Abstract

Three low-cost drying methods (sun, solar, and draft oven) were optimized to produce Spirulina powder of optimal quality. Optimization in the pre-dehydration stage included the use of two antioxidants, α-tocopherol and tertiary-butyl hydroquinone (TBHQ), and two blanching methods, microwave and water bath, to inactivate enzymes. The efficiency of the pre-dehydration treatments at minimizing lipid peroxidation were evaluated in terms of the product’s oxidative stability using the thiobarbituric acid (TBA) test. The sample with the lowest TBA reactive substance (TBARS) value was considered the most stable. TBHQ was found to be significantly better than α-tocopherol in minimizing lipid peroxidation in blanched samples while α-tocopherol was better than TBHQ in unblanched samples. Microwave blanching exerted a greater stabilizing effect than water bath blanching. The combined effect of TBHQ and microwave blanching was found to be the most effective pre-dehydration treatment for minimizing lipid peroxidation in drying Spirulina. Among the three low-cost optimized drying methods, sun-drying produced a dried product with the lowest TBARS value (0.472 mg malondialdehyde.kg−1), which was closest to that of the spray-dried (control) sample (0.434 mg MDA.kg−1). Draft oven and solar drying produced dried products with the same average TBARS value (0.56 mg MDA.kg−1). Sun-drying, when optimized, produced a dried product that was almost as stable as the spray-dried product.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Spirulina, a spiral-shaped cyanobacterium, is gaining worldwide popularity as a food supplement (Belay 1997), being one of the most nutritious, concentrated foods known to man. It has been shown to be an excellent source of proteins, vitamins, and minerals (Switzer 1980). Research shows that among the cyanobacteria, Spirulina platensis and S. maxima appear to be the only producer of γ-linolenic acid (GLA).

Gamma linolenic acid (C18:3ω), a three double-bond polyunsaturated fatty acid (PUFA) of the ω6 family, is a precursor of arachidonic acid, which is required for the formation of the lipid mediators that are, in turn, involved in the control of the immune system (Gerster 1995; Gill and Valivety 1997; Salem 1999). Hernandez (2001) reported that S. platensis could alleviate the toxic side effects of chemotherapeutic drugs used in cancer management. The author cited that the presence of phytocyanins in Spirulina had been credited to induce hematopoiesis in the bone marrow.

Gamma linolenic acid has been shown to be about 170-fold more effective than linoleic acid at lowering serum levels of low-density lipoprotein (Cohen 1997), and can prevent accumulation of cholesterol in the body (Samuels et al. 2002). It also has a positive effect on heart disease, Parkinson’s disease, and multiple sclerosis. Moreover, it is used in the treatment of atopic eczema, and in alleviating the symptoms of premenstrual syndrome. Remirez et al. (2002) observed that Spirulina exerted a significant anti-arthritic effect, which they attribute partly to previously reported anti-inflammatory and anti-oxidative properties of its phycocyanin. Parikh et al. (2001) reported that type-2 diabetes mellitus patients given Spirulina supplementation for 2 months experienced an appreciable lowering of fasting blood glucose and postprandial blood glucose levels, and improved long-term glucose regulation. Triglyceride, total cholesterol and low-density lipoprotein cholesterol levels were also significantly lowered, coupled with a marginal increase in the level of high-density lipoprotein cholesterol. These findings suggest the beneficial effect of Spirulina supplementation in controlling blood glucose levels and in improving the lipid profile of subjects with type 2 diabetes mellitus.

