Abstract

Worldwide, 9600 t of agar is produced annually. Meanwhile, 60% of the waste produced from the agar industry yearly do not get treated. Our present study aims to study the enzymatic saccharification of solid agar waste produced from two of the most widely used agarophytes in the agar industry, Gracilaria verrucosa and Gelidium latifolium. Gracilaria species are the most common raw material in the food grade agar industry, while Gelidium species are the most common raw material used for bacteriological and pharmaceutical purposes because of the high-quality agar that is produced from these species. Our results showed that waste generated from agar extraction still contained sugars which could be optimized by acid pretreatment and enzymatic saccharification. Gracilaria verrucosa resulted in a higher agar yield (35.15 ± 1.17%), but produced less agar waste (20.91 ± 0.43%) than G. latifolium. After sequential acid pretreatment and enzymatic saccharification of the agar waste, the agar waste hydrolysate of G. latifolium resulted in higher glucose, galactose, and ethanol production, and a higher ethanol yield (18.17 ± 0.75, 16.17 ± 2.07, and 10.83 ± 0.30 g L−1 and 0.33 g g−1, respectively) than G. verrucosa. The results from our present study may be used to optimize biorefinery utilization of G. verrucosa and G. latifolium.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

The main commercial use of red seaweed is as a source of hydrocolloids. The two main commercial hydrocolloids used in industry are agar and carrageenan. Hence, the agar and carrageenan industries have been developing rapidly in recent years. The seaweed industry produces many diverse seaweed products from hydrocolloids that have a projected total annual value of 1058 billion US$. Worldwide, agar production exceeds 14,500 t annually (Porse and Rudolph 2017).

Presently, there are several leading agar companies in the world and include Agarindo Bogatama in Indonesia, Green Fresh (Fujian) Foodstuff Co., in China, and Algas Marinas in Chile. These three leading agar companies, together with five agar companies in Morocco, Indonesia, Korea, Spain, and China, fulfill about 62% of the total world agar demand (McHugh 2003; Pambudi et al. 2010; Porse and Rudolph 2017).

Gracilaria and Gelidium species are found worldwide and are two principle agarophyte species that are used as raw materials in the agar industry. Gracilaria species are the most commonly used raw material in the food grade agar industry. Gelidium species are mainly used for bacteriological and pharmaceutical purposes because a higher-quality agar can be produced from Gelidium species than from Gracilaria species. Gelidium continues to be the most commonly chosen raw material to produce bacteriological and pharmaceutical grade agar because the agar produced has high gel strength (McHugh 1991; Bixler and Porse 2011).

During the agar extraction process an enormous amount of waste product is left over; this waste is called agar waste. Agar waste is a surplus non-value solid by-product generated from the agar industry that may still contain a large amount of polysaccharide material. Despite the fact that it has a negative impact on the environment, agar waste has the potential to be used as a raw material for bioethanol production. Previous studies on seaweed biomass have shown the potential of seaweed for bioethanol production (Adams et al. 2009; Choi et al. 2009; Park et al. 2012; Meinita et al. 2013; Hong et al. 2014). Our present study aims to determine if agar waste generated from the two main agar producing species, Gracilaria verrucosa and Gelidium latifolium, can be used for bioethanol production. As raw materials for agar extraction, these species are the two most commonly used agarophytes in the agar industry. We compared the amount of agar and waste produced by extracting agar from G. verrucosa and G. latifolium. We also determined the sugar content of the agar waste and assessed its potential for ethanol production. Our results show that the agar waste generated from G. verrucosa and G. latifolium during agar extraction can be used for ethanol production. Our biorefinery approach involves the utilization of G. verrucosa and G. latifolium agar waste. Utilization of agar waste will decrease the impact that seaweed utilization has on the environment.

Materials and methods

Agar waste material

The solid waste used in this study was generated by extracting agar from two agarophyte species, G. verrucosa and G. latifolium. Solid seaweed waste, which was collected during the agar extraction process, was dried using a freeze drier.

