Abstract

Four transition metals, namely cobalt, iron, manganese, and nickel, were separately combined with lanthanum metal to synthesize LaMO3 (M = Co, Fe, Mn, and Ni) perovskites using a sol–gel method. Electrodes for zinc–air rechargeable batteries were prepared with these perovskites and evaluated in terms of their morphology, crystal structure, electric conductivity, surface area, and particle size distribution. The electrochemical properties of the perovskites were characterized as catalysts of bifunctional electrodes for Hgen reduction reaction and oxygen evolution reaction in alkaline solution. Additionally, partially substituted LaNi x (M1, M2, or M3)1−x O3 (x = 0.25 or 0.5, and M1, 2, 3 = Co, Fe, Mn) perovskites were synthesized to evaluate the effect of partial substitution of a metal in the Ni site, and improved physical and electrochemical properties were obtained.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

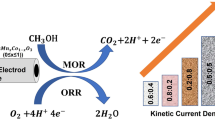

High specific energy, abundant and low-cost materials as well as low-risk operation make Zn–air batteries (100 W kg−1) an attractive alternative energy storage system for different applications such as in back-up power generators, automobiles, portable devices, and electric vehicles. Zn–air batteries are classified as either primary or secondary systems. Primary Zn–air batteries have already been used as power supplies in hearing aids and certain military devices. On the other hand, secondary or rechargeable Zn–air batteries are still at development stage with a number of challenges yet to be overcome. These are related to the low performance and insufficient stability of the bifunctional air-electrode because of the complexity of the oxygen reduction and evolution reactions (ORR and OER) in the cathode [1–5]. An additional and critical problem yet to be solved concerns the irreversible reaction and dissolution of the Zn anode.

ORR and OER govern the discharging and charging of Zn–air batteries and are typically rate-limiting due to their slow and high overpotential kinetics. To improve the performance of Zn–air batteries, a catalyst would be required both capable of decreasing the resistances in the two reactions and stable enough to withstand intense oxidation (in ORR) and reduction (in OER), such a material is called as a bifunctional catalyst [6–8].

At present, the most efficient bifunctional catalysts for rechargeable metal-air batteries are precious metals [9]. However, their high cost, scarcity, and poor durability as well as the limited performance of these electrocatalysts for ORR and OER limit their application for commercial use [10, 11].

Precious metal-free perovskite oxides are good alternative candidates because they provide bifunctional activity for both OER and ORR [12]. The composition of perovskite-structured metal oxides is generally ABO3, where A is a rare earth element such as lanthanum metal and B is a transition metal. The non-stoichiometry of the cation or anion, the possible cation configuration distortion, and the mixed-valence electronic structure make perovskite materials to have flexible physical and chemical properties, enabling partial substitution of either the A- or B-site elements to optimize the desired property. Moreover, the low cost, abundance, and stability in alkaline solutions mean that perovskites are particularly attractive catalysts for Zn–air batteries. Indeed, a number of perovskites, viz. LaCoO3, LaMnO3, and LaNiO3, have been studied for ORR catalysis, but their performance as the bifunctional catalysts for Zn–air batteries is not yet well established [12–16].

In this work, LaMO3 (M = Co, Fe, Mn and Ni) and mixed LaNi x (M1,M2,M3)1−x O3 (x = 0.25 or 0.5) perovskites were prepared using the Pechini-combustion method, and their bifunctional catalytic activity for Zn–air batteries was evaluated. The effects of different calcination temperatures were also determined, as was the influence of each transition metal on the physical and electrochemical properties of the synthesized perovskites.

2 Experimental

Perovskite powders were synthesized using the sol–gel method proposed by Pechini [17]. The LaCoO3 (LCO) and LaMnO3 (LMO) precursors were prepared by dissolving citric acid in deionized water at 60 °C under continuous stirring. Then, lanthanum nitrate (La(NO3)3·6H2O) was added followed by cobalt nitrate (Co(NO3)2·6H2O) or manganese nitrate (Mn(NO3)2·5H2O). After adding the metal nitrates, the temperature was increased to 90 °C at which point ethylene glycol was added. The mixture was stirred continuously for 2 h and the temperature was increased to 150 °C. The mixture was heated for 4–5 h until black powder was obtained. The resulting powder, the perovskite precursor, was pulverized and then calcined at 700 or 900 °C for 5 h. After calcination, the LaMO3 perovskites were pulverized once more [18–20].