Spirulina entered the Philippine functional food market several years ago. The most popular brands include Provimin, Spirutein and Spirulina Cereal. Users attest to its effectiveness at preventing and/or curing a variety of illnesses, particularly hypertension, cardiovascular diseases, and cancer. Samuels et al. (2002) found that Spirulina helps reduce the increased levels of lipids in patients with hyperlipidemic nephrotic syndrome. The price, however, is prohibitive, reaching as much as Php20,000 per kilogram of the capsule (US$1.00 = Php45.00 as of May 22,2007). Based on this premise, government agencies, academic institutions, and entrepreneurs have put much effort into exploring the possibility of optimizing the growth, processing, and utilization of Spirulina in the country. Some of the reported studies include those of Baldia et al. (1990, 1995), Sapin et al. (1993), and Zafaralla et al. (1985, 1989). The study by Talorete et al. (1999), in particular, established parameters for the low-cost production of S. platensis. The technology was intended for small farmers, as it does not require a large capital outlay. However, the processing of products of marketable quality presents a great problem.

Various drying methods differ in the extent of both investment and energy requirement. The selection of a particular drying method therefore depends on the scale of operation and final use of the dried product. At present, small-scale entrepreneurs commercially dry Spirulina using solar and oven/cabinet drying, while large-scale producers use spray drying. Spray drying produces high quality products with high bioavailability, while solar and oven/cabinet drying frequently result in products of low and often inconsistent quality with low bioavailability (Becker 1994).

Spray drying is too costly for small entrepreneurs. It can account for up to 30% of the total cost of algal production. The Department of Science and Technology ITDI in the Philippines installed a spray dryer for this purpose, but the service charge is still prohibitive, not to mention the distance to be traveled just to use the facility. Hence, it is a major economic limitation to the production of low-cost algal products and a significant factor even in the case of higher value products.

When optimized, low-cost drying methods (sun, solar and draft oven-drying) have the potential to approach the advantages derived from spray drying in terms of quality and bioavailability at a lower cost. The development of an optimized drying process would therefore encourage farmers/entrepreneurs to grow Spirulina, as this will give them the assurance that they can produce dried Spirulina of marketable quality. As a result, the country can save a tremendous amount of money spent on the importation of this very expensive commodity. Malnourished individuals, particularly those from the low-income groups, could benefit more from its nutritional contribution and therapeutic effects. Wider applications can likewise be made feasible with a cheaper, locally available product. For example, Spirulina provides complete nutrition for aquarium fishes and other pets.

This study aims to compare the efficiency of two antioxidants (α-tocopherol and tertiary-butyl hydroquinone [TBHQ]), and two blanching methods (water bath and microwave blanching) as pre-dehydration treatments at minimizing lipid peroxidation in Spirulina; to identify which combination of antioxidant/blanching method is the most efficient at minimizing lipid peroxidation, and to determine which of the optimized drying methods produces the most stable (lowest peroxide value) product.

Materials and methods

The raw material was obtained from the project of Dr. Lourdes Cruz at Jasaan, Misamis Oriental. The Spirulina platensis isolate MI2 was grown in an outdoor raceway with seawater-based media formulated by the project, designated CBMS Medium. The initial pH and salinity of the growth media were adjusted to 8.8 and 25 ppt respectively. Ambient temperature was an average of 30 ± 5°C.

Spirulina was harvested with a 300-mesh nylon net and washed in two changes of potable water to rid the cells of salt and media residues. The slurry was chilled during transport to the laboratory.

Raw material characterization

The Spirulina slurry used in the physico-chemical, microbiological, and proximate analyses was freeze-dried on the same day it was harvested. The dried raw material was analyzed and characterized according to the parameters suggested by Vonshak (1997); for heavy metal content (mercury by the AOAC method, lead and cadmium by atomic absorption spectrophotometry), protein (by the Kjeldahl method using Tecator 1030 Auto Analyzer), ash (ashing in the Yamato FP31 muffle furnace at 550°C), moisture (wet and dry using the Eyela FD-81 freeze dryer and the Yamato DN83 constant temperature oven set at 70°C respectively), crude fat (AOAC Soxhlet extraction using SF-6 apparatus). The fatty acid profile was determined using gas chromatography. In addition, the presence and amount of iron was established because of its catalytic role in lipid peroxidation. Iron and calcium were determined by atomic absorption spectrophotometry.

