Abstract

We describe the preliminary extractions from a pilot-scale supercritical carbon dioxide (SC-CO2) extractor for the isolation of algal lipids suitable for small-scale conversion to liquid hydrocarbon fuels. Flowable oils were recovered from SC-CO2 extractions of lyophilized Nannochloropsis granulata. The extracted oils were determined to be composed primarily of triacylglycerols (TAG) by liquid chromatography–mass spectrometry analysis. Gravimetric lipid yield was increased significantly from 15.56 to 28.45 mg g−1 ash-free dry weight (AFDW) with an increase in temperature from 50°C to 70°C, at 35 MPa over 270 min. Varying pressure had no significant effect on lipid yield. Liquid chromatography–mass spectrometry analysis of the SC-SO2 extracts indicated that the TAG profile remained constant regardless of extraction pressure, and analysis of fatty acid methyl esters (FAME) revealed a uniform profile throughout all extraction conditions. Our optimized gravimetric lipid yields from N. granulata (28.45 mg g−1 AFDW) were approximately half of the yields obtained by Soxhlet extraction with hexane (57.53 mg g−1 AFDW); however, the FAME yields were similar regardless of extraction technique (18.23 mg FAME g−1 and 17.35 mg FAME g−1 AFDW from SC-CO2 extraction and hexane extraction, respectively). Further extractions with Botryococcus braunii indicated that fatty acid extraction by SC-CO2 was as efficient as hexane extraction. These results highlight the suitability of SC-CO2 for large-scale oil extraction of microalgae for biofuel or biojet analyses due to its selectivity for TAG extraction.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

There is renewed interest in microalgae as a sustainable source of biofuels and bioenergy. In particular, recent research has focused on these organisms as a source of oil for conversion to biodiesel and biojet fuels. Microalgae exhibit potential as an alternative fuel feedstock as they can have high growth rates, greater areal productivity than land-based alternative energy crops, can be grown in marginal land without displacing food crops, and can store a large fraction of their mass as triacylglycerol (TAG) which can be directly converted to a combustible fuel (McGinn et al. 2011).

Microalgae are diverse in their growth characteristics, lipid accumulation, and physical properties; many have highly robust cell walls, which may complicate the extraction of their energy-rich TAGs. Traditionally, algal oils have been extracted using noxious organic solvents; however, there are high costs, health and safety concerns, and significant wastes associated with these processes. In addition, there is growing interest in using “defatted” algal biomass for value-added products such as nutraceuticals and feed proteins and the use of organic solvents in the lipid extraction process raises concerns about the safety of algal biofuel-derived byproducts for human or animal consumption due to the potential for trace quantities of solvent to persist in the material. Another disadvantage to extraction by organic solvents is that the process can extract polar lipid components such as chlorophyll pigments and phospholipids and other compounds that can lower the conversion efficiency or suitability of the final biofuel product (Van Gerpen 2005; Nagle and Lemke 1990).

An alternative to solvent-based extraction processes is extraction by supercritical fluid. A supercritical fluid is a fluid that is heated and pressurized beyond its critical point such that the liquid and gas phases become indistinguishable. Supercritical fluids are ideal extraction solvents as they retain the permeability and compressibility of a gas and the solvating ability of a liquid. Supercritical carbon dioxide (SC-CO2) is of particular interest as an extraction solvent as it becomes supercritical at relatively low temperature and pressure (31.06°C and 7.38 MPa), causes no ill health effects, and is selective for neutral and non polar lipid components such as (TAG). Upon decompression to a gas, SC-CO2 releases the solute, leaves no trace behind in the extract, and creates virtually no waste material, especially if the CO2 is cycled back to the system for reuse.

Supercritical CO2 has long been used in the food and nutrition industries to extract and analyze oils and other compounds (Raventos et al. 2002; King 2002). It has also been investigated for its utility in the extraction of natural products from a variety of microalgae (Canela et al. 2002; Valderrama et al. 2003; Mendes et al. 2003; Montero et al. 2005; Macias-Sanchez et al. 2007, 2009a, b, 2010). Bench-scale (Canela et al. 2002; Halim et al. 2011; Soh and Zimmerman 2011) and pilot-scale (Andrich et al. 2005, 2006) studies have been conducted to assess the fatty acid profiles and extraction efficiencies of certain microalgae by SC-CO2.

