Abstract

Asparagopsis taxiformis has potent antimethanogenic activity as a feed supplement at 2 % of organic matter in in vitro bioassays. This study identified the main bioactive natural products and their effects on fermentation using rumen fluid from Bos indicus steers. Polar through to non-polar extracts (water, methanol, dichloromethane and hexane) were tested. The dichloromethane extract was most active, reducing methane production by 79 %. Bromoform was the most abundant natural product in the biomass of Asparagopsis (1723 μg g−1 dry weight [DW] biomass), followed by dibromochloromethane (15.8 μg g−1 DW), bromochloroacetic acid (9.8 μg g−1 DW) and dibromoacetic acid (0.9 μg g−1 DW). Bromoform and dibromochloromethane had the highest activity with concentrations ≥1 μM inhibiting methane production. However, only bromoform was present in sufficient quantities in the biomass at 2 % organic matter to elicit this effect. Importantly, the degradability of organic matter and volatile fatty acids were not affected at effective concentrations.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Livestock production systems are a significant contributor to global greenhouse gas (GHG) emission with enteric methane being the largest source within the agricultural sector (reviewed in Patra 2012). In addition to the global warming effect of GHG emissions the production of enteric methane results in a loss of metabolic energy (Hristov et al. 2013). Consequently, there has been a drive to develop strategies to mitigate enteric methane in livestock production systems, with the concomitant goal of improving individual animal productivity. Many of these strategies have focused on the management of nutrition and the use of supplements, both individually and in combination (Patra and Yu 2014). Macroalgae, both freshwater and marine, have been investigated as a supplement for the mitigation of enteric methane based on their natural products, which are strongly differentiated from those of terrestrial plants. Notably, the red seaweed Asparagopsis taxiformis is a potent supplement affecting the in vitro production of methane (Machado et al. 2014, 2015).

The red seaweed genus Asparagopsis has a broad distribution across tropical and temperate marine coastal ecosystems (Guiry and Guiry 2014). It is also a rich source of natural products with more than a hundred low molecular weight natural products described including halomethanes, haloalkanes, haloketones and haloacids (Burreson et al. 1975; McConnell and Fenical 1977; Moore 1977; Woolard et al. 1979). The brominated halomethane (CHX3) bromoform (CHBr3, tribromomethane) is consistently the most abundant of these natural products (Paul et al. 2006a; Vergés et al. 2008) with lower concentrations of dibromoacetic acid, dibromochloromethane and bromochloroacetic acid reported (Burreson et al. 1975; McConnell and Fenical 1977; Paul et al. 2006a). These natural products are produced and stored in specialised gland cells from where they are released onto the surface functioning as a natural defence against herbivores (Paul et al. 2006b; Vergés et al. 2008) and microbes (Paul et al. 2006a).

The two species, Asparagopsis taxiformis and Asparagopsis armata, have strong activity against gram-negative and gram-positive bacteria (Paul et al. 2006a; Salvador et al. 2007). Furthermore, A. taxiformis has demonstrated antimethanogenic activity in in vitro ruminal fermentation assays (Machado et al. 2015). It strongly inhibits the production of CH4 when added at a dose of 2 % of the organic matter (OM) incubated, indicating that these natural products are also active against archaea responsible for the microbial production of CH4. Notably, synthetic halomethanes, including bromoform, have been targeted to manipulate rumen fermentation and methanogenesis (Chalupa 1977; Lanigan 1972) with a recent focus on bromochloromethane (BCM), a synthetic halomethane that inhibits the production of CH4 in vitro (Goel et al. 2009) and in vivo (Tomkins et al. 2009; Abecia et al. 2012; Mitsumori et al. 2012). The mode of action of these low molecular weight halomethanes is through enzymatic inhibition by reaction with reduced vitamin B12 which reduces the efficiency of the cobamide-dependent methyl transferase step required for methanogenesis (Wood et al. 1968). Other haloalkanes, such as 2-bromoethanesulfonate and 2-chloroethanesulfonate, are structural analogs to coenzyme-M and competitively inhibit the methyl transfer reactions that are essential in CH4 biosynthesis (Liu et al. 2011).

The efficacy of synthetic halomethanes as antimethanogens infers a similar mode of action for the natural products in A. taxiformis with an opportunity to use the whole biomass, its extract or purified compounds, to regulate the production of enteric CH4. However, for this to be a practical application, it must be effective and without negative effects on the fermentation parameters including the degradability of organic substrate (OMdeg) and the production of volatile fatty acids (VFA), which are the main source of energy for the animals. Natural products or whole biomass are more likely to receive public acceptance than synthetic inhibitors, such as the synthetic halomethanes BCM and chloroform, that are prohibited in many countries due to their potential ozone-depletion and carcinogenic effects (Hristov et al. 2013).

The aim of this study was to identify the natural products responsible for the antimethanogenic activity of A. taxiformis and quantify their effects on in vitro fermentation using rumen fluid from Bos indicus. A series of extracts of decreasing polarity was used to screen for the strongest antimethanogenic activity. The most abundant natural products in each extract were quantified and the minimum effective dose determined. The quantity of each active natural product in the biomass was then compared with that required to suppress methanogenesis and thereby identify the natural product(s) responsible for activity in the biomass. Finally, the effects of biomass, extracts and natural products on key fermentation parameters were assessed.

