Abstract

In a seawater-based open pond microalgae cultivation system salinity will increase gradually over time due to evaporative loss. Continuous salinity increase would lead to non-optimal salinities which negatively affect the biomass and fucoxanthin productivity. To increase and maintain high overall biomass and fucoxanthin productivity, even in the non-optimal salinity zone, two cultivation methods for marine and halotolerant microalgae were carried out, co-cultivation and stepwise cultivation (sequential cultivation). Two fucoxanthin-producing diatoms, Chaetoceros muelleri (marine) and Amphora sp. (halotolerant), were cultivated at non-optimal salinities between 59 and 65‰. Stepwise cultivation showed approximately 63% higher total biomass and 47% higher fucoxanthin productivity than that of co-culture. The ability to reutilize culture media in the stepwise cultivation increases the sustainability of that method. The use of a stepwise culture regime, coupled with a regimen of gradually increasing salinity, provides the possibility of year round fucoxanthin production from microalgae.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

The algal carotenoid fucoxanthin is beginning to find use as a nutraceutical due to reported bioactivity against cancer, obesity, arthritis, diabetics, bone, cerebro-vascular, and inflammatory diseases (Kim et al. 2012b; Zarekarizi et al. 2018). Brown macroalgae are the current commercial source of this pigment (Kim et al. 2012a, b; Shannon and Abu-Ghannam 2017), although a few studies have found that macroalgal production is not an economically viable source because of a combination of low fucoxanthin content (Airanthi et al. 2011; Terasaki et al. 2012), and slow, seasonally dependent growth resulting in interruption to feedstock requirements (Zou 2005; Aitken et al. 2014). Recently, it has been found that chromist marine microalgae (both diatoms and haptophytes) could be an economically feasible source of fucoxanthin as they contain up to 12 times more fucoxanthin (per gram) than macroalgae (Kim et al. 2012a, b; Gómez-Loredo et al. 2016). Marine microalgae also offer additional advantages over macroalgae as a suitable source for commercial exploitation, like higher biomass productivity, accessibility to year round biomass, and higher tolerance to increased salinity (Borowitzka and Moheimani 2013).

Fucoxanthin-producing microalgae can be cultivated in open ponds (Griffiths and Harrison 2009; Indrayani 2017), the currently preferred method for large-scale cultivation. A major limitation of growing microalgal monocultures in outdoor ponds is the need to utilize freshwater to maintain the culture medium at the salinity for optimum biomass productivity of the particular species being cultivated. Due to the effects of evaporation, the salinity of the culture medium in outdoor ponds increases over time, deviating from the optimum level for high biomass production (Brand 1984; Sigaud and Aidar 1993; Gu et al. 2012). Maintaining high biomass productivity is particularly important as a recent study has shown a positive correlation between high biomass and high fucoxanthin production (Ishika et al. 2017). That work also indicated that high biomass productivity could be achievable under continuously increasing salinity condition by cultivating multiple microalgae at their optimal salinity range, i.e., marine species over the range of 35–55‰ and halotolerant species between 70 and 125‰.

To maintain high biomass productivity at salinities between the optimal salinity zone of the marine and halotolerant species, i.e., 55–70‰, a co-cultivation method could be a viable option. Such an approach has been shown to improve total biomass in microalgae culture. For example, Novoveská et al. (2016) cultivated Dunaliella sp. and Phaeodactylum tricornutum together to produce high biomass. This production technique has yet to be examined for fucoxanthin production from microalgae.

One potential issue with a co-cultivation strategy is the competition between two species that could lead to a reduction in the total biomass productivity of the culture. Therefore, stepwise cultivation, i.e., cultivation of one species after another, also offers a possible approach for continuous production of fucoxanthin containing biomass. In a stepwise culture system, it would be desirable to grow the second species in spent culture media of the initial species. This would minimize the loss of nutrients and the requirement for fresh media leading to a total decrease in the cost of continuous biomass production.

The aim of the study was to investigate the possibilities for continuous, year round fucoxanthin production by comparing the biomass and fucoxanthin productivity of saline microalgae under co-cultivation and stepwise cultivation regimes.

Materials and methods

Species selection and general culture conditions

The marine and halotolerant diatoms Chaetoceros muelleri (CS 176) and Amphora sp. (MUR 258), respectively, were selected for this study as both are known to have high fucoxanthin levels (Ishika et al. 2017) and have been grown successfully in open ponds (Griffiths and Harrison 2009; Indrayani 2017). The origins of C. muelleri and Amphora sp. are Salton Sea, Salt Lake, CA, USA and Perth, Western Australia, respectively.

