Abstract

In this study, the validity of TiO2-based photocatalysts anti-algal effects was examined with Chlorella vulgaris. Cu-modified TiO2 (without N dopants) showed clear anti-algal effect under white LED light. N-doped TiO2 (both with and without Cu modification) and Cu-modified TiO2 (without N dopants) showed clear anti-algal effects when UV light was used together with white LED light. S-doped TiO2 had no anti-algal effects and even promoted the growth of algae. The degree of the anti-algal effect differed depending on the dopants, surface modifications, and irradiation light. Photocatalysts create several active spices during their photocatalytic processes. Of these, the effects of superoxide radical (O ·−2 ) and hydrogen peroxide (H2O2) on algae growth were examined. Photocatalysts with high anti-algal effect produced hydrogen peroxides effectively, while there was no correlation between productivity of superoxide radical and anti-algal effects. Thus, the ability to produce hydrogen peroxide is a plausible factor for determining the efficiency of the anti-algal effect of a photocatalysts.

Graphical Abstract

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

Environmental problems, ongoing food crises, and shortages of resources are becoming global issues. These problems are strongly correlated and an efficient concept and technological system that solves them is in high demand. One potential candidate that has attracted great interest is the hydroponic plant factory. This is a highly controlled system that creates agricultural products all year round, facilitates mass production with a minimal footprint, and is independent of the natural environment. However, contaminants originating from increased fungi and algae growth become prominent after multiple operations in a circulation-type hydroponic system. Algae adhered to growth equipment and absorb nutrients from the cultivation liquid, resulting in the poor growth of products [1]. Some algae contain poisonous substances that cause growth suppression and/or diseases, leading to a decrease in both quality and quantity of the products. Therefore, introducing the cultivation liquid purification system is indispensable for improving production efficiency.

Photocatalysts have attracted great interests as sanitizers since the discovery of the Honda–Fujishima effect in 1972 [2]. Photocatalysts produce highly oxidative active species, which are useful for processes such as the decomposition of pollutants and sterilization [3]. Photocatalysis is less harmful to human health than chemical sanitization and photocatalysts are inexpensive to produce, which is desirable for practical applications. Systems using photocatalysts for cultivation liquid purification have been actively researched and developed. For example, a circulation system with TiO2 filters exposed to solar light has been studied for the purification of cultivation liquid [4], and a purification apparatus with TiO2 filter and equipped UV light has been developed [5].

Although these purification systems are effective for sterilization and decomposition of organic compounds in the circulating cultivation liquid, they are less effective for preventing algae growth attached to the equipment. Indeed, various types of alga proliferate in our hydroponic plant factory that uses a purification system similar to that mentioned above. Photocatalytic reactions are surface reactions and the cleaning effects are diminished for areas far from the photocatalysts. Direct interaction between the photocatalysts and algae should be considered for preventing algae adhesion.

Unmodified TiO2- [6–9] and ZnO [10]-based composites have been mainly studied as photocatalysts to prevent algae. Anion-doped and/or metal-modified TiO2 are more attractive because they absorb a wider range of light toward visible light [11]. Visible light-driven photocatalysts should be more suitable sanitizing photocatalysts in hydroponic plant factories because solar light or artificial white light is used as the light source. In this study, we examined the anti-algal effects of photocatalysts that could be directly coated on the growth equipment. We investigated Cu-modified TiO2, S-doped TiO2, N-doped TiO2, and Cu-modified N-doped TiO2 as well as unmodified TiO2 (both rutile and anatase). Chlorella vulgaris is an alga that generates in the actual hydroponic plant factory and was chosen as a test alga because it is tolerant to environmental stress, and it is easy to cultivate. We gained insight into the properties of suitable photocatalysts for the removal of algae.

