Abstract

The appropriate microalgal species and the optimal nitrogen supply in culture medium are vital factors in maximizing biomass and metabolite productivities in microalgae. Vischeria stellata is an edaphic unicellular eustigmatophycean microalga. Cytological and ultrastructural characteristics and the effects of different initial nitrate-nitrogen concentrations on growth, lipid accumulation, fatty acid profile, and pigment composition were investigated in the present study. The cell structures of V. stellata changed with the degree of nutrient utilization and growth phase. The initial nitrate concentration for the optimal growth of V. stellata ranged from 6.0 to 9.0 mM. The maximum total lipid (TLs), neutral lipid (NLs), and total fatty acid (TFAs) contents were 55.9, 51.9, and 44.7 % of dry biomass, respectively. The highest volumetric productivity of TLs, NLs, and TFAs reached 0.28, 0.25, and 0.21 g L−1 day−1, respectively. V. stellata had a suitable fatty acid profile for biodiesel production, as well as containing eicosapentaenoic acid (EPA) for nutraceutical applications. In addition, the content β-carotene, increased gradually as culture time was prolonged, resulting in its exclusive production at the end of cultivation. V. stellata is a promising microalgal strain for the production of biofuels and bioproducts.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Microalgae are currently considered as a promising alternative feedstock for biofuel production because of their highly efficient conversion of solar energy to biomass, fast growth rate, and high level of lipid production compared to other terrestrial plants (Hannon et al. 2010; Sheehan et al. 1998; Borowitzka 2013a). Although microalgae-based biofuels are far superior than conventional fossil fuels based on their renewable, biodegradable, and nontoxic properties, their extensive industrial application has been hindered by the associated higher production cost relative to that of conventional fossil fuels (Chisti 2007; Hannon et al. 2010). Recent studies have demonstrated that the overall economic feasibility of biofuel production using microalgae largely relies on the identification of the appropriate microalgal species and the optimization of cultivation conditions (Prommuak et al. 2013). Desirable microalgal traits include not only rapid growth rate and high lipid content but also environmental tolerance and the potential for generating other valuable co-products. Mass cultivation of microalgae for biofuel production requires a high amount of nitrogen. The excessive supply of external synthetic nitrogen can lead to a significant reduction in net energy gain, as well as potential competition with other food producers for fertilizers, and increased production cost (Peccia et al. 2013). A few microalgal species contain valuable metabolites other than lipids (Borowitzka 2013b; Harisko and Posten 2014). Current recognized natural co-products in microalgae include carotenoids and long-chain polyunsaturated fatty acids (LC-PUFAs) (Harisko and Posten 2014). These co-products can serve as bridges and bonds for the improvement in the cost-effectiveness of microalgae-based biofuel production (Hannon et al. 2010). Therefore, it is essential that an appropriate microalgal strain with lower nitrogen requirements which produces multiple metabolites for the generation of high-value bioproducts (e.g., pigments), medium-value bulk products (e.g., long-chain polyunsaturated fatty acids; LC-PUFAs), and lipids for biofuels is recognized. In addition, it is critical that the optimal cultivation procedure for this species is identified to maximize metabolite and lipid production, thereby rendering a cost-effective and sustainable technology for biofuel production.

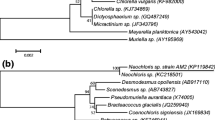

The Eustigmatophyceae (Heterokontophyta) is a small class of unicellular coccoid yellow-green algae, distinct from the coccoid Xanthophyceae on the basis of cytological and ultrastructural properties (Hibberd and Leedale 1970). The potential use of some species of Eustigmatophyceae for commercial production of biofuels and bioproducts has been based on their ability to accumulate and store large amount of lipids, hydrocarbons, LC-PUFAs, especially eicosapentaenoic acid (EPA), and various novel carotenoids (Rodolfi et al. 2009; Santos 1996). Previous studies of eustigmatophytes have mainly concentrated on marine species of the genus Nannochloropsis. Its utilization in the production of aquacultural feeds, biofuels, lipids, EPA, commercial valuable pigments, and vitamin E (α-tocopherol) has been extensively investigated (Lubián et al. 2000; Durmaz 2007; Rodolfi et al. 2009; Ferreira et al. 2009; Doan and Obbard 2014). The genomic characterization of Nannochloropsis, as well as the development of techniques in genetic transformation to qualitatively and quantitatively enhance lipid production, has recently been conducted (Vieler et al. 2012; Kilian et al. 2011). Hence, Nannochloropsis has rapidly emerged as a model organism for studies on EPA and biofuel production. A previous study has also indicated that the Eustigmatophyceae comprise highly diverse species, genera, and families with potential industrial utilizations (Fawley et al. 2013).

