Abstract

The potential of liquid manure as sole nutrient source for cultivation of Ulva lactuca was investigated with the perspective of utilizing the produced biomass for feed and/or energy. Algae grown with manure demonstrated equal growth rates to algae grown with standard f/2-medium. The optimum manure concentration, expressed as ammonium concentration, was 25 μM. At these conditions, the biomass produced was potentially suitable for anaerobic digestion, due to a relative high carbon/nitrogen ratio (approximately 19). At higher manure concentrations, tissue concentrations of nitrogen, phosphorus, proteins, and amino acids increased, making the biomass less suitable for anaerobic digestion but potentially interesting as a feed supplement. Cultivating U. lactuca with manure as nutrient source has potential in terms of bioremediation as well as production of bioenergy and protein-feed.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

For decades, macroalgae species of the genus Ulva (Chlorophyta) have received interest as biomass sources for food and feed purposes, due to its high contents of vitamins, trace metals, and dietary fibers (Lahaye and Jegou 1993; Bolton et al. 2009; Taboada et al. 2010). Recently, global warming issues and limited supply of fossil fuels has drawn attention to algae as energy crop as well. A promising and yet realistic estimate of the production potential of Ulva lactuca cultivated in a northern latitude land-based facility is by Bruhn et al. (2011) who found this to be 45 t DW ha−1 y−1 corresponding to three to five times the production of conventional energy crops, such as wheat straw, willow, Mischanthus, or maize (Seppala et al 2008; McKendry 2002).

Besides its high growth potential, U. lactuca has a capacity for high rates of nutrient assimilation, especially ammonium (NH +4 ), and grows well in eutrophic waters which qualify this species for bioremediation purposes. Several authors (Gaevert et al. 2007; Hernández et al. 2002; Pedersen and Borum 1997) have reported assimilation rates of NH +4 in the range of 50−90 μmol N g−1 DW h−1 among different Ulva species, and these species have been verified as successful biofilters of wastewaters from aquaculture (Hernández et al. 2002; Cahill et al. 2010; Copertino et al. 2009; Neori et al 2003). Aquaculture effluents are rich in NH +4 and therefore highly suitable as nutrient source for Ulva species. Integration of Ulva in multitrophic aquaculture serves a binary purpose: the production of biomass simultaneously with a removal of nutrients from the effluent waters of the aquaculture, thereby reducing the load of dissolved nutrients to the environment.

This dual effect is potentially transferable to other systems, where excessive inorganic nutrients require sustainable handling strategies. Diverse industries deal with several kinds of waste products rich in inorganic nutrients, such as industrial and municipal wastewaters or livestock manure products from the agriculture. From previous studies, it has been shown that these waste products are a promising nutrient source for cultivating a whole range of different algae species (Wang et al. 2010; Woetz et al. 2009; Kebede-Westhead et al. 2003; Mulbry and Wilkie 2001).

Since Denmark is highly influenced by agriculture and has an annual production of livestock manure exceeding 25 million t, it seems obvious to exploit the potential of this waste product for cultivation of algae. This idea has previously proven successful for microalgae (Barlow et al. 1975; Conzález et al. 2008; De Godos et al. 2009; Woetz et al. 2009), whereas knowledge on the potential for macroalgae is more limited.

This study aimed at assessing the potential of using liquid manure as nutrient source for the green macroalga U. lactuca addressing a novel nutrient resource application for Ulva sp. as well as bioremediation of a large waste source. The objective was to describe and evaluate growth responses and bioremediation capacity of U. lactuca cultivated with two different types of liquid manure as nutrient sources: untreated (UT) and anaerobic digested (AD) pig manure. With the perspective of utilizing the produced biomass for feed and/or energy, the biochemical composition of the macroalgae was analyzed with respect to carbon/nitrogen (C/N) ratio, amino acid (AA) composition, as well as heavy metal concentrations. In addition, the feed potential of the macroalgae was evaluated in comparison with soy bean, which is used extensively as a protein source in animal nutrition. The energy potential was evaluated with a focus on anaerobic digestion of the biomass.

Materials and methods

Free-floating Ulva lactuca was collected late summer 2010 in the inner parts of Limfjorden, a eutrophic Danish estuary. The algae were brought to the laboratory and kept in a large 150-L aerated reservoir tank with artificial nutrient-enriched seawater to prevent nutrient limitation. Artificial seawater (ASW) was prepared using commercial marine sea salt (Red Sea Coral Pro salt, Red Sea) and demineralized water. The salinity was 20‰, which was approximately the salinity experienced by the algae in their natural environment in the estuary. Nutrient enrichment was according to standard f/2-medium (Guillard and Ryther 1962). Temperature was kept constant at 16°C and illumination at approximately 120 μmol photons m−2 s−1.

Manure: untreated and anaerobic digested

The liquid manure used came from fattening pigs (30–100 kg) raised on slatted floors, and the manure was removed every 14 days from the slurry channel beneath the floor. UT manure was transported to a completely stirred research digester with a volume of 10 m3. Every day, 200 kg of UT manure was added in four portions, and a similar amount was removed, giving an average hydraulic retention time of 14 days. The digestion temperature was kept in the thermophilic range (52–53°C). The left over from the digestion process is the AD manure, and in this study, it was sampled from a similar digester as described above after 2 months of digestion solely on pig manure. The thermophilic treatment secures an efficient sanitation of the AD manure. UT manure will contain bacteria and virus, including some pathogenic bacteria. The impact of these on the algae was not investigated but is not considered to have negative influence on the algae. The NH +4 -N concentrations of both the UT and the AD manure used in this study were approximately 3.5 g L−1. All manure treatments were performed according to the content of NH +4 -N by diluting the raw and liquid manure with ASW until the preferred concentration of NH +4 was reached (see below for further specifications).