2 Experimental

2.1 Materials

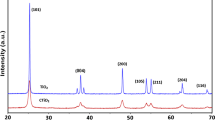

Commercially available TiO2-based photocatalyst powders were mostly used in this study. ST-01 (Ishihara Sangyo Kaisha, Ltd) and MT-150A (TAYCA Corporation) were used as anatase (denoted hereafter as A_TiO2) and rutile (denoted hereafter as R_TiO2) TiO2 powders, respectively. Cu-modified TiO2 (LUMI-RESH) was acquired from Showa Denko KK [denoted hereafter as Cu(m)_TiO2]. S-doped TiO2 was obtained from Pialex Technology Corp (denoted hereafter as S_TiO2). N-doped and Cu-modified/N-doped TiO2 were personally provided [denoted hereafter as N_TiO2 and Cu(m)_N_TiO2, respectively]. The absorption peaks of the modified/doped powders were widened to the visible light region (Fig. S1). Cu(m)_TiO2 has a rutile phase and its particle size is bigger than the other powders (100–200 nm). The other photocatalysts have an anatase phase with similar particle size (ca. 50 nm) (Figs. S2, S3). Photocatalytic performance measured by the decomposition of acetaldehyde is summarized in Fig. S4. Anion-doped samples [S_TiO2, N_TiO2, and Cu(m)_N_TiO2] had stronger photocatalytic activity than unmodified materials (A_TiO2 and R_TiO2), and this enhancement did not occur with Cu modification alone (Cu_TiO2).

Chlorella vulgaris (NIES-227) was purchased from the National Institute for Environmental Studies (NIES). The alga was cultivated under a fluorescent light inside a chamber at 25 °C. The cultivation was conducted with sterilized equipment and medium inside a clean bench. Liquid C medium [12] was used for the cultivation processes.

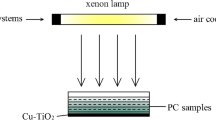

2.2 Measurement of photocatalytic anti-algal effects

The photocatalysts were tested using an environment that simulated a hydroponic plant factory, with a common cultivation liquid (Hoagland solution) and light sources. Prepared Hoagland solution was sterilized in an autoclave at 120 °C before use. 1/10 Hoagland solution (10 mL) was added to an autoclave-sterilized sample tube and C. vulgaris added to give 80 × 104 cells mL−1. Photocatalyst (0.01 g), sterilized by UV light, was added and exposed to white LED light (10,000 Lx) (Fig. S5) or white LED light (10,000 Lx) + UV light (352 nm; 0.3 mW cm−2). Samples without photocatalysts were also prepared as references.

Aliquots of the mixtures (2 mL) were occasionally taken and placed in microtubes (2.5 mL). The samples were centrifuged for 10 min at 15,000 rpm, and the supernatant (1.7 mL) was removed. Methanol (1.0 mL) was added to each sample tube and the tubes shaken for 1 h by vortex mixer to extract chlorophylls. The extraction mixture was centrifuged again. The supernatants (250 µL) were transferred into a 96-well microplate, and the absorbance of chlorophyll (665 nm) was measured with a microplate reader (Multiskan GO ver. 1.00.40). A calibration curve between cell concentration and absorbance was prepared using control samples (without photocatalysts) and used to determine the relative cell concentration in the tubes with photocatalysts.

2.3 Analysis of super oxide generated from photocatalysts

Tetrazolium salt WST-1 (5 mg) was dissolved in 1/10 Hoagland solution (12 mL) and used as a standard solution. Each photocatalyst powder (0.05 g) was dispersed in the standard solution and irradiated under UV light (352 nm; 20 mW cm−2) for 2 h or white LED light (10,000 Lx) for 24 h. WST-1 can be used to selectively detect the concentration of super oxide because it reacts with super oxide (O2 −) and does not react with xanthine oxidase and hydrogen peroxide [13]. When WST-1 reacts with super oxide, it forms a formazan, which has a maximum absorption at 450 nm [14] (Fig. S6). The absorption spectrum of the tested solutions was used to estimate the relative amount of super oxide generated.

2.4 Effect of hydrogen peroxide on anti-algal effect

1/10 Hoagland solution (10 mL) was charged to a sterilized (autoclave) sample tube. C. vulgaris (80 × 104 cells mL−1) was added and cultivated for 4 days. A 0.03 vol % solution of hydrogen peroxide was prepared by diluting 30% hydrogen peroxide (100 µL) with ultrapure water to a total volume of 100 mL. This dilute hydrogen peroxide was added to the cultivation liquid twice a day after the 4 day cultivation. Samples without adding hydrogen peroxide were also prepared as a reference. The cell concentration was estimated using a method similar to that described in Sect. 2.2.

