Abstract

This study investigates the spectral shifting UV-A radiation by fluorescent material as a tool for enhancing Chlorella sp. growth rate in photobioreactors made of UV-stabilized polycarbonate (PC). The fluorescent dye was dissolved in a thermoplastic acrylic resin, and the mixture was applied as a coating on to the substrates. The feasibility of using the fluorescent coating as wavelength shifter layer to shift UV-A radiation of a full spectrum light source to the photosynthetically active region (PAR) was explored. For this purpose, a solution of the fluorescent dye in resin was prepared and used to coat front surface of the reactor. Comparing to the uncoated reactor, the reactor coated with the wavelength shifter layer exhibited about 10 % increase in biomass productivity over the same culture period. It was also found that the elimination of UV-A radiation increases chlorophyll a content in the cells.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Microalgae are photosynthetic microorganisms that convert sunlight, water, and carbon dioxide to biomass. Algal biomass can be a source of commercial high-value chemicals including carotenoids, long-chain polyunsaturated fatty acids, and phycobilins and biodiesel. Also, these photosynthetic microorganisms are useful in bioremediation applications, such as biofertilizers and carbon dioxide biofixation (Chisti 2007; Katsuda et al. 2006; Ranjbar et al. 2008; Borowitzka 2013).

In photoautotrophic cultivation mode, light is the major energy sources for the growth of cells. The properties of the light source, such as spectral power distribution and intensity are critical for the growth of photoautotrophic microalgae. Thus, the specific growth rate, content of photosynthetic pigments, and biochemical composition of cells, such as lipid content, can be influenced by the light source characteristics (Hirata et al. 1998; Matthijs et al. 1996; Danesi et al. 2004; Prokop et al. 1984; Wang et al. 2007; Chrismadha and Borowitzka 1994). Many researchers have investigated the effect of the wavelength on the growth of algae and cyanobacteria (Katsuda et al. 2006; Matthijs et al. 1996; Wang et al. 2010; Katsuda et al. 2008). Ideally, the wavelength of the incident light should be matched with the pigment spectral absorption curve of the individual microorganism to maximize the amount of light utilized for photosynthetic processes. In the case of chlorophyll, absorption bands are present in the blue and in the red region of the visible spectrum (Matthijs et al. 1996; Lee and Palsson 1994; Kohen et al. 1995).

The energy of the sunlight photons can be utilized as a source for carbon dioxide reduction by photosynthetic microorganisms. The spectrum of the sun at the sea level includes wavelengths in the range of >290 nm, while only the band between 400 and 700 nm represents the photosynthetically active radiation (Kohen et al. 1995). Therefore, most of the radiation from the sun remains unused. In fact, by considering the actual photochemical efficiency, all of near-UV (290–400 nm) and IR radiation and a part of visible radiation are not photosynthetically active (Kohen et al. 1995). The spectrum of ultraviolet light ranges from 100 to 400 nm and is divided into UV-A (315–400 nm), UV-B (280–315 nm), and UV-C (<280 nm) (Sinha et al. 1998; Navntoft et al. 2009; Estevez et al. 2001; Holzinger and Lütz 2006). Approximately 90–95 % of the near-UV photons of sunlight are in the UV-A range, while the remaining is composed of UV-B radiation. Both types of UV radiation have been shown to elicit physiological responses in a variety of organisms (White and Jahnke 2002; Turcsányi and Vass 2000; Castenholz 1997). It has been demonstrated that exposing photosynthetic organisms to UV light may result in direct photosynthetic damage and causes photoinhibition (Herrmann et al. 1997; Helbling et al. 1992). Therefore, spectral shifting of UV wavelength to photosynthetically active region (PAR) not only causes less damage to cells but also may lead to a higher number of photons in the PAR which would increase the biomass productivity of microalgae.

