Abstract

The effect of vanillin on the corrosion inhibition of aluminum (Al) alloy in seawater was studied by potentiodynamic polarization (PP), linear polarization resistance (LPR), and electrochemical impedance spectroscopy (EIS) techniques. The surface morphology after its exposure to seawater with and without vanillin was examined by scanning electron microscopy (SEM) and energy dispersive spectrometer (EDS). All the studied parameters showed good inhibitive characteristics against the corrosion of Al alloy in the tested solution, and their performance was observed to increase with the inhibitor concentration. Polarization data indicated that the studied inhibitor is a mixed-type inhibitor. Linear polarization and EIS studies showed that there were significant increases in the overall resistance after the addition of vanillin. The adsorption of inhibitor on Al alloy was found to obey the Langmuir adsorption isotherm. The analysis of SEM and EDS confirmed the formation of precipitates of vanillin on the metal surface, which reduced the overall corrosion reaction.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

Protection of metals from ever progressing corrosion presents one of the topical issues of this century. The increasing industrialization of our life is accompanied with the ever-growing number of metals that corrode and become devalued [1]. The corrosion reaction produces a less desirable material from the original metal and resulted in the reduced function of a component or system, a significant problem encountered everyday.

Few practical examples of corrosion are the rusting of tools and automobiles over many years of use; the failure of pipelines delivering volatile components such as natural gases and environmentally harmful chemicals, like crude oil and hydrochloric acid; bridge failure; and aircraft crashes [2]. Therefore, it is important to understand corrosion, especially in the analysis and design systems that incorporate metal as a major component material, exposed to corrosive environments.

The Al and its alloys are important materials with wide ranges of industrial applications, and are commonly used in marine applications as well [3]. The most popular Al alloys used in corrosive environments, such as seawater, are the AA5XXX and AA6XXX series alloys, which demonstrate adequate strength and excellent corrosion resistance [4].

Corrosion of Al and its alloys has been a subject of numerous studies owing to their importance in the recent civilization. Many researchers focused on studying the corrosion of Al in different aqueous solutions [5–7], and to understand their electrochemical behavior and corrosion inhibition in a wide variety of media [8–10].

Corrosion can be minimized using suitable preventive measures, and several techniques and methods have been developed [11–15] to combat corrosion. The use of inhibitors is one of the most practical methods for protection against corrosion. However, the development of natural source and non-toxic type of corrosion inhibitor [16–19] has been considered more important and desirable.

Vanillin offers interesting possibilities for corrosion inhibition because of its safe use and high solubility in water [20]. In this study, vanillin is examined and proved to possess tremendous potential for industrial usage. Unlike the pure synthetic product that requires enormous investment scale, vanillin can be produced at any type of industrial scale, which is potentially capable of eradicating the disparity among the communities, especially in the third world. Furthermore, the potential usages of vanillin discussed in this research are in line with the recent trend of the environment-friendly concept.

In the previous studies [3, 4, 21, 22], we showed that sodium benzoate, tapioca starch, and natural honey are effective corrosion inhibitors for AA6061 aluminum alloy in seawater. The present study is designed to report the effects of vanillin on the corrosion of Al alloy immerse in seawater using potentiodynamic polarization (PP), linear polarization resistance (LPR), and electrochemical impedance spectroscopy (EIS) measurements, and to clarify its inhibition mechanism. AA6061 alloy is used in this study because of its well-proven medium strength structural alloy that satisfies the requirements of a number of specifications in extruded shapes and most applicable alloy used in marine applications [4].

2 Materials and methods

2.1 Materials

The material employed was AA6061 (25 × 25 × 3 mm coupons) with the following chemical composition (wt): Si (0.40%), Fe (0.7%), Cu (0.15%), Mn (0.15%), Mg (0.80%), Cr (0.04%), Zn (0.25%), Ti (0.15%), and Al (remainder). The samples were mechanically polished using 400, 500, and 600 emery papers, and lubricated using distilled water. The polished samples were cleaned with acetone, washed using distilled water, dried in air, and stored in moisture-free desiccators prior to use.