3 Results

The relationship between the cell concentration within each test tube (Hoagland solution with C. vulgaris and photocatalyst powders) and light-irradiating days is summarized in Fig. 1. The Cu(m)_TiO2 showed a clear anti-algal effect under white LED light, while Cu(m)_N_TiO2 had only a weak effect. Anion-doped TiO2 powders (S_TiO2 and N_TiO2) had no anti-algal effects (Fig. 1a). When UV light was used with the white LED light, N_TiO2 and copper-modified TiO2 [Cu(m)_TiO2 and Cu(m)_N_TiO2] had clear anti-algal effects, with almost all algae decomposed after 8 days. Both S_TiO2 and R_TiO2 had no anti-algal effects and even promoted the growth of algae (Fig. 1b). A_TiO2 can weakly decompose algae, though addition of UV light seemed to have no greater effect.

Photocatalysts create several active spices during their photocatalytic processes. Among these, superoxide radical (O ·−2 ) is a relatively strong oxidizer, and we assumed that the amount of superoxide radical produced could explain the differences of the photocatalysts anti-algal effects. Figure 2 summarizes the absorbance of formalized WST-1 (tetrazolium salt), which corresponds to the amount of superoxide radicals created from each photocatalyst. The largest absorbance was that from the tube containing R_TiO2, indicating this catalyst generated the most superoxide radicals under both white LED light and UV light, despite the continuing increase in algae in the presence of this catalyst (Fig. 1). A relatively large amount of WST-1 was formalized with photocatalysts showing anti-algal effects under UV light [Cu(m)_TiO2, N_TiO2, and Cu(m)_N_TiO2]. However, there was little color change of the test solution with Cu(m)_TiO2 under white light irradiation, despite this catalyst showing the strongest anti-algal effect. These results clarified that there was no correlation between the absorbance of formalized WST-1 (i.e., the amount of superoxide radicals generated from the photocatalysts) and the anti-algal effect. Thus, superoxide radicals alone were not the direct reason for the effect.

Hydrogen peroxide easily releases oxygen, producing strongly oxidizing hydroxy radicals. Hydrogen peroxide is relatively stable with a long lifetime in the water and can effectively reach algae by diffusion. Therefore, we surveyed the influence of hydrogen peroxide on the anti-algal effect. Imase et al. [15] reported that exposing C. vulgaris to hydrogen peroxide made holes in the cell wall and entered the cell through these holes. The hydrogen peroxide that penetrated into the cells possibly oxidized the DNA and proteins, destroying the viability of the cells. We exposed C. vulgaris to hydrogen peroxide (ca. 0.12 µM) and surveyed the change in cell concentration to clarify whether hydrogen peroxide from the photocatalysts was the causative agent of the anti-algal effect. Cell concentration decreased with time when hydrogen peroxide was added (Fig. 3). The cell concentration dropped to about 50 × 104 cells mL−1 after 4 days, which was almost the same level observed in the sample with N_TiO2 under UV light. This suggests that the anti-algal effect of the photocatalysts was because the catalysts photogenerated hydrogen peroxide.

4 Discussion

We first compared S_TiO2 and N_TiO2. Although both are anion-doped TiO2, they showed different effects on algae. This is likely because of the different hydrogen peroxide production abilities of these catalysts. N-doped TiO2 produces more hydrogen peroxide than S-doped TiO2 under visible light [16]. This can be explained by the following mechanisms. First, N-doped TiO2 was excited by visible light irradiation (Eqs. 1, 2).

The excited electrons in the conduction band create superoxide radicals (Eq. 3), which then combine to form hydrogen peroxide at the TiO2 surface (Eq. 4).

However, carrier recombination also rapidly occurs during photo-excitation, slowing the rate of superoxide radical production (Eq. 5).

S-doped TiO2 is also photo-exited by visible light (Eq. 6) and superoxide radical production (Eq. 3) proceeds.