LaFeO3 (LFO) and LaNiO3 (LNO) precursors were similarly prepared but after heating at 150 voC for 4–5 h the powder samples were ignited and heated for another 5 h at 150 °C. Combustion is required to completely burn the organic constituents that are not charred by a simple heating [21, 22].

The effects of each of the four transition elements on the physical and electrochemical properties of the perovskites were evaluated by combining two or more transition metals in LaMO3 perovskite to form four different LaNi x (M1, M2, or M3)1−x O3 (x = 0.25 or 0.5) perovskites, namely LaNi0.5Mn0.5O3 (LNM), LaNi0.5Fe0.5O3 (LNF), LaNi0.5Mn0.25Fe0.25O3 (LNMF), and LaNi0.25Mn0.25Fe0.25Co0.25O3 (LNMFC). The procedure for the preparation of these perovskites was identical to that for the LFO and LNO samples and the calcination temperature was fixed at 700 °C.

The morphology of the prepared perovskites was characterized by field-emission scanning electron microscopy (FE-SEM, Hitachi S-4800), their crystalline structure by X-ray diffraction (XRD, PANalytical), their electric conductivity by resistivity measurements (Changmin Tech, CMT-SR-100N), their surface area using Brunauer–Emmett–Teller (BET) analysis, and the particle size distribution by particle size analysis (PSA, HELOS/RODOX & SUCELL with Sympatec GmbH). For the electric conductivity measurements, the powder was pelletized with 20 % polymer binder (polyvinylidene fluoride, Arkema) and the resistance was measured using the four-point probe method.

For electrochemical characterization, an electrode was prepared by mixing the perovskites (70 wt%) with carbon black (30 wt%, Vulcan XC 72R) in a mortar and pestle with small volume of ethanol. The mixture was then transferred into a container followed by adding solvent (an equal amount of ethylene glycol and glycerol) and a few drops of Triton X-100 surfactant. Thereafter, the mixture was mechanically stirred for 2 h, PTFE was added as a binder, and mixing was prolonged for another 3 min. The resulting mixture was cast on an aluminum foil using a doctor blade with a thickness of 400 μm and then dried in an oven at 60 °C for 18 h and 120 °C for 4 h. The resulting sheet was transferred onto a wet-proofed carbon paper (Ballard Avcarb P50) by pressing at 10 MPa for 10 min at 280 °C. The electrode was baked in a furnace for 30 min at 350 °C. After cooling to room temperature, the electrode was weighed and cut into 2 cm in diameter. The electrode was then inserted into a cell frame containing 8 M KOH solution. The active area and catalyst loading amount of electrode were 1 cm2 and 3.0 ± 0.5 mg cm−2, respectively. The reference and counter electrodes were Zn wire (0.385 V vs. RHE) and Pt mesh, respectively. The electrochemical property of the perovskite was then measured using potentiostat/galvanostat (WBCS 3000, WonATech) over five cycles with voltage ranging from 0.8 to 2.5 V (vs. Zn) at a scan rate of 1 mV s−1 [23].

3 Results and discussion

The physical and electrochemical properties of LaMO3 perovskites depend on the particular transition metal occupying the B site. The effects of transition metals with different sizes and shapes were evaluated by SEM. The SEM images of the synthesized perovskites calcined at 700 and 900 °C are shown in Figs. 1 and 2, respectively. The sample names indicated chemical composition followed by calcination temperature (e.g., LCO-700). In Fig. 1a–c, the particles in the LCO-, LFO-, and LMO-700 samples are smaller than in those with the same compositions calcined at 900 °C. Among the perovskite precursors calcined at 700 °C, LMO-700 has the smallest particles followed by LFO-700, then by LCO-700 and LNO-700. Among the perovskite precursors calcined at 900 °C, LFO-900 has the smallest particle size followed by LCO-900 and LMO-900, and then LNO-900. The particles less than 1 μm in diameter in LCO-900, LFO-900, and LMO-900 (Fig. 2a–c) agglomerate forming a porous microstructure. In LNO-900, the particles, shown in Fig. 2d, are mixed with small amounts of spherical and flake-like particles while the particles in LNO-700 (Fig. 1d) are irregular and smaller.