Natural seawater (Hillary’s Beach, WA, 33‰) was charcoal-filtered before preparing media (Guillard and Ryther 1962). Seawater was autoclaved and cooled before use in preparation of F + Si media (Guillard and Ryther 1962) by addition of sterile nutrient solutions (Online Resource 1). The cultures were grown at 25 ± 3 °C under 150 μmol photons m−2 s−1 irradiance on a 12 h:12 h light:dark cycle. Irradiance level was set based on the maximum photosynthetic (Pmax) rates for microalgae of the same genera (data not shown). The light:dark cycle was modeled on conditions likely to be found in outdoor cultivation in Geraldton, WA, Australia, where it is highly unlikely that a significant light period would extend for more than 12 h. Irradiance was measured with a Li-185B quantum meter (LI-COR Inc., USA) equipped with a PAR Li-190SB quantum sensor. The cultures were stirred using a 40-mm magnetic stirrer and the mixing speed was 0.2 s−1. The mixing speed was determined using the method of Moheimani (2013a) by measuring the time required for India Ink to mix completely in culture media (detailed procedure in Online Resource 5). The cultures were maintained in semi-continuous mode and every 72 h, a maximum 50% of the total culture volume was harvested depending on the cell density and the same amount of fresh medium was added to the harvested flask (Moheimani 2013b). After each harvest, the salinity of the culture medium was increased by 2‰ by adding salt (NaCl). The rate of salinity increase imitated the rate of salinity increase for open ponds located in Geraldton, WA, a potential site for large-scale microalgae cultivation (Boruff et al. 2015). The salinity of media was measured with an automated Atago refractometer (model PAL-03S).

Cultivation

Chaetoceros muelleri and Amphora sp. have been shown to exhibit high biomass productivity at salinity < 55‰ and > 55‰, respectively (Ishika et al. 2017). Both species were adapted to 55‰ salinity for a minimum of 2 weeks prior to the start of experiments under mono, co-, and stepwise culture conditions. All experiments were carried out in four replicates (n = 4).

During co-cultivation (Fig. 1), C. muelleri and Amphora sp. were cultivated together in 250-mL Erlenmeyer flasks containing 150 mL of culture. Co-cultivation was initiated from 55‰ salinity and carried out until one species was totally replaced by the other.

Under stepwise cultivation (Fig. 1), C. muelleri was grown between 55 and 59‰ in 250-mL Erlenmeyer flasks containing 150 mL culture. At 59‰ salinity, C. muelleri was harvested and the growth media were filtered using an Advantec filter (diameter 47 mm, pore size 0.45 μm). The filtrate was then used for cultivation of Amphora sp. from 59‰ salinity. It is to be noted that, after each harvest (after 72 h), the harvested culture volume was replaced by fresh culture medium to maintain the culture volume at 150 mL. The cultivation was continued until a significant increase in biomass productivity was achieved. Monocultures of each species were grown as a control under the same culture conditions described above.

The initial cell density was maintained between 6 and 10 × 104 cells mL−1 in mono, co-, and stepwise cultures. The harvesting technique and time were identical for all cultures.

Culture sampling

On each sampling day, a maximum of 50% of culture volume was harvested depending on the cell density as mentioned previously. Five milliliter of each of harvested microalgal sample was filtered through 2.5 μm GF/C filter (Whatman). The filters containing samples were rinsed with isotonic ammonium formate solution to remove residual salt as previously described by Fon Sing (2010). After filtration, the filters were folded and blotted to remove excess water from the filters. Freshly filtered samples were used to determine the biomass productivity. However, samples for fucoxanthin and lipid extraction were stored in plastic zip lock bags at − 80 °C until further analysis.

Determination of cell density, cell volume, biomass productivity, and specific growth rate

Cell density

The cell density was determined by using the standard hemocytometer method described in Moheimani et al. (2013). Microalgal samples were homogenized gently in a 5-mL glass tissue grinder to prevent large cells clumping together before counting. One drop of Lugol’s solution was added to the sample to immobilize the microalgal cells prior to loading a hemocytometer.

Cell volume

Samples were homogenized gently using a glass tissue grinder to prevent clumping. One drop of Lugol’s solution was added to the sample to immobilize the microalgal cells. One drop of sample was placed on a clean slide, covered with cover slip, and placed under a Leica Dialux 22 compound microscope. A top-mounted Tucsen 9 MP camera was used to take an image which was then downloaded with TSView 7 software. For each sample, at least 16 microalgal cells were examined. The ruler tool in the TSView 7 software was used to measure the cell parameters. Cell volume of each microalga was estimated using equations for cylindrical (C. muelleri) and half elliptic prism (Amphora sp.) microalgae as described by Hillebrand et al. (1999).