Preparation of agar waste

The three main steps of the agarophyte agar extraction procedure included leaching, filtration, and separation; however, the extraction method differed for each agarophyte species. Previous studies were done to optimize the extraction process and improve agar yield and quality. Hence, in this study, we used agar extraction methods that were optimized individually for G. verrucosa and G. latifolium. These methods were developed by Arvizu-Higuera et al. (2008) and Freile-Pelegrín et al. (1995) (Figs. 1 and 2). Agar yield was determined by the following equation:

Agar extraction from Gracilaria verrucosa. This figure was modified from Arvizu-Higuera et al. (2008)

Agar extraction from Gelidium latifolium. This figure was modified from Freile-Pelegrín et al. (1995)

Pretreatment

In our preliminary study, an optimized acid hydrolysis pretreatment method was applied to break down carbohydrates into mono-sugars. Sulfuric acid (H2SO4) was used as the catalyst in acid hydrolysis. Acid hydrolysis was done using 250-mL flasks. The samples consisted of 10 g of agar waste powder in 100 mL of 0.2 M H2SO4. The samples were hydrolyzed in an autoclave at 120 °C for 15 min (Meinita et al. 2012, 2015). The acid-hydrolyzed agar waste slurry was used for sugar content determination and the subsequent steps described below.

Enzymatic saccharification

The agar waste slurry that was pretreated by acid hydrolysis was used for enzymatic saccharification. For enzymatic saccharification of the agar waste, the type and concentration of enzyme and duration of the incubation period were optimized. Four commercial enzymes (Celluclast, Viscozyme, Cellic C Tec II, and Cellic H Tec II) and five mixed enzymes [Celluclast + Viscozyme (1:1), Cellic C tec II + Cellic H tec II (1:1), Viscozyme + Cellic H tec II (1:1), Celluclast + Cellic H Tec II, and Cellic C Tec II + Viscozyme + Cellic H Tec II (1:10:1)] were purchased from Sigma (Novozymes, Denmark) and added to a slurry of hydrolyzed agar waste. Various enzyme concentrations (0, 5, 10, 20, 30, and 40%) were applied to acid-hydrolyzed agar waste. To optimize the duration of the incubation period, the agar waste hydrolysate was incubated with the enzyme, and glucose and galactose production was measured after 0, 3, 6, 9, 12, 24, 36, and 72 h. The pH of the pretreated agar waste was adjusted to 5 before enzymatic saccharification was performed at 50 °C in a water bath shaking at 130 rpm for 72 h. The types of sugars in the enzymatic hydrolysate were evaluated by high-performance liquid chromatography (HPLC).

Microorganisms and medium

Prior to fermentation, the hydrolysate samples were neutralized using 10 N NaOH to reach pH 5. Saccharomyces cerevisiae ATCC 200062 was used for fermentation. The inoculum culture was prepared in yeast medium (10 g yeast extract, 6.4 g urea, and 20 g glucose per liter). The yeast suspension was incubated at 30 °C at 130 rpm in a shaking incubator. Fermentation was performed in triplicate in a 100-mL Erlenmeyer flask at a working volume of 50 mL. Samples were periodically removed for sugar and ethanol production measurements.

Sugar and ethanol determination

Galactose and glucose production were assessed by HPLC, which consisted of an Alltech IOA 1000 organic acid column and RI detector. The ethanol concentration was determined using a gas chromatography (GC) Agilent model 6890N Series equipped with a 2B-WAX column (Agilent, USA). The bioethanol yield was calculated using the following equation:

where Yp/s is the ethanol yield (g g−1), (EtOH)max is the highest ethanol concentration obtained during fermentation (g L−1), and [Sugar]ini is the total initial sugar concentration at the beginning of fermentation (g L−1). The theoretical ethanol yield percentage was calculated using the following equation:

where Y% is the theoretical ethanol yield (%) and 0.51 is the theoretical maximum ethanol yield per unit of hexose sugar from glycolytic fermentation (g g−1).