S+ is more stable than N· and N− because sulfur can exist in various oxidation states. Thus, the rate of carrier recombination mentioned below (Eq. 7) is slower than that in Eq. (5), and superoxide radical production is faster for S-doped TiO2. The S-doped TiO2 catalyst should produce more hydrogen peroxide. However, residual electrons in the conduction band reduce hydrogen peroxide (Eqs. 8, 9).

Therefore, the amount of hydrogen peroxide produced is decreased. In short, the active species generated from the photocatalysts differs depending on the dopant stability (Fig. 4). This difference in active species generation is considered to be the reason for the superior anti-algal effect of N_TiO2 under UV light. However, a clear difference between N_TiO2 and S_TiO2 was not observed under white light. This is probably because the LED light used in this study was too weak to produce a sufficient amount of hydrogen peroxide to remove algae.

Unmodified TiO2 produces hydrogen peroxide by photo-excited electrons (Eqs. 10–12) [17].

However, TiO2 oxidizes hydrogen peroxide at the valence band, decreasing total hydrogen peroxide production (Eq. 13, Fig. 5).

In contrast, this oxidation of hydrogen peroxide does not occur in anion-doped TiO2 [16]. This is because the energy level of the valence band extends to higher energy, which decreases the hole oxidizability. Therefore, pure TiO2 generates less hydrogen peroxide compared with doped/modified TiO2. This explains why pure TiO2 (A_TiO2) has insufficient anti-algal effect, even under UV light.

Cu(m)_TiO2 showed high anti-algal effect under both UV and white light. In contrast, Cu(m)_N_TiO2 showed poor anti-algal effect under white light and sufficient anti-algal effect under UV light. The most characteristic feature of Cu-modified photocatalysts is that Cu(II) oxide clusters reduce to Cu(I) via interfacial charge transfer (IFCT), which works as a reduction co-catalyst [18]. Although electron trapping at oxygen vacancies decrease the photocatalytic activity of N-doped TiO2 [19], Cu modification enhances activity under UV light [20]. The main electron transition under UV light in N-doped TiO2 is O 2p → Ti 3d. Photo-excited electrons in the conduction band, or trapped shallow defect level, diffuse throughout the photocatalyst until they are trapped at deep defect sites, such as oxygen vacancies. Some of the electrons reach Cu before being trapped at the deep sites because the diffusion lifetime is several hundred picoseconds [21]. Direct electron excitation to Cu (II) via IFCT prevents charge recombination, enhancing the photocatalytic activity by increasing the lifetime of carriers. In contrast, the main electron transition under visible light changes to N 2p → Ti 3d. Electrons transfers to Ti atom adjacent to oxygen vacancies induced by N doping, and they tend to be trapped deeply at the vacancies extremely rapidly (within 1 ps). Thus, electrons cannot reach the modified metals [21]. This limits the photocatalytic activity enhancement of Cu(m)_N_TiO2 under UV light, and the anti-algal effect was not improved under visible light (Fig. 6).

Heavy metals, including Cu, are toxic to the microbes. The median lethal dose (ED50) of Cu toward C. vulgaris is 2 µg mL−1, and Cu has an effect on the antioxidative system of the alga at a lower concentration (0.5 µg mL−1). Mallic [22] reported that exposure to Cu induced lipid peroxidation and cell membrane damage in C. vulgaris. The concentration of the antioxidant carotenoid and superoxide dismutase (DOD) increased in the cell with increasing Cu concentration, whereas ascorbic acid salt, glutathione (GSH), catalase (CAT), ascorbate peroxidases (APX), and glutathione reductase (GR) decreased [22]. These antioxidants all play important roles in the glutathione–ascorbate cycle, which is a metabolic pathway that detoxifies hydrogen peroxide. The photocatalysts modified with Cu not only improved the photocatalytic activity, but also obstructed the antioxidative system of the C. vulgaris. This improved the effectiveness of the hydrogen peroxide produced by the photocatalytic reaction against algae.