The test solution used for the investigation was seawater collected from Pantai Teluk Kalong, Kemaman, Terengganu (port area). The inhibitor used was vanillin with the concentration range from 200 to 1,000 ppm, obtained from Merck and used without further purification. The purity is 99.0% w/w on dries basis. Figure 1 shows the molecular structure of vanillin. Fresh seawater solution without any treatments was directly used in all the experiments carried out at room temperature (25 °C).

2.2 Electrochemical measurements

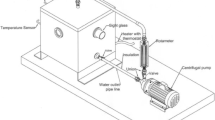

The Al alloy specimens, in triplicate for each inhibitor concentration, were immersed in a 100-mL beaker containing the respective solution for 30 min. All the electrochemical measurements were obtained using Autolab frequency response analyzer (FRA) coupled to an Autolab potentiostat connected to a computer. The cell used comprised the conventional three electrodes with a platinum-wire counter electrode (CE) and a saturated calomel electrode (SCE) as reference, to which all the potentials were referred.

The working electrode was 25 × 25 × 3 mm coupon of AA6061. The electrode was polished mechanically and degreased in acetone. The exposed area to the test solution was 3.75 cm2. A new working electrode was used for each run. The immersion time was 30 min. The working electrode was first immersed in the test solution and after establishing a steady-state open-circuit potential, the electrochemical measurements were performed. The potentiodynamic current–potential curves were recorded by changing the electrode potential automatically from −250 to +250 mV, related to the open-circuit potential, with the scanning rate of 5 mV s−1. Corrosion current densities (i corr) and corrosion potential (E corr) were evaluated from the intersection of the linear anodic and cathodic branches of the polarization curves as Tafel plots. The LPR measurements were carried out from −10 to +10 mV versus E corr at scan rate of 1 mV s−1. The impedance measurements were conducted over a frequency range of 5 × 104 Hz down to 5 × 10−3 Hz with an ac signal amplitude of ±10 mV. EIS results were analyzed with “find circle” analysis program of the FRA software.

2.3 Surface morphology

The scanning electron microscopy (SEM) model JSM–6390LA was used to examine the specimen surface before and after immersion in seawater. Meanwhile, the energy dispersive spectrometer (EDS) was used to analyze the elements in the specimen.

3 Results and discussion

3.1 PP measurements

The effects of vanillin on the corrosion reactions were determined by polarization measurements. The changes observed in the polarization curves after the addition of the inhibitor were usually used as the criteria to classify inhibitors as cathodic, anodic, or mixed [3].

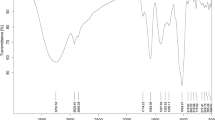

Figure 2 represents the PP curves of AA6061 in seawater in the absence and presence of vanillin. The values of the corrosion potentials and corrosion current densities were estimated from the intersection of the anodic and cathodic Tafel lines using “corrosion rate” analysis program of the general purpose electrochemical system (GPES) software. The corresponding corrosion potentials (E corr), corrosion current density (i corr), anodic Tafel slopes (b a), cathodic Tafel slopes (b c), and corrosion rate (CR) are listed in Table 1.

From Fig. 2 and Table 1, it can be observed that the addition of vanillin at all the studied concentrations decreased the anodic and cathodic current densities, and resulted in significant decline in the i corr. This indicates that vanillin shifted to smallest i corr values and showed leftward displacement in both anodic and cathodic branches of the curves, thus, acting as a mixed-type inhibitor [23], and the decrease is more pronounced with the increase in the inhibitor concentration.

Using LPR technique, polarization-resistant values, R p, for Al alloy in seawater in the presence and absence of inhibitor were determined from the straight lines obtained at ±10 mV in the vicinity of the corrosion potential. The values of R p obtained are tabulated in Table 1. The obtained results show that the addition of the examined inhibitor causes increase in the R p values of the Al alloy.