Integrating the spectral shifting into the photobioreactor wall seems to influence the photosynthetic efficiency both directly and indirectly. The spectrum modification is a well-researched topic in physics and in chemistry and has been applied, for example, to infrared quantum counters or efficient lamp phosphors (Bloembergen 1959; Ronda 1995). It is also one of the third-generation concepts suggested to overcome the classical efficiency limit of silicon solar cells (Klampaftis et al. 2009, Strümpel et al. 2007; Slooff et al. 2007; Richards 2006). There are two possibilities to use the high energy part (350–550 nm) of the solar spectrum more efficiently, namely photoluminescence and down-conversion. For photoluminescence, the quantum efficiency is always ≤1.0, whereas for down-conversion, the quantum efficiency can be >1 (Strümpel et al. 2007; Hovel et al. 1979). Many of the materials like quantum dots (QDs), organic dyes, and rare earth ions/complexes demonstrate that down-conversion or photoluminescence is well suited for silicon solar cell applications (Strümpel et al. 2007; Slooff et al. 2007; Richards 2006; Hovel et al. 1979; van Sark 2008; van Sark et al. 2005; Richards and McIntosh 2007; Maruyama and Kitamura 2001). These materials must exhibit (i) a high quantum efficiency; (ii) a wide absorption band in the region where efficiency of the cell is low; (iii) a high absorption coefficient; (iv) a narrow emission band, coinciding with the peak of the maximum photovoltaic efficiency of the cell; (v) good separation between the absorption and emission bands in order to minimize losses due to reabsorption; and (vi) low-cost and prolonged photostability (Klampaftis et al. 2009; Strümpel et al. 2007; Hovel et al. 1979; van Sark 2008; van Sark et al. 2005). These characteristics also seem to be of interest in wavelength shifting strategies for photosynthetic applications. Wondraczek et al. (2013) used Sr0.4Ca0.59Eu0.01S as a spectral converter in a flat panel reactor growing Haematococcus pluvialis. This converter was placed on the backside of the reactor with a mirror to convert green light of the solar spectrum passing through the broth to red and reflect the red light back into the broth. They observed an about 36 % increase in cell generation compared to the flat plate reactor without the backside converter under solar radiation. Also, Xia et al. (2013) used this technique to increase photosynthetic activity in Spinacia oleracea. They used a Ca0.4Sr0.6S:Eu2+ as converter material on a backlight converter foil and observed a more than 25 % increase in CO2 assimilation rate under metal halide lamp radiation. Furthermore, different Lumogen F dyes as fluorescent material have been used to enhance of Chlorella vulgaris growth in different cultivation modes (Mohsenpour et al. 2012; Mohsenpour and Willoughby 2013). They found that biomass productivity of C. vulgaris increased up to 20 % under Xenon arc lamp radiation. Changes in growth because of the type of spectral conversion of light strategy were dependent on the cultivation mode. Delavari Amrei et al. (2013) used the fluorescent dye, Uvitex OB, for converting UV-A to blue light in 50-mL culture flasks with Synechococcus sp. They used coated polycarbonate sheets with different concentration of the dye in front of each flask and experimentally observed up to 38 % increase in the biomass productivity under UV-A radiation.

In a previous study (Delavari Amrei et al. 2013), a transparent acrylic-based coating on a UV-stabilized polycarbonate (PC) sheet was used to change its optical properties and the effects of shifting of UV-A radiation to blue light by the fluorescent dye Uvitex OB on the growth of cyanobacteria was investigated. For this purpose, a source that emitted only UV-A radiation was used. In this study, a more realistic light source was used. Both UV-A and visible wavelengths exist in the spectral distribution of the light source. In fact, this source was used as a full spectrum light. Also, the effect of Uvitex OB as a photoluminescence material in a PMMA-based resin on shifting the UV-A wavelengths of the full spectrum to PAR for increasing the growth rate of Chlorella sp. was investigated.

Materials and methods

Chlorella sp. (PTCC 6010) from the Iranian Research Organization for Science and Technology was used as a probe for the efficiency of the UV-A to PAR shifts. This microorganism was pre-cultivated in BG11 medium (pH∼8) (Imamoglu et al. 2010). After pre-cultivation in a 250-mL flasks (100 mL working volume) under cool white fluorescent light with 25 μmol photons m−2 s−1, Chlorella sp. was inoculated into a 2,000-mL flask (1,000-mL working volume) containing 900 mL standard inorganic medium. This medium contained (in mg L−1) 300 NaNO3, 20 KH2PO4, 80 K2HPO4, 20 NaCl, 47 CaCl2, 10 MgSO4·7H2O, 0.1 ZnSO4·7H2O, 1.5 MnSO4·H2O, 0.08 CuSO4·5H2O, 0.3 H3BO3, 0.3 (NH4)·6Mo7O24·4H2O, 17 FeCl3·6H2O, 0.2 Co(NO3)2·H2O, and 7.5 EDTA.