Biomass productivity

The organic dry weight (ash-free dry weight—AFDW) and organic biomass productivity were measured using the methods described in Moheimani et al. (2013). To determine dry weight (DW) and ash-free dry weight (AFDW), 5 mL of each microalgal culture was collected and filtered through a pre-weighed 2.5-μm GF/C filter paper (Whatman) using a Millipore filtration unit. Before filtration, the GF/C filters were washed in deionized water and dried at 75 °C for 24 h and the dry weights of the filters were determined. After filtration, the saline microalgal cells were rinsed with equal volumes of isotonic ammonium formate to remove excess salt from the filter paper. As all saline species were grown at different salinities, the concentration of ammonium formate was adjusted to match the osmolarity of the algal culture at different salinities (NaCl concentration) (Fon Sing 2010).

Specific growth rate

The specific growth rate (μ) was determined by measuring the doubling time in the exponential growth phase from semi-log cell density plots. The specific growth was calculated using the following equation from Moheimani et al. (2013):

where, d is the time taken to double the cell number (i.e., the doubling time).

Determination of maximum quantum yield (F v/F m)

The maximum quantum yield of PS II (Photosystem II) was measured for 20 min dark-adapted using a PAM fluorometer (Water-PAM, Walz) and represented as Fv/Fm, where Fv (= Fm − Fo). Fm represents the maximum fluorescence (chlorophyll) yield in dark-adapted cells following a short period of saturating light. Fo represents the minimum steady state fluorescence (chlorophyll) yield in dark-adapted cells. Fv thus represents the variation of chlorophyll fluorescence between the maximal fluorescence (Fm) signal of dark-adapted cells induced by saturating pulse and the minimal fluorescence (Fo) signal of dark-adapted cells (Cosgrove and Borowitzka 2010).

Fucoxanthin extraction and HPLC quantification

Fucoxanthin extraction and quantification were carried out using the methods detailed in Ishika et al. (2017). Briefly, the whole extraction process was performed in the dark with absolute ethanol (100%) to prevent the breakdown of pigment. Ethanol extracts were filtered through a 0.33-μm syringe filter and placed in 2-mL auto sampler vials with Teflon-coated lids. Samples were analyzed with a Shimadzu Prominence HPLC system equipped with an Apollo-C18 analytical column (5 μm, 4.6 mm × 150 mm; Grace Discovery Sciences) and a PDA detector. Fucoxanthin was monitored at an absorbance of 450 nm. The following mobile phases and gradients were used: Solvent A (0.5 M ammonium acetate in 85:15 v/v methanol:water), Solvent B (90:10, v/v acetonitrile:water), and Solvent C (100% ethyl acetate) and programmed as follows: 0–5 min 60:40 Solvent A:Solvent B isocratic 5–10 min linear gradient to 100 B; 10–20 min linear gradient from 100 B to 23:77 B:C, hold for 1 min, then to 100 C over 4 min (Louda et al. 1998). Re-equilibration of the HPLC column consisted of running 100 B for 1 min then gradient to 60:40 A: B over 4 min, hold for 5 min. Total time from injection to injection (including re-equilibration) was 35 min. Using pigment standards purchased from Nova-Chem, Melbourne, Australia (catalog number: PPS-FUCO), an external calibration curve was constructed and the peak area was used for quantification. Fucoxanthin productivity was determined by multiplying fucoxanthin content with biomass productivity and the value was expressed as mg L−1 d−1 of the sample (ash-free dry weight, AFDW).

Lipid extraction and quantification

Lipid was extracted and quantified using the method of Bligh and Dyer (1959) as described in Moheimani et al. (2013). Microalgae containing filters were placed inside plastic centrifuge tubes, treated with liquid nitrogen to rupture the cell wall, and left for half an hour to thaw. Ruptured cells were then crushed with 5.7 mL of a 2:1:0.8 (v/v/v) mixture of methanol:chloroform:deionized water until a smooth green paste was obtained. The lids of the tubes were then tightly screwed on to prevent evaporation of the solvent and the tubes were centrifuged at 3000 rpm for 10 min at room temperature. The supernatant was transferred to a 10-mL glass tube. The algal pellet was resuspended in 5.7 mL of the same solvent and mixed well by vortexing before centrifugation at 3000 rpm for 10 min and the supernatant was added to the first supernatant. Three milliliters of deionized water and 3 mL of chloroform were added to the combined supernatant and mixed before overnight storage in a dark, cool place to allow for phase separation. Following phase separation, the top phase (non-lipid components, methanol/water) was removed carefully with a very fine Pasteur pipette connected to a syringe and discarded. Residual water was removed by adding 6–8 drops of toluene to the remaining chloroform phase and mixing by hand. The upper toluene/water layer was then removed and lipid containing chloroform layer was transferred to a dry, pre-weighed 10-mL vial. The solvent was immediately evaporated on a heating plate at 38 °C under a stream of ultra pure N2 gas. After evaporation, vials were weighed immediately using analytical balance. Lipid weight was determined by subtracting the weight of the empty vial from the weight of the vials with lipid. Lipid productivity was determined by multiplying lipid content by biomass productivity (AFDW), and the value was expressed as mg L−1 d−1 of the sample (ash-free dry weight, AFDW).