Material and methods

Experimental overview

The study was divided into three experiments (Fig. 1). In the first experiment, the natural products of Asparagopsis taxiformis (Delile) Trevisan de Saint-Léon (the filamentous tetrasporophyte stage, hereafter referred to as Asparagopsis) were extracted from dried biomass using four solvents of decreasing polarity followed by the in vitro quantification of the antimethanogenic activity of each extract at a dose equivalent to the addition of 2 % of Asparagopsis as organic matter (OM) incubated in rumen fluid from Bos indicus steers. A dose of Asparagopsis biomass at 2 % OM is an effective dose for the inhibition of methanogenesis (Machado et al. 2015) and was included as a positive control. In the second experiment, the major halogenated natural products within each extract were identified and quantified by GC-MS. In the third experiment, the in vitro antimethanogenic activity of pure natural products was quantified. Each natural product was tested separately using analytical standards at concentrations of 0, 1, 5, 10, and 25 μM in the in vitro assay to determine the minimum effective concentration required to decrease methanogenesis and to quantify their effects on in vitro fermentation.

Experimental design. Experiment 1 tests solvents for the extraction of natural products of Asparagopsis with activity against methanogenesis. Extracts were tested for their activity in an in vitro assay at a dose equivalent to 2 % of organic matter incubated of Asparagopsis. Experiment 2 identifies and quantifies the major natural products within the extracts. Experiment 3 tests a concentration range of each natural product in an in vitro assay (analytical standards from Sigma). DCM dichloromethane

In vitro incubation preparation

The sampling of rumen fluid and in vitro batch fermentation were carried out as described by Machado et al. (2014). In brief, rumen fluid was collected from four rumen-fistulated Brahman (B. indicus) steers, which were maintained according to guidelines approved by CSIRO Animal Ethics Committee (A5/2011) and in accordance with the Australian Code of Practice for the Care and Use of Animals for Scientific Purposes (NHMRC 2004). The steers were fed Rhodes grass hay (Chloris gayana) ad libitum. Rumen fluid was collected from steers 2 h after the morning feeding and transferred to pre-heated vacuum flasks. In the laboratory, rumen fluid were pooled and blended at high speed for 30 s to ensure detachment of microorganisms associated with the solid phase into suspension (Bueno et al. 2005), and then filtered through a 0.5-mm mesh to remove large OM substrate. The rumen fluid was constantly mixed and maintained at 39–40 °C under high purity N2 to maintain anaerobic conditions. Rumen medium for incubations (125 mL per incubation bottle) was made up by mixing rumen fluid and pre-heated buffer solution (Goering and Van Soest 1970) in a 1:4 (v/v) ratio. Batch cultures were incubated for 24 h at 39 °C at 85 rpm (Raytek) and total gas production measured using an Ankom Technology RF Gas Production System (USA). Rhodes grass hay (1 g OM) was used as the basal substrate of the batch cultures. The incubations were repeated on three different occasions for each experiment, producing a total of three (Experiment 1) or four (Experiment 3) replicates per treatment. For each incubation run, bottles were randomly allocated and placed inside incubators.

Experiment 1: effects of crude extracts from Asparagopsis on gas and fermentation parameters

Crude extracts were prepared using four solvents with decreasing polarity: water, methanol, dichloromethane (DCM), and hexane (Fig. 1). For each extract, 10 g of Asparagopsis biomass, which had previously been rinsed, freeze-dried and ground in an analytical mill through a 1-mm sieve, was mixed with 100 mL of solvent, sonicated for 15 min, shaken (100 rpm) for 20 h, and filtered through glass microfiber filter (GF/F, Whatman). The biomass was then covered with an additional 50 mL of solvent, shaken for 3 h and filtered. Subsequently, 50 mL of solvent was added and the biomass shaken for 1 h and filtered. The filtrates from the three consecutive extractions were combined and dried through freeze-drying for the water extract, rotary evaporation (Büchi Rotavapor R-200) for the DCM and hexane extracts at 40 °C to preserve volatile metabolites from evaporation, and a combination of both techniques for the methanol extract.

The crude extracts from the 10 g of Asparagopsis biomass were weighed and subsequently dissolved in 8.1 mL of dimethyl sulfoxide (DMSO). A dose of 20 μL of each extract, an equivalent to a dose of 2 % OM of Asparagopsis biomass (or 0.0247 g DW), was added as a treatment to replicate batch cultures (n = 3) at the beginning of the experiment. Rhodes grass hay (C. gayana) was used as 100 % of the OM. A positive control using Asparagopsis biomass as 2 % of the total OM incubated (0.0247 g DW = 0.02 g OM) was included with Rhodes grass hay as 98 % of the OM (1.1932 g DW = 0.98 g OM). Two controls, one with and one without the addition of 20 μL of DMSO with Rhodes grass hay as 100 % of the OM incubated, were included to evaluate the effects of DMSO on the parameters analysed. Blanks (rumen medium only) were also included.