As an advantage for algal biofuel production, a pilot-scale SC-CO2 extractor enables the relatively rapid extraction of significant amounts of flowable algal oils that can be characterized, converted to biodiesel and analyzed for various combustion and physical properties, or processed into other fuel types. Pilot-scale SC-CO2 extractors can accommodate kilogram quantities of dried algal biomass or algal paste and extractions by SC-CO2 result in large quantities of nearly lipid-free, residual biomass that can be exploited for value-added products or alternative energy production. The economic and energy costs associated with a pilot-scale extractor may prohibit the use of supercritical CO2 extraction (SCE) for extracting production quantities of oil; however, as a means for obtaining significant quantities of oil and of “defatted” biomass, a pilot-scale SC-CO2 extractor is a useful analytical tool when coupled with pilot or industrial scale cultivation systems, where dried biomass can be rapidly produced at kilogram quantities or greater on short time-scales.

We investigated the conditions required for optimal extraction yields from a pilot-scale SC-CO2 extractor for biofuel research purposes using Nannochloropsis granulata, a microalgae species that grows rapidly and can accumulate high levels of neutral lipid. In addition, we determined the TAGs and lipid classes that make up the SC-CO2 extracts by liquid chromatography–mass spectrometry (LC-MS) and characterized the fatty acid methyl ester (FAME) profiles and yields of the biodiesel produced from SCE of dried microalgal biomass.

Materials and methods

Algal growth conditions

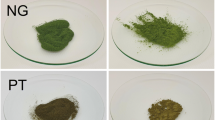

The algal strains employed in this study were strains that we had cultivated in quantities that were adequate to use as feedstocks for a pilot-scale extraction experiment of this capacity. Nannochloropsis granulata Karlson and Potter (a marine eustigatophyte, CCMP 535, Provasoli-Guillard National Center for Culture of Marine Phytoplankton) and Botryococcus braunii Kützing (a freshwater chlorophyte, UTEX 572, The Culture Collection of Algae at the University of Texas at Austin) were grown under a continuous photoperiod in 1,000 L Brite-Box photobioreactors and f/2 nutrients (Guillard 1975; minus Si) in seawater or lake water that had been pre-filtered to 0.5 μm and then passed through a tangential flow filter element with a 500 kDa nominal size cutoff. Cultures were constantly aerated and maintained at a pH of 7.8 by automated CO2 injections. Upon harvest, cell cultures were partially dewatered using a CEPA Z101 continuous flow centrifuge (New Brunswick Scientific, USA) and the resulting algal paste was lyophilized in a VirTis 35 L Ultra freeze dryer (SP Scientific, USA) to a moisture content of 3%. The lyophilized biomass was passed through a 550 W Deni grinder (Keystone Manufacturing Co., USA) and the dried algal powder was stored at −20°C.

Lyophilized N. granulata and B. braunii (0.5 g) were combusted at 550°C to determine the total inorganic fraction of the biomass and all analyses were normalized to ash-free dry weight (AFDW) of the algal biomass.

Lipid extraction by SC-CO2

A flow-through supercritical CO2 extractor (DynaSep LLC, USA) was used for supercritical CO2 extractions. The extractor consisted of one stainless steel extraction vessel (4 L) and two separation vessels (1 L each). Liquid CO2 (Air Liquide, Canada) was supplied to the extraction vessel, after passing through a heat exchanger to bring the CO2 to temperature, by an air-driven pump. Pressure within the extraction vessel was controlled by a combination of the air-driven supply pump and a down-stream automated valve between the extraction and separation vessels. Temperature and pressure within the system were controlled by a computer interface, whereas gas flow rate was controlled by a combination of a manual needle valve and the computer interface.

Dried algal powder (350 g) was loaded into a 5 μm nylon bag and placed in the extraction vessel. A portion of the remaining space within the vessel was filled with inert glass beads and the vessel was sealed to the atmosphere. Supercritical CO2 extraction conditions were established within the extraction vessel and the supercritical fluid was passed through the separation vessels (100 g min−1 CO2 flow rate) in series to achieve decompression before venting to the atmosphere. The lipid components that were extracted by the supercritical fluid were released from the carrier solvent upon decompression into the first separation vessel, with the second vessel serving as a pressure intermediary in a step-wise decompression to one atmosphere. Lipid fractions were collected into borosilicate glass tubes and stored at −20°C under nitrogen gas. The recovered lipid was pooled and gravimetric lipid yield was estimated as a fraction of the AFDW of the algal biomass.