Experimental setup

Two independent experiments were run: one to assess the potential of manure as nutrient source in comparison with inorganic nutrients (f/2 medium, Guillard and Ryther 1962) and one to determine the best suitable concentration of manure for high growth rate, as well as optimal biochemical composition and bioremediation capacity. No vitamins or trace metals were added, since preliminary studies showed no effect of the addition (p = 0.82) (additions of vitamins and trace metals were according to Guillard and Ryther 1962). Both experiments were performed in aerated glass beakers each containing 2 L growth medium and five small fronds of fresh U. lactuca corresponding to a total biomass of 0.2 g ± 0.02 g fresh weight (FW). Temperature was held constant at 15°C, and the light ranged from 120–150 μmol photons m−2 s−1 with a diurnal cycle of 16 h light and 8 h darkness. Light was supplied by a 50/50 combination of Phillips Master TL5 HO 39 W/840 and Phillips Master TL5 HO 39 W/830. Salinity was 20‰ and pH was 7.8–8.3. One week in advance of the experiment, the algae were acclimated to the different nutrient treatments in 10 L aquaria.

N source experiment

The algae growth on four different N sources was compared: two types of manure; UT manure and AD manure, and two variations of standard f/2 medium with either NaNO3 or NH4Cl as the nitrogen (N) source. The stoichiometric ratio between N and phosphorus (P) was approximately 4 for both manure types. All treatments were adjusted to a concentration of 300 ± 20 μM N, equivalent to an 800 times dilution of the liquid manure. The experiment was carried out with four replicate glass beakers in each treatment. To avoid nutrient limitation, growth media was renewed every third day. Duration of the experiment was 14 days. From this experiment, the manure type most optimal for growth was selected for further investigation in the following concentration experiment.

Concentration experiment

Five concentrations of AD manure, expressed as ammonium (NH +4 ) concentration were applied—6, 12, 25, 50, and 100 μM NH +4 . To avoid nutrient depletion, growth media was renewed every day. Each concentration was performed in triplicate glass beakers. Duration of the experiment was 10 days.

Determination of growth rates, biochemical composition, and bioremediation efficiency followed the same procedure for both experiments.

Growth rates

During the experimental period, the specific growth rate (SGR, % FW d−1) for each individual replica was determined frequently (i.e., every second day for the N source experiment and every day for the concentration experiment) from the FW of the algae: \( {\text{SGR}} = {1}00 \times \left( {{ \ln }\left( {{W_t}/{W_0}} \right)} \right)/t \), where W 0 corresponded to the initial biomass and W t to the biomass after t days. Before weighing, algae fronds were blotted with filter cloth to remove excessive surface water.

Biochemical analysis

The algae fronds were periodically (e.g., 2- to 3-day intervals) adjusted to initial biomass density. At the end of the experiment, the biomass of each replicate was harvested and freeze-dried for further analysis.

Carbon and N contents were analyzed on an elemental analyzer (Roboprep C/N, Europa Scientific Ltd., UK) in line with a triple collector isotopic ratio mass spectrometer (Tracermass, Europa Scientific Ltd., UK). Total P content of the algae tissue was analyzed spectrophotometrically according to standard methods (Grasshoff et al. 1983). Prior to analysis, pretreatment of the dried and homogenized biomass was performed in order to extract the P from the tissue. Samples were heated at 550ºC for 2 h, autoclaved with 2 M hydrogen chloride (HCl) (20 mg DW for 7 mL acid), and finally filtered through GF-F filters (Whatman Ltd.).

Based on the analysis of the tissue N and P contents, the bioremediation capacity was assessed. The bioremediation capacity was defined as the ability of the algae to incorporate N and P, thus utilizing the tissue nutrient concentration of these (% of DW) as a measure of the capacity of removing N and P from the water.

Analysis of AAs was performed according to Mason et al. (1980) to assess the content of 16 different AAs.

Metal analysis

Samples were freeze-dried in plastic bags and homogenized. A dry sub-sample of 0.4 g was taken for microwave digestion in closed vessels by Multiwave (Anton Paar, Austria), adding 10 mL of conc. HNO3 (Merck suprapur) and 10 mL of Milli-Q water (>18 MOhm). After digestion, each sample was transferred into a preweighed polyethylene jar. Following 80 mL Milli-Q water and 0.5 mL of 1 ppm iridium (Ir), internal standard solution was added and the jar weighed again to calculate the dilution. Metal concentrations were quantified using a 7,500cs IPC-MS (Agilent, USA) with a Babington nebulizer connected to a cooled spray chamber (5ºC), introducing the mist into an argon (Ar) plasma operating at 1,500 W with 15 L Ar per minute. Standard mass-overlap correction from USEPA method 6020 was used to correct 75As and 111Cd. External calibration was performed on the corrected ion counts. During the run, drift was corrected by using a pumped solution of 100 ppb rhodium (Rh) and indium (In). The Rh was set to 100% for the first sample, and the response of Rh was used to correct to 100% for all elements. The correction was verified by Ir and In response, with normal recovery between 95% and 105%. For Cd, Zn, and Hg, determinations were based on atomic absorption spectrometry. Zn was determined using acetylene-air flame atomic absorption and Cd using transversally heated graphite furnace atomic absorption both on Perkin Elmer 3300, and finally Hg was determined using cold vapor atomic absorption spectroscopy on a Perkin Elmer FIMS 400 system.