The accumulation and storage of lipids in various microalgal species are generally affected by various cultivation conditions such as nutrient type and supply, light intensity, salinity, temperature, and culture age (Pal et al. 2011; Procházková et al. 2014). Among all nutrients, nitrogen (N) is an important factor that regulates lipid accumulation in microalgae. N limitation or starvation can trigger microalgae to accumulate massive amounts of storage lipids (Juneja et al. 2013), except for the green algae Dunaliella primolecta and Tetraselmis suecica, where lipid content decreases in N-limiting conditions (Thomas et al. 1984), and the blue-green algae, where little or no changes in lipid content are observed in conditions of limited N (Piorreck et al. 1984). However, N limitation or starvation affects microalgal growth and lipid accumulation, as well as leading to a decrease in the level of LC-PUFAs (Harisko and Posten 2014). Therefore, determining the appropriate initial N concentration (e.g., an intermediate N concentration) that balances the growth, lipid accumulation, and high-value biomolecules synthesis in microalgae is warranted.

The eustigmatophyte Eustigmatos cf. polyphem has been shown to accumulate large amounts of lipid (60.6 % dry weight) (Zhang et al. 2013). On the other hand, information for Vischeria stellata, a soil microalga from the same family as Eustigmatos, is limited. Therefore, the present study examined changes in the cytological morphology and ultrastructure, as well as growth, lipid accumulation pattern, fatty acid profile, and pigment composition of V. stellata cultured with different initial nitrate concentrations. This research aimed to assess the feasibility of producing lipids, EPA, and β-carotene as biofuel feedstock, as well as biomolecules of high- and medium-value using V. stellata. In addition, the ratio of lipid output and nitrate input in V. stellata was examined.

Materials and methods

Vischeria stellata 33.83 was obtained from the Culture Collection of Algae at Göttingen University (SAG). The stock culture of V. stellata was maintained in a 250-mL flask with 150 mL of modified BG-11 medium (Andersen et al. 2005), containing the following components (per liter): 18.0 mM NaNO3, 0.22 mM K2HPO4, 0.3 mM MgSO4·7H2O, 0.24 mM CaCl2·2H2O, 31.2 μM citric acid, 22.2 μM FeCl3·6H2O, 2.69 μM EDTA disodium salt, 0.19 mM Na2CO3, and 1 mL A5 trace elements solution. The V. stellata inoculum was prepared by transferring stock cultures into a 6.0 × 60 cm glass column photobioreactor and cultivating the under aeration for 6–7 days.

For the experiment using different initial concentrations of sodium nitrate, the cells of the seed cultures were harvested by centrifugation at 1000×g for 3 min at room temperature. The cell pellets were then washed three times with N-free modified BG-11 medium. Then, the cell pellets were resuspended into four different initial sodium nitrate concentrations (18.0, 9.0, 6.0, and 3.6 mM) of modified BG-11 medium using a 3.0 × 60 cm glass column (270 mL working volume) with a conical bottom at a starting optical density (OD750) of 0.6 ± 0.09 at 25 ± 1 °C. The cultures were aerated with compressed air containing 1 % (v/v) CO2 through a hollow glass rod. Continuous illumination was provided using a bank of cool-white fluorescent lamps, giving a light intensity of 300 μmol photons m−2 s−1. The cultures belonging to the four treatment groups (each consisting of five replicates) were maintained for 18 days.

Observation of cell morphology and ultrastructure

The morphology of cells from cultures maintained in photobioreactors was observed daily under a light microscope. Sample preparation for transmission electron microscope (TEM) analysis was based on the methods of Zhang et al. (2013). The cells were harvested by using low-speed centrifugation (600×g), followed by double fixation. The harvested cells were prefixed in 2 % glutaraldehyde in 0.1 M phosphate buffer (pH 7.2) at 4 °C for 2 h and then rinsed three times with 1 % phosphate buffer. Subsequently, the cells were post-fixed in 1 % osmium tetroxide in the same buffer at 4 °C for 2 h. Then, the cells were rinsed again and dehydrated through a series of acetone solutions (30, 50, 70, 90, 95, and 100 %) at room temperature for 30 min. Finally, the dehydrated samples were incubated in a 1:1 mixture of acetone and Epon 812 resin for 3 h, then in a 1:3 mixture of acetone and Epon 812 resin for 3 h, and finally transferred to 100 % resin and kept overnight. The specimens were then polymerized at 45 °C for 12 h, followed by 60 °C for 24 h. The ultra-thin sections of specimens were stained with uranyl acetate and lead citrate for 30 min each and observed in a TEM (Model Philips, Tecnai 10).

Biomass measurements

Approximately 10 mL of the culture suspension was collected from a photobioreactor each day. The biomass concentration was determined daily by filtration of a 10-mL aliquot of the culture suspension on a previously weighed GF/B glass fiber filter (W1). Then, the membrane with cells was dried in an oven at 105 °C overnight and transferred to a dessicator. After cooling to room temperature, the dried membrane with algal cells was weighed (weight, W2) again. The dry weight (dry cell biomass; DW) was calculated using the following equation: DW (g L−1) = (W2 − W1) × 100.