The parameters selected in our extraction studies followed a systematic step-wise approach. Parameters were tested in triplicate with subsamples of lyophilized biomass. Initial extractions examined the effect of varying pressures (35, 45, and 55 MPa) on lipid yield. Upon evaluation of the optimal pressure, experiments were carried out to determine the effect of extraction time (180, 270, 360 min). Finally, investigations were carried out to establish an optimal temperature for extraction (50, 70, and 90°C). All extractions were conducted at a SC-CO2 flow rate of 100 g min−1.

Cell lysis

We attempted to disrupt dried algal biomass to compare the yields of whole and lysed algal cells extracted under optimal SC-CO2 conditions. Dried algal biomass was passed through a ZM 200 Ultracentrifugal Mill (Retsch, USA), equipped with a 24-tooth rotor and a 0.20 mm distance sieve, to disrupt the algal cells and reduce the particle size prior to SCE. Cell wall integrity was assessed microscopically and particle size analysis was performed using a Multisizer 3 Coulter Counter (Beckman Coulter, USA).

Lipid extraction by automated Soxhlet apparatus

All solvents used in the extraction, transesterification, and analysis of algal lipids by gas chromatography were HPLC-grade (Caledon Laboratories, Canada). Lyophilized algal powder (0.5 g) was extracted with hexane using a Soxtec 2050 automated Soxhlet system (Foss, USA) by boiling for 25 min at 155°C followed by a 40-min rinse cycle. Extracts were dried for 1 h at 105°C, brought to room temperature in a vacuum desiccator, and then weighed to determine gravimetric lipid yield. All extracts were stored in a chloroform/methanol solution (2:1) at −20°C under N2.

Fatty acid methyl ester derivatization

Lipid extracts (0.01–0.02 g) from SCE and hexane extraction were subjected to acid-catalyzed transesterification (Christie 1989) in clean, combusted (450°C, 6 h), borosilicate glass tubes. All samples included a nonadecanoic internal standard (Sigma-Aldrich, USA). Briefly, lipid extract was resuspended in anhydrous toluene, combined with a methanolic hydrochloric acid solution (5%), and heated at 105°C for 1 h. Upon cooling to ambient temperature the solution was combined with a sodium chloride solution (5%) and washed with a sodium bicarbonate solution (2%). The resultant organic fraction was combined with sodium sulfate and filtered through glass wool. The extract was evaporated under N2 and the residual FAME extract was weighed and suspended in hexane for immediate analysis by gas chromatography (GC).

Fatty acid methyl ester analysis by gas chromatography

A 7890A GC system (Agilent, USA), equipped with an Omegawax 250 column (Sigma-Aldrich, USA), a flame ionization detector and helium as the carrier gas, was used for FAME quantification and characterization. Fatty acid methyl ester extracts were run at 3 mL min−1 in constant flow mode, heated from 110°C to 250°C (5°C min−1) and maintained for 20 min. The inlet and detector temperatures were 250 and 300°C, respectively. Fatty acid methyl esters were quantified based upon the response factor of a known concentration of a nonadecanoic acid internal standard. Peak identification was based upon the retention times of PUFA 3 and Supelco 37 standard mixtures (Sigma-Aldrich, USA). Results were returned as integrated peak area using Chemstation software (Agilent, USA), subsequently converted to FAME mass (g) and presented as FAME concentration or relative FAME abundance in a particular extract.

Liquid chromatography–mass spectrometry analysis

Liquid chromatography solvents acetonitrile, isopropanol, and methanol were HPLC-grade (Caledon, Canada). TAG standards were purchased from Nu-Chek Prep (Elysian, USA), and polar lipid standards were acquired from Matreya (Pleasant Gap, USA). Ammonium formate (>99.995%) was purchased from Sigma-Aldrich. Nitrogen and argon (UHP) for the source and collision gases of the mass spectrometer, respectively, were obtained from Praxair (Halifax, Canada).