Data analysis

All statistics were performed with SAS-JMP 9.0. ANOVA was used after confirming the assumptions of normality and heterogeneity. In case of significant differences between treatments, a post hoc test (Tukey–Kramer HSD) was run. For all biochemical data, only biomass from the last day of the experiment was analyzed, assuming that steady state was reached. For C, N, and P analyses, one analysis was performed for each replica, making a statistical testing possible. Regarding analyses of AAs and heavy metals, biomass from all replicates from the last day was pooled due to shortage of material, and hence results are not statistically supported and only represent trends.

Results

N source experiment

Average SGR for the entire experimental period did not differ between treatments (ANOVA, p = 0.30), the common mean ± SE being 34.4 ± 3.53% FW d−1, even though individual SGR from the different days and replica ranged from negative to 66% FW d−1 during the experimental period, with considerable variations in all treatments (not shown).

The stoichiometric ratio between C and N was highly affected by type of treatment (Table 1). The highest C/N ratio was found in algae grown with UT manure, whereas algae grown with AD manure showed a significant lower ratio (ANOVA, p < 0.05). The difference in C/N ratio between the two manure exposed treatments was mostly due to a significant difference in the internal concentration of N in the algae (ANOVA, p < 0.005). The differences in C concentrations were less remarkable, although still statistically significant (ANOVA, p < 0.05). Though not significantly different, also the internal concentration of P differed among the two groups, with a 41.4% higher concentration in the algae grown with AD manure than the algae grown with UT manure. Overall, the C and N analyses revealed high similarities among the algae grown with f/2-medium with NH +4 as the N source (f/2-NH +4 ) and AD manure, whereas the algae grown with UT manure more resembled the algae grown with f/2-medium with nitrate as the N source (f/2-NO −3 ).

The bioremediation capacity of the algae grown with AD manure surpassed the capacities found for the algae grown with UT manure by 28.8% and 41.4% for N and P, respectively. The highest total bioremediation capacity, however, was found among the algae grown with f/2-NH +4 , though it was not significantly different from the algae grown with AD manure (ANOVA, p > 0.28) (Table 1).

Analysis of amino acids showed that the algae grown with f/2-NH +4 had the highest total AA content (267 g kg−1 DW), with contents of 241 g kg−1 DW, 210 g kg−1 DW, and 180 g kg−1 DW for the algae grown with AD manure, f/2-NO −3 and UT manure, respectively. The same trend was found for the individual AA with the exceptions of glutamine and proline, of which the content was higher in algae grown with f/2-NO −3 than algae grown with AD manure (not shown). In Table 2, the content of the individual AA in the algae grown with AD manure are listed and compared with an average content of AA in soybeans (Grieshop and Fahey 2001; Boye et al. 2010). The relevance of this will be further outlined in the discussion.

Based on the results obtained from the N source experiment, the AD manure was chosen for further research in the concentration experiment. The motivations for this choice were the higher bioremediation capacity and AA content in the algae grown with AD manure as compared with the algae grown with UT manure, as well as the fact that no significant difference in SGR between the two treatments was observed. Also, in a practical perspective as well as in a more overall perspective of energy and sustainability balances, AD manure would be superior to the UT manure for several reasons: Primarily, the manure has already been exploited for energy purposes prior to serving as a nutrient source (methane being the end product of anaerobic digestion). Through this thermophilic AD process, the liquid manure is sanitized, and the viscosity is reduced, both making the handling of this waste resource more easy and safe. And not less important, the AD process reduces the turbidity of the manure as well as a fraction of the organic bound nutrients are mineralized, both factors improving the quality of the manure as a nutrient source for algae cultivation.

Concentration experiment

Increasing AD manure concentration, measured as external NH +4 concentration, had a pronounced positive effect on SGR at the lowest concentrations, whereas this effect stagnated when NH +4 concentration exceeded 25 μM (Fig. 1a). From the double-reciprocal plot in Fig. 1b, the maximum specific growth rate (SGRmax) and the half-saturation constant K M (i.e., the NH +4 concentration at which the SGR is half of its maximum) were estimated to be 45.7% FW d−1 and 5.6 μM, respectively.

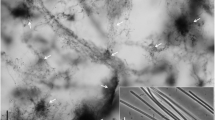

a U. lactuca specific growth rate (SGR) as a function of the ammonium concentration ([NH +4 ]) in treatments with added AD manure. Maximum specific growth rate (SGRmax) and the half-saturation constant for NH +4 (K M ) are shown. Each point represents independent replica as averages of the entire experimental period. b Lineweaver–Burk plot generated by plotting 1/SGR as a function of 1/[NH +4 ]. Function of the fitted line, y = 0.1219 x +0.0219. From this, SGRmax and K M are estimated. Each point represents independent replica as averages of the entire experimental period. Statistics of the fitted line, p < 0.0001, R 2 = 0.86

The carbon content did not differ among treatments (ANOVA, p = 0.53), whereas the N content significantly increased with increasing NH +4 concentration of the growth media (ANOVA, p < 0.01) (Table 3). As a consequence, the C/N ratio was negatively correlated to the NH +4 concentration of the growth media. As with the N content, the P content increased with increasing manure concentration of the growth media (ANOVA, p < 0.01).

