (pH 7.4 was used as control pH) at 30 °C and subjected to dark fermentative H2 production assay. The results showed that the highest H2 production of 39.13 ± 1.15 μmol H2 g−1 dry weight h−1 was found in immobilized cells incubated in medium at pH 7.4 under anaerobic dark incubation for 1 day (Fig. 3a). No significant differences with 95% confidence level of H2 production were found in agar-immobilized cells incubated in medium at pH 7.4 and 8.0. Agar-immobilized cells at pH 6.0 showed the lowest H2 production (Fig. 3a). To investigate the effect of temperature on H2 production, agar-immobilized cells were incubated in BG110 supplemented with Turk Island salt solution (pH 7.4) under darkness at temperature ranging from 20 to 45 °C. The highest H2 production of 54.30 ± 1.38 μmol H2 g−1 dry weight h−1 was observed in immobilized cells incubated at 40 °C under anaerobic dark incubation for 1 day (Fig. 3b). H2 production was decreased when immobilized cells were incubated at higher or lower temperature than 40 °C (Fig. 3b).

Effect of pH of medium (a) and incubation temperature (b) on H2 production by immobilized cells of A. halophytica under N deprivation. Cells were immobilized with 3% (w/v) agar and final cell concentration was 0.2 mg dry cell weight per mL of gel solution. The agar cubes of immobilized cells were incubated in BG110 at various pH, 30 °C in the light for 24 h before determination of H2 production by further incubating the cubes for another 24 h in the dark (a). For H2 production of A. halophytica under various temperatures, 3% (w/v) agar cubes with immobilized cells were incubated in BG110 at pH 7.4, 30 °C in the light for 24 h before determination of H2 production by further incubating the cubes at various temperatures for another 24 h in the dark (b). Data are means ± SD (n = 3). Different letters indicate the significant difference, and the same letter indicates no significant difference according to Duncan’s multiple range tests at p < 0.05

Effect of volumetric size of glass vial, immobilized cells, and headspace on H2 production by agar-immobilized cells

The cubes of agar-immobilized cells with total volumes of 6 and 36 cm3 were transferred to 20- and 120-mL glass vials containing 9 and 54 mL of BG110 supplemented with Turk Island salt solution, respectively (the volumetric ratio of immobilized cells, medium, and headspace was 6:9:5). H2 production of immobilized cells was measured under dark anaerobic condition at 40 °C for 24 h. The results revealed that immobilized cells in the 120-mL glass vial gave higher H2 production than those in the 20-mL glass vial (Table 2), indicating the significant effect of container size on H2 production by immobilized cells. Interestingly, agar-immobilized cells in the 120-mL glass vial showed long-term H2 production of 2169.87 ± 191.66 μmol H2 g−1 dry weight after 3 days of anaerobic dark incubation, twofold higher than that produced by immobilized cells in the 20-mL glass vial (Table 2). To investigate the effect of immobilized cell volume on H2 production, cubes of agar-immobilized cells with total volumes of 15, 24, 36, and 60 cm3 were transferred to 120-mL glass vials and medium was added into vials with the different volumes in order that headspace volume was fixed at 30 mL. The results showed that lower immobilized cell volume gave higher H2 production (Table 2). The 15-cm3 cube of agar-immobilized cells gave the highest H2 production of 135.54 ± 1.92 μmol H2 g−1 dry weight h−1 with the maximum H2 production yield of 4410.88 ± 56.84 μmol H2 g−1 dry weight at 3 days of anaerobic dark incubation (Table 2). To study the effect of headspace volume on H2 production, immobilized cells with a total volume of 36 cm3 were transferred to a 120-mL glass vial and medium was added into vials with the different volumes in order that headspace volume was different. It was shown that at the same volume of immobilized cells, the differences of headspace volume affected H2 production. The results showed that an increase in headspace volume led to an increase of both H2 production rate and H2 production yield of immobilized cells (Table 2).