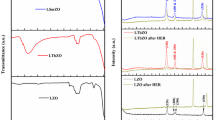

The use of the Pechini method and combined Pechini-combustion method ensures that crystalline perovskites are produced, as confirmed by the XRD patterns shown in Fig. 3a and b, obtained from the metal oxides calcined at 700 and 900 °C, respectively. LCO (ICSD 98-015-6452) perovskite has a hexagonal crystal structure in the R-3c space group [19, 21]; LFO (ICSD 98-015-3536) is orthorhombic with a Pnma space group; LMO (ICOD 01-086-1231) is rhombohedral with a R-3c space group; and LNO has orthorhombic symmetry in the Fmmm space group. The XRD patterns of perovskites formed at 700 °C (Fig. 3a) contain untraceable amounts of La2O3 and NiO. Those of LCO-900 and LMO-900 have small peaks that correspond to La2O3 (ICSD 98-002-8555, ICOD 00-005-0602, and ICOD 01-074-2430), while for LFO-900 and LNO-900, no trace of La2O3 is observed. The XRD pattern for LNO-900 has peaks that correspond to NiO (ICOD 01-089-7101).

The electric conductivities of the perovskites calcined at 700 and 900 °C are presented in Table 1. LNO is the most conductive perovskite followed by LMO and LCO, and then LFO. The LaMO3 perovskites calcined at 700 °C are more conducting than those calcined at 900 °C because the particles are smaller and more tightly packed in the former than in the latter. The surface areas determined by BET analysis and the average particle sizes determined by PSA are shown in Table 1. The larger particles tend to have smaller surface areas. The particles (surface areas) in the perovskites calcined at 900 °C are larger (smaller) than in the perovskites calcined at 700 °C. Figure 4a and b shows the particle size distributions of LaMO3 perovskites calcined at 700 and 900 °C, respectively. The size distributions of LaMO3 particles calcined at 900 °C are slightly shifted to larger sizes compared with those corresponding to the samples calcined at 700 °C.

The ORR and OER performances of the LaMO3 (M = Co, Fe, Mn, and Ni) perovskites calcined at 700 and 900 °C are shown in Fig. 5a and b, respectively. After calcination at 700 °C, similar ORR performances are obtained for all samples, while LCO- and LNO-700 have the highest OER current density. LCO-900 shows the highest current density in OER among the perovskites calcined at 900 °C. For ORR, however, LMO-900 shows the highest performance, while the performances of LCO- and LNO-900 are similar. LFO-900 performs worst for both reactions.

Table 2 shows the current densities (I based on the apparent electrode area), mass activities (I MA based on the mass of catalyst per 1 cm2 of electrode), and specific activities (I SA based on the surface area of the catalysts) at 1.0 and 2.4 V (vs. Zn) for ORR and OER. A similar ORR current density is measured for all perovskites calcined at 700 °C, while LCO-700 shows the highest current density for the OER. On the other hand, among the perovskites calcined at 900 °C, LMO-900 provides the highest current density for the ORR, followed by LCO-900, LNO-900, and LFO-900. For the OER, as for the samples calcined at 900 °C, the highest current density is measured for the LCO-900 sample, but LMO-900 shows a lower current density than LNO-900. The mass activity is higher in the LCO and LMO samples calcined at 900 °C rather than 700 °C, but the opposite trend is observed for the other two samples. The specific activity of the catalysts increases with calcination temperature, such that the catalytic activity of the surface of the powder is greater following calcination at higher temperatures. Generally also, increasing the calcination temperature leads to greater crystallinity, and thereby to increased catalytic activity. However, this may cause the decrease of the surface areas induced by larger particles.