Statistical analysis

Pearson’s correlations were used to determine the relationships between different parameters. One-way analysis of variance (ANOVA) and Tukey’s test were conducted to identify significant differences between cultivation methods. One-way repeated measure analysis of variance (rmANOVA) and Tukey’s test were used to test significant differences at different salinity conditions for a particular cultivation method. In each case, P value < 0.05 was considered significant with a sample size, n = 4. Statistical analyses were performed using Sigmaplot software (version 13.0).

Results

In order to find out the most efficient cultivation method for high fucoxanthin containing biomass production under gradually increasing salinity, first co-cultivation and then stepwise cultivation were undertaken. Both cultivation methods were compared to monocultures of both species to ascertain the most sustainable, effective, and productive procedure.

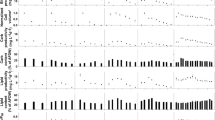

Monoculture

The biomass productivity trend in C. muelleri monoculture was different from that of Amphora sp. monocultures (Fig. 2). A gradual reduction in biomass productivity was observed in C. muelleri monoculture at an increased salinity. For instance, the biomass productivity of 24.3 mg L−1 d−1 was found at 55‰ salinity which was reduced by 95% at 69‰ salinity (1.2 mg L−1 d−1) (rmANOVA, P < 0.05). Pearson’s correlations showed that biomass productivity of C. muelleri monoculture was negatively correlated to increased salinity of the culture medium (Pearson’s correlation coefficient, r = − 0.815, P < 0.05). The cell density, cell volume, and specific growth rate of C. muelleri monoculture also mirrored the same trend as biomass productivity. Similarly, the highest fucoxanthin and lipid productivity of this alga were found at 55‰ salinity and the lowest productivity was seen at 69‰ salinity (r = − 0.74, P < 0.05). Fucoxanthin content per cell also showed the same pattern of that of productivity (Online Resource 6). The Fv/Fm value of C. muelleri monoculture was unchanged up to 65‰ after which it decreased rapidly (rmANOVA, P < 0.05) (Fig. 2). In addition, Fv/Fm values were found to be negatively correlated to increased salinity and positively correlated to biomass, fucoxanthin, and lipid productivities (Online Resource 2).

Biomass productivity, cell density, cell volume, specific growth rate, maximum quantum yield (Fv/Fm), fucoxanthin, and lipid productivity in monoculture and co-culture at increasing salinity. Means ± S.E., n = 4. (For significant differences in results see Online Resource 3). Filled circles indicate C. muelleri and open circles indicate Amphora sp

However, Amphora sp. monoculture showed a positive correlation between increased salinity and biomass productivity (r = 0.617, P < 0.05). Increasing culture medium salinity from 55 to 69‰ salinity resulted in 29% increase in biomass productivity (Fig. 2) (rmANOVA, P < 0.05). Under the same conditions, the maximum cell density also increased by 32% but the cell volume was found to be reduced (Fig. 2). Higher specific growth rate of this alga was achieved when grown at salinities above 63‰ (rmANOVA, P < 0.05). Fucoxanthin and lipid productivity in Amphora sp. monoculture also followed the same pattern as its biomass productivity (Fig. 2). The Fv/Fm values of Amphora sp. monoculture were found to be above 0.6 over the range of increased salinity and strongly positively correlated to salinity, biomass, fucoxanthin, and lipid productivity (Online Resource 2).

Co-culture

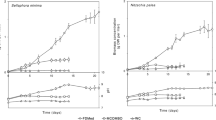

Total biomass productivity in the co-culture was a combination of that observed for the individual monocultures (Fig. 3). For instance, total biomass productivity of the C. muelleri and Amphora co-culture decreased by 84% when salinity increased from 55 to 67‰ as a result of a reduction in cell density, specific growth rate, and cell volume of C. muelleri (one-way ANOVA, P < 0.05). On the other hand, at 69‰, a rapid increase in Amphora cell density was observed with Amphora able to completely dominate the culture. The total biomass productivity of Amphora when grown in co-culture at 69‰ also showed 85% increase compared to that of at 55‰, which is similar to that observed in monoculture (Fig. 2). Basically, when salinity reached 69‰, the co-culture system returned to an Amphora monoculture as all C. muelleri cells were completely dead (Fig. 2). However, the total biomass productivity, cell density, and specific growth rate of the co-culture was 37, 35, and 46% lower than that of Amphora when grown as a monoculture (see Fig. 2). Fucoxanthin and lipid productivity were found to follow the same reduction pattern of biomass productivity (Pearson’s correlation coefficient, r = 0.655 (fucoxanthin productivity and biomass productivity) and r = 0.730 (lipid productivity and biomass productivity), P < 0.05). However, in co-culture, the Fv/Fm values were always higher than 0.6.