3.2 EIS studies

The effects of the inhibitor concentration on the impedance behavior of the Al alloy in seawater were studied. Nyquist plots of Al alloy in the presence and absence of various concentrations of vanillin are given in Fig. 3. It is clear from the figure that the impedance diagrams obtained yield a semi-circular shape. This indicates that the corrosion process is mainly controlled by charge transfer. The general shape of the curves can be observed to be very similar for all the samples and this is maintained throughout the whole test period, indicating that almost no change in the corrosion mechanism occurred owing to the inhibitor addition [3]. Similar results have been reported in the literature for the corrosion of Al in aggressive media [3, 5].

The equivalent circuit fitting for these experimental data was a Randles circuit. The Randles equivalent circuit is one of the simplest and most common circuit models of electrochemical impedance. It includes a solution resistance, R s in series to a parallel combination of resistor, R ct, representing the charge transfer (corrosion) resistance and a double-layer capacitor, C dl, representing the electrode capacitance [11]. In this case, the value of R s can be neglected because the value is too small as compact to that of the value of R ct. The equivalent circuit for the Randles cell is shown in Fig. 4.

The values of polarization or charge-transfer resistance, R ct, and double-layer capacitance, C dl, for AA6061 at various concentrations of vanillin are presented in Table 2. The results show that the R ct values increase with the addition of inhibitor when compared with those without the inhibitor. Furthermore, the values of R ct are observed to increase with the increasing inhibitor concentration. It should be noted that while R ct values increase with the addition of inhibitor, the C dl values decrease indicating the formation of a surface film. Thus, effective corrosion resistance is observed to be associated with high R ct and low C dl values [11]. Increase in R ct values and decrease in C dl values by vanillin indicated that the studied inhibitor inhibit the corrosion of Al alloy in seawater by the adsorption mechanism [24] and the thickness of the adsorbed layer increases with the increase of inhibitor concentration.

3.3 Inhibition efficiency

Owing to the adsorption of the inhibitor onto the surface of the Al alloy, a thin film is formed on the Al alloy to retard the corrosion. Thus, in this case, vanillin worked as the filming inhibitor to control the corrosion rate. Instead of reacting with or removing an active corrosive species, the filming inhibitors function by strong adsorption and decrease the attack by creating a barrier between the metal and their environment [15].

The calculation of IE (%) was carried out as previously reported [21]. The values of IE (%) from the PP, LPR, and EIS tests are presented in Table 3. The data reveal that IE (%) of vanillin increases with the inhibitor concentrations ranging from 200 to 1,000 ppm. It can be observed that the IE (%) for all the measurements obtained from the three different methods, namely, PP, LPR, and EIS, are in good agreement.

The inhibition process of vanillin could be explained as follows: vanillin is an aromatic aldehyde containing carbonyl, methoxy, and hydroxyl groups arranged around the aromatic ring (Fig. 1). Thus, the adsorption of vanillin onto the surface of the Al alloy may take place through all these functional groups. The simultaneous adsorption of the three functional groups forces the vanillin molecule to be horizontally oriented at the surface of the Al alloy [25]. As the inhibitor concentration increases, the area of the metal surface covered by the inhibitor molecule also increases, leading to an increase in the IE.

Seawater predominantly consists of about 3.5% of sodium chloride (NaCl) and many other ions. Chloride ions are very strong and could easily penetrate the passive film. Thus, dissolution of the Al-alloy substrate occurs and results in corrosion. The adsorption of the inhibitor competes with anions such as chloride. By assuming that the inhibitor preferentially reacts with Al3+ to form a precipitate of salt or complex on the surface of the Al substrate, the anodic and cathodic processes are subsequently suppressed by vanillin. Thus, this result suggests that the protective films that are formed comprise Al hydroxide, oxide, and salts or complexes of the inhibitor anions.

3.4 Adsorption considerations

Organic inhibitors establish their inhibition though the adsorption of the inhibitor molecules onto the metal surface. It depends on the nature as well as the surface charge of the metal, the adsorption mode, its chemical structure, and the type of the electrolyte solution [26].