Figure 6a and b, respectively, shows the mass activity (based on the mass of catalyst in the electrode) and the specific activity (based on the surface area of the catalyst) as a function of the surface area of the catalyst. Although the points in Fig. 6a are somewhat scattered, there seems to be a slight increase in the mass activities for both ORR and OER with increasing the surface areas of the perovskite. This behavior therefore results from an increase in the contact area, the three-phase boundary, between the catalysts (solid), gas, and electrolyte (liquid) [24, 25]. Zhuang also noted that catalysts with high specific areas have enhanced electrocatalytic activity due to an increased number of reaction sites [14]. The relationship between the ORR mass activity and the surface area is clearer than for the OER with a greater scatter. In Fig. 6b, a sharp decrease in surface activity is observed with increasing surface areas. This means that larger surface areas do indeed increase the number of reaction sites and thereby the catalytic activity, but the activity per reaction site is lower. The effect of the electric conductivity of the catalyst was also investigated (data not shown), but this showed no correlation with the catalytic activity. As reported by Zhuang, the activity of the catalyst correlates to its surface area much more than to its conductivity.

Figure 7 shows Tafel plots for the LaMO3 perovskites, in which the data from Fig. 5 are plotted as potential versus current density on a logarithmic scale. Table 2 shows the Tafel slopes obtained for the ORR and OER, respectively. For the perovskites calcined at 700 °C, LCO-700 and LFO-700 have lower Tafel slopes than LMO-700 and LNO-700. The Tafel slopes are steeper for the samples calcined at the higher temperature, 900 °C, the only exception being LNO-900 for which the Tafel slope decreases. Singh et al. reported OER Tafel slopes for sol–gel synthesized LaMnO3, LaNiO3, and LaCoO3 of ~110 [26], 65 [27], and ~65 mV dec−1 [28], respectively. Kiros and co-workers measured an ORR Tafel slope for LaNiO3 of 125 mV dec−1 [29]. Suresh et al. reported Tafel slopes in La0.9Sr0.1FeO3 synthesized by solution combustion of 105–120 mV dec−1 and 62–67 mV dec−1 for ORR and OER, respectively [30]. The Tafel slopes reported here for LaCoO3, LaMnO3, and LaNiO3 are therefore similar to those in the literature, LaFeO3 excepted. The relationships between the Tafel slopes and the surface areas or the conductivities of the materials are shown in Fig. 8. It is well known that the Tafel slope is strongly related to the nature of the materials. Here, no correlation is observed between the Tafel slopes and the surface areas or electric conductivities. This means that the Tafel slope is not affected by the physical properties of the materials.

As listed in Table 2, LCO-900 showed the highest catalytic activity for the OER, while LNO-700, LMO-900, LCO-900, and LNO-900 showed better performance than others. The electrochemical performances of the perovskites calcined at 900 °C were relatively better than those of the perovskites calcined at 700 °C. It means that the activity of the perovskite calcined at high temperature is improved in spite of decreasing the surface area. Thus, LCO-900 may be appropriate material for the ORR and OER as the catalyst of bifunctional electrode.

Previous studies have noted that the metal ion occupying the B site in the perovskites is the main factor governing the oxidative catalytic reaction because of its ability to shift from one oxidation state to another [20]. Even if LaCoO3 showed relatively better performance than others, LaNiO3 was selected because of its relatively high current density, its intrinsic ORR activity comparable to that of Pt/C, its metal-like electric conductivity and inadequate results for ORR and OER in literatures [12, 16, 31]. Ni in LaNiO3 was therefore partially substituted by Mn and/or Fe and/or Co to improve the properties of the perovskites and to investigate the influence thereon of different metals. Samples with the composition LaNi x M1−x O3 were obtained thereby, with x = 0.25 or 0.5.