Cycle of H2 production by immobilized cells

H2 production by agar-immobilized cells and free cells was investigated for three cycles. H2 production of agar-immobilized cells was approximately two- to threefold higher than that of free cells (Fig. 4a-d). In each cycle of H2 production, agar-immobilized cells showed the highest H2 production after 24 h of anaerobic dark incubation (Fig. 4a-d). After that, little or no increase of H2 production was detected. When the immobilized cells were repeatedly used in the second and third cycles, H2 production was decreased (Fig. 4a). However, replacement of 30, 50, and 100% of the immobilized cells after the first cycle with the same respective volume of newly fresh immobilized cells resulted in the stability of H2 production by immobilized cells in the second and third cycles (Fig. 4b-d ). The replacement with all newly fresh immobilized cells gave the maximum H2 production in cycles 2 and 3 comparable with that found in cycle 1 (Fig. 4d). Interestingly, 50% of immobilized cell replacement caused similar H2 production in cycle 2 as compared with that in cycle 1 (Fig. 4c).

H2 production cycles by the cubes with agar-immobilized cells of A. halophytica under N deprivation. Cells were immobilized with 3% (w/v) agar and final cell concentration was 0.2 mg dry cell weight per mL of gel solution. The cubes were incubated at 30 °C in the light for 24 h before determination of H2 production in the dark for three cycles (36 h for each cycle). After finishing each H2 production cycle, the old medium was removed and replaced with a fresh medium. The cubes of immobilized cells were used in another two cycles of H2 production without a replacement with fresh cubes of immobilized cells (a) and with 30% (b), 50% (c), and 100% (d) replacement with fresh agar cubes in cycles 2 and 3. The fresh agar cubes with immobilized cells were earlier adapted in N-deprived medium at 30 °C under the light for 24 h. Free cell experiments were done in the same manner but without a procedure of cell immobilization

Discussion

In this study, H2 production of unicellular halotolerant cyanobacterium A. halophytica immobilized with the three support materials (agar, agarose and κ-carrageenan) was higher than that of free cells (Fig. 1). The immobilization of cells on support materials enables the cells to separate from a liquid phase, thus protecting bidirectional hydrogenase of the cells from O2, a strong cyanobacterial hydrogenase inhibitor, in an external environment. As a result of uninhibited hydrogenase activity, an increase of H2 production could be observed.

In our immobilized system we used BG110 supplemented with Turk Island salt solution as a solution for suspension of cyanobacterial cells and solubility of agar, agarose and κ-carrageenan gels. This BG110 medium lacking nitrogen sources has been shown as an optimal medium for maximizing H2 production by A. halophytica (Taikhao et al. 2013). Among all support materials cells immobilized with agar gave the highest H2 production compared with cells immobilized with other support materials (Fig. 1). In addition, agar gel showed a high stability when solubilized in BG110 supplemented with Turk Island salt solution. It has been reported that agar had an advantage with regard to gel solidity and stability under both alkaline and acidic conditions, and even in the presence of salts, minerals, and chelating agents (Scott 2012). For carrageenan gel formation, NaCl in the medium might decrease the strength of carrageenan gel as previously reported (Nguyen et al. 2014), resulting in a low stability of carrageenan gel. Likewise, agarose gel also had lower stability than agar gel (Semenchuk et al. 2000). It is highly likely that cells immobilized in a low strength or less stable gel may leak from the gel, leading to a decreased H2 production. In this study, agar-immobilized cells showed higher H2 production than alginate-immobilized cells as previously reported (Pansook et al. 2016). Our results were consistent with a previous study showing that the average H2 production by 1.5% (w/v) agar-immobilized blocks of non-diazotrophic cyanobacterium Oscillatoria subbrevis strain 111 was slightly higher than that by 1.5% (w/v) alginate-immobilized cells (Kumar et al. 1991). On the other hand, in filamentous cyanobacterium Lyngbya perelegans, H2 production by 2% (w/v) alginate-immobilized cells was slightly higher than that by 2% (w/v) agar-immobilized cells (Anjana and Kaushik 2014). Moreover, 2% (w/v) carrageenan-immobilized cells of heterocystous cyanobacterium Anabaena N-7363 had slightly higher H2 production than 2.5% (w/v) agar-immobilized cells and 3% (w/v) alginate-immobilized cells (Karube et al. 1986). Therefore, it was suggested that the suitable type of support material for H2 production by immobilized cells is dependent on the species of cyanobacteria.