Dried Spirulina samples were likewise subjected to microbial assay for coliforms, and the yeast and mold counts using BAM-AOAC methods. The sensory quality of the dried sample was likewise evaluated in terms of color and taste by a laboratory panel.

Optimization of pre-dehydration treatments

There are several choices for enzyme inactivation as well as antioxidants, but the question of which of these can provide adequate protection at a reasonable cost was the focus of the optimization study. The seven treatments, representing the different antioxidant/enzyme inactivation methods and a control, were designated as follows:

-

1.

Treatment 1—tocopherol + water bath blanching (TWB)

-

2.

Treatment 2—tocopherol + microwave blanching (TMB)

-

3.

Treatment 3—tocopherol + no heat treatment (TCtrl)

-

4.

Treatment 4—TBHQ + water bath blanching (TBWB)

-

5.

Treatment 5—TBHQ + microwave blanching (TBMB)

-

6.

Treatment 6—TBHQ + no heat treatment (TBCtrl)

-

7.

Treatment 7—control: no antioxidant, no heat treatment

The DL-α form of tocopherol was used because it is the principal antioxidant used in vegetable oils, is cheaper and readily available, besides being efficient at high levels of oxygen pressure. TBHQ was likewise chosen because of its effectiveness at providing oxidative stability to crude and polyunsaturated oils, especially vegetable oils (Giese 1996). Both of the antioxidants used were of food grade. Figure 1 presents the flowchart for the optimization of the pretreatment process.

Antioxidant preparation and dispersion

Stock solutions of DL-α tocopherol and TBHQ were prepared in absolute ethanol. The amount of antioxidants added (0.03% for tocopherol and 0.02% for TBHQ) were based on the predetermined crude fat content of dried Spirulina (about 6%). Each of the required aliquots of antioxidant was diluted with 50 ml of deionized water to facilitate its dispersion in the thick slurry. Each of the two antioxidants was dispersed separately into the 450 g of slurry and blended for 5 min at speed 4 in an Oster kitchen blender before subdividing the slurry into three equal portions allocated to the two blanching treatments and a corresponding no blanch control. Treatment 7 represented the samples without antioxidant and heat treatment.

Enzyme inactivation

The following figures present flowcharts for the water bath (Fig. 2) and microwave (Fig. 3) blanching of Spirulina. In water bath blanching, the slurry was heated to 80°C for 3 min as suggested by Giese (1992). An equivalent process for microwave blanching was done by setting the power and time control at “high” and 3 min respectively.

Drying of pretreated samples

The blanched slurry was immediately dried in a constant temperature draft oven (Yamato DN 83) set at 65°C, to a constant weight (about 7% moisture content). Drying trays were placed in the oven in random positions and interchanged three times during the drying period. Dried samples were immediately subjected to the TBA test for lipid peroxidation.

TBA test

The TBA/TCA stock reagent was prepared by mixing 15% w/v trichloroacetic acid (TCA), 0.375% w/v thiobarbituric acid (TBA), and 0.25N hydrochloric acid. The solution was mildly heated to facilitate the dissolution of the thiobarbituric acid. Both reagents used were of analytical grade.

Spirulina powder (0.4 g) was placed in a 10-mL test tube and vortexed with 5 mL of deionized distilled water for 15 s. Butylated hydroxyanisole (50 μL, 7.2%) and TBA/TCA stock solution (2 mL) were added to the sample, vortexed for 15 min, and then incubated in a boiling water bath for 15 min to develop color. Samples were cooled in iced water for 10 min and centrifuged for 15 min at 2,000 g. Absorbance of the resulting supernatant was determined at 531 nm against a blank containing 1 mL of deionized distilled water and 2 mL of TBA/TCA stock solution. The TBARS value, expressed as milligrams of malonyldialdehyde (MDA) per kg of sample, was calculated using a molar extinction coefficient of the standard (1.56 × 10°M−1 cm−1).