The SEM images of the LNM-700, LNF-700, LNMF-700, and LNMFC-700 are shown in Fig. 9. The micrographs show less particle agglomeration than for the unsubstituted LaMO3 perovskites. Partial substitution in the Ni site should indeed provide smaller particles. Similar XRD patterns and peak positions are obtained for the four partially substituted LaNi x M1−x O3 powders, as shown in Fig. 10. The peaks in the XRD pattern correspond to those observed for the LaMO3 perovskites in Fig. 3. The surface area, average particle size, and electric conductivity of the LaNi x M1−x O3 perovskites are also listed in Table 3. In comparison with the values shown in Table 1, the partial substitution of LaNi x M1−x O3 leads to much smaller particles and larger surface areas. In terms of conductivity, Table 3 shows that LNF-700 is the most conductive perovskite followed by LNMF-700, LNM-700, and lastly by LNMFC-700. Comparing these values with those in Table 1 shows that the partial substitution of the Ni ion increases the conductivity of the LMO and LFO perovskites. It is well known that the surface area and the particle size in perovskites are inversely proportional. The particle size distributions obtained for the LaNi x M1−x O3 perovskites are shown in Fig. 11. The partially substituted perovskite particles are between 0.5 and 120 μm in diameter. The particle size distributions are similar in the unsubstituted perovskites calcined at the same temperature, but in the partially substituted perovskites, the particles are slightly smaller.

The linear sweep voltammograms and Tafel plots of LaNi x M1−x O3 perovskites for the ORR and OER are shown in Fig. 12 and Table 4. The order of the samples in terms of current density in the OER is LNMF > LNF > LNMFC ≅ LNM. Similarly, in terms of ORR performance, the order is LNF ≅ LNM > LNMF > LNMFC. In particular, the LNF sample shows a higher catalytic activity than either the LNO or LFO. Hyodo et al. reported that unsubstituted perovskites, such as LaMnO3 and LaCoO3, showed better performance than partially substituted ones, but for LaNiO3 and LaFeO3 the partial substitutions of B site lead to increased activity [32]. Partially substituted perovskites generally show higher catalytic performance than non-substituted perovskites, even though their surface areas are similar. The Tafel slopes listed in Table 4 are much shallower for the partially substituted LaNi x M1−x O3 perovskites than unsubstituted LaNiO3, except for the LNM-700 sample in the OER.

The Tafel slopes are plotted in Fig. 13 as a function of the Fe or Mn content in the Ni-based perovskites. Figure 13a shows that the partial substitution of Fe in LaNiO3 leads to shallower Tafel slopes in the ORR and OER than for unsubstituted LaNiO3 and LaFeO3, while the addition of Mn decreases the Tafel slope only for the ORR, as shown in Fig. 13b. 25 % Mn in the Ni-based perovskites shows low Tafel slope in the OER because the sample contains 25 % Fe. As shown in Figs. 12 and 13, other than for the effect of Mn addition on the OER, the partial substitution of the metal in the B site of ABO3 perovskites leads to improved catalytic activity in both the ORR and OER.

Variation of Tafel slopes as a function of Fe (a) and Mn (b) content in LaNi x M1−x O3 perovskites calcined at 700 °C for ORR (closed square, continuous line) and OER (closed diamond, dotted line). LaNi x (M1, M2, or M3)1−x O3 (x = 0, 0.25, 0.5, or 1, and M1, 2, 3 = Co, Fe, or Mn) perovskites (LNO, LFO, LMO, LNM, LNF, LNMF, and LNMFC)

For various La-based perovskites, the variation of their electrochemical parameters was investigated on physical properties, surface area and electric conductivity, and chemical composition. Conclusively, their catalytic activities were strongly related to the intrinsic nature of perovskite rather than their physical properties, even if the increase of the surface area could improve the cell performance.

