Abstract

Garden compost has already been identified as a source of efficient electro-active (EA) biofilms. The work described here consisted of lixiviating the compost and then using the leachate as a microbial source. This procedure gave promising results for the treatment of yogurt waste (YW) in a microbial fuel cell (MFC). Experiments performed in MFC set-ups were compared with electrochemical cells under polarization at +0.1 V versus SCE. Different parameters were tested to optimize the microbial anode. Preliminary acclimation of the compost microbial flora to YW was revealed to be unnecessary. Forming biofilms firstly in pure leachate before exposing them to YW showed that high concentrations of this type of substrate were detrimental to current generation. Pre-treatment of the electrode by pre-adsorbing YW led to a 10-fold increase in the current density. The highest current densities were obtained at 40 and 60 °C, revealing the diversity of electro-active microorganisms coming from soils. Values up to 1,450 mA m−2 were reached at 40 °C.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

The double benefits of microbial fuel cells (MFCs) electricity production simultaneously with waste removal have been reported since at least 1983 [1]. Interest in MFCs saw a strong revival in the early years of this century thanks to the discovery of the capacity of microbial biofilms to achieve direct electron transfer with the electrode surface [2, 3]. Since then, MFCs have continuously increased their performance levels and widened their field of application as reviewed in numerous articles [4–6]. The double benefit of MFCs has been largely confirmed, mainly with domestic wastewater [7]. Most MFCs have been implemented with abiotic cathodes, and commonly with air-reducing cathodes [8, 9]. Microbial cathodes have been proposed [10–13] but remain less numerous. Most studies devoted to MFCs have focused on the anode process, where consumption of the waste occurs. For the anode, the environment in which the MFC is implemented can play two different roles: it can provide the substrate (fuel) on the one hand, and can be the source of the microbial consortium that forms the electro-catalytic biofilm on the other.

Research on MFCs was started by using low-molecular-weight molecules such as glucose and acetate as fuels [14, 15]; then complex substrates such as cellulose and chitin were tested to extend MFC applicability [16, 17]. Wastes and wastewaters of different origins have been investigated: food wastewaters from the starch [18], cereal [19], potato [20], meat [21] or dairy [22] industries, and farm wastes such as swine wastewater [23], farm manure [22], and corn stover [24]. Surprisingly, when they were tested in the same MFC setup, higher performance was obtained for the more complex substrates: acetate generated 506 mW m−2 [15], while hydrolyzed corn stover generated 971 mW m−2 [24].

Several reports have shown that current generally increases with the substrate concentration until a plateau value is reached, following a Monod-like profile. The current plateau obtained at high fuel concentrations may be caused by saturation of the electro-microbial process or by physical limitations or by an increase in alternative (soluble) electron acceptors that compete with the anode [5, 15, 25]. This diversity of possible causes of limitations can explain the large range of half-saturation constant (Ks) values that have been reported. For mixed bacterial culture coming from domestic wastewater fuelled with monosaccharides, Ks values ranged from 111 to 724 mg L−1 substrate [26]. In a two-chamber MFC inoculated with anaerobic sludge and fed with ethanol, Ks of 0.0149 mM was obtained, while a one-chamber MFC led to Ks = 4.86 mM [27]. A membrane-free single chamber MFC inoculated with domestic wastewater gave Ks = 43 mg L−1 with acetate and Ks = 93 mg L−1 with butyrate [15] while, in the same type of MFC fuelled with hydrolyzed corn stover, Ks of 170–347 mg L−1 COD were obtained [24]. In a flat plate MFC inoculated and fed with domestic wastewater, Ks was between 461 and 719 mg L−1 COD [28]. This short review shows the large range of values that Ks can take. They are difficult to compare because of the diversity of the “biofilm/substrate” systems and also the differences in cell designs [23].