Three replicates were used for each treatment—crude extract, Asparagopsis biomass and the controls. The incubations were conducted over 24 h. The gas parameters total gas (TGP) [Ankom Technology RF Gas Production System (USA)], CH4, and H2 production, and the fermentation parameters organic matter degradability (OMdeg) and volatile fatty acid (VFA) were measured. Samples to quantify total gas production, CH4 and H2 were collected at 2, 4, 6, 8, 10, 12, and 24 h (Fig. S1). The quantification of CH4 and H2 were made by GC-MS (Agilent 7890 GC with FID – Agilent 5975C EI/TurboMS) as described in detail in Machado et al. (2015). The fermentation parameters OMdeg and VFA were sampled at the end of the incubation period (24 h) and quantified as described in detail previously (Machado et al. 2015).

Experiment 2: identification and quantification of the major metabolites produced by A. taxiformis

Crude extracts (three replicates per solvent) were prepared as described except that naphthalene was included as an internal standard at a concentration of 10 μg mL−1 prior to extraction (Paul et al. 2006a). Crude extracts were reconstituted to a concentration of 0.04 g DW biomass mL−1 of solvent (25 mL final volume) in the same solvent used for extraction for methanol, DCM, and hexane crude. The crude extracts of water were reconstituted in methanol due to the incompatibility of water and the GC-column. Initially, all extracts were analysed in scan mode by gas chromatography–mass spectrometry (GC-MS, Agilent 7890c equipped with a Zebron ZB-wax capillary column, 30 m, 0.25 mm i.d., Phenomenex, Australia) using 1 μL injections, pulsed (35 psi) split less mode, with temperatures of the injection port (250 °C), GC-MS interface (300 °C), and oven (held at 40 °C for 1 min, ramped at 16 °C min−1 to 250 °C, then held at 250 °C for 2 min) programmed as described by Paul et al. (2006a) with He as the carrier gas at 2 mL min−1 (initial pressure 1448 HPa).

The major natural products were bromoform, dibromochloromethane, bromochloroacetic acid, and dibromoacetic acid (see section “Experiment 2: identification and quantification of the main natural products in A. taxiformis ”) and these were subsequently quantified (GC-MS) in the extracts using selective ion mode based on ion fragments as described by Paul et al. (2006a). Analytical standards of these natural products were run prior to the extracts, generating a standard curve based on a minimum of five concentrations for each product. Calculation of the concentration of natural products was based on the ratio of the peak areas of target products and the internal standard. The concentration of natural products from the biomass of Asparagopsis is presented as μg g−1 DW, while the final concentration of natural products within the in vitro assay (total volume 125 mL) after addition of extract (equivalent to the addition of 2 % of OM extracted or 0.0247 g DW) is presented as μM (Fig. 3a, b).

Experiment 3: effects of pure compounds on gas and fermentation parameters

The in vitro effects on methanogenesis and fermentation kinetics were evaluated for the four major natural products produced by Asparagopsis (bromoform, dibromochloromethane, bromochloroacetic acid, and dibromoacetic acid; see section “Experiment 2: identification and quantification of the main natural products in A. taxiformis ”). Stock solutions of each product (analytical standards, Sigma-Aldrich, Australia) were made up in 25 mL of DMSO and further diluted such that the addition of 20 μL gave assay-concentrations of 1, 5, 10, and 25 μM (final volume of DMSO in treatments = 20 μL). A DMSO control (20 μL) was also used. Bromochloromethane (BCM), a known inhibitor of methanogenesis, was included at the same concentrations (0, 1, 5, 10, and 25 μM) in the assay for comparison. The controls, with and without the addition of 20 μL of DMSO, and blanks (rumen medium only) were also included. Each treatment consisted of four replicates. All the gases and fermentation parameters were analysed after 24 h of in vitro batch incubation following the same sampling scheme applied in experiment 1. In addition, the final concentration of ammonia (NH3-N) was analysed to identify the effects of natural products on the concentration of NH3-N, as this is the simplest and main source of N used by rumen microbes and availability influences the production of microbial growth and production of microbial crude protein (Satter and Slyter 1974). The concentration of NH3-N in the digestate was determined through distillation using a Buchi 321 distillation unit (Buchi; Labortechnik AG, Switzerland) with saturated sodium tetraborate (>260 g L−1). The distillate was titrated (Titralab 840; Radiometer Analytical SAS, France) with 0.01 M HCl to calculate total N content.

Data analysis

The TGP data were corrected for the blank and fitted to a modified Gompertz sigmoidal model as described in Machado et al. (2014), using the non-linear procedure of JMP statistical software (JMP 10, SAS Institute, USA).

A t test (two samples, assuming equal variances) was carried out to compare the controls with and without addition of DMSO. Since there were no significant differences (p = 0.47) among controls, only control + DMSO (referred to as control in tables and graphs) data are formally analysed and presented.

Data from the extracts (Experiment 1) and from the quantification of the major natural products produced by Asparagopsis (Experiment 2) were analysed separately using a one-way analysis of variance (ANOVA, JMP software). The effects of extracts on each gas (Table S1) and fermentation parameter were examined individually, with treatment as the fixed factor. The quantity of the natural products between extracts was compared using individual ANOVAs for each product (Table S2). Post-hoc comparisons were made using Tukey’s HSD multiple comparisons.