Bioremediation capacity, as defined in this study, showed a positive linear correlation with nutrient accessibility at the range of concentrations tested in this study (Fig. 2). Thus, the maximum internal concentrations of N and P were reached at an external NH +4 concentration of 100 μM.

Concentrations of heavy metals were to some degree dependent on concentrations of manure (Table 4). Content of mercury (Hg) and cadmium (Cd) did not show any clear difference between treatments, whereas concentrations of chromium (Cr), copper (Cu), and zinc (Zn) were positively related to manure concentration. Concentrations of arsenic (As) decreased with increasing manure concentration. In all treatments, concentrations were lower than the threshold values given by EU concerning undesirable substances in animal feed (EU 2002) (Table 4).

Total content of AA was positively correlated with N concentration of the growth media (Table 5). U. lactuca grown at 6 μM N was not analyzed due to shortage of biomass. The lowest total amino acid (TAA) content of 6.86% of DW was found for algae grown at 12 μM N, whereas algae grown with 100 μM N had a TAA content of 16.05% of DW. Despite large differences in TAA content, the relative composition of AA was fairly similar among treatments (% of TAA in Table 5), with asparagine and glutamine being the far most abundant ones.

Discussion

Our results demonstrate that liquid pig manure is a valid nutrient source for cultivation of U. lactuca and thereby call attention to a novel nutrient resource application for Ulva sp. The manure supported growth of U. lactuca without addition of vitamins or micronutrients, and there was no evidence that the growth was being inhibited by potentially harmful substances in the manure, at least not in the low but optimal concentrations applied here.

Bioremediation of manure

The bioremediation capacity was highly dependent on nutrient availability: The higher the N and P concentration of the growth media, the higher the N and P concentration in the algal tissue (Fig. 2), which was the definition of bioremediation capacity in this study. Maximum bioremediation capacity, for the concentration experiment, was achieved at N concentrations at 100 μM, regarding the uptake of N as well as P. At these conditions, the N and P contents were 4% and 0.4% of DW, respectively. These values are comparable to previously reported N and P contents (Cohen and Neori 1991; Msuya and Neori 2010), however, based on the results from the N source experiment, it seems reasonable to assume it possible to obtain even higher values (Table 1). Combining the internal N concentrations of U. lactuca from this study grown at 100 μM N with a growth potential of 45 t DW ha−1 y−1 (Bruhn et al. 2011) gives an estimate of the potential for recycling N from manure into algae biomass. This adds up to a potential consumption of 1,840 kg N ha−1 y−1, corresponding to 420 t of manure ha−1 y−1. Thus, on a local scale, it might be of interest to utilize excessive nutrients from manure for algae cultivation.

In the approach of addressing bioremediation, two points should be stressed: In this study, we have focused on “bioremediation capacity” defined as the internal storage capacity of the algae growing on different N sources and different concentrations of the same N source. Other studies have focused on the “bioremediation efficiency” defined as the percent amount of nutrients extracted by the algae comparing the inflow and the outflow water (e.g., Neori et al. 2003). This latter concept is crucial and must be taken in consideration when constructing efficient bioremediation facilities since it deals with the purity of the water before it leaves the facility into the recipient. The bioremediation efficiency has been documented not to depend on the N concentration of the media, but instead on the total areal N load. This means, in practical terms, that N can be as efficiently removed from media with lower N concentrations and higher flow rate, as from media with a high concentration of N. Our results support this concept, since we documented maximum growth rate of the algae and hence a more productive system at relative low N concentrations. In order to support production of a large biomass, however, high flow rates are required in order to keep the N concentration at a constant level. The second issue to emphasize in discussing bioremediation is that the N uptake in the algae tissue did not account for all N removal from the cultivation media. This phenomenon was also described by Neori et al (2003) where the protein content of the harvested algae did not fully account for the total N removed from the system. Loss of biomass from the system was here discussed as a plausible explanation for the “missing” N. The same mechanism may account for the loss of N in our experiments, the loss of biomass occurring as minor disintegration of the algae discs or through excretion of dissolved organic N from the algae. The specific role of alternative pathways for N removal was not studied in detail. Denitrification and anammox are possible pathways for N removal due to the potential presence of microniches with very low concentrations of oxygen in the experimental setup, but also volatilization of ammonia could be considered a subject for further investigation.