Determination of nitrate concentration in the culture medium

Ten-milliliter aliquots of the microalgal suspension were collected daily from the photobioreactors and centrifuged at 1000×g for 5 min. The supernatant was filtered through a 0.22-μm filter (GF/C filter China), and the filtrate was transferred into another clean test tube for the determination of nitrate concentration. Measurement of nitrate concentration was conducted on an AutoAnalyzer3 instrument (Bran-Luebbe, Germany).

Lipid extraction and quantification

The cells were harvested by centrifugation at 1000×g for 5 min and then freeze-dried in a freeze drier. Total lipid (TL) content was determined by gravimetric measurement after extraction from freeze-dried microalgal powder as described elsewhere (Khozin-Goldberg et al. 2005), with minor modifications. Lyophilized biomass was extracted with 2 mL of 10 % DMSO-methanol solution in a 50 °C water bath for 10 min, followed by extraction for 30 min at 4 °C. The mixture was then centrifuged at 1000×g for 5 min to isolate the supernatant. The residue was re-extracted with 4 mL 1:1 (v/v) diethyl ether and hexane at 4 °C for 1 h and centrifuged. The extraction process was repeated twice, and the supernatants were combined. Finally, distilled water was added to the methanol extract and diethyl ether-hexane extract to a ratio of 1:1:1:1 (water/methanol/diethyl ether/hexane, v/v/v/v). The upper phase, which contained the lipids, was collected and dried under N2 and weighed.

Separation of lipid fractions and quantification

The lipid extracts were separated on a solid-phase silica gel column (Sep-Pak Plus Silica, Waters) and then extracted using the technique described by Christie (1982). The column was equilibrated with chloroform, and then, the lipid extracts were dissolved in chloroform and loaded onto the column. Three sequential eluting solvents, namely, chloroform, acetone/methanol (9:1, v/v), and methanol, were used to isolate the neutral lipids (NLs), glycolipids (GLs), and phospholipids (PLs), respectively. Each fraction was dried under N2 and weighed.

Fatty acid analysis

For fatty acid profile analysis, the freeze-dried microalgal powder was used for in situ transesterification with a methanol/toluene mixture (90:10, v/v) containing 2 % H2SO4 and incubated in an 80 °C water bath for 1.5 h (Cohen et al. 1993). The fatty acid methyl esters (FAME) were analyzed in an Agilent 6890 N Gas Chromatograph (Agilent, USA), equipped with a CD-2560 and a 100 m × 0.25 mm × 0.20 μm column. The injector temperature was 250 °C and that of the detector was 260 °C. The eluant gas was N2. The flow velocity was 23 mL min−1. The first temperature procedure was at a constant 140 °C for 5 min. The temperature was then increased to 240 °C, using increasing increments of 4 °C min−1 and then was held constant for 20 min. Each fatty acid was identified by comparison between the observed retention time and those of the standards.

TL, NL, and total fatty acid productivities

TL, NL, and total fatty acid (TFA) productivities were estimated by using the following equation:

where P x is the productivity of either TLs, NLs, or TFAs; DW is the dry weight; C x is the respective content of TLs, NLs, or TFAs based on dry biomass, and t is the culture time.

TL, NL, and TFA yields based on nitrate utilization

The TL, NL, and TFA yields based on nitrate utilization were calculated by using the following equation:

where Y x is the TL, NL, or TFA yields based on the amount of nitrate; C x is the respective content of TLs, NLs, or TFAs based on dry biomass, and N is the total amount of initial nitrate supplied in the medium of the different treatment groups.

Pigment extraction and analysis

The pigments were extracted from 10 mg of each freeze-dried sample mixed with 5 mL acetone and kept for 24 h at 4 °C. The pigment extracts were filtered through a 0.2-μm nylon membrane filter (Millipore, USA) prior to high-performance liquid chromatography (HPLC) analysis. Pigment analysis was performed on a Dionex model U-3000 HPLC (Dionex, USA) using a Kromasil C18 reverse phase column (5 μm particle size, 250 × 4.6 mm ID, Dionex,) coupled with a C18 guard column (5 μm particle size, 15 × 4.6 mm ID). The binary mobile phase was acetonitrile/water (9:1, v/v) (eluent A) and 100 % ethyl acetate (eluent B). Pigments were eluted at 1 mL min−1 as follows: initial 100 % A and 0 % B, 0–20 min linear gradient to 100 % B, 20–22 min 100 % B, 22–23 min return to 100 % A, and 23–25 min, 100 % A for re-equilibration.