Data from the pure natural products (Experiment 3) was analysed using two-factor permutational analysis of variance because of assumptions of homogeneity of variance (PERMANOVA (Anderson et al. 2008). The effects of the concentration (0, 1, 5, 10, 25 μM) of each natural product (bromoform, dibromochloromethane, bromochloroacetic acid, dibromoacetic acid, and bromochloromethane) and the interaction between these fixed factors were analysed individually for each gas (Table S3) and fermentation parameter (Table S4) after 24 h of incubation in Primer v6 (Primer-E Ltd, UK), using Bray-Curtis dissimilarities on fourth root transformed data and 9999 unrestricted permutations of raw data. A dummy variable of 0.0001 was added prior for the construction of the Bray-Curtis matrix to accounts for zeros.

Results

Experiment 1

Effects of crude extracts from Asparagopsis on gas parameters

The positive control (Asparagopsis 2 % OM and Rhodes grass 98 % OM) significantly decreased in vitro TGP by 25 % (113.6 mL g−1 OM) compared with the Rhodes grass control (100 % OM) (151.4 mL g−1 OM, Fig. 2a). In contrast, there was no significant effect of any extract (when added at a dose equivalent to 2 % OM of Asparagopsis biomass) on TGP compared with the Rhodes grass control. The DCM extract had the lowest TGP at 143.2 mL g−1 OM (5 % lower than control) and the water extract had the highest TGP (165.8 mL g−1 OM).

Effects of Asparagopsis biomass and extracts on gas parameters at 24 h of incubation. The doses were equivalent to Asparagopsis as 2 % of the organic matter. Asparagopsis biomass was included as positive control. a Total gas production (TGP), b production of methane (CH 4 ), c production of hydrogen (H 2 ). Error bars represent ± SE (n = 3).*Indicates treatment effect is significant (p < 0.05) according to the ANOVA analysis. DCM dichloromethane. These data are also tabulated in Table S1

The positive control of Asparagopsis 2 % OM also had the lowest production of CH4 (0.7 mL g−1 OM) with a significant reduction of 95 % compared to the control (13.5 mL g−1 OM, Fig. 2b). The DCM extract (2.6 mL g−1 OM) also significantly reduced the production of CH4 with a reduction of 79 % compared with the control (Fig. 2b) and this was not significantly different from the positive control of Asparagopsis 2 % OM. The water, methanol, and hexane extracts had no significant effect on the production of CH4. Asparagopsis 2 % OM was the only treatment to significantly (p < 0.5) increase the production of H2 (Fig. 2c).

Effects of crude extracts from Asparagopsis on fermentation parameters

Total VFA was not affected by any treatment compared with the control (Table 1). However, there were differences in the production of individual VFA with Asparagopsis 2 % OM causing a 20 % decrease in the proportion of acetate and a 50 % increase in the proportion of propionate. Consequently, there was also a significant decrease in the acetate to propionate ratio (Table 1). OMdeg was variable among treatments, but not significantly different from the control (Table 1).

Experiment 2: identification and quantification of the main natural products in A. taxiformis

The water extract had the highest yield among all solvents with the extract representing 24.9 % of the dry weight (DW) of the biomass. Methanol had a yield of 10.2 % DW, and DCM and hexane had the lowest yields of 1.9 and 0.5 % DW, respectively. The halogenated compounds identified by mass spectrometry in scan mode were bromoform, dibromochloromethane, bromochloroacetic acid, and dibromoacetic acid (Fig. 3a, b). Non-halogenated compounds were identified as alkanes or fatty acid derivatives. The four solvents differed in their extraction yields in terms of both amount and proportion of natural products. DCM extracted the highest total amount of natural products from the biomass, followed by methanol, hexane and water (Fig. 3c). The DCM extract had the highest yield of bromoform (Fig. 3c) corresponding to 1723.2 μg g−1 DW of biomass. This is 5.7 times higher than the methanol (301.2 μg g−1 DW) and hexane (297.0 μg g−1 DW) extracts. The DCM extract also had a yield of dibromochloromethane (15.8 μg g−1 DW, Fig. 3c) 1.2 times higher than for methanol (13.3 μg g−1 DW) and 5.5 times higher than for hexane (2.9 μg g−1 DW). However, methanol yielded a higher concentration of bromochloroacetic acid (100.8 μg g−1 DW) and dibromoacetic acid (128.3 μg g−1 DW, Fig. 3c). The DCM extract equivalent to an inclusion of Asparagopsis biomass (DW) at 2 % of the total OM (98 % Rhodes grass hay OM) resulted in a concentration of 1.3 μM of bromoform and 0.02 μM of dibromochloromethane (Fig. 3d) in incubations (equal to 42.5 μg of bromoform and 0.5 μg of dibromochloromethane in 125 mL of rumen medium per replicate).