Biomass production

In general, studies of U. lactuca exposed to a variety of different conditions and treatments report growth rates in the range of 15–30% d−1 (Msuya and Neori 2010; Geertz-Hansen and Sand-Jensen 1992; Frost-Christensen and Sand-Jensen 1990; Neori et al. 1991), though some report growth rates comparably high to the ones found in this study (Aguiar et al. 2003; Pedersen and Borum 1997). It should however be emphasized that this experiment mainly was conducted in order to determine the relative differences in responses to a number of treatments, and hence a small-scale laboratory setup with controllable and optimal conditions was chosen. We used high volume-to-biomass ratios, carefully picked out healthy fronds for the experiment, and glass beakers were frequently cleaned to avoid contamination. We also took liberty to exclude discs from the study that showed signs of sporulation. The frequency of sporulating algae discs, however, did not differ among treatments or over time. All in all conditions were applied, that would not be possible on a larger scale, wherefore the SGR found here should not be used to predict a potential biomass production in a large scale facility, but instead to compare the potential between use of different N sources. In this sense, manure proved just as good nutrient qualities as traditionally applied N sources and thus a biomass production potential for U. lactuca cultivated on manure should be equated with production potentials estimated for U. lactuca in general.

Optimal conditions for cultivation of U. lactuca grown with AD manure was found to be at 25 μM N, since increased concentrations did not have any further positive effect on growth (ANOVA, p = 0.70) (Fig. 1a), and cultivation at the lowest possible NH +4 concentration is preferable in order to minimize NH3 volatilization, which is highly dependent on NH +4 concentration in the growth media (Zimmo et al. 2003). At similar concentrations, good growth performance for U. lactuca has previously been reported in large-scale trials with biomass yields of 28.4–37.6 g DW m−2 d−1 (assuming a water content of 90%) (Msuya and Neori 2008) and 25.1 g DW m−2 d−1 (Bruhn et al. 2011). The latter being performed in Denmark makes it the preferred reference for yields of U. lactuca in temperate latitudes for forming the basis for an extrapolation to estimate a realistic production potential for U. lactuca grown with AD manure as sole nutrient source.

Various considerations must be addressed if wanting to cultivate Ulva with manure on a larger scale. One such consideration is the fact that Ulva has a nature of sporadic sporulation events, in which large quantities of the biomass disintegrates and dies. The environmental conditions trigging these sporulation events are so far not fully understood and thus not possible to control, although a lunar rhythm has been proposed, as well as artificial moonlight has been suggested as a means of preventing sporulation in cultivation tanks (Lüning et al. 2008). Another consideration is that cultivation of Ulva requires saltwater, and hence a cultivation facility needs to be situated near a salt water body to minimize production costs. For the concept to be sustainable in terms of energy balances, CO2 emissions, as well as economy, the source of manure should be located relatively close to the facility. This disqualifies the concept for inland manure producers. However, certain freshwater algae species have proved qualified for extracting nutrients from manure in a pilot scale system, producing algae biomass in the order of 27 t DW ha−1 y−1 (Mulbry et al. 2008). The issue of using saltwater or fresh water species is also relevant in the discussion of the potential utilization of the biomass. In most processes for converting the algae biomass to energy, the salt content of the biomass is a nuisance (Bruhn et al. 2011), whereas in other applications—such as for use as a feed additive—it may even be a benefit.

Potential utilization of biomass

Depending on the preferred application of the biomass, the optimum conditions for cultivation vary. The biomass grown at 25 μM N was characterized by having a relative low N content and consequently a relative high C/N ratio. The C/N ratio of the feedstock is an important parameter when evaluating the potential of a given biomass for anaerobic digestion (Yen and Brune 2007), which is the most promising and best described technology for converting U. lactuca biomass into bioenergy (Bruhn et al. 2011). An optimum C/N ratio is still debatable, but the majority find it to be in the range of 20–30 (Yen and Brune 2007; Habig et al. 1984; Parkin and Owen 1986). Anaerobic digestion of biomass with considerably lower C/N ratios leads to ammonia accumulation and increases in pH, providing a toxic environment for the methanogenic bacteria. Here, the biomass grown with 25 μM N had a C/N ratio very close to the optimum range of 20–30, which potentially makes it highly suitable for AD. Composition of the biomass grown at 100 μM N, the N concentration supporting the highest bioremediation capacity, would not be well suited as feedstock for AD, due to the low C/N ratio. This disadvantage could be overcome by co-digesting the algae with more carbon-dense materials such as waste paper as proposed by Yen and Brune (2007), or by exposing the algae to an N-starving treatment prior to digestion to reduce the N content of the algae.

Conversion of Ulva into methane has been carried out successfully, leading to methane yields in the range of 180–330 mL CH4 g−1, which is comparable to the yields of manure or medium yield energy crops (Habig et al. 1984; Briand and Morand 1997; Bruhn et al. 2011). Taking the high production rate into account, the area specific methane potential (m3 CH4 ha−1 y−1) for U. lactuca is higher than that of existing energy crops. Still, biogas production with Ulva sp. as substrate may have its limitations: The relatively low biodegradability of the algae carbohydrates causes the actual methane yield to be below the potential maximum, and also the seasonality in the seaweed production posing a barrier to sustain a continuous digestion, are mentioned as obstacles to be considered if U. lactuca are to be utilized for energy production by AD (Habig et al. 1984; Briand and Morand 1997; Bruhn et al. 2011). Another obstacle is the high sulfur content in Ulva sp., which leads to a high proportion of H2S in the biogas, making it unsuitable for energy recovery without treatment (Peu et al. 2011; Briand and Morand, 1997).