Light source

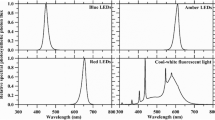

A metal halide lamp (MH-DE RX7S Daylight, Alite, Germany) was used as a full spectrum light source. About 10 % of emitted radiation from this lamp is in the UV region. This lamp shows very sharp peaks in the visible region. The color rending index (CRI) for this lamp is between 80 to 90 %.

Wavelength shifter sheets

In order to make wavelength shifter sheets, PC was used as the substrate. Solutions of fluorescent dye Uvitex OB (BASF, Germany) in a thermoplastic acrylic resin \( \left(\frac{0.1g-0B}{30g-\mathrm{re} \sin}\right) \) were applied on the sheets by air spray technique at 3.5 bar using an air spray gun (Iwata W101, Japan). The coatings were then dried after a short flash-off time at 60 °C for 5 min.

Experimental setup

After cultivation in a 2,000-mL flask, 540 mL of the broth was distributed equally in two polycarbonate-based flat plate reactors with a capacity of 400 mL each (working volume of 270 mL or 3 × 9 × 10 cm3). All sides of reactors are covered with aluminum foil which acts as a light reflector, except for the side facing the light source (Fig. 1). In one of these reactors, this face was coated with the fluorescent material. The whole setup was placed in a black enclosure at 27 ± 1 °C for 14 days.

Measurement of the growth

The optical density (OD) of the broth was determined by measuring the absorbance of the broth at 560 nm in a double beam UV/vis spectrophotometer (V-550, JASCO, USA) with cell path length of 1 cm. For measurement of biomass dry weight, a 10-mL sample of algal suspension was filtered through a pre-dried and pre-weighed 47-mm Whatman paper filter (GF/F, nominal pore size of 0.7 μm) and washed twice with 20 mL of distilled water. After that, the filter was dried in 105 °C overnight. It was then placed in a desiccator and weighed to the nearest 0.1 mg for the determination of biomass dry weight.

The relationship between the biomass concentration (X, mg L−1) or dry weight (R 2 = 0.97) and OD is obtained as follows:

The specific growth rate of the culture was calculated using Eq. (2):

where μ is the specific growth rate (day−1) and X t and X 0 are the biomass concentration at time t and at the beginning, respectively.

The biomass productivity rate (P in mg L−1 day−1) was estimated by Eq. (3):

where X F is the biomass concentration at the end of the cultivation (t F).

Cell examination and counting was carried out by an improved Neubauer hemocytometer (Brand, Wertheim, Germany).

In order to obtain the concentration and absorption spectra of pigments, cells collected in 2-mL centrifuge tubes were disrupted in an ultrasonic bath (LBS1, Falc, Italy) for 45 min. The pigments were extracted with 2-mL methanol overnight in an ice bath. The mixture was centrifuged at 2,500×g for 10 min to sediment the cell debris. Supernatant liquid was used for the determination of the absorption curve of the pigments using the UV/vis spectrophotometer. Finally, the content of chlorophyll a and b and total carotenoids was calculated according to Lichtenthaler and Wellburn (1985).

Absorption, emission, and transmittance spectra

Absorption spectra of the shifter sheets were determined using the double beam UV-vis spectrophotometer with air as reference. Absorption spectra of shifter layers for different samples were obtained by considering uncoated PC sheet as reference. Emission spectra of the shifter layer and output spectrum of the light source were determined using a high-resolution spectrometer (HR4000 Ocean Optics, USA).