Biomass productivity, cell density, cell volume, specific growth rate, maximum quantum yield (Fv/Fm), fucoxanthin, and lipid productivity in stepwise culture and co-culture at increasing salinities. Means ± S.E., n = 4. (For significant differences in results see Online Resource 3). Filled circles indicate C. muelleri and open circles indicate Amphora sp

Stepwise culture

In stepwise culture, the reduction in biomass productivity compared to separate monocultures was still observed. However, the total biomass productivity was not as low as that recorded for co-culture conditions in the critical growth salinity range of 59–65‰ (Fig. 3). In fact, total biomass productivity was 63% higher when C. muelleri and Amphora were grown in the stepwise culture compared to co-culture conditions (one-way ANOVA, P < 0.005). Increased cell density (by 37%), higher specific growth rate (by 19%), and a larger cell volume (by 20%) of Amphora were also observed when grown in stepwise culture compared to co-culture (one-way ANOVA, P < 0.05) which is reflected in the higher total biomass productivity of the culture. Again, Fv/Fm values of C. muelleri and Amphora in stepwise culture were similar to that of their monocultures and Fv/Fm of Amphora was constantly above 0.6 while grown in the filtrate of C. muelleri (Fig. 3). The fucoxanthin productivity of Amphora when grown in stepwise culture was 46.6% higher than that of co-culture over the same salinity range between 59 and 65‰ (one-way ANOVA, P < 0.05) (Fig. 3). When algal cultures grown under stepwise cultivation strategy, a positive correlation was seen between fucoxanthin productivity and biomass productivity as well as specific growth rate (Pearson’s correlation coefficient, r = 0.819 (fucoxanthin and biomass productivity) and r = 0.694 (biomass productivity and specific growth rate), P < 0.05). Lipid productivity in stepwise culture was found to be approximately 12 mg L−1 d−1 throughout the period of increased salinity from 59 to 65‰ (Fig. 3), which was 54% more than that in co-culture (one-way ANOVA, P < 0.05).

Discussion

There have been several studies on the effect of salinity increase on microalgal growth, biomass, and secondary products (Sigaud and Aidar 1993; Takagi and Karseno 2006; Gu et al. 2012). However, to the best of our knowledge, this is the first study investigating the effect of gradual salinity increase in co-culture and stepwise cultivation of marine and halotolerant diatoms for fucoxanthin production. The effect of salinity on the biomass productivity of monoculture, co-culture, and stepwise culture is particularly important to delineate in the intermediate/transition salinity where C. muelleri is at the extreme upper limit of its salinity tolerance range and Amphora sp. is at the lower end of its salinity tolerance range. As fucoxanthin production is known to be positively correlated to biomass productivity in monoculture (Ishika et al. 2017), any changes in biomass productivity seen in co-culture or stepwise culture are likely to have an effect on the amount of fucoxanthin that can be extracted.

Monoculture

Biomass productivity of C. muelleri was found to decrease rapidly with increased salinity due to reduction in individual cell volume. This is consistent with the previous work of Takagi and Karseno (2006) and Ishika et al. (2018), where all marine species including diatoms showed reduced cell volume and specific growth rate under increased salinity conditions. The trend in specific growth rate of C. muelleri was also slightly downward as previously reported by Fon-Sing and Borowitzka (2016) working with euryhaline Tetraselmis spp. The same trends were also seen in the lipid and fucoxanthin productivity of C. muelleri. Decline in total productivity of these chemicals in the microalga mirrors the decline in biomass productivity, which is in accordance with Ishika et al. (2017).