Selection of best drying method for optimally pretreated Spirulina

The combined antioxidant/enzyme inactivation pretreatment method that gave the lowest TBARS value was used in the preparation of another batch of samples that were subjected to sun, solar, and cabinet drying to constant weight (7 ± 0.2% moisture content). Figure 4 presents the flowchart for the determination of the best drying method. Their corresponding TBARS values were analyzed and compared with that of the spray dried sample.

The Spirulina slurry used in the three low-cost drying methods was subjected to the best pre-dehydration treatment, then poured into plastic-lined trays to a depth of 0.5 cm. The samples were dried to a constant weight. The following figures present flowcharts for different methods of drying Spirulina, such as: sun (Fig. 5), solar (Fig. 6), and cabinet drying (Fig. 7).

For solar drying, a solar dryer as described by Becker (1994) was used to for a temperature range of 50–55°C.

A control batch of Spirulina was dried using a Niro spray dryer equipped with an electric air hose, a 24-vessel centrifugal atomizer, and a peristaltic pump for delivering the sample to the atomizer. Inlet air temperature was set at 225°C, while the exhaust temperature was maintained at 100°C. Drying time was adjusted to about 20 s by controlling the flow rate of the suspended Spirulina sample to the atomizer. Dried samples were subjected to the TBA test following the procedure described above. The drying method with the lowest TBARS value was considered the best drying method.

Results

Physico-chemical and microbiological evaluation of the raw material

The results of the physico-chemical and microbiological analyses are presented in Table 1. Heavy metal determination revealed significantly negligible amounts of mercury and lead in the sample. The iron content was 0.10%. Total coliform count determination yielded negative results. The freshly harvested Spirulina had a dark green color and mild taste, and was shown to contain 67.9% protein, and 5.7% ash. The crude fat/lipid content of freeze-dried Spirulina was 6.017% by Soxhlet extraction and 6.15% by gas chromatography.

Comparative efficiency of antioxidants at minimizing lipid peroxidation

The effects of different antioxidants and blanching methods as pre-dehydration treatments on lipid peroxidation in Spirulina are presented in Table 2. In unblanched Spirulina, α-tocopherol-treated samples had a significantly lower mean TBARS value (0.73 mg MDA.kg−1) than TBHQ-treated samples (0.83 mg MDA.kg−1). In blanched samples, however, TBHQ-treated samples had significantly lower mean TBARS values than α-tocopherol-treated samples.

Comparative effects of the two blanching methods

Water bath blanching

Antioxidant-treated Spirulina samples subjected to water bath blanching (80°C for 3 min) had a generally higher mean TBARS value than that of the corresponding unblanched samples.

Microwave blanching

The mean TBARS value of Spirulina treated with TBHQ and subsequently subjected to microwave blanching (0.54 mg MDA.kg−1) was significantly lower than that for its unblanched counterpart (0.83 mg MDA.kg−1). On the other hand, the α-tocopherol-treated, microwave-blanched Spirulina had significantly higher TBARS value (0.78 mg MDA.kg−1) than its unblanched counterpart (0.73 mg MDA.kg−1).

The results indicate that the use of TBHQ as an antioxidant combined with microwave blanching for enzyme inactivation is the best option for minimizing lipid peroxidation in Spirulina. On the other hand, in the absence of a microwave the use of α-tocopherol with no subsequent blanching is the next best option.

Evaluation and selection of the best drying method

The effects of the pre-dehydration treatment and different drying methods on lipid peroxidation in Spirulina are presented in Table 3. In draft oven and sun dried Spirulina, TBARS values of 0.56 and 0.47 mg MDA.kg−1 respectively were obtained from TBHQ microwave blanching treated samples versus 0.65 and 0.49 mg MDA.kg−1 respectively for the untreated counterparts. No significant enhancement in oxidative stability was observed in treated solar dried samples.