Major natural products of Asparagopsis. Gas chromatograph of the a DCM extract and b methanol extract of Asparagopsis showing the major halogenated metabolites peak (a dibromochloromethane, b bromoform, c bromochloroacetic acid, d dibromoacetic acid). IS is the internal standard and peaks 1–3 indicate non-halogenated metabolites. c Natural product yields of each solvent extract of Asparagopsis (biomass) [μg g−1 dry weight (DW)]. Error bars represent ± SE (n = 4). DCM dichloromethane, MeOH methanol. *Indicates extract significantly (p < 0.05) different from other extracts for each natural product according to the ANOVA analysis. d Concentration of natural products in the in vitro assay in extract equivalent to 2 % of the total organic matter of Asparagopsis (0.0247 g DW). BF bromoform, DBCM dibromochloromethane, BCA bromochloroacetic acid, DBA dibromoacetic acid, BCM bromochlomethane. These data are also tabulated in Table S2

Experiment 3

Effects of natural products on gas parameters

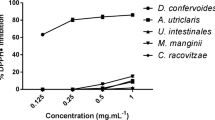

Total gas production (TGP) was significantly decreased by the addition of bromoform, dibromochloromethane, and bromochloromethane at concentrations ≥ 5 μM (Fig. 4a) compared with the control. Although there were minor differences between the three halomethanes, they resulted in a similar TGP at each concentration. Bromoform decreased TGP by 23 to 26 % at 5 and 10 μM, while dibromochloromethane decreased TGP by 20 to 22 %. Bromoform was the strongest inhibitor of TGP at 25 μM. In contrast, the haloacids, dibromoacetic acid and bromochloroacetic acid had no significant effect on TGP regardless of concentration (Fig. 4a).

Effects of natural products on gas parameters after 24 h. a Total gas production (TGP), b production of methane (CH 4 ), c production of hydrogen (H 2 ). Error bars represent ± SE (n = 4).*Indicates treatments significantly (p < 0.05) different from control according to PERMANOVA (Table S3). BF bromoform, DBCM dibromochloromethane, BCA bromochloroacetic acid, DBA dibromoacetic acid, BCM bromochlomethane. These data are also tabulated in Table S4

The production of CH4 in vitro was significantly affected by bromoform, dibromochloromethane, and bromochloromethane (Fig. 4b). At a concentration of 1 μM, bromoform and dibromochloromethane inhibited the production of CH4 by an average of 52 and 43 %, respectively, compared to the control. The effects were much stronger and the production of CH4 was significantly inhibited to below detection levels by all three compounds at ≥5 μM. The two haloacids, bromochloroacetic acid and dibromoacetic acid, had no significant effect on the production of CH4 regardless of concentration. The production of H2 significantly increased for all halomethanes at assay-concentrations ≥5 μM. Bromoform was the only compound to induce the production of H2 at 1 μM (Fig. 4c). The production of H2 by the control, dibromoacetic acid, and bromochloroacetic was below the level of detection for all concentrations (Fig. 4c).

Effects of natural products on fermentation parameters

The production of total VFA (mM) was significantly affected by natural product and concentration (Table 2). However, the production of total VFA for bromoform (minimum of 32.6 mM VFA) and dibromochloromethane (minimum of 33.6 mM VFA) were similar to the control (35.7 mM VFA) for concentrations ≤10 μM (Table 2), even though the production of CH4 was markedly decreased. At the higher concentration of 25 μM, bromoform and dibromochloromethane decreased the production of total VFA by 20 and 30 %, respectively, compared with the control. In contrast, the production of total VFA increased for bromochloroacetic acid at a concentration of 5 μM and dibromoacetic at concentrations <25 μM. There were no significant differences in OMdeg between controls and all treatments for concentrations <25 μM. Bromoform and dibromochloromethane decreased the OMdeg by 14 % compared with the control at the concentration of 25 μM (Table 2).

The final concentration of NH3-N was significantly decreased by all compounds with the exception of bromochloroacetic acid, which increased the concentration of NH3-N at <25 μM. Bromoform and bromochloromethane significantly decreased NH3-N by 16 to 17 % at a concentration of 1 μM, compared to the control.

Discussion

Asparagopsis is a potent inhibitor of methanogenesis at low inclusions of biomass, and bromoform is the natural product affecting this response in vitro. Bromoform effectively inhibited methanogenesis at all concentrations (1 to 25 μM) including 1 μM, which is equivalent to the inclusion of Asparagopsis at 2 % OM (24.7 mg) in vitro. Bromoform was the most abundant natural product in the biomass by more than an order of magnitude, and the only compound for which the concentration was high enough in the biomass (1723.2 μg g−1 DW) to provide the antimethanogenic activity of Asparagopsis at an inclusion of 2 % OM. This concentration in the biomass corresponds to a concentration of 1.3 μM at the rate of inclusion of 2 % OM in the assay. Notably, dibromochloromethane also effectively inhibited methanogenesis at concentrations of 1 to 25 μM. However, the concentration of dibromochloromethane in the biomass (15.8 μg g−1 DW) was not sufficient to inhibit methanogenesis at the rate of inclusion of 2 % OM as it only corresponds to a concentration of 0.02 μM. Notably, Asparagopsis at 2 % OM and bromoform led to a decrease in the production of CH4 that is larger than that of many terrestrial plants, extracts and natural products (Durmic et al. 2014; Patra 2012).