In addition, maximum quantum yield (Fv/Fm) of C. muelleri monoculture was always less than 0.6 over the increased salinity range. Basically, Fv/Fm indicates the effect of stress on photosystem II (PSII) (Cosgrove and Borowitzka 2010). It is used to measure physiological stress or limitations on the growth of cells (Dao and Beardall 2016). If Fv/Fm values are higher than 0.6, it indicates that cells are not stressed or in “good health”; however, any value less than 0.6 confirms the stress (Bhola et al. 2016) In the present study, Fv/Fm values for C. muelleri monoculture were between 0.54 and 0.4 which indicates stress. According to Torzillo and Vonshak (2013), osmotic stress inhibits microalgal photosynthesis when grown under non-optimal salinity condition. This could be associated with the inhibition of quantum yield of PSII photochemistry due to an increase in noncyclic electron transport and non-photochemical quenching. Satoh et al. (1983) showed that salt stress decreases the excitation energy reaching PSII reaction centers and inhibits the oxidizing side of PSII that results in a decrease in PSII activity. All of these parameters indicated that the C. muelleri culture is stressed to the point of actual death at salinities above 65‰.

On the other hand, being a halotolerant species, Amphora sp. showed the opposite trend to C. muelleri in monoculture (Fig. 2). The total biomass productivity was increased by 62.4% compared to C. muelleri over the same salinity range which is in line with Ishika et al. (2017). Fv/Fm values were consistently between 0.6–0.7 indicating a healthy culture (Bhola et al. 2016). Again, the fucoxanthin productivity mirrors that of the biomass productivity. The lipid productivity increases more dramatically—almost exponentially—which is consistent with the literature (Ishika et al. 2018). These results indicated that the cultures of both species adapted to a 55‰ salinity behaved as expected.

Co-culture

Chaetoceros muelleri and Amphora sp. co-culture showed a total reduction trend in biomass productivity, cell density, cell volume, and specific growth rate compared to that of their monocultures. This total reduced growth under co-culture conditions could be due to the secretion of growth inhibitory substances by dying C. muelleri cells (Phatarpekar et al. 2000) (Borowitzka 2016). Evidence exists that some microalgal cells produce growth inhibitory substances when in direct competition or are placed under stressed conditions by abiotic factors (Jørgensen 1956; Imada et al. 1991; Yingying et al. 2008; Venâncio et al. 2017). According to Cermeño and Figueiras (2008) and Finkel et al. (2010), phytoplankton abundance, species composition, and competition between species could be a reason for reduced cell volume in mixed culture; and population abundance is found to be negatively correlated to species cell volume which is in line with the findings of the present study.

Fucoxanthin and lipid productivity showed exactly the same trends as biomass productivity further emphasizing that production of intracellular chemicals of interest is closely tied to biomass productivity (Fon-Sing and Borowitzka 2016; Ishika et al. 2017). Our results clearly indicated that the total biomass productivity dropped in co-culture compared to Amphora sp. monoculture. Further, C. muelleri culture collapsed in co-culture but the Fv/Fm values in co-culture were always consistent and well above 0.6. The statistical analysis indicated that co-culture Fv/Fm mirrors the Fv/Fm of Amphora sp. in monoculture (Online Resource 3). Considering that Amphora was in the co-culture from the start, this result is most likely due to that Water-PAM is only capable of capturing the overall signal of the microalgae in the co-culture and not the individual species Fv/Fm. This means that in the present study, we recorded the Fv/Fm values of Amphora sp. in the co-culture. That is why the Fv/Fm values in co-culture were always above 0.6.

Stepwise culture

During stepwise culture, the halotolerant Amphora sp. was grown in the filtrate of the marine C. muelleri. No negative effects on the growth or biochemical content of Amphora sp. were apparent using the recycled media. It could be possible that growth-retarding substances were absent in the filtrate of C. muelleri monoculture, under the stepwise culture protocol, as there was no interspecies competition to induce allelopathic chemical production (Borowitzka 2016). Similarly, Fv/Fm showed no effect of allelopathic chemicals and was consistently above 0.6 indicating a non-stressed culture. Again, high biomass productivity resulted in the production of high fucoxanthin and lipid in stepwise culture which is in accordance with the reports of Ishika et al. (2017) and Griffiths and Harrison (2009). Griffiths and Harrison (2009) showed a positive correlation between lipid and biomass productivity for 55 microalgae including C. muelleri and Amphora sp.

Conclusion

A stepwise cultivation method coupled with a gradually increasing salinity showed the possibility of maintaining high fucoxanthin productivity across a salinity range from marine to halotolerant (35–125‰). The stepwise cultivation protocol minimized reductions in biomass, fucoxanthin, and lipid productivities at intermediate salinities. Stepwise cultivation showed approximately 63, 47, and 54% higher total biomass, fucoxanthin, and lipid productivity, respectively, than that of co-culture. Stepwise cultivation is better at minimizing factors that negatively affect biomass productivity during co-cultivation e.g., salinity stress, competition between species, and production of growth inhibitory materials. The ability to reutilize culture media makes the stepwise protocol a sustainable, practical, and, potentially, cost-effective method for fucoxanthin production.