Many different sources of inoculum have been tested, such as marine sediments [29, 30], aerobic and anaerobic sludge [27, 31], garden compost [32], rumen microorganisms [33], and yogurt bacteria [22]. Acclimation or adaptation of the inoculum has sometimes been performed in a specific phase or observed during MFC running [27, 34, 35]. The electro-activity of a microbial consortium can also be obtained by re-cultivating biofilm collected from a running MFC. Power densities of up to 3 W m−2 have thus been obtained using glucose as the substrate in a two-chamber MFC [14].

The surface state of the electrodes has been found to be an important parameter affecting MFC performance, either because it affects the electrochemical properties of the electrode [36–38] or through its effect on biofilm formation. Ammonia gas treatment of anodes or their oxidation in sulphuric acid has been reported to affect bacterial adhesion or microbial communities in anode biofilms [36, 39]. Temperature is also an important parameter, as for any microbial process. Nevertheless, attempts to correlate MFC performance with temperature [40] through a Van’t Hoff-Arrhenius equation [41] did not lead to clear conclusions. Two thermophilic microorganisms tested in the range 30–70 °C in a two-chamber MFC showed maximal efficiency at 50 °C, whereas the performance decreased rapidly at 70 °C [42].

The purpose of this study was to optimize a microbial anode for the treatment of wastes from a yogurt production line. These wastes themselves did not form efficient electro-active (EA) biofilms in a reproducible way (data not shown). Consequently, it was decided to form biofilms from garden compost, which has proved to be a source of efficient EA microorganisms [43–46], and to study the capability of these biofilms to treat the yogurt wastes (YWs). Preliminary experiments performed by forming the biofilm first in solid garden compost as already reported [32] and then transferring the bioanode into solution caused the biofilm to lose its EA properties. A new procedure was tested here: microbial species were first extracted from the compost by lixiviating it, and the leachate obtained was then used to form EA biofilms in solution. The first experiments, which were performed in a two-chamber MFC, confirmed that cell design could drastically affect the assessment of anode efficiency. Consequently, much of the study was carried out under well-controlled electrochemical conditions. The objective was to find optimal procedures and parameters (electrode pre-treatment, inoculum adaptation, operating temperature, and substrate concentrations) that allowed the best synergy between the biofilm formed from compost and the dairy waste to be treated.

2 Experimental

2.1 Electrochemical setups

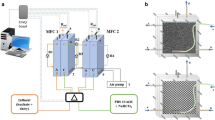

A two-chamber MFC was constructed by connecting two culture flasks (500 mL) through a glass tube equipped with a 3-cm diameter proton exchange membrane in the middle (Ultrex, CMI-7000 Membranes International Inc., USA). Graphite felt (2 cm × 5 cm × 0.5 cm) and platinum mesh (2 cm × 5 cm) were employed as the anode and cathode, respectively. The catholyte was a phosphate buffer solution of pH 6.7. The anolyte and catholyte were stirred with magnetic bars (350 rpm). Cell voltage and anode and cathode potentials versus Ag/AgCl reference electrode were measured with a multimeter (Integra series 2700, Keithley Instruments, Inc. USA) interfaced with a computer. The MFC electrical circuit was closed with an external resistance of 1,000 Ω, following a rule of thumb commonly used in studies dealing with similar experimental set-ups [21, 23]. It was observed that this value of the external resistance generally ensured power densities that were not far from the maximum during the test period. Power curves were plotted by varying the external resistance from 100 to 56,324 Ω over a 3-min period.

Potentiostatic electrolysis and cyclic voltammetry (CV) were performed using a multichannel potentiostat (SVP, BioLogic Science Instruments SA, EC/Lab 2.0 software) in 100–150 mL electrochemical cells with a three-electrode set-up: graphite felt (2 cm × 5 cm × 1 cm or 2 cm × 2 cm × 1 cm) as the working electrode, saturated calomel (SCE) or Ag/AgCl as the reference electrode, and platinum mesh (2 cm × 5 cm) as the counter-electrode.