Participation of reactive oxygen species with transcription factors and enzyme activation has been reported [23]. The active species from the photocatalysts are possibly involved in the promotion of algae growth, depending on the concentration. However, few studies into this affect have been conducted. Both R_TiO2 and S_TiO2 increased algae growth compared with the control sample (without photocatalyst). One possible reason is that the active species produced stimulate the cells and activate cell division. Understanding the detailed mechanism of photocatalysts-induced algae growth should be investigated in future work.

5 Conclusions

The anti-algal effects of various TiO2 powder photocatalysts were examined using C. vulgaris. Through a series of studies, we clarified that hydrogen peroxide generated from the photocatalysts is the likely cause of the anti-algal effect. The following insights were obtained for each photocatalyst.

-

1.

A_TiO2 and R_TiO2 have low ability to generate hydrogen peroxide because oxidation of hydrogen peroxide occurs at the valence band. Therefore, these catalysts show low anti-algal effect, even under UV light.

-

2.

S_TiO2 has low anti-algal effect because stable dopant decreases the production of hydrogen peroxide.

-

3.

N_TiO2 shows good anti-algal effect under UV light because of its high hydrogen peroxide generation ability. However, the anti-algal effect drops under visible light, caused by electron trapping at oxygen vacancies.

-

4.

Cu(m)_TiO2 shows good anti-algal effect under both UV and white light because IFCT improves its photocatalytic activity. In addition, modified Cu weakens the antioxidant system of the algae, which enhances the effectiveness of the active species formed on the photocatalyst.

-

5.

Cu(m)_N_TiO2 has the preferable properties of both N_TiO2 and Cu(m)_TiO2 and shows good anti-algal effect under UV light. However, electron trapping at oxygen vacancies is promoted under white light, and electron transfer to Cu is prevented. Therefore, an anti-algal effect is not observed.

We concluded that Cu(m)_N_TiO2 and Cu(m)_TiO2 are effective photocatalysts to prevent algae generation under UV and white light, respectively.

References

Asao T, Kitazawa H, Ban T, Pramanik MHR, Matsui Y, Hosoki T (2004) Search of autotoxic substances in some leaf vegetables. J Jpn Soc Hortic Sci 73:247–249. doi:10.2503/jjshs.73.247

Fujishima A, Honda K (1972) Electrochemical photolysis of water at a semiconductor electrode. Nature 238:37–38. doi:10.1038/238037a0

Fujishima A, Zhang X, Tryk DA (2008) TiO2 photocatalysis and related surface phenomena. Surf Sci Rep 63:515–582. doi:10.1016/j.surfrep.2008.10.001

Miyama Y, Sunada K, Fujikawa S, Hashimoto K (2009) Photocatalytic treatment of waste nutrient solution from soil-less cultivation of tomatoes planted in rice hull substrate. Plant Soil 318:275–283. doi:10.1007/s11104-008-9837-4

Tajima M, Fukuda K, Komatsubara S (2014) Japan patent, P5419029 (in Japanese)

Peller JR, Whitman RL, Griffith S, Harris P, Peller C, Scalzitti J (2007) TiO2 as a photocatalyst for control of the aquatic invasive alga, Clodophora, under natural and artificial light. J Photochem Photobiol A Chem 186:212–217. doi:10.1016/j.photochem.2006.08.009

Shin H-J, Kim B-H, Seo HS, Kim CS, Kook J-K, Lim G-T, Cho D-L, Kim D, Ohk SH, Ko Y-M (2009) Degradation of Cochlodinium polykrikoides using photocatalytic reactor with TiO2-coated alumina. Biotechnol Bioprocess Eng 14:531–535. doi:10.1007/s12257-009-0048-5

Ochiai T, Fukuda T, Nakata K, Murakami T, Tryk DA, Koide Y, Fujishima A (2010) Photocatalytic inactivation and removal of algae with TiO2-coated materials. J Appl Electrochem 40:1737–1742. doi:10.1007/s10800-010-0133-7

Metzler DM, Li M, Erdem A, Huang CP (2011) Responses of algae to photocatalytic nano-TiO2 particles with an emphasis on the effect of particle size. Chem Eng J 170:538–546. doi:10.1016/j.cej.2011.02.002