Results

Light microscopy morphology and ultrastructure

The genus Vischeria was established by Pascher in 1937 (Hibberd 1981). The typically identifiable characteristic of this genus is a cell wall raised as projections or ridges in the newly dividing cell or early developmental cell. As cultivation time progresses, the most actively growing vegetative cells in liquid culture have completely smooth, unornamented walls. The cells in logarithmic phase cultures were oval to spherical in shape, although a certain amount of young cells presented an angular, slightly polyhedral, shape (Fig. 1a (A, B, F)), mostly 5–12 μm in diameter, and some of the cells increased in size to a maximum of 35 μm in the late logarithmic phase and stationary phases. There was a single parietal, lobed chloroplast in the cytoplasm. Projections emerged from the cell wall during early culture (Fig. 1a (A, E)), which gradually disappeared over time, and the great majority of cells eventually possess completely smooth walls (Fig. 1a (B)). Massive conspicuous lipid bodies were visible in the cytoplasm, and their volume markedly increased during the later growth stages of cultures (Fig. 1a (C, D)). Vegetative reproduction involved the formation of two or four autospores (Fig. 1a (E, F)) or sometimes zoospores. The zoospore was vase-shaped with a single emergent flagellum attached to the anterior end and a large extraplastidial eyespot under the swollen body of the flagellum (Fig. 1a (G)).

Morphology (a) and ultrastructure (b) of Vischeria stellata. Pyrenoid (P), chloroplast (CP), stalk (S), lamellar compound (CL), thylakoid (T), nucleus (N), mitochondria (M), lamellate vesicle (LV), and red body (RB). The scale bar represents 10 μm in a and 1 μm in b, except for b, 4 and 5, where it represents 500 nm. The cell is in the logarithmic phase and early culture in a, A and B; the cell is in stationary phase and at the later growth stage of culture in a, C and D

The TEM images showed a single large pyrenoid (P) protruding from the inner face of chloroplast (CP) by forming a small stalk (S) and surrounded by several flat lamellate vacuoles (LV) (Fig. 1b (1–3)); the stroma of the pyrenoid was not penetrated by the thylakoids (T) (Fig. 1b (4)). The thylakoids were equally distributed, grouped into three, passing through the entire chloroplast matrix, almost to the chloroplast margins, and the girdle lamella was diminished (Fig. 1b (5)). The chloroplast double-membrane envelope was enveloped by the chloroplast endoplasmic reticulum. A large reddish globule with droplets (RB) was located in the cytoplasm of vegetative cells (Fig. 1b (2)). Several smaller vesicles with identical contents (CL) were also freely scattered within the cytoplasm (Fig. 1b (1)). The nucleus (N) is always located proximal to the pyrenoid of vegetative cells. Several lipid bodies (LB) were formed in the cytoplasm of stationary stage cells (Fig. 1b (1, 2, 6)).

The effect of initial nitrate concentration on growth rate and lipid accumulation pattern

The effect of initial nitrate concentration on biomass accumulation in V. stellata is shown in Fig. 2a. The maximum biomass concentration (9.8 g L−1) was observed in the 6.0 mM nitrate treatment group. However, the biomass concentration 7.9 g L−1 at the low initial nitrate concentration of 3.6 mM was significantly less than that of the other three treatments. The nitrate level in culture media with 3.6 mM and 6.0 mM initial nitrate concentrations was almost depleted after 2 days, whereas those of 9.0 mM and 18.0 mM initial nitrate concentrations were depleted after 3 and 5 days, respectively (Fig. 2a).

Time-course changes in biomass and nitrate concentration in the culture medium (a) and lipid accumulation (b) of Vischeria stellata grown under four different initial nitrate concentrations in modified BG-11 medium (solid line represents the biomass, dash line represents the nitrate concentration in the medium, and %DW represents percentage of dry weight)

During the growth period, TLs of the four different initial nitrate supply treatment groups constantly increased (Fig. 2b), and the initial nitrate concentration significantly influenced lipid content with low nitrate-nitrogen concentration accelerating lipid accumulation. The maximum TL was 55.9 % of dry biomass in the 3.6 mM initial nitrate treatment group on day 18, whereas TL content reached only 43.3 % of dry biomass in the 18.0 mM nitrate treatment group.

Effect of initial nitrate concentrations on lipid classes

The extracted lipids consisted of polar lipids and nonpolar lipids. The polar lipids could be further classified into GLs and PLs, which are the major constituents of membrane lipids. As shown in Fig. 3, GL and PL levels gradually decreased over culture time. NL content progressively increased with the accumulation of storage triacylglycerols (TAGs). In addition, NL content increased more at lower initial nitrate concentrations. The NLs were in the main fraction of the TLs of the four different initial nitrate treatment groups. Neutral lipids reached 93 % of TLs in the cultures with an initial 3.6 mM nitrate concentration. Even in the 18.0-mM treatment group, NL content also reached 88 % of the TLs at harvest time.