Lipid extracts were diluted to 10 mg mL−1 in chloroform/methanol (2:1) then diluted to 0.1 mg mL−1 in methanol/isopropanol (1:1). The samples were then filtered using 0.22 μm Ultrafree-MC centrifugal filter devices (Amicon Bioseparations, Millipore, USA) before injection onto the system.

Data was acquired on a Waters Acquity UPLC coupled to a Waters QTOF Premier mass spectrometer equipped with an electrospray ionization (ESI) source. The system was run under MassLynx 4.1 software (Waters, USA). A Waters Acquity UPLC BEH C18 column (2.1 × 100 mm) at 55°C was used to analyze lipid extracts. The mobile phase was delivered at 0.4 mL min−1 and consisted of (A) 40% water with 10 mM ammonium formate/60% methanol, and (B) 90% isopropanol/10% methanol. The gradient started at 40%B and increased to 100%B from 0 to 10 min, then was held at 100%B from 10 to 12 min, then equilibrated back to 40%B from 12 to 17 min. Injection volume was 3 μL and each extract was analyzed in triplicate. The MS was operated in ESI positive-mode with scans alternating between low and high collision energy (5 and 35 eV) to collect accurate mass data on intact lipids and their fragment ions. The operating MS parameters were as follows: capillary voltage 3.20 kV, sample cone 32 V, extraction cone 2.0 V, source temperature 120°C, desolvation temperature 400°C, cone gas 50 L h−1, desolvation gas 600 L h−1, scan time 0.1 s, inter-scan delay 0.02 s, scan range m/z 200–1,500.

Statistical analysis

All results are presented as the mean of a minimum of three replicates accompanied by the standard error (SE) of the mean of the replicates. Means were compared using single-factor analysis of variance (ANOVA), followed by Tukey’s HSD test where p ≤ 0.05 was considered statistically significant.

Results

Lipid yields from supercritical CO2 extraction

We did not observe any statistically significant effect of extraction pressure on lipid yield (Fig. 1, single-factor ANOVA, n = 3, p ≥ 0.05). Lipid yields ranged from 8.67 ± 2.29 mg g−1 AFDW (n = 3 ± SE) under 35 MPa SC-CO2 (50°C, 180 min) to 10.87 ± 1.59 mg g−1 AFDW (n = 3 ± SE) at 55 MPa (Fig. 1) and, therefore, further extractions were performed at 35 MPa. Increasing extraction time resulted in differences in lipid yield that ranged from 8.67 ± 2.29 mg g−1 AFDW (n = 3 ± SE) over 180 min (35 MPa, 50°C) to 15.56 ± 2.72 mg g−1 AFDW (n = 3 ± SE) over 270 min, and to 16.91 ± 1.65 mg g−1 AFDW (n = 3 ± SE) over 360 min; however, the differences in yields were not statistically significant (Fig. 1, single-factor ANOVA, n = 3, p > 0.05). We selected 270 min for further extractions due to the time-dependant increase in yield from 180 min to 270 min that, while not statistically significant, resulted in higher extraction yields. An increase in extraction temperature from 50°C at constant pressure and time (35 MPa, 270 min), resulted in a statistically significant increase in yield from 15.56 ± 2.72 mg g−1 AFDW to 28.45 ± 2.46 mg g−1 AFDW at 70°C (n = 3 ± SE), and 25.75 ± 1.15 mg g−1 AFDW at 90°C (Fig. 1, single-factor ANOVA, Tukey’s HSD, n = 3, p = 0.014). The slight decrease in yield that we observed with an increase in extraction temperature from 70°C to 90°C was not determined to be statistically significant (p ≥ 0.05).

Lipid yield from SCE of lyophilized N. granulata under varying extraction conditions: a varying pressure (50°C, 180 min, 100 g min−1 CO2) b varying time (50°C, 35 MPa, 100 g min−1 CO2) c varying temperature (35 MPa, 270 min, 100 g min−1 CO2). Error bars represent the standard error of the mean of triplicate extractions and bars labeled with different lower-case letters indicate extraction yields that were determined to be significantly different (single-factor ANOVA, n = 3, p ≤ 0.05)

Pretreatment of lyophilized biomass

Microscopic and particle size analyses revealed that our attempts at cell lysis of lyophilized algal biomass were unsuccessful.