Spray-dried Spirulina had a significantly lower TBARS value than samples dried using the three low-cost drying methods. Sun-dried Spirulina had a TBARS value (0.47 mg MDA.kg−1) closest to that of the spray-dried sample (0.43 mg MDA.kg−1).

Discussion

Physico-chemical and microbiological evaluation of the raw material

The physico-chemical and microbiological analyses revealed that freshly harvested S. platensis MI2 biomass meets international quality standards for food-grade Spirulina. Proximate analyses revealed that the freshly harvested biomass conforms to set standards for biochemical quality. The higher value obtained for cadmium may be due to instrumental limitations, since the analyzer used could only detect cadmium up to 0.0003% and not quantities below 0.0001%, which is the lower limit specified by Vonshak (1997). The negative coliform count indicates that the freshly harvested biomass is microbiologically safe for human consumption.

The crude fat/lipid content of freeze-dried Spirulina determined by Soxhlet extraction closely agreed with values obtained by gas chromatography. Although Spirulina may not be considered a lipid-rich food, its high PUFA content, which was found to be unique for this microalga, makes it a valuable source of the ω6 series of essential fatty acids, particularly GLA.

Comparative efficiency of antioxidants at minimizing lipid peroxidation

Alpha-tocopherol is more effective at minimizing lipid peroxidation in unblanched Spirulina while TBHQ is more effective in blanched samples. In unblanched Spirulina, the significantly lower mean TBARS value obtained from α-tocopherol-treated samples compared with TBHQ-treated samples implies that α-tocopherol is more effective than TBHQ at minimizing lipid peroxidation. Min and Bradley (1992) and Elliott (1999) explained that α-tocopherol can work both singly and synergistically with β-carotene when used as a free radical scavenger to minimize or retard lipid peroxidation. Spirulina contains 2.1 mg β-carotene per gram (Belay 1997), suggesting a possible synergistic effect.

In blanched Spirulina, significantly higher mean TBARS values obtained from α-tocopherol-treated samples compared with TBHQ-treated samples indicate that the efficiency of α-tocopherol as an antioxidant was adversely affected by the heat treatment. Tocopherol has an energy of activation (E a = 9–13) falling within the range for lipid oxidation (E a = 10–25). This means that its degradation is almost as temperature-dependent as the lipid it is supposed to protect, so that both are degraded simultaneously.

Although free tocopherols are generally stable in heat in the absence of oxygen, these can be oxidized by atmospheric oxygen in unsaturated lipid systems in the presence of light, heat or metal ions (Elliott 1999; Huber et al. 1995; Floros 1992; Villota and Hawkes 1992). Physico-chemical analysis revealed that Spirulina is rich in unsaturated fatty acids and iron. Frankel (1984) pointed out that transition metals with a redox potential, such as iron, catalyze autoxidation by promoting the initiation step in the chain reaction, or may inhibit antioxidative action.

Tertiary-butyl hydroquinone, on the other hand, appears to be heat-stable, thus providing better protection to lipids in blanched Spirulina.

Comparative effects of the two blanching methods

Water bath blanching

Ahn et al. (1995) explained that heating, as in water bath blanching, causes cellular structural damage and subsequent thermal maceration that enhances the contact of oxygen with membrane lipids, which accelerates lipid peroxidation. Lamb (1986) likewise pointed out that heat causes oxidation of labile nutrients when the temperature used disrupts tissues, but does not inactivate enzymes, causing the enzymes and substrates to mix. The longer time associated with conventional water-bath blanching of thick slurries (4 min in this case) provided sufficient time for enzymes to accelerate lipid peroxidation and cause damage in the food material before being inactivated.

Microwave blanching

Microwave blanching enhanced the oxidative stability of TBHQ-treated, but not α-tocopherol-treated Spirulina. This suggests that microwave heating diminishes the antioxidant activity of α-tocopherol.