The major halogenated natural product in Asparagopsis is bromoform. The concentration of bromoform was 1723.2 μg g−1 DW (0.17 % DW) and this was more than 100-fold higher than the concentration of the next most abundant natural product, dibromochloromethane (15.8 μg g−1 DW biomass, 0.0016 % DW). Although the identity of the main natural products is consistent with previous studies, the concentration of metabolites within the biomass is lower than concentrations previously reported for the tetrasporophyte or gametophyte of A. armata, with an average of 1.45 % DW (ranging from 0.58 to 3.11 % DW) for bromoform (Paul et al. 2006a). This could be due to differences in processing or storage times between studies, but there are also clear differences in natural products within and between species of Asparagopsis depending on the environment, in particular the availability of carbon and nitrogen (Mata et al. 2012) and life history stage [tetrasporophyte vs. gametophyte, (Vergés et al. 2008)].

In comparison with existing strategies for chemical additives to reduce methanogenesis, bromoform had similar effects to that of the commercially available methane inhibitor bromochloromethane (BCM) for all the measured gas and fermentation parameters. This supports the mechanism of action of bromoform as a direct suppressor/inhibitor of methanogenesis through the inhibition of cobamide-dependent methyl transfer (Wood et al. 1968) required for the synthesis of coenzyme-M, the key enzyme involved in the final step of methanogenesis (DiMarco et al. 1990). Nevertheless, although bromoform is the most abundant natural product and the one likely to be driving the antimethanogenic activity of Asparagopsis, this compound might act synergistically with other halogenated products increasing the effectiveness of the biomass in reducing the production of CH4. This mechanism is also supported by a lack of the effect on total VFA production and organic matter degradability. Bromoform also inhibited methanogenesis in rumen fermentation of sheep in vivo (Lanigan 1972). However, the effective single dose required for the short-term inhibition of methanogenesis in vivo was 25 times higher than that of the in vitro experiment (Lanigan 1972). Long term in vivo studies to test the antimethanogenic effects of bromoform are now required.

The suppression in the production of CH4 using bromoform was accompanied by an increase in the production of H2, and similar results have been found for BCM in vivo (Mitsumori et al. 2012). Methanogens are the main users of H2 within the rumen, and the inhibition of CH4 can lead to an increase in the partial pressure of H2 if alternative H2 utilising pathways, such as production of propionate and NH3-N, are not available (Martin et al. 2010; Morgavi et al. 2010). Increases in the partial pressure of H2 often restrain the fermentation process by affecting the functioning of oxidative coenzymes (e.g. NADH – NAD+) involved in the degradation of substrates and production of VFA (Martin et al. 2010). However, anaerobic fermentation is a robust process with microbes able to withstand a wide range of H2 pressure [functioning normally in pressures between 0.0001 and 0.01 atm (Ungerfeld and Kohn 2006)]. Therefore, the lack of negative effects on OMdeg, or on the production of total VFA, indicates that the fermentation process was not significantly affected. Nevertheless, there was a shift in the production of specific VFAs during fermentation with bromoform. An assay-concentration of bromoform of 5 μM decreased the production of acetate by 44 %, while the production of propionate and butyrate increased by 42 and 125 % (in mM), respectively, compared with the control. This resulted in lower acetate to propionate ratios. Similar shifts in the production of VFAs occur for other methane inhibitors such as BCM (Tomkins et al. 2009; Mitsumori et al. 2012; Goel et al. 2009) and nitro-compounds (Anderson et al. 2010).

Bromoform also led to a slight decrease in NH3-N, suggesting a decrease in the degradation of protein and deamination of dietary amino acids (Wang et al. 2008). Ammonia-N is the simplest and main source of N used by rumen microbes for the production of microbial protein (Satter and Slyter 1974). Nevertheless, bromoform resulted in concentrations of NH3-N above the threshold (50 mg L−1) required for the maximum growth of rumen bacteria (Satter and Slyter 1974; Yusuf et al. 2012) and optimum fibre digestion (50 mg L−1, Nagadi et al. 2000). Ingested protein that escapes microbial degradation in the rumen through fermentation is transferred into the small intestine where it is directly absorbed by the animal (Tamminga 1979), improving protein utilisation efficiency. Therefore, the overall nutrition of the rumen, quantified in vitro, has no apparent negative effects while methanogenesis is severely inhibited. These results support a mechanism to reduce methane emissions from ruminants while retaining animal productivity.

In conclusion, the red seaweed Asparagopsis consistently suppresses the in vitro production of CH4 when added as a supplement (2 % OM) with bromoform being the only natural product present in sufficient concentration in the biomass to be effective with this addition. There was no adverse effect on degradability of substrate or production of total VFAs for either Asparagopsis biomass (2 % OM) or bromoform (≤10 μM). Consequently, these options could be considered in a techno-economic analysis for the use of Asparagopsis and its bioactive natural products as feed additives that inhibit methanogenesis.