Lipid yields from Soxhlet extraction

The residual biomass from SCE was re-extracted with a Soxhlet apparatus using hexane as the solvent to compare yields from SCE with those of a more traditional solvent extraction. After all SCE treatments, we extracted additional lipid components during the re-extraction with hexane, which demonstrated that SCE is not specific for the same complement of lipid components as traditional hexane extraction. The sum of the SCE yields and the follow-up hexane extraction yields were compared with a hexane extracted control, which had not previously been extracted with SC-CO2, to determine if we could recover the entire lipid yield of the control treatments. Regardless of SCE conditions used, the sum of the lipid yield from SCE and hexane extraction of each treatment was not significantly different than that of the control yield with hexane alone (Fig. 2, single-factor ANOVA, n = 3, p > 0.05), and between the two extraction techniques the full complement of extractable neutral lipid material in unlysed lyophilized biomass was recovered.

The sum of the lipid yield from SCE of N. granulata (open bars) under varying extraction conditions and Soxhlet extraction with hexane (shaded bars) of the residual biomass after SCE: a varying pressure (50°C, 180 min, 100 g min−1 CO2) b varying time (50°C, 35 MPa, 100 g min−1 CO2) c varying temperature (35 MPa, 270 min, 100 g min−1 CO2). The sums were compared to a control treatment which was Soxhlet extraction of N. granulata biomass that had not been extracted by SCE. Error bars represent the standard error of the mean of three replicates, except the control treatment (n = 8 ± SE). Single-factor ANOVA analysis revealed the sum of the extraction yields was not significantly different from the control extraction (p > 0.05 in all cases)

Fatty acid methyl ester yields and profiles

We determined the yield of the FAME components of the lipid extracts following acid-catalyzed transesterification. When normalized to the mass of lipid extract, SCE of N. granulata under all extraction conditions resulted in a FAME yield of 640.55 ± 8.44 mg g−1 (n = 21 ± SE). The control hexane extract resulted in a FAME per lipid extract yield of 327.12 ± 53.39 mg g−1 (n = 3 ± SE). Although we observed a large difference in FAME yield normalized to mass of lipid extract from varying extraction techniques, we did not observe a difference in FAME yield when normalized to AFDW of N. granulata regardless of extraction technique (Fig. 3). Supercritical CO2 extraction resulted in a yield of 18.23 ± 2.17 mg FAME g−1 AFDW and Soxhlet extraction with hexane resulted in a yield of 17.35 ± 2.82 mg FAME g−1 AFDW. To verify the efficiency of extraction by SC-CO2 with another algal strain, we extracted lyophilized B. braunii under the conditions that generated the highest yields from N. granulata biomass samples (i.e., 35 MPa, 270 min., 70°C). The FAME analysis results from B. braunii extraction showed a similar pattern in FAME yield per lipid extract with SCE (642.81 ± 1.57 mg g−1, n = 4) compared with Soxhlet extraction with hexane (342.81 ± 34.48 mg g−1, n = 3). The FAME yield per AFDW of B. braunii was similar regardless of extraction technique with SCE resulting in 60.00 ± 2.23 mg g−1 AFDW and hexane extraction yields of 70.85 ± 6.85 mg g−1 AFDW.

Comparison of the lipid and FAME yields normalized to AFDW of lyophilized a N. granulata and b B. braunii extracted by SC-CO2 (open bars) and by hexane (dark bars). Although there are large differences in lipid yield between the extraction methods, no differences are observed in FAME yield regardless of extraction condition

We compared the FAME profiles of SC-CO2 extracts obtained under varying extraction conditions with the extracts from Soxhlet extraction with hexane (Fig. 4). All treatments were analyzed in triplicate. There were no instances where the FAME profile from any one SCE condition was significantly different from the others in all FAMEs extracted (single-factor ANOVA). In addition, the FAME yield where hexane extraction was significantly different from all SCE treatments was observed as an increase in eicosapentaenoic acid (EPA), C20:5(n3), from an average of 98.4 mg EPA g−1 FAME from SCE to 130.8 mg EPA g−1 FAME (single-factor ANOVA, Tukey’s HSD, p = 3.347 × 10−8).