Application of the digestate from AD as a slow release fertilizer could take advantage of the slowly degradable carbohydrates, the N, S, and mineral content in the Ulva biomass. Hereby the economic as well as environmental value of using U. lactuca for bioenergy production would improve.

Using the Ulva biomass as a feed additive would be another way to take advantage of the N, S, and minerals in the biomass still combining the high bioremediation capacities found when cultivating U. lactuca under high N regimes with an alternative utilization of the simultaneously produced biomass. Since the N content of green algae is positively correlated to protein content with a nitrogen-to-protein conversion factor of 5.13 (Lourenco et al. 2002), exploitation of the biomass rich in N as protein source in animal or fish feed seems obvious and is already to some degree applied in aquaculture (Neori et al 2000; Bolton et al 2009). The highest N content of U. lactuca grown with AD manure found in this experiment was 5.4% of DW (Table 1), corresponding to a protein content of 28% of DW. However, protein contents above 40% of DW have been shown previously (Msuya and Neori 2008). At protein concentrations this high, U. lactuca may be of interest as an alternative protein source to soybean products in aquaculture as well as in agriculture. However, for this application, the amino acid composition must also be taken into careful consideration

In this study, TAA content highly depended on treatment, with increasing content as N concentration in the growth media increased. TAA content was however much higher in soybean than in U. lactuca in all treatments, and this trend was also valid for the individual AAs, with the exceptions of methionine and alanine in U. lactuca grown with AD manure in the N source experiment. However, looking at the relative AA composition (% of TAA), which did not differ much among treatments, the pattern was different. The relative content of methionine, threonine, valine, alanine, aspartate, and glycine were higher in U. lactuca grown with AD manure than in soybean, whereas the relative contents of isoleucine, cystine, and serine were comparable to that of soybean. Thus, nine out of 16 AAs had a higher or equal relative abundance in U. lactuca as compared with soybeans, but of most interest was the content of methionine and cystine. In agricultural practices, it is often necessary to supplement animal diets with synthetic sulfur-containing AAs (i.e., methionine and cystine) due to the low content of these in soybean, which traditionally serves as protein source (Panthee et al. 2006). This practice can be expensive and adds complexity to the diet formulation process, thus finding alternative protein sources with higher content of these sulfur-containing AAs is of highest interest. The relative content of methionine in U. lactuca is notable and may have potential for this application. In this perspective, the high sulfur content that causes problems in the AD may here turn into an advantage, due to the need of sulfur-containing AAs in livestock production, even though the TAA contents found in this study were not competitive with soybean. Hence, further investigation is needed concerning the use of U. lactuca as animal nutrition to enhance protein content and optimize AA composition. As mentioned in “Materials and methods,” conclusions regarding amino acids and heavy metals are limited because of lack of replications.

Another aspect to deal with in the context of utilizing biomass of U. lactuca for feed purposes is its content of heavy metals. For some heavy metals (Cr, Cu, Zn), tissue content increased with increasing manure concentration in the growth media, whereas for other metals this effect was absent (Hg, Cd) or even opposite, as was the case for arsenic. A negative correlation between phosphorus availability and arsenic content has been suggested (Klumpp 1980), due to chemical similarities between arsenate and phosphate. Thereby, in environments scarce in phosphate, assimilation of arsenate in replacement for phosphate is hypothesized. This may explain the pattern for arsenic content in algae tissue in our study, since decreasing manure concentrations represents decreasing P availability as well.

None of the analyzed heavy metals were found in concentrations exceeding the thresholds set by EU feed directive (Directive 2002/32/EC). Extra attention, however, should be kept on the content of arsenic, for which the threshold for feed materials derived from seaweed is 40 ppm, provided that the content of inorganic arsenic is lower than 2 ppm. In our analysis, we did not distinguish between different species of arsenic, and thus, the content of 2.12 ppm found in U. lactuca grown at 25 μM N could potentially exceed the threshold. However, in most species of seaweed, more than half the arsenic is organic (Almela et al. 2002), and the threshold for inorganic arsenic is therefore unlikely to be exceeded in our study. Conclusively, based on this study, concentrations of arsenic and heavy metals in general should not be an obstacle for utilizing U. lactuca as animal feed supplement.

In addition to supplementing essential AAs, the application of U. lactuca as supplementary livestock feed may serve additional perspectives in livestock production. For example, the application of enhancing health conditions has been reported for pigs fed with seaweeds as nutritional supplement (Dierick et al. 2010; Gardiner et al. 2008), and also, improvements in milk composition from algae fed dairy cows and ewes have been documented (Papadopoulos et al. 2002; Singh et al. 2004). However, to what extent benefits like this can be obtained through utilization of U. lactuca as feed supplement in livestock production as well requires further research. Still, the application of U. lactuca for feed purposes compared with energy production may be advantageous and represent a higher economic value in a future with increased pressure on agricultural land, and hence, this potential deserves further attention.