References

Abecia L, Toral PG, Martín-García AI, Martínez G, Tomkins NW, Molina-Alcaide E, Newbold CJ, Yáñez-Ruiz DR (2012) Effect of bromochloromethane on methane emission, rumen fermentation pattern, milk yield, and fatty acid profile in lactating dairy goats. J Dairy Sci 95:2027–2036

Anderson M, Gorley R, Clarke K (2008) PERMANOVA + for PRIMER: guide to software and statistical methods. PRIMER-E

Anderson RC, Huwe JK, Smith DJ, Stanton TB, Krueger NA, Callaway TR, Edrington TS, Harvey RB, Nisbet DJ (2010) Effect of nitroethane, dimethyl-2-nitroglutarate and 2-nitro-methyl-propionate on ruminal methane production and hydrogen balance in vitro. Bioresour Technol 101:5345–5349

Bueno I, Cabral Filho SL, Gobbo SP, Louvandini H, Vitti DM, Abdalla AL (2005) Influence of inoculum source in a gas production method. Anim Feed Sci Technol 123:95–105

Burreson B, Moore RE, Roller P (1975) Haloforms in the essential oil of the alga Asparagopsis taxiformis (Rhodophyta). Tetrahedron Lett 16:473–476

Chalupa W (1977) Manipulating rumen fermentation. J Anim Sci 45:585–599

DiMarco AA, Bobik TA, Wolfe RS (1990) Unusual coenzymes of methanogenesis. Annu Rev Biochem 59:355–394

Durmic Z, Moate PJ, Eckard R, Revell DK, Williams R, Vercoe PE (2014) In vitro screening of selected feed additives, plant essential oils and plant extracts for rumen methane mitigation. J Sci Food Agric 94:1191–1196

Goel G, Makkar HP, Becker K (2009) Inhibition of methanogens by bromochloromethane: effects on microbial communities and rumen fermentation using batch and continuous fermentations. Br J Nutr 101:1484–1492

Goering H, Van Soest PJ (1970) Forage fiber analyses (apparatus, reagents, procedures, and some applications). US Agricultural Research Service Washington, DC

Guiry M, Guiry G (2014) AlgaeBase. World-wide electronic publication. National University of Ireland, Galway. http://www.algaebase.org accessed 17 Nov 2014

Hristov A, Oh J, Meinen R, Montes F, Ott T, Firkins J, Rotz A, Dell C, Adesogan A, Yang W, Tricarico J, Kebreab E, Waghorn G, Dijkstra J, Oosting S (2013) Mitigation of greenhouse gas emissions in livestock production—a review of technical options for non-CO2 emissions. In: Gerber P, Henderson B, Makkar H (eds) FAO Animal Production and Health Paper No. 177. Rome, Italy, p 231

Lanigan G (1972) Metabolism of pyrrolizidine alkaloids in the ovine rumen. IV. Effects of chloral hydrate and halogenated methanes on rumen methanogenesis and alkaloid metabolism in fistulated sheep. Crop Pasture Sci 23:1085–1091

Liu H, Wang J, Wang A, Chen J (2011) Chemical inhibitors of methanogenesis and putative applications. Appl Microbiol Biotechnol 89:1333–1340

Machado L, Magnusson M, Paul NA, de Nys R, Tomkins N (2014) Effects of marine and freshwater macroalgae on in vitro total gas and methane production. PLoS ONE 9(1):e85289

Machado L, Magnusson M, Paul NA, Kinley R, de Nys R, Tomkins N (2015) Dose–response effects of Asparagopsis taxiformis and Oedogonium sp. on in vitro fermentation and methane production. J Appl Phycol: doi: 10.1007/s10811-015-0639-9

Martin C, Morgavi D, Doreau M (2010) Methane mitigation in ruminants: from microbe to the farm scale. Animal 4:351–365

Mata L, Gaspar H, Santos R (2012) Carbon/nutrient balance in relation to biomass production and halogenated compound content in the red alga Asparagopsis taxiformis (Bonnemaisoniaceae). J Phycol 48:248–253

McConnell O, Fenical W (1977) Halogen chemistry of the red alga Asparagopsis. Phytochemistry 16:367–374

Mitsumori M, Shinkai T, Takenaka A, Enishi O, Higuchi K, Kobayashi Y, Nonaka I, Asanuma N, Denman SE, McSweeney CS (2012) Responses in digestion, rumen fermentation and microbial populations to inhibition of methane formation by a halogenated methane analogue. Br J Nutr 108:482–491

Moore RE (1977) Volatile compounds from marine algae. Acc Chem Res 10:40–47

Morgavi D, Forano E, Martin C, Newbold CJ (2010) Microbial ecosystem and methanogenesis in ruminants. Animal 4:1024–1036

Nagadi S, Herrero M, Jessop NS (2000) The effect of fermentable nitrogen availability on in vitro gas production and degradability of NDF. Anim Feed Sci Technol 87:241–251

NHMRC (2004) Australian code of practice for the care and use of animals for scientific purposes. National Health and Medical Research Council, Camberra

Patra AK (2012) Enteric methane mitigation technologies for ruminant livestock: a synthesis of current research and future directions. Environ Monit Assess 184:1929–1952

Patra AK, Yu Z (2014) Combinations of nitrate, saponin, and sulphate additively reduce methane production by rumen cultures in vitro while not adversely affecting feed digestion, fermentation or microbial communities. Bioresour Technol 155:129–135