Results

Agar was the main polysaccharide extracted from G. verrucosa and G. latifolium. The agar yields from G. verrucosa and G. latifolium are summarized in Table 1. Gracilaria verrucosa resulted in a higher agar yield (35.15 ± 1.17%) than G. latifolium (23.64 ± 2.37%). On the other hand, G. latifolium produced more agar waste (28.64 ± 1.25%) than G. verrucosa (20.91 ± 0.43%). The agar yield of G. verrucosa was comparable to that of Gracilaria species from previous studies (Rebello et al. 1996, 1997; Mollet et al. 1998; Marinho-Soriano 2001; Arvizu-Higuera et al. 2008; Vergara-Rodarte et al. 2010). The agar yield of G. latifolium was also comparable to that of Gelidium species from previous studies (Lemus et al. 1991; Mouradi-Givernaud et al. 1993; Freile-Pelegrín et al. 1995). The agar yields from previous studies ranged from 13.4 to 39.5%. The yield and quality of agar varied depending on the species, environmental parameters, and extraction process. Agar extracted from Gracilaria species is typically more sulfated than that of Gelidium species; hence, alkali treatment is needed for desulfation to break down 3,6-anhydrogalactose.

Galactose and glucose after acid pretreatment

Acid hydrolysis is the most common method used to hydrolyze polysaccharides into simple saccharides, and is applied either as a chemical pretreatment method or a chemical hydrolyzing method. Our previous study showed that dilute acid hydrolysis using sulfuric acid was the most effective method for hydrolyzing red seaweed polysaccharides (Meinita et al. 2012, 2015).

The galactose and glucose content of agar waste acid hydrolysate is summarized in Table 1. The contents of galactose and glucose in agar waste were higher in G. latifolium (7.7 ± 0.44 and 0.3 ± 0.02 g L−1, respectively, based on dry weight) than in G. verrucosa.

Enzymatic saccharification optimization

Enzymatic saccharification is an important process in bioethanol production. In this process, polysaccharides are hydrolyzed into simple saccharides. Enzymatic saccharification has many benefits compared with chemical saccharification. In enzymatic saccharification, mild pH and temperature conditions are used. These mild conditions do not lead to the production of toxic and corrosive by-product compounds (Alvira et al. 2010). There are some important factors, such as pH and the type of enzyme, which may influence enzymatic saccharification (Wu et al. 2014). In this study, we considered these factors by optimizing the type and concentration of enzyme, and the duration of the incubation period.

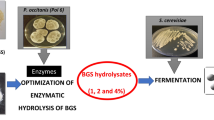

Comparison of single and mixed enzymes

We extracted agar from G. verrucosa and G. latifolium and subjected the agar waste by-product to enzymatic saccharification. The enzymatic saccharification optimization results from G. verrucosa and G. latifolium are shown in Figs. 3 and 4. Among the different single and mixed enzymes tested, an enzyme mixture consisting of Cellic C Tec II + Viscozyme + Cellic H tec II (1:10:1) was the most effective (Figs. 3(a) and 4(a)). Using this mixed enzyme on agar waste produced from G. verrucosa agar extraction, the highest galactose content was 7.60 ± 0.20 g L−1 and the highest glucose content was 14.33 ± 0.77 g L−1. From G. latifolium agar extraction, the highest galactose content was 17.83 ± 0.29 g L−1 and the highest glucose content was 16.67 ± 1.041 g L−1. Hence, we used this mixed enzyme to determine the optimal enzyme concentration and incubation time in subsequent experiments on agar waste generated from agar extraction from G. verrucosa and G. latifolium.