References

Aguiar AB, Morgan JA, Teichberg M, Fox S, Valiela I (2003) Transplantation and isotopic evidence of the relative effects of ambient and internal nutrient supply on the growth of Ulva lactuca. Biol Bull 205:250–251

Almela C, Algora S, Benito V, Clemente MJ, Devesa V, Súñer MA, Vélez D, Montoro R (2002) Heavy metal, total arsenic, and inorganic arsenic contents of algae food products. J Agric Food Chem 50:918–923

Barlow EWR, Boersma L, Phinney HK, Miner JR (1975) Algal growth in diluted pig waste. Agr Environ 2:339–355

Bolton JJ, Robertson-Andersson DV, Shuuluka D, Kandjengo L (2009) Growing Ulva (Chlorophyta) in integrated systems as a commercial crop for abalone feed in South Africa: a SWOT analysis. J Appl Phycol 21:575–583

Boye J, Zare F, Pletch A (2010) Pulse proteins: processing, characterization, functional properties and applications in food and feed. Food Res Int 43:414–431

Briand X, Morand P (1997) Anaerobic digestion of Ulva sp. 1. Relationship between Ulva composition and methanisation. J Appl Phycol 9:511–524

Bruhn A, Dahl J, Nielsen HB, Nikolaisen L, Rasmussen MB, Markager S, Olesen B, Arias C, Jensen PD (2011) Bioenergy potential of Ulva lactuca: biomass yield, methane production and combustion. Bioresour Technol 102:2595–2604

Cahill PL, Hurd CL, Lokman M (2010) Keeping the water clean—seaweed biofiltration outperforms traditional bacterial biofilms in recirculating aquaculture. Aquaculture 306:153–159

Cohen I, Neori A (1991) Ulva lactuca biofilters for marine fishpond effluent. 1. Ammonia uptake kinetics and nitrogen content. Bot Mar 34:475–482

Conzález C, Marcicniak J, Villaverde S, Carcía-Encina PA, Muñoz R (2008) Microalgae-based processes for the biodegradation of pretreated piggery wastewaters. Appl Microbiol Biotechnol 80:891–898

Copertino MS, Tormena T, Seeliger U (2009) Biofiltering efficiency, uptake and assimilation rates of Ulva clathrata (Roth) J. Agardh (Chlorophyceae) cultivated in shrimp aquaculture waste water. J Appl Phycol 21:31–45

De Godos I, Blanco S, Carcía-Encina PA, Becares E, Muñoz R (2009) Influence of flue gas sparging on the performance of high rate algae ponds treating agro-industrial wastewaters. J Hazard Mater 179:1049–1054

Dierick N, Ovyn A, De Smet S (2010) In vitro assessment of the effect of intact marine brown macro-algae Ascophyllum nososum on the gut flora of piglets. Livest Sci 133:154–156

EU (2002) EU directive 2002/32/EC of the European Parliament and of the Council of 7 May 2002 on undesirable substances in animal feed.

Frost-Christensen H, Sand-Jensen K (1990) Growth rate and carbon affinity of Ulva lactuca under controlled levels of carbon, pH and oxygen. Mar Biol 104:497–501

Gaevert F, Barr NG, Rees TAV (2007) Diurnal cycle and kinetics of ammonium assimilation in the green alga Ulva pertusa. Mar Biol 151:1517–1524

Gardiner GE, Campbell AJ, O’Doherty JV, Pierce E, Lynch PB, Leonard FC, Stanton C, Ross RP, Lawlor PG (2008) Effect of Ascophyllum nodosum extract on growth performance, digestibility, carcass characteristics and selected intestinal microflora populations of grower-finisher pigs. Anim Feed Sci Technol 141:259–273

Geertz-Hansen O, Sand-Jensen K (1992) Growth rate and photon yield of growth in natural populations of marine macroalgae Ulva lactuca. Mar Ecol Prog Ser 81:179–183

Grasshoff K, Ehrhardt M, Krembling K (1983) Methods of seawater analysis. Weinheim, Verlag Chemie

Grieshop CM, Fahey GC (2001) Comparison of quality characteristics of soybeans from Brazil, China, and United States. J Agric Food Chem 49:2669–2673

Guillard RR, Ryther JH (1962) Studies of marine planktonic diatoms. I. Cyclotella nana Hustedt and Detomula confervacae Cleve. Can J Microbiol 8:229–239

Habig C, DeBusk TA, Ryther JH (1984) The effect of nitrogen content on methane production by the marine algae Gracilaria tikvahiae and Ulva sp. Biomass 4:239–251

Hernández I, Martínez-Aragón JF, Tovar A, Pérez-Lloréns JL, Vergara JJ (2002) Biofiltering efficiency in removal of dissolved nutrients by three species of estuarine macroalgae cultivated with sea bass (Dicentrarchus labrax) waste waters. 2. Ammonium. J Appl Phycol 14:375–384

Kebede-Westhead E, Pizarro C, Mulbry WW (2003) Production and nutrient removal by periphyton grown under different loading rates of anaerobically digested flushed dairy manure. J Phycol 39:1275–1282

Klumpp DW (1980) Characteristics of arsenic accumulation by the seaweed Fucus spiralis and Ascophyllum nodosum. Mar Biol 58:257–264

Lahaye M, Jegou D (1993) Chemical and physical-chemical characteristic of dietary fibres from Ulva lactuca (L.) Thuret and Enteromorpha compressa (L.) Grev. J Appl Phycol 5:195–200

Lourenco SO, Barbarino E, De-Paula JC, Pereira LOS, Marquez UML (2002) Amino acid composition, protein content and calculation of nitrogen-to-protein conversion factors for 19 tropical seaweeds. Phycol Res 50:233–241