The 3% (w/v) agar-immobilized cells of A. halophytica gave the highest H2 production compared with 1, 1.5, 2 and 2.5% (w/v) agar-immobilized cells (Fig. 2 a). The results indicated that higher agar concentrations led to higher level of polymerization, thus resulting in a decrease of gel porosity. The reduced pore sizes of 3% (w/v) agar gel can hinder the access of O2 existing in the system. Therefore, bidirectional hydrogenase would be more active due to a decrease of O2. This led to an increase of H2 production in cells immobilized with high agar concentrations. In addition, an increase of agar concentration could enhance cell survival and mechanical stability of gel (Seol et al. 2011). Our results indicate that the suitable concentration of support material for immobilization is an important contributing factor for the improvement of H2 production by immobilized cells.

Further investigation was performed to study the effect of cell concentration on H2 production by 3% (w/v) agar-immobilized A. halophytica. Agar-immobilized cells containing 0.2 mg dry cell weight per mL of gel solution gave the highest H2 production rate (Fig. 2b). The lower H2 production rate by agar-immobilized cells of A. halophytica with higher cell concentrations might also be due to the diffusional problems of essential nutrients or minerals, thus reducing the ability of entrapped cells for effective exposure to available nutrients. This may lead to the reduction in metabolic activity of cells with the consequence of the reduced electrons flow towards bidirectional hydrogenase, resulting in a decrease of H2 production. In addition, higher cell concentrations in agar gel might lead to the competition of substrate binding and also an insufficient amount of substrate or cofactor. The high cell concentration of immobilized cyanobacterium L. perelegans has been reported to decrease the mechanical stability of immobilization system, further leading to the increased porosity which allowed for easier diffusion of O2 into the gel matrix that caused an inhibition of hydrogenase activity (Anjana and Kaushik 2014).

Not only the type of support material, but its volumetric size could also affect H2 production of the immobilized cells. The volumetric sizes higher than 0.125 cm3 showed a decrease of H2 production due to the difficulty of H2 diffusion in or out of the gel (Fig. 2c). Nevertheless, it should be noted that the optimal volumetric size of support material for high H2 production can vary depending on cyanobacterial species (Karube et al. 1986; Kumar et al. 1991; Rashid et al. 2009; Anjana and Kaushik 2014).

Immobilized cells of A. halophytica incubated in nitrate-free BG11 (BG110) supplemented with Turk Island salt solution showed the highest H2 production (Table 1). Under N deprivation, cyanobacteria reduce protein synthesis but rather accumulate glycogen within the cells. When cells are under anoxic condition, storage glycogen as a source of electron donor is degraded and the released electrons are used for H2 evolution by bidirectional hydrogenase activity (Troshina et al. 2002). Previous studies on H2 production by immobilized cells of cyanobacteria such as non-heterocystous filamentous Plectonema boryanum, unicellular Gloeocapsa alpicola CALU 743, and unicellular Synechocystis sp. PCC 6803 were also performed under nitrogen deprivation (Sarkar et al. 1992; Serebryakova and Tsygankov 2007; Touloupakis et al. 2016). The effect of nitrogen deprivation on H2 production by these immobilized cells was similar to that reported in free cells of several cyanobacterial strains such as Oscillatoria sp. Miami BG7 (Kumazawa and Mitsui 1981), G. alpicola (Serebryakova et al. 1998; Troshina et al. 2002), Arthrospira maxima (Ananyev et al. 2008), A. halophytica (Taikhao et al. 2013), and Anabaena siamensis TISTR 8012 (Taikhao and Phunpruch 2017).