Changes in the contents of lipid fractions of V. stellata cultured in four different nitrate concentrations in modified BG-11 medium (percentage of the total lipids (a), percentage of the dry biomass (b); from left to right, column in each group represents 18.0, 9.0, 6.0, and 3.6 mM of initial nitrate concentration, respectively)

Effect of initial nitrate concentrations on fatty acid profiles and levels

The main fatty acids in V. stellata were palmitic acid (C16:0), palmitoleic acid (C16:1), oleic acid (C18:1), arachidonic acid (C20:4), and eicosapentaenoic acid (C20:5) (Fig. 4). The content of monounsaturated fatty acids (%TFAs), including palmitoleic acids and oleic acids, slightly increased over culture time. In addition, the polyunsaturated fatty acids, C20:4 and C20:5 (%TFAs), gradually decreased (Fig. 4a). On the other hand, the content of fatty acids in terms of dry weight gradually increased with lower initial nitrate concentrations, which is consistent with the changes in TL content (Fig. 4b). As shown in Fig. 5b, the highest fatty acid content of 44.7 % DW was observed using the 3.6 mM initial nitrate concentration, which was 13 % higher than the 18.0 mM treatment. The content of palmitic acid (C16:0) was the highest, reaching 16–28 % DW, and EPA (C20:5) reached 1.3–1.44 % DW at the end of cultivation.

The content of individual fatty acid is given as a percentage of the total fatty acid content (%TFAs) (a), and the content of individual fatty acid given as a percentage of the dry biomass weight (%DW) (b) (the four columns show different initial nitrate concentration groups; from left to right as 18.0, 9.0, 6.0, and 3.6 mM NaNO3, respectively)

Effect of initial nitrate concentrations on the productivities and yields of TLs, NLs, and TFAs

The productivities of TLs, NLs, and TFAs are important in the evaluation of the potential of microalgal species as biodiesel production (Griffiths and Harrison 2009). The highest volumetric productivity of TLs, NLs, and TFAs was achieved in the cultures with 6.0 mM initial nitrate concentration, and the productivities were 0.28 g L−1 day−1 (TLs), 0.25 g L−1 day−1 (NLs), and 0.21 g L−1 day−1 (TFAs) (Fig. 5a).

The TL, NL, and TFA yields on the basis of initial nitrate concentration increased with lower initial nitrate concentrations (Fig. 5b). The highest TL yield was 14.7 g g−1 nitrate in the 3.6 mM nitrate cultures, which was 5.7-times the yield of TL using 18.0 mM nitrate. The maximum NL and TFA yields were also observed with 3.6 mM nitrate, was and were 13.7 and 11.8 g g−1, respectively.

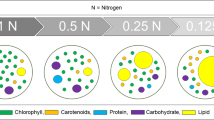

Effect of initial nitrate concentrations on pigment composition and β-carotene content

The major pigments of V. stellata were violaxanthin, vaucheriaxanthin, chlorophyll a, and β-carotene (Fig. 6). The color of the culture medium changed from green to yellow and orange in the lower initial nitrate concentration treatment group (data not shown). The content of β-carotene in V. stellata rapidly increased after the growth phase and was the predominant pigment on day 18. The initial nitrogen concentration affected β-carotene accumulation. The highest content of β-carotene was observed in the 18.0 mM initial nitrate concentration treatment group, reaching 1.3 % of dry weight.

Discussion

The general morphology and ultrastructure of the vegetative cells and zoospores, including the flagellar apparatus of V. stellata, has been previously described (Santos and Leedale 1991). The release of zoospores in V. stellata was induced by transferring the culture from light to dark, as in other species of Eustigamtophyceae (Santos 1996).

N is an essential element for all microalgae, and its limitation or deprivation leads to metabolic changes (Procházková et al. 2014). The effects of N limitation on growth rate and lipid content are species-specific. In V. stellata, the maximum biomass concentration was observed using an initial nitrate concentration of 6.0 mM and not using the highest initial nitrate concentration, 18.0 mM. This suggests that high nitrate concentrations inhibit the growth of V. stellata. The optimal nitrate concentration for the growth of V. stellata was between 6.0 and 9.0 mM. Similarly, Griffiths et al. (2014a) found that the maximum growth rate of Chlorella vulgaris was achieved in cultures supplemented with 40 to 100 mg L−1 nitrate and slightly decreased at higher nitrate concentrations of up to 2000 mg L−1. The nitrate in the medium was rapidly utilized by V. stellata and was almost depleted in all treatments after 5 days, whereas growth continued and biomass concentration gradually increased. The continuous accumulation of biomass was at least partly dependent on intracellular N sources (Pruvost et al. 2009). On the other hand, the growth of Neochloris oleoabundans was immediately terminated after total nitrate consumption (Pruvost et al. 2009). The response of lipid accumulation to N stress in V. stellata was relatively rapid and started on day 3. Lower initial N concentration supply accelerated lipid accumulation. The TL content reached 40 % DW on day 6 with a 3.6 mM initial nitrate concentration supply, which was >14 % higher than that observed in the 18.0 mM treatment group.