Lüning K, Kadel P, Pang S (2008) Control of reproduction rhythmicity by environmental and endogenous signals in Ulva pseudocurvata (Chlorophyta). J Phycol 44:866–873

Mason VC, Bech-Andersen S, Rudemo M (1980) Hydrolysate preparation for amino acid determinations in feed constituents. 8. Studies of oxidation conditions for streamlined procedures. J Anim Phys Anim Nutr 43:146–164

McKendry P (2002) Energy production from biomass (part 1): overview of biomass. Bioresour Technol 83:37–46

Msuya FE, Neori A (2008) Effect of water aeration and nutrient load level on biomass yield, N uptake and protein content of the seaweed Ulva lactuca cultured in seawater tanks. J Appl Phycol 20:1021–1031

Msuya FE, Neori A (2010) The performance of spray-irrigated Ulva lactuca (Ulvophyceae, Chlorophyta) as a crop and as a biofilter of fishpond effluents. J Phycol 46:813–817

Mulbry WW, Wilkie AC (2001) Growth of benthic freshwater algae on dairy manures. J Appl Phycol 13:301–306

Mulbry W, Kondrad S, Pizarro C, Kebede-Westhead E (2008) Treatment of dairy manure effluents using freshwater algae: algal productivity and recovery of manure nutrients using pilot-scale algal turf scrubbers. Bioresour Technol 99:8137–8142

Neori A, Cohen I, Gordin H (1991) Ulva lactuca biofilters for marine fishpond effluent 2. Growth rate, yield and C-N ratio. Bot Mar 34:483–489

Neori A, Neori A, Shpigel M, Ben-Ezra D (2000) A sustainable integrated system for culture of fish, seaweed and abalone. Aquaculture 186:279–291

Neori A, Msuya FE, Shauli L, Schuenhoff A, Kopel F, Shpigel M (2003) A novel three-stage seaweed (Ulva lactuca) biofilter design for integrated mariculture. J Appl Phycol 15:543–553

Panthee DR, Pantalone VR, Sams CE, Saxton AM, West DR, Orf JH, Killam AS (2006) Quantitative trait loci controlling sulfur containing amino acids, methionine and cysteine, in soybean seeds. Theor Appl Genet 112:546–553

Papadopoulos G, Goulas C, Apostolaki E, Abril R (2002) Effects of dietary supplements of algae, containing polyunsaturated fatty acids, on milk yield and the composition of milk products in dairy ewes. J Dairy Res 69:357–365

Parkin GF, Owen WF (1986) Fundamentals of anaerobic digestion of wastewater sludges. J Environ Eng 112:867–920

Pedersen MF, Borum J (1997) Nutrient control of estuarine macroalgae: growth strategy and the balance between nitrogen requirements and uptake. Mar Ecol Prog Ser 161:155–163

Peu P, Jassi JF, Girault R, Picard S, Saint-Cast P, Béline F, Dabert P (2011) Sulphur fate and anaerobic biodegradation potential during co-digestion of seaweed biomass (Ulva sp.) with pig slurry. Bioresour Technol 102:10794–10802

Seppala M, Paavola T, Lehtomaki A, Pakarinen O, Rintala J (2008) Biogas from energy crops-optimal pre-treatments and storage, co-digestion and energy balance in boreal conditions. Water Sci Technol 58:1857–1863

Singh AP, Avramis CA, Kramer JKG, Marangoni AG (2004) Algal meal supplementation of the cows´ diet alters the physical properties of the milk fat. J Dairy Res 71:66–73

Taboada C, Millan R, Miguez I (2010) Composition, nutritional aspects and effect on serum parameters of marine algae Ulva rigida. J Sci Food Agric 90:445–449

Wang L, Li Y, Chen P, Min M, Chen Y, Zhu J, Ruan RR (2010) Anaerobic digested dairy manure as a nutrient source for cultivation of oil-rich green microalgae Chlorella sp. Bioresour Technol 101:2623–2628

Woetz I, Feffer A, Lundquist T, Nelson Y (2009) Algae grown on dairy and municipal wastewater for simultaneous nutrient removal and lipid production for biofuel feedstock. J Environ Eng 135:115–1123

Yen HW, Brune DE (2007) Anaerobic co-digestion of algal sludge and waste paper to produce methane. Bioresour Technol 98:130–134

Zimmo OR, van der Steen NP, Gijzen HJ (2003) Comparison of ammonia volatilization rates in algae and duckweed-based waste stabilisation ponds treating domestic wastewater. Water Res 37:4587–4594

Acknowledgments

This study was financially supported and carried out as a part of the EU FP7 project “BioWalk4Biofuels” funded by the European Commission, as well as the Danish regional project “Algae for biogas in the Central Denmark Region” funded by the Central Denmark Region. Experimental work was performed as part of R&D activities at Algae Center Denmark. We thank Kitte Linding Gerlich, Tanja Quottrup Egholm, and Egon Frandsen for valuable assistance in the laboratory and also express our gratitude to two anonymous reviewers whose comments and suggestions have improved the manuscript.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Nielsen, M.M., Bruhn, A., Rasmussen, M.B. et al. Cultivation of Ulva lactuca with manure for simultaneous bioremediation and biomass production. J Appl Phycol 24, 449–458 (2012). https://doi.org/10.1007/s10811-011-9767-z

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10811-011-9767-z