2.2 Inoculum, substrate, and procedures

Leachate from garden compost was used as the source of electrochemically active bacteria. NaCl solution (10 mM) was added to 1 L of garden compost to obtain a final volume of 3 L. This mix was placed in 2-L Erlenmeyer flasks and stirred for 24 h using magnetic bars. The mix was filtered through felt cloth, and the filtrate was used as inoculum.

Yogurt waste (YW) was used as fuel. It was collected from the waste compaction process of a dairy firm and stored in bottles of 1.5 L at 3 °C for a short period or was frozen for long-term storage. Substrate dilutions were made with phosphate buffer solution pH 6.7 (g L−1): Na2HPO4, 2.75; NaH2PO4, 3.67; NaCl, 0.584.

When indicated, anode pre-treatment was carried out by adsorbing YW onto anodized graphite felt. Anodization was achieved in 150 mL buffer solution by imposing a potential of +1.5 V versus SCE on the graphite felt for 2 minutes and then using CV at 30 mV s−1 in the range from −1.0 V to +1.0 V versus SCE. This cycle was repeated five times. Pre-treatment was performed in a vessel containing 250 mL YW by 10 min sonication (water sonicator Transsonic 950 H−1 35 kHz. Prolabo, Germany) to encourage YW adsorption by homogenizing the suspension. Finally, the electrode was cleaned by 5 min sonication in 500-mL distilled water.

In temperature tests, electrochemical cells filled with 150 mL-compost leachate were placed in temperature-controlled water baths at 10, 30, 40, 50, and 60 °C. Pre-treated anodes with adsorbed YW were used.

2.3 Analysis

Total chemical oxygen demand (COD) was determined in anolyte samples using standard methods (Method 8000 for 0–1,500 mg L−1 COD, HACH France S.A.S.). pH was measured with a pH-meter CG 882 (Schott Gerate GMBH). Conductivity was determined with a conductimeter (Metrohm 660, Swiss). Colonized felt graphite electrodes obtained from MFC studies were observed by SEM at 7.5 kV (Leo 435VP microscope, Germany, SRV-32 software). Samples were fixed with 4% glutaraldehyde solution, post-fixed with 2% OsO4 solution, gradually dehydrated with acetone 50, 70, 100% solutions, and finally coated with gold.

Charge was calculated from chronoamperograms by integrating current over time. COD/mg L−1, corresponding to the experimental charge observed, was estimated using the equation

where C is experimental coulombs, \( {\text{MW}}_{{{\text{O}}_{2} }} \) is the oxygen molecular weight (32,000 mg mol−1), F is the Faraday’s constant (96,485 coulombs electron-mol−1), n is the number of electrons transferred (4 electron-mol COD-mol−1), and V is the reaction volume (0.1 or 0.15 L).

3 Results and discussion

3.1 Performance of microbial fuel cells

A two-chamber MFC was implemented with phosphate buffer solution, pH 6.7, as the catholyte and platinum mesh as the cathode. The anode compartment contained 500 mL of compost leachate prepared following the procedure described in the “Experimental” section. The compost leachate was the source of the microbial population that formed the electrochemically active biofilm. The anode compartment was fed with 1 mL raw YW and the electrical circuit was closed through a 1,000 Ω resistance. The power provided reached 45 mW m−2 after around 11 days and was sustained for more than one week. From time to time, the global behavior of the MFC was characterized by changing the external resistance and recording the current provided. Plotting the power density provided for each resistance value as a function of the current density commonly gives a bell-shaped polarisation curve that allows the maximal power provided by the cell to be assessed. Polarization recorded on the 17th day gave a maximal power density of 91 mW m−2 with a current density of 400 mA m−2. SEM pictures taken after 34 days’ operation showed no obvious biofilm formation on the external surface of the electrode (Fig. 1a). It was necessary to explore the fiber surface in depth to observe a weak microbial colonization, mainly with single cells or small spots in a monolayer structure (Fig. 1b). Such a poor colonization indicates that considerable improvement may be achieved by improving the colonization of the electrode surface.