Under optimal growth conditions, microalgae synthesize fatty acids principally for esterification into membrane lipids: PLs for plasma membranes and various organelle membranes and GLs for chloroplast membranes. However, when microalgae are stressed by N-limiting conditions that continue to permit carbon fixation, lipid biosynthesis patterns are altered, usually resulting in the accumulation of NLs (López et al. 2000; Piorreck et al. 1984). The NLs were mainly triacylglycerols, which are a major energy reserve in lipid bodies of cells and which also can be readily converted to biodiesel (Guschina and Harwood 2009). Therefore, a high proportion of NLs in microalgae could be used as a major selection criterion for biofuel production (Griffiths and Harrison 2009). V. stellata could accumulate high levels of NLs, reaching up to 88 to 93 % of TLs and 38 to 52 % of dry weight.

The fatty acid profiles of microalgae vary with species and physiological state (Juneja et al. 2013). The fatty acid composition of V. stellata was similar to other Eustigmatophyceae. C16:0, C16:1, C18:1, and C20:5 fatty acids were the major constituents, accounting for >80 % of TFAs. N deprivation enhanced the TFA content with a decrease in the proportion of PUFAs, C20:4 and C20:5, and an increase in the percentage of the monounsaturated fatty acids (MUFAs), C16:1 and C18:1 (Hoffmann et al. 2010). Fatty acid composition significantly influences biodiesel quality, including cetane number, cold filter plug point, viscosity, density, higher heating value, iodine value, acid value, and saponification value (Olmstead et al. 2013). The abundance of saturated and monounsaturated fatty acids, especially those rich in decanoic and palmitoleic acid, as well as a low level of PUFA would likely produce biodiesel with better overall properties (Knothe 2013; Olmstead et al. 2013). V. stellata possesses the appropriate fatty acid profile for biodiesel production.

Lipid productivity is a suitable evaluation parameter for lipid production. N deficiency usually increases lipid accumulation, but at a slow growth rate, which generally leads to lower lipid productivity (Brennan and Owende 2010). Therefore, maximum lipid productivity is often achieved by using an intermediate nitrogen concentration. Griffiths et al. (2014a) reported that maximum lipid productivity of Chlorella vulgaris occurred with a starting nitrate concentration ranging from 241 to 305 mg L−1. Maximum lipid productivity in Neochloris oleoabundans is 133 mg mg L−1 day−1 using 5 mM nitrate concentration (Li et al. 2008). The maximum volumetric productivity of TLs in V. stellata of 280 mg L−1 day−1 was achieved using a 6.0 mM initial nitrate concentration. As crude lipid components cannot be totally converted to biodiesel, therefore, NL productivity and fatty acid productivity are more suitable criteria in determining the potential of the microalgae for biodiesel production, especially when reports on a particular species are limited. Because V. stellata could accumulate high levels of NLs, comprising 88 to 93 % of the TLs, no significant difference between lipid productivity and NL productivity was observed. The maximum NL productivity was 254 mg L−1 day−1, which was also obtained with a 6.0 mM initial nitrate concentration. Fatty acid productivity was much lower than lipid productivity, and the maximum fatty acid productivity was 213 mg L−1 day−1. The consumption of N sources also directly affects the production cost of microalgae-based biofuels. By considering the factors of cost and the environment, the lipid yield based on nitrate utilization has also been determined to be a key evaluation index for lipid production (Griffiths et al. 2014b). V. stellata generated the highest yield of TLs (14.7 g g−1) using 3.6 mM nitrate, which was much higher than the reported highest yield of lipid per gram nitrate in Chlorella vulgaris (4.6 g g−1), in N-limited batch cultures (Griffiths et al. 2014b).

Chlorophyll has been considered a N reservoir in several previous studies, providing N when it is unavailable in the environment (Pruvost et al. 2009). The degradation of chlorophyll and the increase in certain carotenoid pigments often accompany lipid synthesis (Lien and Spencer 1983). V. stellata accumulated β-carotene following the growth phase. While the content of β-carotene decreased with lower nitrate concentrations in V. stellata, this pattern was not observed in Dunaliella salina (Ben-Amotz and Avron 1983).

V. stellata is an edaphic unicellular eustigmatophycean microalga that undergoes cytological and ultrastructural changes with culture age. It can accumulate large amounts of storage lipids comprising high-quality fatty acids suitable for biodiesel production, as well as extractable eicosapentaenoic acid and a certain amount of β-carotene for potential nutraceutical uses. The initial nitrate supply significantly affects growth, lipid accumulation, fatty acid composition, and the pigment profile of V. stellata. The highest lipid productivity was achieved with an intermediate level of initial nitrate supply. However, a high level of storage lipids and high yield of lipids based on nitrate-nitrogen can be obtained with a low level of initial nitrate supply.