Effect of enzyme concentration

The results from the enzyme concentration optimization experiments are shown in Figs. 3(b) and 4(b). Generally, as the enzyme concentration increased from 0 to 20% (w/v) of biomass weight, the glucose yield also increased. This result shows that more cellulose was available that could be converted to glucose. However, when the substrate concentration was increased from 20 to 40% (w/v), the opposite result was observed and the glucose yield decreased. The highest galactose content from agar waste was obtained at an enzyme concentration of 20% and was 7.25 ± 0.05 g L−1 for G. verrucosa and 17.68 ± 0.71 g L−1 for G. latifolium. The highest glucose content from agar waste was obtained at an enzyme concentration of 20% and was 14.00 ± 0.50 g L−1 for G. verrucosa and 16.33 ± 0.58 g L−1 for G. latifolium. Hence, we can conclude that 20% were the optimal enzyme concentration. This results show that it is important to optimize the enzyme concentration. An enzyme concentration that is too high will cause a decrease in the sugar yield and low reaction mixture due to the high viscosity of the enzyme substrate.

Effect of enzyme incubation time

The results from the incubation time optimization experiments are shown in Figs. 3(c) and 4(c). A time course of enzymatic saccharification of agar waste generated from agar extraction from G. verrucosa revealed an increase in glucose release at 24 h, which remained almost constant thereafter. In contrast, a time course of enzymatic saccharification of agar waste generated from agar extraction from G. latifolium showed a significant increase in glucose release at 12 h. The pattern of galactose release differed between agar waste generated from G. verrucosa and G. latifolium. Galactose release from G. verrucosa was relatively constant. Based on this result, we can conclude that enzymatic saccharification is more efficient at generating glucose than galactose from agar waste generated from G. latifolium agar extraction. On the other hand, enzymatic saccharification effectively generated both galactose and glucose from agar waste generated from G. verrucosa and G. latifolium agar extraction. Both acid pretreatment and enzymatic saccharification effectively converted polysaccharides into sugar and increased the sugar content in agar waste hydrolysate. Agar waste from G. verrucosa and G. latifolium agar extraction showed different patterns of enzymatic saccharification. These differences may have been caused by different composition of compounds, which caused the enzymes to react differently. Figure 5 shows how enzymatic saccharification led to an increase in sugar compounds. The resulting enzymatic hydrolysate was used for ethanol fermentation.

Fermentation and ethanol production

We observed the time course of ethanol fermentation from agar waste hydrolysate from G. verrucosa and G. latifolium (Figs. 6 and 7). Based on the results from a previous study, S. cerevisiae ATCC 200062 was the best microorganism for bioethanol production from red seaweed (Meinita et al. 2015). During fermentation, this yeast utilizes major sugars, especially hexose sugars including glucose and galactose, which are generated from acid pretreatment and enzymatic saccharification. The enzymatic agar waste hydrolysate of G. verrucosa, which contained 7.26 g L−1 galactose and 14.03 g L−1 glucose, was fermented using S. cerevisiae ATCC 200062. The enzymatic agar waste hydrolysate of G. latifolium, which contained 16.17 g L−1 galactose and 18.17 g L−1 glucose, was also fermented using S. cerevisiae ATCC 200062.

Time course of ethanol production and galactose and glucose release from agar waste hydrolysate from G. verrucosa. Fermentation was performed in a 100-mL Erlenmeyer flask with a working volume of 50 mL at 30 °C with shaking at 130 rpm. All samples were taken aseptically. Values represent mean ± SD (n ≥ 3)

Time course of ethanol production and galactose and glucose release from agar waste hydrolysate from G. latifolium. Fermentation was performed in a 100-mL Erlenmeyer flask with a working volume of 50 mL at 30 °C with shaking at 130 rpm. All samples were taken aseptically. Values represent mean ± SD (n ≥ 3)

During ethanol fermentation of the agar waste hydrolysate from G. verrucosa, the ethanol production rate in the first couple of hours of the fermentation process was comparatively slow. However, after 12 h of fermentation, the ethanol production rate rapidly increased and reached a maximum ethanol yield of 0.29 g g−1 sugar. The glucose was entirely exhausted after 9 h, while galactose decreased but still remained until 96 h of fermentation. A maximum ethanol concentration of 5.52 g L−1 was obtained, which is 57% of the theoretical yield. During ethanol fermentation of the agar waste hydrolysate from G. latifolium, the highest ethanol concentration was 10.83 g L−1 at 12 h of fermentation, which is 64.2% of the theoretical yield of sugars (glucose and galactose). Glucose was completely consumed after 9 h, while galactose still remained until 96 h of fermentation.