The second MFC, designed with an anode pre-treated by YW adsorption and maintained at 40 °C, gave similar performance with a stable value around 38 mW m−2. Substrate additions of 1 mL YW generated only small increases in cell voltage. Compared with the first MFC, anode pre-treatment, higher temperature, and addition of substrate did not affect this MFC performance. It was concluded that this MFC was not limited by factors linked to the bio-electrochemical kinetics at the anode but more probably by internal resistance. This kind of limitation in H-type MFCs has already been observed [23], because of too small a surface area of the membrane and deformation of the electric field by the geometry of two containers joined by a tube [47, 48]. In order to overcome limitations due to MFC design, further studies were carried out with a standard three-electrode electrochemical set-up, under constant polarization at +0.1 V versus SCE. The value of +0.1 V versus SCE was chosen for the potentiostatic experiments because this value ensured a fair development of EA biofilms [32, 45] while not being unrealistically positive, the aim being to approach optimal operating conditions in the MFC.

3.2 Potentiostatic studies

The effect of acclimation of the inoculum to YW was investigated. Five containers (n° 1–5) initially contained 100 mL compost leachate with 0.3 mL raw YW. Container n° 1 was immediately equipped with 4 cm2 graphite felt electrode polarized at +0.1 V versus SCE. At time t = 72 h, 0.3 mL YW was added to containers n° 2–5 and container n° 2 was equipped with a polarized graphite felt electrode. The same operation was repeated on containers n° 3–5 at time t = 144 h, then on containers n° 4 and 5 at time t = 216 h, and finally on container n° 5 at t = 312 h.

The current density recorded during chronoamperometry is shown in Fig. 2 for the five different acclimation periods. Extended acclimation resulted in fast current increase at the beginning of the polarization. The current then showed an almost constant value throughout the chronoamperometry (24 h). In contrast, the solution that was used for chronoamperometry just after mixing with YW produced a current that rose slowly but constantly and, after around 10 h, overtook the current produced by the acclimated microbial populations. Inocula that were acclimated for longer periods before starting chronoamperometry gave faster initial current increases. It can be concluded that the acclimation phase induced the development of microbial species that were able to metabolize YW efficiently but the acclimated inocula were not able to sustain high current density. This behavior was reproducible. The acclimation procedure of successive substrate addition resulted in substrate accumulation in the microbial environment. It is known that biofilm formation is enhanced by low substrate concentrations [49], and so the high substrate accumulation resulting from the successive additions probably hindered biofilm formation. High substrate concentrations enhance the growth of suspended microorganisms, promoting a fermentative microbial population rather than an anodophilic population [25]. Moreover, microorganisms aged in the vessel during the acclimation period and the microbial cells were probably no longer in their active growth phase when the electrode was plunged into the vessel. The cells were consequently in a less active state when the surface was made available to them. In order to sum up, the acclimation step produced microbial cells that were more active in metabolizing the organic matter contained in YW but it either favored competitive oxidative pathways and/or resulted in detrimental cell ageing. As the actual gain of acclimation was only observed on the first few hours, further studies were carried out without an acclimation phase.

Effect on current generation of acclimation of the inoculum to yogurt waste substrate. Chronoamperogram on graphite felt polarized at +0.1 V versus SCE in compost leachate, which had been acclimated for increasing periods from 0 h to 312 h. The x-axis gives the time from beginning of chronoamperometry. The acclimation periods that preceded chronoamperometry are given as the label of each curve