Visible light and UV-A intensity were measured by a light meter (TES-1330A, Taiwan) and UV light meter (UV-340, Lutron, Taiwan), respectively. The bulb-sample distance was regulated so that the intensity of the light at the front surface of reactors was 1,200 lx. This corresponds to a photon flux rate of about 25 μmol photons m−2 s−1 for the metal halide lamp. A linear relationship was found between the intensity of the radiation measured by the lux-meter or the UV-A-meter and the area under the spectral distribution curve obtained by the spectrometer.

Results

As presented in Fig. 2, the shifter layer shows two different absorption peaks: one at 370 nm and the other at 380 nm. Emission spectra of the coated sheets exhibit two peaks at 435 nm and the other at 465 nm. The former is close to one of the absorption peaks of chlorophyll a at 430 nm, and the latter is close to one of the absorption peaks of chlorophyll b at 460 nm. Both peaks of the emission spectrum corresponded to the absorption band of chlorophylls + carotenoids (gray area in Fig. 2) (Kohen et al. 1995; Solovchenko 2010).

In order to obtain the highest photostability, PC is stabilized using UV absorber additives. In PC plates, the light emerging at the broth does contain a very low amount of UV-A radiation. By coating plates with fluorescent material, some of the UV-A radiation converts to visible light and therefore the transmittance of the UV-A radiation from plates becomes less than that of the uncoated plates. Therefore, it is rational to compare the effect of the coated and uncoated PC-based reactors. This can show how the wavelength shifting strategy will influence the specific growth rate and the biomass productivity.

The uncoated PC sheet shows an acute absorption of UV-A wavelengths (Fig. 3). This minimizes the transmission of the UV-A radiation through the uncoated PC sheet. For the coated PC sheet, due to the fluorescent characteristic of the wavelength shifter layer, some of the UV-A radiations are converted to visible light (400–600 nm), while hitting this layer and most of the remaining UV-A radiation was absorbed by the PC itself.

The spectral power distributions of the light reaching the broth of coated and uncoated reactors are presented in Fig. 4. By considering spectra B and C in this figure, most of the UV-A radiations emitted from the metal halide lamp (spectrum C) are removed by the reactor wall. In fact, a little UV-A radiation reaches the broth in the uncoated reactor, whereas for the coated reactor, all of the UV-A radiations were absorbed by the shifter layer and reactor wall. The percentage of UV-A and PAR radiation and total intensity for different spectra are presented in Table 1. The intensity of different spectra was calculated from the surface area under the corresponding curve in Fig. 4. This surface area and intensity have a linear relation (R 2 = 0.98). As shown in Table 1, total and visible light intensity that reaches the broth in the coated reactor is more than that in the uncoated reactor. Furthermore, because of the reflectance and absorbance characteristic of PC sheet (or the reactor wall), intensity of spectra A and B is about 80 % of intensity of spectrum C.

Time course for Chlorella sp. growth in the different reactors is shown in Fig. 5, and the growth parameters are presented in Table 2. The maximum specific growth rate in the coated reactor showed higher values. Comparing to the uncoated reactor, the coated reactor with the wavelength shifter layer exhibited a 10 % increase in the biomass productivity during the same culture period.

The chlorophyll content in the cell for the broth of coated reactor is higher than uncoated one (Table 2). In fact, reduction of UV-A radiation enhanced the chlorophyll content in the cells. Therefore, it seems that for its production, spectral distribution of the light is important.

Discussion

Shifting of UV-A wavelengths of the full spectrum light source to blue light was investigated for improving the growth rate of microalgae. Using Chlorella sp. in a PC-based reactor that was coated with Uvitex OB, an increase in the biomass productivity rate of 10 % compared to the reactor without coating was achieved. Despite of the fact that the energy intensity reaching the broth of the coated reactor is lower than that of the uncoated reactor, the biomass productivity in the coated reactor is more than the uncoated one. In other words, converting the UV-A radiation emerging at the surface of the walls of the photobioreactor into visible light by a shifter layer increases the biomass productivity rate. For this purpose, Uvitex OB was used as fluorescent dye to shift UV-A photons to PAR. Because of corresponding of peaks of emission spectrum of the dye with absorption band of chlorophyll + carotenoids (Kohen et al. 1995; Solovchenko 2010), the fluorescent dye is suitable for shifting the wavelengths from UV-A range to PAR. Furthermore, absorption and emission spectra of the dye overlapped at a very short range (∼400–420 nm) (Fig. 2), and this can cause the reabsorption and energy loss to be minimized.