References

Andersen RA, Berges JA, Harrisson PJ, Watanabe MM (2005) Recipes for freshwater and seawater media. In: Anderson RA (ed) Algal culturing techniques. Elsevier, Amsterdam, pp 429–538

Ben-Amotz A, Avron M (1983) On the factors which determine massive β-carotene accumulation in the halotolerant alga Dunaliella bardawil. Plant Physiol 72:593–597

Borowitzka MA (2013a) Energy from microalgae: a short history. In: Borowitzka MA, Moheimani NR (eds) Algae for biofuels and energy. Springer, Dordrecht, pp 1–15

Borowitzka MA (2013b) High-value products from microalgae—their development and commercialisation. J Appl Phycol 25:743–756

Brennan L, Owende P (2010) Biofuels from microalgae—a review of technologies for production, processing, and extractions of biofuels and co-products. Renew Sustain Energy Rev 14:557–577

Chisti Y (2007) Biodiesel from microalgae. Biotechnol Adv 25:294–306

Christie WW (1982) Lipid analysis. Isolation, separation, identification, and structural analysis of lipid, 2nd edn. Pergamon Press, Oxford, p 207

Cohen Z, Norman HA, Heimer YM (1993) Potential use of substituted pyridazinones for selecting polyunsaturated fatty acid overproducing cell lines of algae. Phytochemistry 32:259–264

Doan YTT, Obbard JP (2014) Two-stage cultivation of a Nannochloropsis mutant for biodiesel feedstock. J Appl Phycol. doi:10.1007/s10811-014-0490-4:1-6

Durmaz Y (2007) Vitamin E (α-tocopherol) production by the marine microalgae Nannochloropsis oculata (Eustigmatophyceae) in nitrogen limitation. Aquaculture 272:717–722

Fawley KP, Eliáš M, Fawley MW (2013) The diversity and phylogeny of the commercially important algal class Eustigmatophyceae, including the new clade Goniochloridales. J Appl Phycol 26:1773–1782

Ferreira M, Coutinho P, Seixas P, Fábregas J, Otero A (2009) Enriching rotifer with “premium” microalgae, Nannochloropsis gaditana. Mar Biotechnol 11:585–595

Griffiths MJ, Harrison STL (2009) Lipid productivity as a key characteristic for choosing algal species for biodiesel production. J Appl Phycol 276:23–25

Griffiths MJ, van Hille RP, Harrison STL (2014a) The effect of nitrogen limitation on lipid productivity and cell composition in Chlorella vulgaris. Appl Microbiol Biotechnol 98:2345–2356

Griffiths MJ, van Hille RPV, Harrison STL (2014b) The effect of degree and timing of nitrogen limitation on lipid productivity in Chlorella vulgaris. Appl Microbiol Biotechnol 98:6147–6159

Guschina IA, Harwood JL (2009) Algal lipids and effect of the environment on their biochemistry. In: Arts MT, Brett MT, Kainz MJ (eds) Lipids in aquatic ecosystems. Springer, New York, pp 1–25

Hannon M, Gimpel J, Tran M, Rasala B, Mayfield S (2010) Biofuels from algae: challenges and potential. Biofuels 1:763–784

Harisko I, Posten C (2014) Biorefinery of microalgae—opportunities and constraints for different production scenarios. Biotechnol J 9:739–752

Hibberd DJ (1981) Notes on the taxonomy and nomenclature of the algal classes Eustigmatophyceae and Tribophyceae (synonym Xanthophyceae). Bot J Linn Soc 82:93–119

Hibberd DJ, Leedale GF (1970) Eustigmatophyceae—a new algal class with unique organization of the motile cell. Nature 225:758–760

Hoffmann M, Marxen K, Schulz R, Vanselow KH (2010) TFA and EPA productivities of Nannochloropsis salina influenced by temperature and nitrate stimuli in turbidostatic controlled experiments. Mar Drugs 8:2526–2545

Juneja A, Ceballos RM, Murthy GS (2013) Effects of environmental and nutrient availability on the biochemical composition of algae for biofuels production: a review. Energies 6:4607–4638

Khozin-Goldberg I, Shrestha P, Cohen Z (2005) Mobilization of arachidonyl moieties from triacylglycerols into chloroplastic lipids following recovery from nitrogen starvation of the microalga Parietochloris incisa. Biochim Biophys Acta 1738:63–71

Kilian O, Benemann CS, Niyogi KK, Vick B (2011) High-efficiency homologous recombination in the oil-producing alga Nannochloropsis sp. Proc Natl Acad Sci U S A 108:21265–21269

Knothe G (2013) Production and properties of biodiesel from algal oils. In: Borowitzka MA, Moheimani NR (eds) Algae for biofuels and energy. Springer, Dordrecht, pp 207–221

Li YQ, Horsman M, Wang B, Wu N, Lan CQ (2008) Effects of nitrogen sources on cell growth and lipid accumulation of green alga Neochloris oleoabundans. Appl Microbiol Biotechnol 81:629–636