A series of experiments were performed by first forming the EA biofilm under chronoamperometry at +0.1 V versus SCE in pure compost leachate for 2 days. Thereafter, the inoculum solution was eliminated and electrochemical cells were refilled with yogurt waste diluted 20, 50, 100, or 200 times in phosphate buffer, corresponding to 6770 ± 14, 2855 ± 106, 1360 ± 28 and 729 ± 7 mg L−1 COD, respectively. The fast current increase (Fig. 3a) observed as soon as biofilm on the anode came into contact with YW dilutions confirmed the efficiency of the compost microorganisms in oxidizing organic matter contained in YW. The fastest current increases were observed with the lowest COD values. The high concentrations of YW clearly delayed the establishment of an active biofilm and also decreased the maximal current densities reached. The procedure consisting of two separate phases, biofilm formation followed by exposure of the anode to pure YW, revealed that low concentrations of this particular type of substrate increased current generation, contrarily to observations with other substrates [24, 26–28]. Removing the microbial species coming from the inoculum reduced current density as compared with the acclimation test. At end of chronoamperometry, COD values were 594 ± 76, 285 ± 28, 250 ± 49, 91 ± 8 mg COD L−1 for dilutions 20, 50, 100, and 200, respectively, corresponding to COD removal of 91, 90, 81, and 87%.

Influence of yogurt waste dilutions on anode performance. a Chronoamperometry on graphite felt polarized at +0.1 V versus SCE. Arrow indicates removal of compost leachate from the electrochemical cells and refilling with dilutions (20–200 times) of yogurt waste. b Cyclic voltammetry carried out at end of chronoamperometry, 13 and 20 days. Scan rate 10 mV s−1

CV performed at days 13 and 20 showed close to reversible peaks, which were directly correlated with YW dilutions (Fig. 3b). In contrast to what was observed in chronoamperometry, the current peak increased with COD concentration. Clearly, the current densities obtained in CV with a moderate scan rate (10 mV s−1) were extremely high with respect to the current values recorded under chronoamperometry. This indicates that the two techniques addressed phenomena controlled by different limiting steps, as already reported with biofilm-covered electrodes [12, 44]. Intermediate CV, performed from time to time by briefly interrupting chronoamperometry, indicated that current peaks increased with time. It can be concluded that the current peaks were either linked to the accumulation of metabolites in the reactor or to establishment of the biofilm. Such CV evolution may, for instance, be explained by the accumulation of an electrochemical mediator either linked to the cell or entrapped in the biofilm matrix. CV identified the quasi-reversible characteristics of this mediator, while chronoamperometry was limited by the rate of mediator oxidation by the microbial metabolism. Further investigations are needed to explain the surprisingly high currents obtained in CV. Nevertheless, this study went ahead with a view to actually optimizing the electrode efficiency under chronoamperometry.

The surface state of the electrodes has been noted as an important parameter affecting MFC performance levels. A new procedure for biofilm formation was designed using pre-treated graphite felt. Pre-treatment consisted of graphite anodization followed by substrate (YW) adsorption. Then, the electrode was polarized in 150 mL pure compost leachate (Fig. 4). Early on (first two days), a peak current was observed with the YW pre-adsorbed anode, while the clean control anode did not provide any significant current. Adding 0.3 mL YW at the end of day 2 led to an immediate current increase on the clean anode, up to 600 mA m−2, but the current dropped back to zero around day 8. In contrast, the pre-adsorbed anode presented a 3.5-day lag phase after YW addition but the current density then increased up to 1,000 mA m−2. The charge generated by substrate addition (integrating the current as a function of time) was 138 and 607 coulombs for the clean and pre-adsorbed anodes, respectively, which corresponded to 76 and 335 mg L−1 COD consumed. The initial COD concentration was 792 ± 131 mg L−1 COD on average. The pre-adsorbed anode allowed around 42% of the initial COD to be treated by the electrochemical process, while only 17% was treated when the biofilm was formed on a clean electrode.