The shifter layer was assumed to be a homogeneous medium, consisting of PMMA and the fluorescent dye. PMMA is a suitable matrix for dissolving the luminescent species and exhibits high transmittance, particularly in the PAR region where the cell’s response is high. In this medium, a photon can experience different events. As can be seen in Fig. 6, the incident photons (a) are absorbed and reemitted with wavelength longer than that at the absorption band of the shifter layer. The majority of the shifted photons will leave the shifter layer directly (b) or following internal reflection at air: shifter layer interface (c) or via reabsorption (d) and through reemission by dye molecules (e). A fraction of the shifted photons will exit through the top of shifter layer (f) or through its sides (g); a small amount will be absorbed by the host material (h). Also, some of the incident photons could be absorbed completely by the host material (i) or dye molecules (j). A small part of the incident photons can also be reflected (k) through the surface of the shifter layer or unabsorbed (l) (Klampaftis et al. 2009; Rowan et al. 2008). Some of the emitted photons toward the top or the side of the wavelength shifter layer will escape. For the case of air and PMMA (with refractive index of 1.5), photons that escape from the top plane have been quantified to be in the range of ∼12.5 % (Klampaftis et al. 2009). The losses from the side of the sheet for thin large-area layer are usually not included in calculation and estimation of overall losses (Klampaftis et al. 2009). Furthermore, the number of emitted photons absorbed by the transparent host material (PMMA) is negligible. Thus, about 87 % of emitted (blue) photons leave the shifter layer. The enhancement of the number of blue photons within the reactor is the reason for the improvement in the biomass productivity and cell generation.

Based on the polynomial interpolation of the data of McCree (1972) for a variety of crop plants, the average quantum efficiency in photosynthesis for blue light is ∼0.67 and for red light is ∼0.82. Therefore, it seems that shifting of UV-A to red region compared to blue region causes increased biomass production. Regardless of the shifting strategy, more work is needed since fluorescent materials which are used for this purpose should be characterized for their quantum efficiency, photostability, and filtration of PAR.

Since the fluorescent material used in this study is only excited with UV radiation and is transparent to PAR, the air spray technique and drying conditions of the shifter layer should be carefully done to prevent any translucency or opacity in the PAR. Otherwise, the nontransparent sheet will filter PAR of the full spectrum light and causing the wavelength shifting technique to become less efficient. Also, since both intensity and spectral distribution of the light have a direct impact on the biochemical composition of microalgae cells including lipids and the metabolism of fatty acid synthesis (Chrismadha and Borowitzka 1994; Sukenik 1991), it is suggested that biochemical composition of microorganisms should also be considered in choosing a suitable wavelength shifting strategy.

In conclusion, it was found that converting the UV-A radiation of the full spectrum light emerging at the surface of the photobioreactor walls into visible light using an integrated wavelength shifting strategy increases the biomass productivity rate. This can be attributed to the improved quality and the optimized quantity of the light emerging at the broth. The implications of this work are significant in the area of design and construction of photobioreactors for large-scale production.

References

Bloembergen N (1959) Solid state infrared quantum counters. Phys Rev Lett 2:84–85

Borowitzka MA (2013) High-value products from microalgae—their development and commercialization. J Appl Phycol 25:743–756

Castenholz RW (1997) Multiple strategy for UV tolerance in cyanobacteria. Spectrum 10:10–16

Chisti Y (2007) Biodiesel from microalgae. Biotechnol Adv 25:294–306

Chrismadha T, Borowitzka MA (1994) Effect of cell density and irradiance on growth, proximate composition and eicosapentaenoic acid production of Phaeodactylum tricornutum grown in a tubular photobioreactor. J Appl Phycol 6:67–74

Danesi EDG, Rangel-Yagui CO, Carvalho JCM, Sato S (2004) Effect of reducing the light intensity on the growth and production of chlorophyll by Spirulina platensis. Biomass Bioenerg 26:329–335