4 Conclusions

LaMO3 (M = Co, Fe, Mn, and Ni) perovskites were synthesized as bifunctional catalysts for Zn–air batteries, and their catalytic activities for the ORR and OER were evaluated in the alkaline solution. The physical and electrochemical properties of the perovskite materials varied with the calcination temperature, with 900 °C proving more effective in this regard than 700 °C. In cell tests for ORR and OER, LaCoO3 performed best among the different perovskites, even though its electric conductivity was relatively low compared to that of the other samples. The catalytic activity of highly conductive LaNiO3 can be improved by the partial substitution of the Ni ion with one or more of the transition elements, Mn, Fe, and/or Co. The partial substitution of Ni in LaNiO3 led to more favorable physical and electrochemical properties; adding Fe led to improved catalytic activity both in the ORR and OER, while with Mn, only the ORR activity was improved.

References

Hilder M, Winther-Jensen B, Clark NB (2012) The effect of binder and electrolyte on the performance of thin zinc–air battery. Electrochim Acta 69:308–314

Wang X, Sebastian PJ, Smit MA, Yang H, Gamboa SA (2003) Studies on the oxygen reduction catalyst for zinc–air battery electrode. J Power Sources 124:278–284

Li X, Qu W, Zhang J, Wang H (2010) Electrocatalytic activities of perovskite toward oxygen reduction reaction in concentrated alkaline electrolytes. ESC Trans 28:45–56

Lee SH, Jeong Y, Lim S, Lee EA, Yi CW, Kim K (2010) The stable rechargeability of secondary Zn–air batteries: is it possible to recharge a Zn–air battery? J Korean Electrochem Soc 13:45–49

Wang T, Kaempgen M, Nopphawan P, Wee G, Mhaisalkar S, Srinivasan M (2010) Silver nanoparticle-decorated carbon nanotubes as bifunctional gas-diffusion electrodes for zinc–air batteries. J Power Sources 195:4350–4355

Lee JS, Kim ST, Cao R, Choi NS, Liu M, Lee KT, Cho J (2011) Metal-air batteries with high energy density: Li–air versus Zn–air. Adv Energy Mater 1:34–50

Shim J, Park YS, Lee HK, Park SG, Lee JS (1996) Oxygen reduction reaction of La1-xCaxCoO3 of gas diffusion electrode in alkaline fuel cell. J Korean Ind Eng Chem 7:992–998

Jorissen L (2006) Bifunctional oxygen/air electrodes. J Power Sources 155:23–32

Chen Z, Choi JY, Wang H, Li H, Chen Z (2011) Highly durable and active non-precious air cathode catalyst for zinc air battery. J Power Sources 196:3673–3677

Chen Z, Yu A, Higgins D, Li H, Wang H, Chen Z (2012) Highly active and durable core-corona structured bifunctional catalyst for rechargeable metal-air battery application. Nano Lett 12:1946–1952

Zhou W, Sunarso J (2013) Enhancing Bi-functional electrocatalytic activity of perovskite by temperature shock: a case study of LaNiO3−δ. J Phys Chem Lett 4:2982–2988

Hardin WG, Slanac DA, Wang X, Dai S, Johnston KP, Stevenson KJ (2013) Highly active, nonprecious metal perovskite electrocatalysts for bifunctional metal-air battery electrodes. J Phys Chem Lett 4:1254–1259

Zhang H, Li N, Li K, Xue D (2007) Structural stability and formability of ABO3-type perovskite compounds. Acta Crystallogr Sect B 63:812–818

Zhuang S, Liu S, Huang C, Tu F, Zhang J, Li Y (2012) Electrocatalytic activity of nanoporous perovskite La1-xCaxCoO3 towards hydrogen peroxide reduction in alkaline medium. Int J Electrochem Sci 7:338–344

Neburchilov V, Wang H, Martin JJ, Qu W (2010) A review on air cathodes for zinc–air fuel cells. J Power Sources 195:1271–1291

Suntivich J, Gasteiger HA, Yabuuchi N, Nakanishi H, Goodenough JB, Shao-Horn Y (2011) Design principles for oxygen-reduction activity on perovskite oxide catalysts for fuel cells and metal-air batteries. Nat Chem 3:546–550

Pechini MP (1967) Method of preparing lead and alkaline earth titanates and niobates and coating method using the same to form a capacitor. US Patent No. 3.330.697