Gu N, Gao J, Wang K, Yang X, Dong W (2015) ZnO-montmorillonite as photocatalyst and flocculant for inhibition of cyanobacterial bloom. Water Air Soil Pollut 226:136. doi:10.1007/s11270-015-2407-5

Pelaez M, Nolan NT, Pillai SC, Seery MK, Falaras P, Kontos AG, Dunlop PSM, Hamilton JWJ, Byrne JA, O’Shea K, Entezari MH, Dionysiou DD (2012) A review on the visible light active titanium dioxide photocatalysts for environmental applications. Appl Catal B Environ 125:331–349. doi:10.1016/j.apcatb.2012.05.036

Details of this microbial culture is described in the following web site. http://mcc.nies.go.jp/02medium-e.html#c

Ukeda H (2004) Detection of superoxide anion with WST-1 and its application. Dojin News 112:1–8 (in Japanese)

Oritani T, Fukuhara N, Okajima T, Kitamura F, Ohsaka T (2004) Electrochemical and spectroscopic studies on electron-transfer reaction between novel water-soluble tetrazolium salts and a superoxide ion. Inorg Chim Acta 357:436–442. doi:10.1016/j.ica.2003.05.007

Imase M, Ohko Y, Takeuchi M, Hanada S (2013) Estimating the viability of Chlorella exposed to oxidative stresses based around photocatalysis. Int Biodeterior Biodegrad 78:1–6. doi:10.1016/j.ibiod.2012.12.006

Hirakawa T, Nosaka Y (2008) Selective production of superoxide ions and hydrogen peroxide over nitrogen- and sulfur-doped TiO2 photocatalysts with visible light in aqueous suspension systems. J Phys Chem C 112:15818–15823. doi:10.1021/jp8055015

Hirakawa T, Nosaka Y (2002) Properties of O ·−2 and OH· formed in TiO2 aqueous suspensions by photocatalytic reaction and the influence of H2O2 and some ions. Langmuir 18:3247–3254. doi:10.1021/la015685a

Liu M, Qiu X, Miyauchi M, Hashimoto K (2011) Cu(II) oxide amorphous nanoclusters grafted Ti3+ self-doped TiO2: an efficient visible light photocatalyst. Chem Mater 23:5282–5286. doi:10.1021/cm203025b

Yamanaka K, Morikawa T (2012) Charge-carrier dynamics in nitrogen-doped TiO2 powder studied by femtosecond time-resolved diffuse reflectance spectroscopy. J Phys Chem C 116:1286–1292. doi:10.1021/jp209210u

Morikawa T, Irokawa Y, Ohwaki T (2006) Enhanced photocatalytic activity of TiO2−xNx loaded with copper ions under visible light irradiation. Appl Catal A 314:123–127. doi:10.1016/j.apcata.2006.08.011

Yamanaka K, Ohwaki T, Morikawa T (2013) Charge-carrier dynamics in Cu- or Fe-loaded nitrogen-doped TiO2 powder studied by femtosecond diffuse reflectance spectroscopy. J Phys Chem C 117:16448–16456. doi:10.1021/jp404431z

Mallick N (2004) Copper-induced oxidative stress in the chlorophycean microalga Chlorella vulgaris: response of the antioxidant system. J Plant Physiol 161:591–597. doi:10.1078/0176-1617-01230

Wang W, Vinocur B, Altman A (2003) Plant responses to drought, salinity and extreme temperatures: towards genetic engineering for stress tolerance. Planta 218:1–14. doi:10.1007/s00425-003-1105-5

Acknowledgements

This work was partially supported by the Strategic International Collaborative Research Program (SICORP) of the Japan Science and Technology Agency (JST).

Author information

Authors and Affiliations

Corresponding author

Additional information

Norihiro Suzuki and Takuo Sanada have contributed equally to this work.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Suzuki, N., Sanada, T., Terashima, C. et al. Systematic studies of TiO2-based photocatalysts anti-algal effects on Chlorella vulgaris . J Appl Electrochem 47, 197–203 (2017). https://doi.org/10.1007/s10800-016-1031-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10800-016-1031-4