Delavari Amrei H, Nasernejad B, Ranjbar R, Rastegar S (2013) Spectral shifting of UV-A wavelengths to blue light for enhancing growth rate of cyanobacteria. J Appl Phycol. doi:10.1007/s10811-013-0187-0

Estevez MS, Malanga G, Puntarulo S (2001) UV-B effects on Antarctic Chlorella sp. cells. J Photochem Photobiol B 62:19–25

Helbling EW, Villafane V, Ferrario M, Holm-Hansen O (1992) Impact of natural ultraviolet radiation on rates of photosynthesis and on specicfic marine phytoplankton species. Mar Ecol Prog Ser 80:89–100

Herrmann H, Häder DP, Ghetti F (1997) Inhibition of photosynthesis by solar radiation in Dunaliella salina: relative efficiencies of UV-B, UV-A and PAR. Plant Cell Environ 20:359–365

Hirata S, Taya M, Tone S (1998) Continuous cultures of Spirulina platensis under photoautotrophic conditions with change in light intensity. J Chem Eng Jpn 31:636–639

Holzinger A, Lütz C (2006) Algae and UV irradiation: effects on ultrastructure and related metabolic functions. Micron 37:190–207

Hovel HJ, Hodgson RT, Woodall JM (1979) The effect of fluorescent wavelength shifting on solar cell spectral response. Sol Energ Mater 2:19–29

Imamoglu E, Dalay M, Sukan F (2010) Semi-continuous cultivation of Haematococcus pluvialis for commercial production. Appl Biochem Biotech 160:764–772

Katsuda T, Shimahara K, Shiraishi H, Yamagami K, Ranjbar R, Katoh S (2006) Effect of flashing light from blue light emitting diodes on cell growth and astaxanthin production of Haematococcus pluvialis. J Biosci Bioeng 102:442–446

Katsuda T, Shiraishi H, Ishizu N, Ranjbar R, Katoh S (2008) Effect of light intensity and frequency of flashing light from blue light emitting diodes on astaxanthin production by Haematococcus pluvialis. J Biosci Bioeng 105:216–220

Klampaftis E, Ross D, McIntosh KR, Richards BS (2009) Enhancing the performance of solar cells via luminescent down-shifting of the incident spectrum: a review. Sol Energ Mat Sol C 93:1182–1194

Kohen E, Santus R, Hirschberg JG (1995) Photobiology. Academic, London

Lee CG, Palsson BØ (1994) High-density algal photobioreactors using light-emitting diodes. Biotechnol Bioeng 44:1161–1167

Lichtenthaler HK, Wellburn AR (1985) Determination of total carotenoids and chlorophylls a and b of leaf in different solvents. Biochem Soc Trans 11:591–592

Maruyama T, Kitamura R (2001) Transformations of the wavelength of the light incident upon solar cells. Sol Energ Mat Sol C 69:207–216

Matthijs HCP, Balke H, Van Hes UM, Kroon BMA, Mur LR, Binot RA (1996) Application of light-emitting diodes in bioreactors: flashing light effects and energy economy in algal culture (Chlorella pyrenoidosa). Biotechnol Bioeng 50:98–107

McCree KJ (1972) The action spectrum, absorptance and quantum yield of photosynthesis in crop plants. Agr Forest Meteorol 9:191–216

Mohsenpour SF, Willoughby N (2013) Luminescent photobioreactor design for improved algal growth and photosynthetic pigment production through spectral conversion of light. Bioresource Technol 142:147–153

Mohsenpour SF, Richards B, Willoughby N (2012) Spectral conversion of light for enhanced microalgae growth ratesand photosynthetic pigment production. Bioresource Technol 125:75–81

Navntoft C, Dawidowski L, Blesa MA, Fernandez-Ibanez P, Wolfram EA, Paladini A (2009) UV-A (315–400 nm) irradiance from measurements at 380 nm for solar water treatment and disinfection: comparison between model and measurements in Buenos Aires, Argentina and Almeria, Spain. Sol Energ 83:280–286

Prokop A, Quinn MF, Fekri M, Murad M, Ahmed SA (1984) Spectral shifting by dyes to enhance algae growth. Biotechnol Bioeng 26:1313–1322