FAME profile from GC-FID analysis of lipid extracts from N. granulata obtained by SCE at varying extraction conditions and by Soxhlet extraction with hexane. Error bars represent the standard error of the mean of triplicate extractions. “Other” represents the sum of individual FAMEs that accounted for less than 1% of the total FAME extract mass

Liquid chromatography–mass spectrometry

In order to assess the specificity of SC-CO2 for extraction of TAGs, LC-MS was employed to profile intact lipids. Shown in Fig. 5 is the base peak chromatogram for the SC-CO2 extract from N. ganulata at 45 MPa. The LC-MS data shows an abundance of TAGs eluting between 7 and 10 min as well as diacylglycerols (DAGs) eluting between 4 and 7 min. By using a combination of accurate mass measurements and diagnostic fragment ions, over 50 unique TAGs were identified. The most abundant TAGs were 16:1/16:1/16:0, 18:1/16:1/16:0, and 16:1/16:0/16:0, and their abundances did not vary significantly over the range of pressures studied (35, 45, and 55 MPa).

LC-MS base peak chromatogram of intact lipids from N. granulata in SC-CO2 extract at 45 MPa. LC-MS conditions as described in the “Materials and methods” section

While the SC-CO2 extract exhibited predominantly TAGs and DAGs, the algal biomass also contained a wide range of more polar lipids, such as phospholipids and pigments, in addition to DAGs and TAGs. Figure 6 shows LC-MS chromatograms comparing the polar lipid content between a hexane extract of the algal biomass (A) and the SC-CO2 extract (B). As phospholipids co-eluted with DAGs under the LC conditions employed, extracted ion chromatograms were used to display the specific compound classes. Upon fragmentation in the mass spectrometer, phosphocholines generate a diagnostic fragment ion at mass-to-charge m/z 184.07 that can be used as an indicator for phosphocholines. Similarly, plotting m/z 871.57 corresponded to the intact mass of the cholorophyll-type compound pheophytin-a. Figure 6a shows the relatively high abundance of both phosphocholines and pheophytin-a in the hexane extract of the algal biomass. As displayed in Fig. 6b, the SC-CO2 extract contains no detectable phosphocholines and yields greatly reduced levels of pheophytin-a. While phosphocholines were the major class of phospholipids identified, it should be noted that other types of phospholipids were also present in the algal biomass, but were not detected in the SC-CO2 extract of N. granulata . These LC-MS results demonstrate the viability of supercritical-CO2 lipid extraction as a means to selectively extract triaclyglycerols over more polar lipids.

Discussion

Nannochloropsis spp. can accumulate high lipid yields when cultivation conditions are manipulated to promote TAG accumulation within the cell. Griffiths and Harrison (2009) reported average Nannochloropsis spp. lipid yields across a range of published literature of 41% of dry weight, and Hu and Gao (2006) report lipid yields from Nannochloropsis sp. of up to 62% of dry weight. The N. granulata biomass used in our study was not optimized for lipid production, as evidenced by the low gravimetric lipid yield. Yields from SCE may be increased by employing a pretreatment technology that disrupts the cell wall (Mendes et al. 1995a, 1995b; Soh and Zimmerman 2011). We attempted to disrupt lyophilized N. granulata using an ultracentrifugal mill; however, particle size analysis and microscopic examination of the biomass post-milling showed no signs of cell lysis and the extraction yields of milled biomass were not different from lipid yield of whole cells extracted under the same SCE conditions. Preliminary attempts at cell disruption by homogenization under high pressure of N. granulata in cell culture or of lyophilized biomass resuspended in liquid were also unsuccessful (S. MacKinnon pers. communication). These results highlight the difficulty in obtaining a cell disruption technology that is suitable for all strains of algae cultivated for algal biofuels production and the challenges of selecting cell disruption technologies that are appropriate for kilogram quantities of algae.

Our SCE optimization studies with N. granulata indicated that extraction temperature significantly influences the lipid yield from intact, lyophilized, N. granulata biomass. Our results also suggest that extraction time has an effect on extraction yield. Although the increase in extraction yield that we observed with increases in extraction time was statistically insignificant, it is likely that the single-factor ANOVA result was due to high variability in measured lipid yield when extracted over 180 min. The lipid yields obtained over 180 min of extraction were extremely low and complete collection of the lipid fraction from the separatory vessels proved to be challenging. It is likely that if our N. granulata biomass had a higher intracellular lipid content we would have been able to recover the complete lipid fraction more readily from the separation vessel by minimizing the loss of the lipid fraction by adhesion to vessel walls and tubing.