Popa M, Kakihana M (2002) Synthesis of lanthanum cobaltite (LaCoO3) by the polymerizable complex route. Solid State Ion 151:251–257

Kuo JH, Anderson HU, Sparlin DM (1990) Oxidation-reduction behavior of undoped and Sr-doped LaMnO3: defect structure, electrical conductivity, and thermoelectric power. J Solid State Chem 87:55–63

Worayingyong A, Kangvansura P, Ausadasuk S, Praserthdam P (2008) The effect of preparation: Pechini and Schiff base methods, on adsorbed oxygen of LaCoO3 perovskite oxidation catalysts. Colloids Surf A 315:217–225

Popa M, Frantti J, Kakihana M (2002) Characterization of LaMeO3 (Me: Mn Co, Fe) perovskite powders obtained by polymerizable complex method. Solid State Ion 154–155:135–141

Fernandes JDG, Melo DMA, Zinner LB, Salustiano CM, Silva ZR, Martinelli AE, Cerqueira M, Alves Júnior C, Longo E, Bernardi MIB (2002) Low-temperature synthesis of single-phase crystalline LaNiO3 perovskite via Pechini method. Mater Lett 53:122–125

Ahn S, Kim K, Kim H, Nam S, Eom S (2010) Synthesis and electrochemical performance of La0.7Sr0.3Co1−xFexO3 catalysts for zinc air secondary batteries. Phys Scr T139:014014

Matsushima H, Majima W, Fukunaka Y (2013) Three-phase interfacial phenomena in alkaline unitized regenerative fuel cell. Electrochim Acta 114:509–513

Matsuno Y, Suzawa K, Tsutsumi A, Yoshida K (1996) Characteristics of three-phase fluidized-bed electrodes for an alkaline fuel cell cathode. Int J Hydrog Energy 21:195–199

Singh NK, Lal B, Singh RN (2002) Electrocatalytic properties of perovskite-type La1−xSrxMnO3 obtained by a novel sol–gel route for O2 evolution in KOH solutions. Int J Hydrogen Energy 27:885–893

Singh RN, Tiwari SK, Singh SP, Jain AN, Singh NK (1997) Electrocatalytic activity of high specific surface area perovskite-type LaNiO3 via sol–gel route for electrolytic oxygen evolution in alkaline solution. Int J Hydrog Energy 22:557–562

Lal B, Raghunandan MK, Gupta M, Singh RN (2005) Electrocatalytic properties of perovskite-type La1-xSrxCoO3 (0≤×≤4) obtained by a novel stearic acid sol–gel method for electrocatalysis of O2 evolution in KOH solutions. Int J Hydrog Energy 30:723–729

Bursell M, Pirjamali M, Kiros Y (2002) La0.6Ca0.4CoO3, La0.1Ca0.9MnO3 and LaNiO3 as bifunctional oxygen electrodes. Electrochim Acta 47:1651–1660

Suresh K, Panchapagesan TS, Patil KC (1999) Synthesis and properties of La1−xSrxFeO3. Solid State Ion 126:299–305

Sarma DD, Shanthi N, Barman SR (1995) Band Theory for Ground-State Properties and Excitation Spectra of Perovskite LaMO3 (M = Mn, Fe Co, Ni). Phys Rev Lett 75:1126–1129

Hyodo T, Shimizu Y, Miura N, Yamazoe N (1994) Investigation of materials for gas diffusion-type oxygen cathode aiming at electric power-saving brine electrolysis. Denki Kagaku 62:158–164

Acknowledgments

This work was supported by the National Research Foundation of Korea Grant funded by the Korean Government (MEST) (NRF-2012-M1A2A2-029538).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Lopez, K., Park, G., Sun, HJ. et al. Electrochemical characterizations of LaMO3 (M = Co, Mn, Fe, and Ni) and partially substituted LaNi x M1−x O3 (x = 0.25 or 0.5) for oxygen reduction and evolution in alkaline solution. J Appl Electrochem 45, 313–323 (2015). https://doi.org/10.1007/s10800-015-0798-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10800-015-0798-z