The composition and concentration of some nutrients and mineral ions in medium play an important role in H2 production of cyanobacteria. H2 production by immobilized cells of A. halophytica was highest in BG110 containing either 0.5 M NaCl, 30 mM MgSO4·7H2O, 4 μM Fe3+ or 0 μM Ni2+ (Table 1). These concentrations of each compound were present in BG11 supplemented with Turk Island salt solution and were optimal for H2 production by free cells of A. halophytica (Taikhao et al. 2013). Due to the typical halophilic characteristic of A. halophytica, NaCl is required for intracellular metabolism and cell survival including optimal H2 production. In marine cyanobacterium Lyngbya sp. strain 108, the highest H2 production was observed in cells grown in medium containing 3% (w/v) or 0.5 M NaCl (Kuwada and Ohta 1989). Sulfur is a constituent of amino acids, cysteine and methionine, that are very important for the function of many enzymes and proteins, especially D1 protein which is essential for photosystem II. In this study, the sulfur deprivation did not promote H2 production by these immobilized cells. Since we focused on the dark fermentative H2 production by immobilized cells of A. halophytica, the lowering D1 protein as affected by sulfur deprivation played no role in dark fermentative H2 production. Iron and nickel ions are bimetallic cofactors of NiFe-hydrogenase (Peters et al. 2015). The availability of iron facilitates more electron transport towards hydrogenase to evolve H2 (Lin and Stewart 1997). However, in this study, an addition of nickel in the medium did not promote H2 production by immobilized cells of A. halophytica, possibly due to the toxicity of nickel to cyanobacterial cells (Babich and Stotzky 1983).

The headspace volume of glass vial was found to affect H2 production by agar-immobilized cells. When the same sizes of glass vial and immobilized cells were used, an increase in the headspace volume caused an increase in H2 production (Table 2), confirming that H2 production was dependent on the headspace volume. This increased H2 production could be due to the equilibrium of the bidirectional hydrogenase reaction favoring the production rather than the uptake when there is a larger headspace volume. These results were consistent with those in the three microalgal strains of Chlamydomonas reinhardtii (CC-125, CC-4169, and CC-4170) (Altimari et al. 2014). Interestingly, H2 production rate and H2 accumulation were maximum in immobilized cells with their lowest volumetric size (Table 2). This might be ascribed to the high efficiency of H2 diffusion when using a small volume of immobilized cells. This result was similar to that of the above study on the effect of cell concentration on H2 production.

Finally, to sustain H2 production, the re-use of immobilized cells of A. halophytica was determined for three cycles. H2 production of immobilized cells was evidently higher than that of free cells in all three cycles (Fig. 4). In addition, the repeated use of immobilized cells in all three cycles led to the lower H2 yield in cycles 2 and 3 (Fig. 4a). It is not clear as to what caused the decrease of H2 production by the free cells after the first cycle. It might be possible that cells were inactive and had decreasing amounts of the accumulated carbohydrates and reducing powers after 36 h of dark anaerobic incubation for the first cycle of H2 production. The replacement by fresh immobilized cells was a choice for sustainable H2 production by immobilized cells of A. halophytica. The 50% replacement by fresh immobilized cells gave similarly high H2 yield in cycle 2 to that found in cycle 1 (Fig. 4c). Much effort has been made to promote and sustain H2 production from immobilized cells incubated for several cycles. Until now, it has not been successful yet. This is probably due to the high O2 sensitivity of bidirectional hydrogenase of A. halophytica and limitation of support materials used for immobilization. H2 production of immobilized cells for many cycles has been previously studied in several species of cyanobacteria. Alginate-immobilized cells of wild type and ΔhupL mutant of Calothrix 336/3 prolonged H2 production over several cycles whereas suspension cultures reduced significantly H2 production after the first cycle (Leino et al. 2009). Agar-immobilized cells of Microcystis aeruginosa could produce H2 up to three cycles and H2 was stably generated for more than 40 h in each cycle (Rashid et al. 2009). Notably, Gloeocapsa alpicola CALU 743 immobilized in glass fiber produced H2 in a long-term cyclic regime and provided relatively stable H2 production over a period of not less than 20 days (Serebryakova and Tsygankov 2007).

In conclusion, cell immobilization clearly enhances H2 production efficiency in the unicellular halotolerant cyanobacterium A. halophytica. The type and concentration of support material for immobilization including cell concentration influence H2 production. BG110 supplemented with Turk Island salt solution contains suitable amount of nutrients and minerals for H2 production in immobilized cells. The optimal pH and incubation temperature were 7.4 and 40 °C, respectively. Higher size of container and headspace volume increases H2 production whereas higher volume of immobilized cells decreases H2 production. H2 production by agar-immobilized cells becomes lower after repeated use. Lastly, the replacement with fresh immobilized cells could help sustain H2 production in this cyanobacterial strain.