The initial small peak observed with the pre-treated electrode was easily explained by the oxidation of some adsorbed organic compounds by the forming EA biofilm. The differences that followed between pre-adsorbed and clean electrodes can be explained by the complex YW composition, including insoluble proteins, fatty acids, and small solid particles, which masked a part of the electrode surface and/or modified its surface properties. It thus took longer for the settled bacteria to organize into a structured biofilm and to acquire the capability to provide current. This phenomenon is fully consistent with the delay in biofilm establishment that was observed with the higher concentration of YW in Fig. 3a. Actually, the effect of protein adsorption on biofilm formation is not clearly stated in the literature. It has been reported that casein enhances bacterial adsorption and albumin inhibits it [49]. On the other hand, the adsorption of non-soluble particles can induce mass transfer limitation during the early phase of biofilm formation, when the biofilm is composed of small colonies dispersed among the mineral and organic adsorbed matter. It took time for the biofilm to develop over the amount of adsorbed matter and to fully access the utilizable organic matter. Finally, although a few days were lost for biofilm formation, pre-adsorbing the substrate onto the anode surface was an effective strategy to increase long-term current generation and total substrate consumption.

The effect of temperature on MFCs has been dealt with in several studies [30, 40, 42, 50]. Two thermophilic microorganisms tested in the range from 30 to 70 °C showed maximal efficiency at 50 °C, whereas the performance decreased rapidly at 70 °C [42]. Here, the effect of temperature was assessed in chronoamperometric conditions to reduce side-effects from other parameters as much as possible. Graphite felt electrodes were pre-treated by YW adsorption and polarized at +0.1 V versus SCE in 150 mL compost leachate. Current generation increased until either a peak or plateau was reached due to adsorbed substrate. When the current began to fall (after 2–5 days), 0.3 mL YW were added. The current density variation with time was highly dependent on temperature. A peak current was observed at low and high temperatures of 10, 50, and 60 °C (Fig. 5a), while two current peaks were observed at medium temperatures of 30 and 40 °C.

Effect of temperature on current generation. Graphite felt pre-treated by yogurt waste adsorption, polarized at +0.1 V versus SCE in 150 mL compost leachate fuelled with 0.3 mL of yogurt waste. a Example of chronoamperogram at 60 °C. Arrow indicates substrate addition. b Maximal current density reached at different temperatures. Error bars correspond to 2–6 replicates

The maximal current densities obtained during the chronoamperometry at each temperature are reported in Fig. 5b (2–6 experiments for each temperature). The maximal current density increased with temperature from 10 to 40 °C, reaching 1,452 ± 216 mA m−2. Then it fell at 50 °C and increased again at 60 °C. Such a profile can be compared to the behavior of composting processes which enable the development of great diversity of mesophilic and thermophilic microorganisms [51]. It was observed here that six different experiments performed at 40 °C gave a significant standard deviation, while the two experiments performed at 60 °C gave exactly the same current/time variation (Fig. 5a). This may indicate a larger diversity of mesophilic microorganisms that showed electro-activity at 40 °C, while only a few EA microorganisms were revealed at 60 °C. Moreover, observation of two peaks at intermediate temperatures (30 and 40 °C) may also confirm a higher microbial diversity at medium temperature.

The assumption was made that current generation was correlated with the microbial metabolism rate. Microbial electro-catalysis as a function of temperature was approached using the Arrhenius equation:

where I is current (A), μ is the specific microbial growth rate (h−1), k is a constant (h−1), E a is the activation energy (J mol−1), R is the ideal gas constant (8.317 J mol−1 K−1), and T is the temperature (K). Activation energy calculated from the maximal current values in the range 10–40 °C was 85 kJ mol−1. This value is in the same order of magnitude as E a for bacterial growth at temperatures lower than that of maximal growth, 40–75 kJ mol−1 [52]. It seems that E a increases as growth temperature decreases, since E a = 110 kJ mol−1 is reported for bacteria in permafrost [52] and 25–57 kJ mol−1 for species growing in the 31–40 °C range [53]. Activation energy is a measure of microbial activity in response to temperature, in this case of electro-activity of the communities in compost leachate.

4 Conclusions

Garden compost has already been identified as an interesting source of efficient electro-active (EA) biofilms. Nevertheless, it was difficult to exploit the biofilms formed in garden compost by transferring them directly into solution. For the first time, a procedure is reported here that consists of lixiviating the compost and then using the leachate obtained as a microbial source. This procedure proved to be fully efficient to form electroactive biofilms.