The diffusivity of SC-CO2 increases with temperature, which may explain our observed increase in extraction yield associated with increased temperature. An increase in the temperature of extraction can increase the volatility or vapor pressure of the components being extracted (Reverchon and DeMarco 2006) and an increase in SC-CO2 temperature has been reported to increase the solubility of TAGs from soybeans (King 2002). Increased temperatures may also compromise the integrity of the cell wall or cellular components, allowing for a more complete extraction of algal lipids.

An increase in pressure of a supercritical fluid results in an increase in its density. A difference in the density of a supercritical fluid can result in a difference in the components extracted and of the solvating ability of supercritical fluid (Raventos et al. 2002); however, this effect does not seem significant for the extraction of algal TAGs with different fatty acid (FA) units of various chain length and degree of saturation. This result is consistent with other studies that included FAME analysis from SCE of algal biomass (Andrich et al. 2005 , 2006 ; Halim et al. 2011). The solubility of smaller molecules in SC-CO2 increases with an increase in SC-CO2 density; however, our LC-MS data indicates that shorter-chain FA moieties are not necessarily associated with smaller TAG molecules since each of the three FA molecules on the glycerol backbone can be different. King (2002) reported that TAG solubility is inversely related to SC-CO2 density; therefore, it may be possible to selectively extract individual TAGs by varying the density of SC-CO2 rather than selectively extracting individual FAs and, regardless of extraction condition, we are likely to extract a lipid fraction with a uniform FA profile.

Due to the uniformity of the FA profile among extraction conditions, optimizations based on gravimetric lipid yield or based on FAME yield can be appropriate means of resolving optimal extraction conditions, without the need for rigorous FA analysis at each condition. The uniformity of the FA profile facilitates the implementation of a SC-SCO2 extractor for pilot or industrial scale by greatly reducing the time and personnel needs to commission a new extractor.

While the gravimetric yield from SCE is considerably lower than that of hexane extractions, the FAME yield and the FA profile do not significantly differ regardless of the extraction technique (Fig. 3). This result demonstrates that, as an extraction technology for conversion of algal oils to biodiesel fuels and based upon the composition of the extract, SCE can be considered to be more efficient than extraction with hexane. Liquid chromatography–mass spectrometry data confirms that SCE produces a lipid extract that is devoid of polar lipid classes. Phospholipids are undesirable in the refining process of biodiesel and their absence in SCE oils argues for its suitability as a technique for algal biofuel research.

Although it has been suggested that SCE may be a good extraction technology for biofuel production and may be well suited to a biorefinery approach (Soh and Zimmerman 2011), we believe that the immediate potential of this technology for algal biofuels is in providing meaningful amounts of nearly pure TAGs that can be used to assess the lipid properties and fuel potential from a given algal strain. With a pilot-scale extraction platform, large quantities of oil can be extracted in a short time; if operating a pilot or industrial scale algal biomass production facility producing kilogram quantities of algal biomass, a pilot-scale SC-CO2 extractor could be a safe, rapid and practical, analytical tool.

References

Andrich G, Nesti U, Venturi A, Zinnai A, Fiorentini R (2005) Supercritical fluid extraction of bioactive lipids from the microalga Nannochloropsis sp. Eur J Lipid Sci 107:381–386

Andrich G, Zinnai A, Nesti U, Venturi F, Fiorentini R (2006) Supercritical fluid extraction of oil from microalga Spirulina (Arthrospira) platensis. Acta Aliment 35:195–203

Canela APRF, Rosa PTV, Marques MOM, Meireles MAA (2002) Supercritical fluid extraction of fatty acids and carotenoids from the microalgae Spirulina maxima. Ind Eng Chem Res 41:3012–3018

Christie WW (1989) Gas chromatography and lipids. The Oily Press, Ayr, UK

Griffiths MJ, Harrison STL (2009) Lipid productivity as a key characteristic for choosing algal species for biodiesel production. J Appl Phycol 21:492–507