References

Altimari P, Di Caprio F, Toro L, Capriotti AL, Pagnanelli F (2014) Hydrogen photo-production by mixotrophic cultivation of Chlamydomonas reinhardtii: interaction between organic carbon and nitrogen. Chem Eng Trans 38:199–204

Ananyev G, Carrieri D, Dismukes GC (2008) Optimization of metabolic capacity and flux through environmental cues to maximize hydrogen production by the cyanobacterium “Arthrospira (Spirulina) maxima”. Appl Environ Microbiol 74:6102–6113

Anjana K, Kaushik A (2014) Enhanced hydrogen production by immobilized cyanobacterium Lyngbya perelegans under varying anaerobic conditions. Biomass Bioenergy 63:54–57

Babich H, Stotzky G (1983) Toxicity of nickel to microbes: environmental aspects. Adv Appl Microbiol 29:195–265

Bickerstaff GF (1995) Impact of genetic technology on enzyme technology. Genet Eng Biotechnol 15:13–30

Chen PC, Fan SH, Chiang CL, Lee CM (2008) Effect of growth conditions on the hydrogen production with cyanobacterium Anabaena sp. strain CH3. Int J Hydrog Energy 33:1460–1464

Freeman A (1984) Gel entrapment of whole cells and enzymes in crosslinked, prepolymerized polyacrylamide hydrazide. Ann N Y Acad Sci 434:418–426

Garlick S, Oren A, Padan E (1997) Occurrence of facultative anoxygenic photosynthesis among filamentous and unicellular cyanobacteria. J Bacteriol 129:623–629

Karube I, Ikemoto H, Kajiwara K, Tamiya E, Matsuoka H (1986) Photochemical energy conversion using immobilized blue-green algae. J Biotechnol 4:73–80

Kotay SM, Das D (2008) Biohydrogen as a renewable energy resource - prospects and potentials. Int J Hydrog Energy 33:258–263

Kumar S, Subhashini CHT, Polasa H (1991) Photoproduction of molecular hydrogen by an immobilized non-diazotrophic cyanobacterium, Oscillatoria subbrevis strain 111. Proc Indian Natl Sci Acad B57:89–94

Kumazawa S, Mitsui A (1981) Characterization and optimization of hydrogen photoproduction by saltwater blue-green algae, Oscillatoria sp. Miami BG7. I. Enhancement through limiting the supply of nitrogen nutrients. Int J Hydrog Energy 6:339–348

Kuwada Y, Ohta Y (1989) Hydrogen production and carbohydrate consumption by Lyngbya sp. (No. 108). Agric Biol Chem 53:2847–2851

Leino H, Kosourov SN, Saari L, Sivonen K, Tsygankov AA, Aro EM, Allahverdiyeva Y (2009) Extended H2 photoproduction by N2-fixing cyanobacteria immobilized in thin alginate films. Int J Hydrog Energy 37:151–156

Lin JT, Stewart V (1997) Nitrate assimilation by bacteria. Adv Microb Physiol 39:1–30

Nguyen BT, Nicolai T, Benyahia L, Chassenieux C (2014) Synergistic effects of mixed salt on the gelation of κ-carrageenan. Carbohydr Polym 112:10–15

Pansook S, Incharoensakdi A, Phunpruch S (2016) Hydrogen production by immobilized cells of unicellular halotolerant cyanobacterium Aphanothece halophytica in alginate beads. Asia Pac J Sci Technol 22:248–255

Perry JH (1963) Chemical engineers’ handbook. McGraw-Hill, New York

Peters JW, Schut GJ, Boyd ES, Mulder DW, Shepard EM, Broderick JB, Adams MW (2015) [FeFe]-and [NiFe]-hydrogenase diversity, mechanism, and maturation. Biochim Biophys Acta-Mol Cell Res 1853:1350–1369

Phunpruch S, Taikhao S, Incharoensakdi A (2016) Identification of bidirectional hydrogenase genes and their co-transcription in unicellular halotolerant cyanobacterium Aphanothece halophytica. J Appl Phycol 28:967–978