Comparing different procedures for forming EA biofilms for the treatment of yogurt waste (YW) gave useful information on the way to optimize microbial anodes. Preliminary acclimation of the microbial flora did not prove to be useful; it was more important to work with microorganisms just after extraction from the compost. Forming biofilms first in pure leachate before exposing them to YW was also not the best procedure. In contrast, pre-treatment of the electrode by pre-adsorbing YW led to an increase in the current density by a factor of more than 10. Temperature around 40 °C ensured the best performance, leading to current densities up to 1,450 mA m−2 at +0.1 V versus SCE. YW pre-adsorption was an excellent way to improve biofilm efficiency but some compounds of YW were suspected of having a detrimental effect on biofilm formation.

One of the most promising results of this study is certainly the new procedure based on using compost leachate rather than the raw medium. It should open up a new easy-to-handle route for exploiting the rich microbial flora contained in soils to form efficient EA biofilms. Investigations will be pursued to compare the microbial population of the biofilms formed following this new procedure to the population composing the EA biofilms formed directly in compost.

References

Roller SD, Benetto HP, Delaney GM, Mason JR, Stirling JL, Thurston CF (1983) In: Proceedings of the international conference on the commercial applications and implications of biotechnology. Online Publications, London

Bond DR, Holmes DE, Tender LM, Lovley DR (2002) Science 295:483

Tender LM, Reimers CE, Stecher HA, Holmes DE, Bond DR, Lowy DA, Pilobello K, Fertig SJ, Lovley DR (2002) Nat Biotechnol 20:821

Logan B, Hamelers B, Rozendal R, Schröder U, Keller J, Freguia S, Aelterman P, Verstraete W, Rabaey K (2006) Environ Sci Technol 40:5172

Rabaey K, Rodriguez J, Blackall LL, Keller J, Gross P, Batstone D, Verstraete W, Nealson KH (2007) ISME J 1:9

Rozendal RA, Hamelers HVM, Rabaey K, Keller J, Buisman CJN (2008) Trends Biotechnol 26:450

Liu H, Ramnarayanan R, Logan BE (2004) Environ Sci Technol 38:2281

Liu H, Cheng S, Huang L, Logan BE (2008) J Power Sources 179:274

Erable B, Etcheverry L, Bergel A (2009) Electrochem Commun 11:6

Bergel A, Féron D, Mollica A (2005) Electrochem Commun 7:9

He Z, Angenent LT (2006) Electroanalysis 18:2009

Dumas C, Mollica A, Féron D, Basséguy R, Etcheverry L, Bergel A (2007) Electrochim Acta 53:468

Rabaey K, Read ST, Clauwaert P, Freguia S, Bond PL (2008) ISME J 1:9

Rabaey K, Lissens G, Siciliano S, Vestraete W (2003) Biotechnol Lett 25:1531

Liu H, Cheng S, Logan B (2005) Environ Sci Technol 39:658

Niessen J, Schröder U, Harnisch F, Scholz F (2005) Lett Appl Microbiol 41:286

Rezaei F, Richard TL, Brennan RA, Logan BE (2007) Environ Sci Technol 41:4053

Gil G, Chang I, Kim B, Kim M, Jang J, Park H, Kim H (2003) Biosens Bioelectron 18:327

Oh SE, Logan B (2005) Water Res 39:4673

Rabaey K, Clauwaert P, Aelterman P, Verstraete W (2005) Environ Sci Technol 39:8077

Heilmann J, Logan B (2006) Water Environ Res 78:531

Scott K, Murano C (2007) J Chem Technol Biotechnol 82:92

Min B, Kim JR, Oh SE, Reagan J, Logan B (2005) Water Res 39:49

Zuo Y, Maness P, Logan B (2006) Energy Fuels 20:1716

Freguia S, Rabaey K, Keller J (2007) In: 11th IWA world congress on anaerobic digestion. Brisbane, Australia