Lien S, Spencer KG (1983) Algal oil production and lipid metabolism research. In: Aquatic Species Program Review: Proceedings of the March Principal Investigators’ Meeting. Solar Energy Research Institute, Golden, Colorado. SERI/CP-231-1946 pp 3–18

López AD, Belardi E, Fernández-Sevilla JM, Rodríguez-Ruiz J, Molina-Grima E (2000) Acyl lipid composition variation related to culture age and nitrogen concentration in continuous culture of the microalga Phaeodactylum tricornutum. Phytochemistry 54:461–471

Lubián LM, Montero O, Moreno-Garrido I, Huertas IE, Sobrino E, Valle MG, Parés G (2000) Nannochloropsis (Eustigmatophyceae) as source of commercially valuable pigments. J Appl Phycol 12:249–255

Olmstead ILD, Hill DRA, Dias DA, Jayasinghe NS, Callahan DL, Kentish SE, Scales PJ, Martin GJO (2013) A quantitative analysis of microalgal lipids for optimization of biodiesel and omega-3 production. J Biotechnol Bioeng 110:2096–2104

Pal D, Khozin-Goldberg I, Cohen Z, Boussiba S (2011) The effect of light, salinity, and nitrogen availability on lipid production by Nannochloropsis sp. Appl Microbiol Biotechnol 90:1429–1441

Peccia J, Haznedaroglu B, Gutierrez J, Zimmerman JB (2013) Nitrogen supply is an important driver of sustainable microalgae biofuel production. Trends Biotechnol 31:134–138

Piorreck M, Baasch KH, Pohl P (1984) Biomass production, total protein, chlorophylls, lipids and fatty acids of freshwater green and blue-green algae under different nitrogen regimes. J Phytochem 23:207–216

Procházková G, Brányiková I, Zachleder V, Brányik T (2014) Effect of nutrient supply status on biomass composition of eukaryotic green microalgae. J Appl Phycol 26:1359–1377

Prommuak C, Pavasant P, Quitain AT, Goto M, Shotipruk A (2013) Simultaneous production of biodiesel and free lutein from Chlorella vulgaris. Chem Eng Technol 36:733–739

Pruvost J, Vooren GV, Cogne G, Legrand J (2009) Investigation of biomass and lipids production with Neochloris oleoabundans in photobioreactor. Bioresour Technol 100:5988–5995

Rodolfi L, Zittelli GC, Bassi N, Padovani G, Biondi N, Bonini G, Tredici MR (2009) Microalgae for oil: strain selection, induction of lipid synthesis and outdoor mass cultivation in a low-cost photobioreactor. Biotechnol Bioeng 102:100–112

Santos LMA (1996) The Eustigmatophyceae: actual knowledge and research perspectives. Nova Hedwigia 112:391–405

Santos LMA, Leedale GF (1991) Vischeria stellata (Eustigmatophyceae): ultrastructure of the zoospores, with special reference to the flagellar apparatus. Protoplasma 164:160–167

Sheehan J, Dunahay T, Benemann J, Roessler P (1998) A look back at the U.S. Department of Energy’s Aquatic Species Program—biodiesel from algae. National Renewable Energy Laboratory, Golden, Colorado. NREL/TP-580-24190, pp 1–328

Thomas WH, Seibert DLR, Alden M, Neori A, Eldridge P (1984) Yields, photosynthetic efficiencies and proximate chemical composition of dense marine microalgal cultures. I. Introduction and Phaeodactylum tricornutum experiments. Biomass 5:181–209

Vieler A, Wu GX, Tsai CH, Bullard B, Cornish AJ et al (2012) Genome, functional gene annotation, and nuclear transformation of the heterokont oleaginous alga Nannochloropsis oceania CCMP1779. PLoS Genet 8, e1003064

Zhang JJ, Wan LL, Xia S, Li AF, Zhang CW (2013) Morphological and spectrometric analyses of lipids accumulation in a novel oleaginous microalga, Eustigmatos cf. polyphem (Eustigmatophyceae). Bioprocess Biosyst Eng 36:1125–1130

Acknowledgments

This work was supported by the following funding: the Natural Science Foundation of China (No. 31170337); the National High Technology Research and Development Program of China (863 Program) (No. 2013AA065805); the National Basic Research Program of China (973 Program) (No. 2011CB2009001); the Special Program for Low-Carbon, Reform and Development Commission of Guangdong Province (2011–051).

Author information

Authors and Affiliations

Corresponding author

Additional information

Baoyan Gao and Jin Yang contributed equally to this work.

Rights and permissions

About this article

Cite this article

Gao, B., Yang, J., Lei, X. et al. Characterization of cell structural change, growth, lipid accumulation, and pigment profile of a novel oleaginous microalga, Vischeria stellata (Eustigmatophyceae), cultured with different initial nitrate supplies. J Appl Phycol 28, 821–830 (2016). https://doi.org/10.1007/s10811-015-0626-1

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10811-015-0626-1