Rashid N, Song W, Park J, Jin HF, Lee K (2009) Characteristics of hydrogen production by immobilized cyanobacterium Microcystis aeruginosa through cycles of photosynthesis and anaerobic incubation. J Ind Eng Chem 15:498–503

Reddy PM, Spiller H, Albrecht SL, Shanmugam KT (1996) Photodissimilation of fructose to H2 and CO2 by a dinitrogen-fixing cyanobacterium, Anabaena variabilis. Appl Environ Microbiol 62:1220–1226

Rippka R, Deruelles J, Waterbury J, Herdman M, Stanier R (1979) Generic assignments, strain histories and properties of pure cultures of cyanobacteria. J Gen Microbiol 111:1–61

Sarkar S, Pandey KD, Kashyap AK (1992) Hydrogen photoproduction by filamentous non-heterocystous cyanobacterium Plectonema boryanum and simultaneous release of ammonia. Int J Hydrog Energy 17:689–694

Scott CL (2012) The use of agar as a solvent gel in objects conservation. Objects Specialty Group Postprints 19:71–83

Semenchuk IN, Taranova LA, Kalenyuk AA, Il’yasov PV, Reshetilov AN (2000) Effect of various methods of immobilization on the stability of a microbial biosensor for surfactants based on Pseudomonas rathonis T. Appl Biochem Microbiol 36:69–72

Seol E, Manimaran A, Jang Y, Kim S, Oh Y-K, Park S (2011) Sustained hydrogen production from formate using immobilized recombinant Escherichia coli SH5. Int J Hydrog Energy 36:8681–8686

Serebryakova LT, Tsygankov AA (2007) Two-stage system for hydrogen production by immobilized cyanobacterium Gloeocapsa alpicola CALU 743. Biotechnol Prog 23:1106–1110

Serebryakova LT, Sheremetieva M, Tsygankov AA (1998) Reversible hydrogenase activity of Gloeocapsa alpicola in continuous culture. FEMS Microbiol Lett 166:89–94

Taikhao S, Phunpruch S (2017) Increasing hydrogen production efficiency of N2-fixing cyanobacterium Anabaena siamensis TISTR 8012 by cell immobilization. Energy Procedia 138:366–371

Taikhao S, Junyapoon S, Incharoensakdi A, Phunpruch S (2013) Factors affecting biohydrogen production by unicellular halotolerant cyanobacterium Aphanothece halophytica. J Appl Phycol 25:575–585

Taikhao S, Incharoensakdi A, Phunpruch S (2015) Dark fermentative hydrogen production by the unicellular halotolerant cyanobacterium Aphanothece halophytica grown in seawater. J Appl Phycol 27:187–196

Takabe T, Incharoensakdi A, Arakawa K, Yokota S (1988) CO2 fixation rate and RuBisCO content increase in the halotolerant cyanobacterium, Aphanothece halophytica, grown in high salinities. Plant Physiol 88:1120–1124

Tamagnini P, Leitão E, Oliveira P, Ferreira D, Pinto F, Harris DJ, Heidorn T, Lindblad P (2007) Cyanobacterial hydrogenases: diversity, regulation and applications. FEMS Microbiol Rev 31:692–720

Touloupakis E, Rontogiannis G, Benavides AMS, Cicchi B, Ghanotakis DF, Torzillo G (2016) Hydrogen production by immobilized Synechocystis sp. PCC 6803. Int J Hydrog Energy 41:15181–15186

Troshina O, Serebryakova LT, Sheremetieva M, Lindblad P (2002) Production of H2 by the unicellular cyanobacterium Gloeocapsa alpicola CALU743 during fermentation. Int J Hydrog Energy 27:1283–1289

Funding

This study was financially supported by research grant from the Office of the Higher Education Commission under the contract no. 2558A11862004 and also by research grant from Faculty of Science, King Mongkut’s Institute of Technology Ladkrabang. A.I. received research grant from the Thailand Research Fund (IRG5780008).

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Pansook, S., Incharoensakdi, A. & Phunpruch, S. Enhanced dark fermentative H2 production by agar-immobilized cyanobacterium Aphanothece halophytica. J Appl Phycol 31, 2869–2879 (2019). https://doi.org/10.1007/s10811-019-01822-9

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10811-019-01822-9