References

Airanthi M, Hosokawa M, Miyashita K (2011) Comparative antioxidant activity of edible Japanese brown seaweeds. J Food Sci 76:C104–C111

Aitken D, Bulboa C, Godoy-Faundez A, Turrion-Gomez JL, Antizar-Ladislao B (2014) Life cycle assessment of macroalgae cultivation and processing for biofuel production. J Clean Prod 75:45–56

Bhola VK, Swalaha FM, Nasr M, Kumari S, Bux F (2016) Physiological responses of carbon-sequestering microalgae to elevated carbon regimes. Eur J Phycol 51:401–412

Bligh EG, Dyer WJ (1959) A rapid method of total lipid extraction and purification. Can J Biochem Physiol 37:911–917

Borowitzka MA (2016) Chemically-mediated interactions in microalgae. In: Borowitzka MA, Beardall J, Raven JA (eds) The physiology of microalgae. Springer, Cham, pp 321–357

Borowitzka MA, Moheimani NR (2013) Sustainable biofuels from algae. Mitigat Adapt Strat Global Change 18:13–25

Boruff BJ, Moheimani NR, Borowitzka MA (2015) Identifying locations for large-scale microalgae cultivation in Western Australia: a GIS approach. Appl Energy 149:379–391

Brand LE (1984) The salinity tolerance of forty-six marine phytoplankton isolates. Estuar Coast Shelf Sci 18:543–556

Cermeño P, Figueiras FG (2008) Species richness and cell-size distribution size structure of phytoplankton communities. Mar Ecol Prog Ser 357:79–85

Cosgrove JJ, Borowitzka MA (2010) Chlorophyll fluorescence terminology: an introduction. In: Suggett DJ, Borowitzka MA, Prášil O (eds) Chlorophyll a fluorescence in aquatic sciences: methods and applications. Springer, Dordrecht, pp 1–17

Dao LH, Beardall J (2016) Effects of lead on growth, photosynthetic characteristics and production of reactive oxygen species of two freshwater green algae. Chemosphere 147:420–429

Finkel ZV, Beardall J, Flynn KJ, Quigg A, Rees TAV, Raven JA (2010) Phytoplankton in a changing world: cell size and elemental stoichiometry. J Plankton Res 32:119–137

Fon-Sing S, Borowitzka MA (2016) Isolation and screening of euryhaline Tetraselmis spp. suitable for large-scale outdoor culture in hypersaline media for biofuels. J Appl Phycol 28:1–14

Fon Sing S (2010) Strain selection and outdoor cultivation of halophilic microalgae with potential for large-scale biodiesel production. PhD Thesis, Murdoch University, Western Australia 221 pp

Gómez-Loredo A, Benavides J, Rito-Palomares M (2016) Growth kinetics and fucoxanthin production of Phaeodactylum tricornutum and Isochrysis galbana cultures at different light and agitation conditions. J Appl Phycol 28:849–860

Griffiths MJ, Harrison ST (2009) Lipid productivity as a key characteristic for choosing algal species for biodiesel production. J Appl Phycol 21:493–507

Gu N, Lin Q, Li G, Tan Y, Huang L, Lin J (2012) Effect of salinity on growth, biochemical composition, and lipid productivity of Nannochloropsis oculata CS 179. Eng Life Sci 12:631–637

Guillard RR, Ryther JH (1962) Studies of marine planktonic diatoms: I. Cyclotella nana Hustedt, and Detonula confervacea (Cleve) Gran. Can J Microbiol 8:229–239

Hillebrand H, Dürselen CD, Kirschtel D, Pollingher U, Zohary T (1999) Biovolume calculation for pelagic and benthic microalgae. J Phycol 35:403–424

Imada N, Kobayashi K, Tahara K, Oshima Y (1991) Production of an autoinhibitor by Skeletonema costatum and its effect on the growth of other phytoplankton. Nippon Suisan Gakkaishi 57:2285–2290

Indrayani I (2017) Isolation and characterization of microalgae with commercial potential. PhD Thesis, Murdoch University, Western Australia 214 pp

Ishika T, Bahri PA, Laird DW, Moheimani NR (2018) The effect of gradual increase in salinity on the biomass productivity and biochemical composition of several marine, halotolerant, and halophilic microalgae. J Appl Phycol 30:1453–1464

Ishika T, Moheimani NR, Bahri PA, Laird DW, Blair S, Parlevliet D (2017) Halo-adapted microalgae for fucoxanthin production: effect of incremental increase in salinity. Algal Res 28:66–73

Jørgensen EG (1956) Growth inhibiting substances formed by algae. Physiol Plant 9:712–726