Discussion

Agar is the main polysaccharide of agarophyte species. It is extracted from two main agarophyte species, Gracilaria and Gelidium. The characteristics of agar extracted from Gracilaria and Gelidium species differ. Agar isolated from Gracilaria species is typically more sulfated than that obtained from Gelidium species (Murano 1995). Our preliminary study showed that agarophyte seaweeds including Gelidium amansii, Gracilaria tenuistipitata, and Gracilariopsis chorda have the potential to be used for bioethanol production. Of these agarophytes, G. amansii produced the highest yield of total carbohydrate, reducing sugars, galactose, and ethanol (Meinita et al. 2013). Agarophytes are potential candidates for bioethanol production because they have high biomass and polysaccharide content, low lignin content, and are easy to culture. However, the utilization of agarophytes as raw materials for bioethanol production is challenging due to competition driven by the high demand for agar in industrial applications. New alternative raw materials for bioethanol production are needed to overcome this problem. Agar waste is one of the most promising candidates for bioethanol production because it still contains polysaccharides, and is an abundant and inexpensive biomass that will not compete with other applications. Furthermore, based on our study, the bioethanol yield from agar waste is comparable with previously reported values from Gracilaria and Gelidium species.

Agar waste generated as a by-product of agar extraction from G. verrucosa and G. latifolium is a promising biomass for bioethanol production because the agar industry has developed rapidly, and G. verrucosa and G. latifolium are the principle agarophyte species that are utilized as raw materials in the agar industry. According to Bixler and Porse (2011), total agar production is approximately 9600 t per year. Of this, 7650 t of agar was from Gracilaria species and 1950 t was from Gelidium species. Based on our study, we believe that agar extraction from G. verrucosa and G. latifolium will produce 20.91 and 28.64% agar waste, respectively.

Pretreatment, saccharification, and the fermentation process play important roles that determine the success of bioethanol production. The sugar content in agar waste was significantly increased when the optimum acid hydrolysis pretreatment conditions (10 g agar waste powder in 100 mL of 0.2 M H2SO4 at 120 °C for 15 min of hydrolysis) and optimum enzymatic saccharification conditions (20% mixed enzyme of Cellic C Tec II + Viscozyme + Cellic H tec II (1:10:1) for a 24-h incubation time) were used. After sequential acid pretreatment and enzymatic saccharification, the galactose and glucose content in agar waste from G. latifolium increased 2.1-fold and 60.6-fold, respectively. The galactose and glucose content in agar waste from G. verrucosa increased 1.2-fold and 70.1-fold, respectively. These results show that sequential acid pretreatment and enzymatic hydrolysis can increase the concentration of glucose and galactose. Therefore, sequential acid pretreatment and enzymatic hydrolysis is an efficient way to increase the content of fermentable sugar. We estimate that enzymatic saccharification can produce the equivalent of 133.57 t year−1 of galactose and 258.02 t year−1 of glucose for Gracilaria species, and 103.77 t year−1 of galactose and 116.61 t year−1 of glucose for Gelidium species.

We used Saccharomyces cerevisiae ATCC 200062 for bioethanol production. Saccharomyces cerevisiae converts galactose and glucose, which were produced from sequential acid pretreatment and enzymatic saccharification, to ethanol. The highest ethanol concentrations produced from agar waste hydrolysate were 5.52 g L−1 from G. verrucosa and 10.83 g L−1 from G. latifolium. We estimated that, at large scale, the ethanol yield from agar waste hydrolysate would be approximately 114.06 t year−1 from G. verrucosa and 72.07 t year−1 from G. latifolium. A schematic of bioethanol production is shown in Fig. 8. Ethanol production yield estimates from agar waste hydrolysate from G. verrucosa and G. latifolium are shown in Table 2.