In order to acquire a better understanding of the adsorption mode of the inhibitor on the surface of the Al alloy, the data obtained from the three different techniques were tested with several adsorption isotherms, including Langmuir, Frumkin, and Temkin. The Langmuir adsorption isotherm was found to fit well with the experimental data (Fig. 5), and can be expressed as [27]:

where K is the adsorption equilibrium constant, c is the inhibitor concentration, and θ is the surface coverage. This isotherm is based on the assumption that all the adsorption sites are equivalent and that the particle binding occurs independently from the nearby sites being occupied or unoccupied.

3.5 SEM studies

The SEM micrographs of the specimen surface after 60 days of immersion in seawater are shown in Fig. 6. Flakes showing corrosion products like metal hydroxides and its oxides can be observed [3]. However, no pits or cracks can be seen in the micrographs.

Figure 7 depicts the SEM of specimen surface after 60 days of immersion in seawater, with the addition of (a) 600 and (b) 1,000 ppm of vanillin. It can be seen that the flakes in the surface of the specimens are reduced when compared with that of the micrograph given in Fig. 6. The specimen surface can be observed to be covered with a thin layer of the inhibitor molecules, giving protection against corrosion.

3.6 EDS studies

The EDS spectra were used to determine the elements present on the surface of the Al alloy after 60 days of exposure to the uninhibited and inhibited seawater. Figure 8a shows the EDS analysis result on the composition of AA6061 without the inhibitor treatment. The EDS analysis indicates that only Al and oxygen were detected, with the ratio of about 2:3, which shows that the passive film contained only Al2O3.

Figure 8b and c portrays the EDS analysis of the AA6061 in seawater in the presence of 600 and 1,000 ppm of vanillin. The spectra show an additional line, demonstrating the existence of C (owing to the carbon atoms of the vanillin). These data show that the carbonaceous material covered the specimen surface. This layer is entirely owing to the inhibitor, because the carbon signal is absent on the specimen surface exposed to uninhibited seawater.

4 Conclusions

The corrosion studies of the Al alloy were carried out at room temperature using seawater, and the results indicated that vanillin is an effective corrosion inhibitor for AA6061 in seawater. The studied inhibitor was observed to act as a mixed-type inhibitor, and the EIS measurements clarified that the corrosion process was mainly controlled by charge-transfer, and that no change in the corrosion mechanism occurred owing to the addition of inhibitor in seawater. The values of R ct increased with the addition of inhibitor, while the capacitance values decreased, indicating the formation of a surface film. The morphology study elucidated the development of thin film on the specimen immersed in seawater with vanillin.

References

Kalendova A, Kalenda P, Vesely D (2006) Comparison of the efficiency of inorganic nonmetal pigments with zinc powder in anticorrosion paints. Prog Org Coatings 57:1–10

Radia A (2004) Examination of the corrosion mechanism and corrosion control of metals in saltwater environments. Department of Chemical Engineering, University of Toronto, Toronto

Rosliza R, Senin HB, Wan Nik WB (2008) Electrochemical properties and corrosion inhibition of AA6061 in tropical seawater. Colloids Surf A 312:185–189

Rosliza R, Wan Nik WB (2010) Improvement of corrosion resistance of AA6061 alloy by tapioca starch in seawater. Curr Appl Phys 10:221–229

Yurt A, Ulutas S, Dal H (2006) Electrochemical and theoretical investigation on the corrosion of aluminum in acidic solution containing some Schiff bases. Appl Surf Sci 253:919–925

Maayta AK, Al-Rawashdeh NAF (2004) Inhibition of acidic corrosion of pure aluminum by some organic compounds. Corros Sci 46:1129–1140

Badawy WA, Al-Kharafi FM, El-Azab AS (1999) Electrochemical behaviour and corrosion inhibition of Al, Al-6061 and Al–Cu in neutral aqueous solutions. Corros Sci 41:709–727

Hintze PE, Calle LM (2006) Electrochemical properties and corrosion protection of organosilane self-assembled monolayers on aluminum 2024–T3. Electrochim Acta 51:1761–1766

Gundersen JTB, Aytac A, Ono S, Nordlien JH, Nisancioglu K (2004) Effect of trace elements on electrochemical properties and corrosion of aluminum alloy AA3102. Corros Sci 46:265–283