Paul N, de Nys R, Steinberg P (2006a) Chemical defence against bacteria in the red alga Asparagopsis armata: linking structure with function. Mar Ecol Prog Ser 306:87–101

Paul NA, De Nys R, Steinberg PD (2006b) Seaweed-herbivore interactions at a small scale: direct tests of feeding deterrence by filamentous algae. Mar Ecol Prog Ser 323:1–9

Salvador N, Gómez Garreta A, Lavelli L, Ribera MA (2007) Antimicrobial activity of Iberian macroalgae. Sci Mar 71:101–114

Satter L, Slyter L (1974) Effect of ammonia concentration on rumen microbial protein production in vitro. Br J Nutr 32:199–208

Tamminga S (1979) Protein degradation in the forestomachs of ruminants. J Anim Sci 49:1615–1630

Tomkins N, Colegate S, Hunter R (2009) A bromochloromethane formulation reduces enteric methanogenesis in cattle fed grain-based diets. Anim Prod Sci 49:1053–1058

Ungerfeld E, Kohn R (2006) The role of thermodynamics in the control of ruminal fermentation. In: Sejrsen K, Hvelplund T, Nielsen MO (eds) Ruminant physiology: digestion, metabolism and impact of nutrition on gene expression, immunology and stress. Wageningen Academic Publishers, Wageningen, The Netherlands, pp 55–85

Vergés A, Paul NA, Steinberg PD (2008) Sex and life-history stage alter herbivore responses to a chemically defended red alga. Ecology 89:1334–1343

Wang Y, Xu Z, Bach S, McAllister T (2008) Effects of phlorotannins from Ascophyllum nodosum (brown seaweed) on in vitro ruminal digestion of mixed forage or barley grain. Anim Feed Sci Technol 145:375–395

Wood J, Kennedy FS, Wolfe R (1968) Reaction of multihalogenated hydrocarbons with free and bound reduced vitamin B12. Biochemistry 7:1707–1713

Woolard FX, Moore RE, Roller PP (1979) Halogenated acetic and acrylic acids from the red alga Asparagopsis taxiformis. Phytochemistry 18:617–620

Yusuf RO, Noor ZZ, Abba AH, Hassan MAA, Din MFM (2012) Methane emission by sectors: a comprehensive review of emission sources and mitigation methods. Renew Sust Energy Rev 16:5059–5070

Acknowledgments

This research is supported by funding from the Australian Government Department of Agriculture, the Australian Government through the Australian Renewable Energy Agency, and the Advanced Manufacturing Cooperative Research Centre (AMCRC), funded through the Australian Government’s Cooperative Research Centre Scheme. We thank Dr. Mike Devery for kindly supplying the bromochloromethane used in this study. We also thank Pedro Henrique de Paula Silva for reviewing the manuscript.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Rumen fluid was collected from four rumen-fistulated Brahman (B. indicus) steers, which were maintained according to guidelines approved by CSIRO Animal Ethics Committee (A5/2011) and in accordance with the Australian Code of Practice for the Care and Use of Animals for Scientific Purposes.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Figure S1

Effects of Asparagopsis biomass and extracts (doses equivalent to Asparagopsis 2 % OM) on production of (A) total gas (TGP), and (B) CH4 over a 24 h fermentation period. Error bars represent ± SE (n = 3). DCM = dichloromethane. (GIF 73 kb)

Table S1

Results of full factorial permutational analyses of variance (PERMANOVAs) testing the effects of the fixed factors pure compound, and assay-concentration on total gas production (TGP), methane (CH4), and hydrogen (H2). Analyses were conducted in Primer v6 (Primer-E Ltd, UK) using Bray-Curtis dissimilarities on fourth root transformed data and 9999 unrestricted permutations of raw data. Pseudo F (F) and P values are presented (n = 3). (DOCX 14 kb)

Table S2

ANOVA results of the natural product yields of each solvent extract of Asparagopsis biomass [μg g-1 dry weight (DW)], (Experiment 2). (DOCX 14 kb)

Table S3

Results of full factorial permutational analyses of variance (PERMANOVAs) testing the effects of the fixed factors pure compound, and assay-concentration on total gas production (TGP), methane (CH4), and hydrogen (H2). Analyses were conducted in Primer v6 (Primer-E Ltd, UK) using Bray-Curtis dissimilarities on fourth root transformed data and 9999 unrestricted permutations of raw data. Pseudo F (F) and P values are presented (n = 3). (DOCX 14 kb)

Table S4

Results of full factorial permutational analyses of variance (PERMANOVAs) testing the effects of the fixed factors pure compound and assay-concentration on total gas production (TGP), methane (CH4), and hydrogen (H2), (Experiment 3). Analyses were conducted in Primer v6 (Primer-E Ltd, UK) using Bray-Curtis dissimilarities on fourth root transformed data and 9999 unrestricted permutations of raw data (n = 4). (DOCX 18 kb)

Rights and permissions

About this article

Cite this article

Machado, L., Magnusson, M., Paul, N.A. et al. Identification of bioactives from the red seaweed Asparagopsis taxiformis that promote antimethanogenic activity in vitro. J Appl Phycol 28, 3117–3126 (2016). https://doi.org/10.1007/s10811-016-0830-7

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10811-016-0830-7