Oxidative stability of TBHQ-treated Spirulina was most likely enhanced by rapid enzyme inactivation. Mullin (1995) reported that microwaves deliver a more homogenous heat treatment taking less time to come up to the desired process temperature than conventional heating. Likewise, Giese (1992) stated that the high rate of heat transfer for a specified level of enzyme destruction would be expected to result in reduced losses of heat-sensitive nutrients. These findings agree with Klein’s (1986) observation that in about half of the studies on microwave cooking, nutrient retention was higher than in conventional cooking.

These results indicate that the best pretreatment for minimizing lipid peroxidation in Spirulina is to use TBHQ as an antioxidant and microwave blanching for enzyme inactivation.

Evaluation and selection of the best drying method

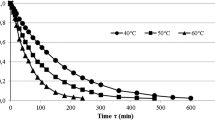

Pretreatment of Spirulina enhanced the oxidative stability of draft oven and sun-dried, but not solar dried samples. The effect of photosensitized degradation in sun drying seems to be less extensive compared with the effect of the longer drying time in solar drying and higher temperature in draft oven drying. Drying took 12–14 h in the solar dryer, compared with 8–10 h in sun drying. On the other hand, the draft oven temperature was 65°C compared with the average sun-drying temperature of 45°C.

Spray drying has the advantage of an extremely short drying time with minimal exposure to heat and oxygen (Becker 1994), which resulted in a significantly lower TBARS value than that obtained from the three low-cost drying methods. That TBARS value obtained from sun-dried Spirulina was closest to the spray-dried sample, suggests that sun drying, when optimized, produces a product that is almost as stable as the spray dried samples.

References

Ahn DU, Wolfe FH, Sim JS (1995) Dietary α-linolenic acid and mixed tocopherols, and packaging influences on lipid stability in broiler chicken breast and leg muscle. J Food Sci 60:1013–1018

Baldia SF, Fukami K, Nishijima T, Hata V (1990) Effects of physico-chemical factors and nutrients on the growth of Spirulina platensis isolated from Lake Kojima, Japan. Nippon Suisan Gakkaishi 57:481–490

Baldia SF, Fukami K, Nishijima T, Hata V (1995) Growth responses of Spirulina platensis to some physicochemical factors and the kinetics of phosphorus utilization. Fish Sci 61:331–335

Becker M (1994) Microalgae: biotechnology and microbiology. Cambridge University Press, Cambridge

Belay A (1997) Mass culture of Spirulina outdoors—the earthrise farms experience. In: Vonshak A (ed) Spirulina platensis (Arthrospira): physiology, cell-biology and biotechnology. Taylor and Francis, London, pp 131–158

Cohen Z (1997) The chemicals of Spirulina. In: Vonshak A (ed) Spirulina platensis (Arthrospira): physiology, cell-biology and biotechnology. Taylor and Francis, London, pp 175–204

Elliott JG (1999) Application of antioxidant vitamins in foods and beverages. Food Tech 53:46–48

Floros JD (1992) Optimization methods in food processing and engineering. In: Hui YH (ed) Encyclopedia of food science and technology, vol 3. Wiley, London, pp 1952–1965

Frankel EN (1984) Lipid oxidation: mechanism, products and biological significance. J Am Oil Chem Soc 61:1908–1914

Gerster H (1995) The use of –3 PUFAs (fish oil) in enteral nutrition. Int J Vitam Nutr Res 65:3–20

Giese J (1992) Advances in microwave food processing. Food Tech 46:118–123

Giese J (1996) Antioxidants: tools for preventing lipid peroxidation. Food Technol 11:73–81

Gill I, Valivety R (1997) Polyunsaturated fatty acids. I. Occurrence, biological activities and applications. Tibtech 15:401–409