Guillard RRL (1975) Culture of phytoplankton for feeding marine invertebrates. In: Smith WL, Chanley MH (eds) Culture of marine invertebrate animals. Plenum, New York, pp 26–60

Halim R, Gladman B, Danquah MK, Webley PA (2011) Oil extraction from microalgae for biodiesel production. Bioresour Technol 102:178–185

Hu H, Gao K (2006) Response of growth and fatty acid compositions of Nannochloropsis sp. to environmental factors under elevated CO2 concentration. Biotechnol Lett 28:987–992

King JW (2002) Supercritical fluid extraction: present status and prospects. Gracias Aceites 53:8–21

Macias-Sanchez MD, Mantell C, Rodriguez M, Martinez del al Ossa E, Lubian LM, Montero O (2007) Supercritical fluid extraction of carotenoids and chlorophyll a from Synechococcus sp. J Supercrit Fluids 39:323–329

Macias-Sanchez MD, Mantell C, Rodriguez M, MartinezdelalOssa E, Lubian LM, Montero O (2009a) Comparison of supercritical fluid and ultrasound assisted extraction of carotenoids and chlorophyll a from Dunaliella salina. Talanta 77:948–952

Macias-Sanchez MD, Serrano CM, Rodriquez MR, Martinez de la Ossa E (2009b) Kinetics of the supercritical fluid extraction of carotenoids from microalgae with CO2 and ethanol as cosolvent. Chem Eng J 150:104–113

Macias-Sanchez MD, Fernandez-Sevilla JM, Acien Fernandez FG, Ceron Garcia MC, Molina Grima E (2010) Supercritical fluid extraction of carotenoids from Scenedesmus almeriensis. Food Chem 123:928–935

McGinn PJ, Dickinson KE, Bhatti S, Frigon J-C, Guiot SR, O’Leary SJB (2011) Integration of microalgae cultivation with industrial waste remediation for biofuel and bioenergy production: opportunities and limitations. Photosynth Res. 109:231–247

Mendes RL, Coelho JP, Fernandes HL (1995a) Applications of supercritical CO2 extraction to macroalgae and plants. J Chem Technol Biotechnol 62:53–59

Mendes RL, Fernandes HL, Coelho JP, Reis EC, Cabral JMS, Novais JM, Palavra AF (1995b) Supercritical CO2 extractions of carotenoids and other lipids from Chlorella vulgaris. Food Chem 53:99–103

Mendes RL, Nobre BP, Cardoso MT, Pereira AP, Palavra AF (2003) Supercritical carbon dioxide extraction of compounds with pharmaceutical importance from microalgae. Inorg Chim Acta 356:328–334

Montero O, Macias-Sanchez MD, Lama CM, Lubian LM, Mantell C, Rodrigez M, Martinez de la Ossa E (2005) Supercritical CO2 extraction of B-carotene from a marine strain of the cyanobacterium Synechococcus species. J Agric Food Chem 53:9701–9707

Nagle N, Lemke P (1990) Production of methyl ester fuel from microalgae. Appl Biochem Biotechnol 24–5:355–361

Raventos M, Duarte S, Alarcon R (2002) Application and possibilities of supercritical CO2 extraction in food processing industry: an overview. Food Sci Tech Int 8:269–284

Reverchon E, DeMarco I (2006) Supercritical fluid extraction and fractionation of natural matter. J Supercrit Fluids 38:146–166

Soh L, Zimmerman J (2011) Biodiesel production: the potential of algal lipids extracted with supercritical carbon dioxide. Green Chem 13:1422–1429

Valderrama JO, Perrut M, Majewski W (2003) Extraction of astaxantine and phycocyanine from microalgae with supercritical carbon dioxide. J Chem Eng Data 48:827–830

Van Gerpen J (2005) Biodiesel processing and production. Fuel Process Technol 86:1097–1107

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Bjornsson, W.J., MacDougall, K.M., Melanson, J.E. et al. Pilot-scale supercritical carbon dioxide extractions for the recovery of triacylglycerols from microalgae: a practical tool for algal biofuels research. J Appl Phycol 24, 547–555 (2012). https://doi.org/10.1007/s10811-011-9756-2

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10811-011-9756-2