Gracilaria verrucosa produced more agar, but less agar waste than G. latifolium. On the other hand, the sugar content (glucose and galactose), ethanol production, and ethanol yield from G. latifolium agar waste was higher than that of agar waste from G. verrucosa. This work showed that G. latifolium performed better than G. verrucosa with regards to sugar and ethanol production. However, the total world production of Gelidium is lower than that of Gracilaria. In 2015, the total amounts of production of Gracilaria and Gelidium were 114,100 and 11,100 t, respectively (Porse and Rudolph 2017). Gracilaria still plays an important role in the agar industry, as evidenced by the fact that approximately 91% of agar raw material were extracted from Gracilaria (Porse and Rudolph 2017). Three forms of commercial agar product, powder, square, and strip, are produced from Gracilaria and Gelidium species. Since 2009, Gracilaria agar powder production has increased compared with Gelidium agar powder production (Bixler and Porse 2011). This increase reflects the availability and feasibility of cultivated Gracilaria compared to wild Gelidium. There are some challenges to utilizing agar waste from Gelidium species as the raw material in bioethanol production. The main challenge is that Gelidium species have not been commercially cultivated. The supply of Gelidium species still depends on its availability in the wild. For large-scale utilization of Gelidium species for bioethanol production, it will be necessary to develop a cultivation method for Gelidium species, and begin a pilot study to develop a fermentation technique that will result in high bioethanol efficiency.

The main finding of this study is that agar waste, generated from agar extraction from Gracilaria and Gelidium species, can be used for bioethanol production. Currently, Gracilaria and Gelidium species are mainly used as a source of agar polysaccharide, and the waste and by-products of agar extraction are not utilized. The use of agar waste generated from agar extraction from Gracilaria and Gelidium species for bioethanol production is sustainable from both economic and environmental points of view.

References

Adams JM, Gallagher JA, Donnison IS (2009) Fermentation study on Saccharina latissima for bioethanol production considering variable pre-treatments. J Appl Phycol 21:569–574

Alvira P, Tomás-Pejó E, Ballesteros M, Negro MJ (2010) Pretreatment technologies for an efficient bioethanol production process based on enzymatic hydrolysis: a review. Bioresour Technol 101:4851–4861

Arvizu-Higuera DL, Rodríguez-Montesinos YE, Murillo-Álvarez JI, Muñoz-Ochoa M, Hernández-Carmona G (2008) Effect of alkali treatment time and extraction time on agar from Gracilaria vermiculophylla. J Appl Phycol 20:515–519

Bixler HJ, Porse H (2011) A decade of change in the seaweed hydrocolloids industry. J Appl Phycol 23:321–335

Choi D, Sim HS, Piao YL, Ying W, Cho H (2009) Sugar production from raw seaweed using the enzyme method. J Ind Eng Chem 15:12–15

Freile-Pelegrín Y, Robledo DR, García-Reina G (1995) Seasonal agar yield and quality in Gelidium canariensis (Grunow) Seoane-Camba (Gelidiales, Rhodophyta) from Gran Canaria, Spain. J Appl Phycol 7:141–144

Hong IK, Jeon H, Lee SB (2014) Comparison of red, brown and green seaweeds on enzymatic saccharification process. J Ind Eng Chem 20:2687–2691

Lemus A, Bird K, Kapraun DF, Koehn F (1991) Agar yield, quality and standing crop biomass of Gelidium serrulatum, Gelidium floridanum and Pterocladia capillacea in Venezuela. Food Hydrocoll 5:469–479

Marinho-Soriano E (2001) Agar polysaccharides from Gracilaria species (Rhodophyta, Gracilariaceae). J Biotechnol 89:81–84