Kim SM, Jung Y-J, Kwon O-N, Cha KH, Um B-H, Chung D, Pan C-H (2012a) A potential commercial source of fucoxanthin extracted from the microalga Phaeodactylum tricornutum. Appl Biochem Biotechnol 166:1843–1855

Kim SM, Kang S-W, Kwon O-N, Chung D, Pan C-H (2012b) Fucoxanthin as a major carotenoid in Isochrysis aff. galbana: characterization of extraction for commercial application. J Korean Soc Appl Biol Chem 55:477–483

Louda JW, Li J, Liu L, Winfree MN, Baker EW (1998) Chlorophyll-a degradation during cellular senescence and death. Org Geochem 29:1233–1251

Moheimani NR (2013a) Inorganic carbon and pH effect on growth and lipid productivity of Tetraselmis suecica and Chlorella sp (Chlorophyta) grown outdoors in bag photobioreactors. J Appl Phycol 25:387–398

Moheimani NR (2013b) Long-term outdoor growth and lipid productivity of Tetraselmis suecica, Dunaliella tertiolecta and Chlorella sp (Chlorophyta) in bag photobioreactors. J Appl Phycol 25:167–176

Moheimani NR, Borowitzka MA, Isdepsky A, Fon Sing S (2013) Standard methods for measuring growth of algae and their composition. In: Borowitzka MA, Moheimani NR (eds) Algae for biofuels and energy. Springer, Dordrecht, pp 265–284

Novoveská L, Franks DT, Wulfers TA, Henley WJ (2016) Stabilizing continuous mixed cultures of microalgae. Algal Res 13:126–133

Phatarpekar P, Sreepada R, Pednekar C, Achuthankutty C (2000) A comparative study on growth performance and biochemical composition of mixed culture of Isochrysis galbana and Chaetoceros calcitrans with monocultures. Aquaculture 181:141–155

Satoh K, Smith CM, Fork DC (1983) Effects of salinity on primary processes of photosynthesis in the red alga Porphyra perforata. Plant Physiol 73:643–647

Shannon E, Abu-Ghannam N (2017) Optimisation of fucoxanthin extraction from Irish seaweeds by response surface methodology. J Appl Phycol 29:1027–1036

Sigaud TCS, Aidar E (1993) Salinity and temperature effects on the growth and chlorophyll-α content of some planktonic aigae. Bol Inst Oceanogr 41:95–103

Takagi M, Karseno YT (2006) Effect of salt concentration on intracellular accumulation of lipids and triacylglyceride in marine microalgae Dunaliella cells. J Biosci Bioeng 101:223–226

Terasaki M, Narayan B, Kamogawa H, Nomura M, Stephen NM, Kawagoe C, Hosokawa M, Miyashita K (2012) Carotenoid profile of edible Japanese seaweeds: an improved HPLC method for separation of major carotenoids. J Aquat Food Prod Technol 21:468–479

Torzillo G, Vonshak A (2013) Environmental stress physiology with reference to mass cultures. In: Richmond A (ed) Handbook of microalgal mass cultures. Blackwell, Oxford, pp 90–113

Venâncio C, Anselmo E, Soares A, Lopes I (2017) Does increased salinity influence the competitive outcome of two producer species? Environ Sci Pollut Res 24:5888–5897

Yingying S, Changhai W, Jing C (2008) Growth inhibition of the eight species of microalgae by growth inhibitor from the culture of Isochrysis galbana and its isolation and identification. J Appl Phycol 20:315–321

Zarekarizi A, Hoffmann L, Burritt D (2018) Approaches for the sustainable production of fucoxanthin, a xanthophyll with potential health benefits. J Appl Phycol. https://doi.org/10.1007/s10811-018-1558-3

Zou D (2005) Effects of elevated atmospheric CO2 on growth, photosynthesis and nitrogen metabolism in the economic brown seaweed, Hizikia fusiforme (Sargassaceae, Phaeophyta). Aquaculture 250:726–735

Acknowledgements

We are thankful to Emeka G. Nwoba, PhD student, Algae R& D Centre, School of Veterinary and Life Sciences, Murdoch University, Western Australia, for his assistance in extracting fucoxanthin and lipid.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

ESM 1

(DOCX 31 kb)

Rights and permissions

About this article

Cite this article

Ishika, T., Laird, D.W., Bahri, P.A. et al. Co-cultivation and stepwise cultivation of Chaetoceros muelleri and Amphora sp. for fucoxanthin production under gradual salinity increase. J Appl Phycol 31, 1535–1544 (2019). https://doi.org/10.1007/s10811-018-1718-5

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10811-018-1718-5