Ranjbar R, Inoue R, Katsuda T, Yamaji H, Katoh S (2008) High efficiency production of astaxanthin in an airlift photobioreactor. J Biosci Bioeng 106:204–207

Richards BS (2006) Luminescent layers for enhanced silicon solar cell performance: down-conversion. Sol Energ Mater Sol C 90:1189–1207

Richards BS, McIntosh KR (2007) Overcoming the poor short wavelength spectral response of CdS/CdTe photovoltaic modules via luminescence down-shifting: ray-tracing simulations. Prog Photvoltaics Res Appl 15:27–34

Ronda CR (1995) Phosphors for lamps and displays: an applicational view. J Alloy Compd 225:534–538

Rowan BC, Wilson LR, Richards BS (2008) Advanced material concepts for luminescent solar concentrators. IEEE J Sel Top Quant 14:1312–1322

Sinha RP, Klisch M, Gröniger A, Häder DP (1998) Ultraviolet-absorbing/screening substances in cyanobacteria, phytoplankton and macroalgae. J Photochem Photobiol B 47:83–94

Slooff LH, Kinderman R, Burgers AR, Bakker NJ, Van Roosmalen JAM, Buchtemann A (2007) Efficiency enhancement of solar cells by application of a polymer coating containing a luminescent dye. J Sol Energ Eng 129:272–276

Solovchenko A (2010) Photoprotection in plants. Optical screening-based mechanisms. Springer, Heidelberg

Strümpel C, McCann M, Beaucarne G, Arkhipov V, Slaoui A, Svrcek V (2007) Modifying the solar spectrum to enhance silicon solar cell efficiency—an overview of available materials. Sol Energ Mater Sol C 91:238–249

Sukenik A (1991) Ecophysiological considerations in the optimization of eicosapentaenoic acid production by Nannochloropsis sp. (Eustigmatophyceae). Bioresource Technol 35:263–269

Turcsányi E, Vass I (2000) Inhibition of photosynthetic electron transport by UV-A radiation targets the photosystem II complex. Photochem Photobiol 72:513–520

Van Sark WG (2008) Simulating performance of solar cells with spectral downshifting layers. Thin Solid Films 516:6808–6812

Van Sark WG, Meijerink A, Schropp REI, van Roosmalen JAM, Lysen EH (2005) Enhancing solar cell efficiency by using spectral converters. Sol Energ Mat Sol C 87:395–409

Wang C-Y, Fu C-C, Liu Y-C (2007) Effects of using light-emitting diodes on the cultivation of Spirulina platensis. Biochem Eng J 37:21–25

Wang W-J, Sun X-T, Wang G-C, Xu P, Wang X-Y, Lin Z-L, Wang F-J (2010) Effect of blue light on indoor seedling culture of Saccharina japonica (Phaeophyta). J Appl Phycol 22:737–744

White AL, Jahnke LS (2002) Contrasting effects of UV-A and UV-B on photosynthesis and photoprotection of beta-carotene in two Dunaliella spp. Plant Cell Physiol 43:877–884

Wondraczek L, Batentschuk M, Schmidt MA, Borchardt R, Scheiner S, Seemann B, Schweizer P, Brabec CJ (2013) Solar spectral conversion for improving the photosynthetic activity in algae reactors. Nat Commun 4:2047. doi:10.1038/ncomms3047

Xia Q, Batentschuk M, Osvet A, Richter P, Häder DP, Schneider J, Brabec CJ, Wondraczek L, Winnacker A (2013) Enhanced photosynthetic activity in Spinacia oleracea by spectral modification with a photoluminescent light converting material. Opt Express 21:A909–A916

Acknowledgments

We would like to thank Dr. Madanipour and Mr. Hosseini from optical measurement Central Laboratory of Optics, Laser & Photonics Institute of Amirkabir University of Technology for assisting us with light-measuring devices and methods.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Delavari Amrei, H., Ranjbar, R., Rastegar, S. et al. Using fluorescent material for enhancing microalgae growth rate in photobioreactors. J Appl Phycol 27, 67–74 (2015). https://doi.org/10.1007/s10811-014-0305-7

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10811-014-0305-7