McHugh DJ (1991) Worldwide distribution of commercial resources of seaweeds including Gelidium. Hydrobiologia 221:19–29

McHugh DJ (2003) A guide to the seaweed industry. Fisheries Technical Paper, FAO, Rome

Meinita MDN, Hong YK, Jeong GT (2012) Comparison of sulfuric and hydrochloric acids as catalysts in hydrolysis of Kappaphycus alvarezii (cottonii). Bioprocess Biosyst Eng 35:123–128

Meinita MDN, Marhaeni B, Winanto T, et al (2015) Catalytic efficiency of sulfuric and hydrochloric acids for the hydrolysis of Gelidium latifolium (Gelidiales, Rhodophyta) in bioethanol production. J Ind Eng Chem 27:108–114

Meinita MDN, Marhaeni B, Winanto T, Jeong GT, Khan MNA, Hong YK (2013) Comparison of agarophytes (Gelidium, Gracilaria, and Gracilariopsis) as potential resources for bioethanol production. J Appl Phycol 25:1957–1961

Mollet JC, Rahaoui A, Lemoine Y (1998) Yield, chemical composition and gel strength of agarocolloids of Gracilaria gracilis, Gracilariopsis longissima and the newly reported Gracilaria cf. vermiculophylla from Roscoff (Brittany, France). J Appl Phycol 10:59–66

Mouradi-Givernaud A, Givernaud T, Morvan H, Cosson J (1993) Annual variations of the biochemical composition of Gelidium latifolium (Greville) Thuret et Bornet. Hydrobiologia 260/261:607–612

Murano E (1995) Chemical structure and quality of agars from Gracilaria. J Appl Phycol 7:245–254

Pambudi LT, Dyah M, Meinita N, Ariyati RW (2010) Seaweed cultivation in Indonesia: recent status. Mar Biosci Biotech 4:6–10

Park JH, Hong JY, Jang HC, Oh SG, Kim SH, Yoon JJ, Kim YJ (2012) Use of Gelidium amansii as a promising resource for bioethanol: a practical approach for continuous dilute-acid hydrolysis and fermentation. Bioresour Technol 108:83–88

Porse H, Rudolph B (2017) The seaweed hydrocolloid industry: 2016 updates, requirements, and outlook. J Appl Phycol. doi:10.1007/s10811-017-1144-0

Rebello J, Ohno M, Ukeda H, Sawamura M (1996) Agar quality of commercial agarophytes from different geographical origins: 1. Physical and rheological properties. J Appl Phycol 8:517–521

Rebello J, Ohno M, Ukeda H, Kusunose H, Sawamura M (1997) 3,6-Anhydrogalactose, sulfate and methoxyl contents of commercial agarophytes from different geographical origins. J Appl Phycol 9:367–370

Vergara-Rodarte MA, Hernández-Carmona G, Rodríguez-Montesinos YE, Arvizu-Higuera DL, Riosmena-Rodríguez R, Murillo-Álvarez JI (2010) Seasonal variation of agar from Gracilaria vermiculophylla, effect of alkali treatment time, and stability of its Colagar. J Appl Phycol 22:753–759

Wu FC, Wu JY, Liao YJ, Wang MY, Shih IL (2014) Sequential acid and enzymatic hydrolysis in situ and bioethanol production from Gracilaria biomass. Bioresour Technol 156:123–131

Acknowledgments

The Ministry of Research, Technology, and Higher Education of Republic of Indonesia supported this work. We thank the Biotechnology Department at Pukyong National University for their collaboration.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Meinita, M.D.N., Marhaeni, B., Hong, YK. et al. Enzymatic saccharification of agar waste from Gracilaria verrucosa and Gelidium latifolium for bioethanol production. J Appl Phycol 29, 3201–3209 (2017). https://doi.org/10.1007/s10811-017-1205-4

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10811-017-1205-4