Catal T, Li K, Bermek H, Liu H (2008) J Power Sources 175:196

Kim JR, Jung SH, Regan JM, Logan B (2007) Bioresour Technol 98:2568

Min B, Logan BE (2004) Environ Sci Technol 38:5809

Reimers CE, Tender LM, Fertig S, Wang W (2001) Environ Sci Technol 35:192

Mathis BJ, Marshall CW, Milliken CE, Makkar RS, Creager SE, May HD (2008) Appl Microbiol Biotechnol 78:147

Lee J, Phung N, Chang I, Kim B, Sung H (2003) FEMS Microbiol Lett 223:185

Parot S, Délia ML, Bergel A (2008) Bioresour Technol 99:4809

Rismani-Yazid H, Christy AD, Dehority BA, Morrison M, Yu Z, Tuovinen OH (2007) Biotechnol Bioeng 97:1398

Kim N, Choi Y, Jung S, Kim S (2000) Biotechnol Bioeng 70:109

Liu Z, Li H, Liu J, Su Z (2008) J Appl Microbiol 104:1163

Liu JL, Lowy DA, Baumann RG, Tender LM (2007) J Appl Microbiol 102:177

Niessen J, Schröder U, Rosenbaum M, Scholz F (2004) Electrochem Commun 6:571

Scott K, Rimbu GA, Katuri KP, Prasad KK, Head IM (2007) Trans IChemE 85(B5):481

Cheng S, Logan BE (2007) Electrochem Commun 9:492

Liu H, Cheng S, Logan B (2005) Environ Sci Technol 39:5488

Tchobanoglous G, Burton FL (1991) Wastewater engineering. Treatment, disposal, reuse, 3rd edn. McGraw-Hill International Editions, Singapore

Choi E, Jung H, Park S, Paik S, Jung S, Kim B (2004) Bull Korean Chem Soc 25:813

Niessen J, Harnisch F, Rosenabaum M, Schröder U, Scholz F (2006) Electrochem Commun 8:869

Dulon S, Parot S, Délia ML, Bergel A (2007) J Appl Electrochem 37:173

Parot S, Délia ML, Bergel A (2008) Electrochim Acta 53:2737

Parot S, Nercessian O, Delia ML, Achouak W, Bergel A (2009) J Appl Microbiol 106:1350

Larminie J, Dicks A (2003) Fuel cell systems explained, 2nd edn. Wiley, London

Wendt H, Kreysa G (1999) Electrochemical engineering. Springer-Verlag, Berlin

Characklis WG (1990) In: Characklis WG, Marshall KC (eds) Biofilms. Wiley, Toronto

Min B, Roman OB, Angelidaki I (2008) Biotechnol Lett 30:1213

Miyatake F, Iwabuchi K (2005) Bioresour Technol 96:1821

Buford P, Sowers T (2004) Proc Natl Acad Sci USA 101:4631

Yongjun L, Yangjun D, Zhaodong N, Haitao S, Hongling Z (1997) J Therm Anal Calorim 50:897

Acknowledgments

B. Cercado Quezada is supported through scholarship No. E06D101223MX by the European Union Programme of High Level Scholarships for Latin America (Program AlBan). The authors gratefully thank Luc Etcheverry (Engineer CNRS-LGC), Benjamin Erable (Researcher CNRS-LGC), Marie-Line DeSolan (Microscopy manager at LGC), Dr. Claire Albasi (Senior researcher CNRS-LGC), and Dr. Regine Basseguy (Senior researcher CNRS-LGC) for their efficient help.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Cercado-Quezada, B., Delia, ML. & Bergel, A. Treatment of dairy wastes with a microbial anode formed from garden compost. J Appl Electrochem 40, 225–232 (2010). https://doi.org/10.1007/s10800-009-0001-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10800-009-0001-5