Hernandez ZB (2001) A hematological study on the protective effects of Spirulina against cyclophosphamide-treated mice (University of the Philippines Institute of Biology). http://webdb.stii.dost.gov.ph/search.jsp?dbname=rnd&pg=1 (Accessed December 10, 2005)

Huber KC, Pike OA, Huber CS (1995) Anti-oxidant inhibition of cholesterol oxidation in a spray-dried food system during accelerated storage. J Food Sci 60:909–912

Klein B (1986) Effect of processing on nutritive value of food: microwave cooking. In: Rechcigl MJ (ed) Handbook of nutritive value of processed foods, vol 1: food for human use. CRC, Boca Raton, pp 209–235

Lamb FC (1986) Effect of processing on nutritive value of food: canning. In: Recheige MJ (ed) Handbook of nutritional value of processed foods, col. 1: food for human use. CRC, Boca Raton

Min DB, Bradley DG (1992) Fats and oils: flavors. In: Hui YH (ed) Encyclopedia of food science and technology, vol 2. Wiley, New York, pp 828–832

Mullin J (1995) Microwave processing. In: Gould GW (ed) New methods of food preservation. Blackie Academic and Professional, Glasgow, pp 112–134

Parikh P, Mani U, Iyer U (2001) Role of Spirulina in the control of glycemia and lipidemia in type 2 diabetes mellitus. J Med Food 4(4):193–199

Remirez D, Gonzalez R, Merino N, Rodriguez S, Ancheta O (2002) Inhibitory effects of Spirulina in zymosan-induced arthritis in mice. Mediat Inflamm 11:75–79

Salem N Jr (1999) Introduction to polyunsaturated fatty acids. Backgrounder 3:1–8

Samuels R, Mani UV, Iyer UM, Nayak US (2002) Hypocholesterolemic effect of Spirulina in patients with hyperlipidemic nephrotic syndrome. J Med Food 5:91–96

Sapin AB, del Rosario RR, Zafaralla MT (1993) Some physico-chemical properties of the crude blue pigment protein isolated from Spirulina alga. Philipp J Biotechnol 4:135–148

Switzer L (1980) Spirulina, the whole food revolution. Proteus Corporation, Albuquerque, p 69

Talorete TPN, Butardo V, Cruz LJ (1999) Low-cost production of Spirulina platensis using brackish water. Abstracts, Biotechnology for the Next Millennium, BAPI International Conference, Feb. 24–26, 1999, Mandaluyong, Metro Manila

Villota R, Hawkes JG (1992) Reaction kinetics in food systems. In: Heldman D, Lund D (eds) Handbook of food engineering. Dekker, New York, pp 39–144

Vonshak A (1997) Outdoor mass production of Spirulina: The basic concept. In: Vonshak A (ed) Spirulina platensis (Arthrospira): physiology, cell-biology and biotechnology. Taylor and Francis, London, pp 79–99

Zafaralla MT, Barill CR, Vidal LR, Serrana MS, Aguila LG, Tansinsin LO (1985) Protein from Spirulina. NSTA Tech J 10:18–26

Zafaralla MT, Mangaban MLM, Sapin AB, Valenton DB, Alip TG (1989) Year-round mass production of Spirulina in open pond. Philipp Agric 72:347–352

Acknowledgements

Thanks is due to the Nueva Vizcaya State University for a scholarship grant to the principal author, and the Office of the Vice-Chancellor for Research and Development of the University of the Philippines Diliman, National Research Council of the Philippines, UP-College of Home Economics Foundation, Coca-Cola Foundation, Philippine Society of Microbiologists, and Broadway Centrum for financial support.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Tiburcio, P.C., Galvez, F.C.F., Cruz, L.J. et al. Optimization of low-cost drying methods to minimize lipid peroxidation in Spirulina platensis grown in the Philippines. J Appl Phycol 19, 719–726 (2007). https://doi.org/10.1007/s10811-007-9215-2

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10811-007-9215-2