Abd El Rehim SS, Hassan HH, Amin MA (2003) The corrosion inhibition study of sodium dodecyl benzene sulphonate to aluminum and its alloy in 1.0 M HCl solution. Mater Chem Phys 78:337–348

Yagan A, Pekmez NO, Yildiz A (2006) Corrosion inhibition by poly(N-ethylaniline) coatings of mild steel in aqueous acidic solutions. Prog Org Coatings 57:314–318

Aramaki K (2001) Effects of organic inhibitors on corrosion of zinc in an aerated 0.5 M NaCl solution. Corros Sci 43:1985–2000

Battocchi D, Simoes AM, Tallman DE, Bierwagen GP (2006) Electrochemical behaviour of a Mg-rich primer in the protection of Al alloys. Corros Sci 48:1292–1306

Hu JM, Zhang JT, Zhang JQ, Cao CN (2005) Corrosion electrochemical characteristics of red iron oxide pigmented epoxy coatings on aluminum alloys. Corros Sci 47:2607–2618

Al-Juhni AA, Newby BZ (2006) Incorporation of benzoic acid and sodium benzoate into silicone coatings and subsequent leaching of the compound from the incorporated coatings. Prog Org Coatings 56:135–145

Avwiri GO, Igho FO (2003) Inhibitive action of Vernonia amygdalina on the corrosion of aluminium alloys in acidic media. Mater Lett 57:3705–3711

Oguzie EE (2007) Corrosion inhibition of aluminium in acidic and alkaline media by Sansevieria trifasciata extract. Corros Sci 49:1527–1539

Abdel-Gaber AM, Khamis E, Abo-ElDahab H, Adeel S (2008) Inhibition of aluminium corrosion in alkaline solutions using natural compound. Mater Chem Phys 109:297–305

Obot IB, Obi-Egbedi NO (2009) Ipomoea involcrata as an ecofriendly inhibitor for aluminium in alkaline medium. Portugaliae Electrochimica Acta 27:517–524

Et-Etre AY (2001) Inhibition of acid corrosion of aluminum using vanillin. Corros Sci 43:1031–1039

Rosliza R, Wan Nik WB, Senin HB (2008) The effect of inhibitor on the corrosion of aluminum alloys in acidic solutions. Mater Chem Phys 107:281–288

Rosliza R, Wan Nik WB, Izman S, Prawoto Y (2010) Anti-corrosive properties of natural honey on Al–Mg–Si alloy in seawater. Curr Appl Phys 10:923–929

Gao BJ, Zhang X, Sheng YL (2008) Studies on preparing and corrosion inhibition behaviour of quaternized polyethyleneimine for low carbon steel in sulfuric acid. Mater Chem Phys 108:375–381

Noor EA (2009) Evaluation of inhibitive action of some quaternary N-heterocylic compounds on the corrosion of Al–Cu alloy in hydrochloric acid. Mater Chem Phys 114:533–541

Li XH, Deng SD, Fu H, Mu GN, Zhoa N (2008) Synergism between rare earth cerium (IV) ion and vanillin on the corrosion of steel in H2SO4 solution: weight loss, electrochemical, UV–vis, FTIR, XPS, and AFM approaches. Appl Surf Sci 254:5574–5586

Sherif ESM, Erasmus RM, Comins JD (2006) Corrosion of copper in aerated acidic pickling solutions and its inhibition by 3-amino-1, 2, 4-triazole-5-thiol. J Colloid Interface Sci 306:96–104

Chaieb E, Bouyanzer A, Hammouti B, Benkaddour M (2005) Inhibition of the corrosion of steel in 1 M HCl by eugenol derivatives. Appl Surf Sci 246:199–206

Acknowledgment

The authors thank the late Professor H.B. Senin for his early guidance and encouragement in doing this research.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Rosliza, R., Nora’aini, A. & Wan Nik, W.B. Study on the effect of vanillin on the corrosion inhibition of aluminum alloy. J Appl Electrochem 40, 833–840 (2010). https://doi.org/10.1007/s10800-009-0066-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10800-009-0066-1