Abstract

The aim of this work is the study of the effectiveness of different parameter estimation techniques for proton exchange membrane fuel cells (PEMFC) under normal operating conditions. The procedure for the estimation of the real time parameters described herein in good approximation meets the requirements posed regarding such techniques, i.e., to obtain data without interrupting the functioning of the fuel cell and to be as simple as possible. In this approach a fuel cell combined with a step-down voltage regulator system was analyzed and the potential relaxation was used to determine PEMFC electrochemical properties. A screening measurement technique was applied using the analysis of variance (ANOVA) to elucidate the effect of the different operating conditions on the obtained parameter, hence to validate the developed algorithm. The results show that the operating conditions of the step-down regulator device affect some parameters, but the weak correlations predict that the method can be used in real applications.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

The real-time determination of the state of health (SOH) of a functioning fuel cell and the optimization of the operating conditions are as important as novel materials. Usually such investigations still require complicated experiments and instrumentations such as potentiostats, frequency analyzers as for electrochemical impedance spectroscopy, and the regulations need time consuming algorithms, i.e., these procedures cannot be applied in field operations.

With the help of real time parameter estimation unwanted phenomena, such as catalyst poisoning, flooding or drying of the membrane etc. can be monitored, and the working parameters of an FC can be quickly regulated.

In this study measurement techniques suitable for in field application and the determination of the basic electrochemical properties of fuel cells, especially proton exchange membrane fuel cells (PEMFCs) are surveyed. Based on the analysis of their properties and capabilities the potential relaxation method seemed to be the most suitable for real time parameter estimation.

A PEMFC combined with a step-down voltage regulator system was analyzed and relaxation was used to determine its electrochemical properties. A screening measurement technique was applied using the analysis of variance (ANOVA) to elucidate the effect of different operating conditions. 2p ANOVA analysis supplies information regarding correlations between the measured parameters. If there was no significant correlation, the estimation technique could be applied in field applications.

1.1 Main parameter estimation techniques

Analysis of potential vs. current (or power vs. current) curves, i.e., determination of so-called performance diagrams is the most widely used procedure. Kim et al. [1] have elaborated a model to derive the reversible potential E 0 (V), and the Tafel parameter b (V dec−1) for the oxygen reduction reaction (ORR) and the resistance R (Ω cm2) from the experimental data. R involves the ohmic resistance of the proton exchange membrane and the charge transfer resistance of the hydrogen oxidation reaction (HOR). At higher current densities the mass-transport overpotential was also taken into account. These yielded the following equation at an applied current density j:

where m (V), and n (cm2 A−1) parameters related to mass transport limitation.

A nonlinear parameter estimation software was used and precise values for the parameters were obtained. The measurements were carried out by changing the potential in discrete steps and, at each potential, the current was recorded after 20–30 s delay time. The measurement time was approximately 400 s, which seems long for real time retrieval.

Cyclic voltammetry (CV) and linear sweep voltammetry (LSV) can be carried out over a shorter time range. Adequate results can be obtained, however, only when the electrodes are studied separately, i.e., a 3-electrode cell is used, and inert gases replace the anode or cathode fuel [2].

Parameters obtained from lifetime operation [3] are only relevant if steady-state current or potential can be maintained. However, in this case the prehistory of the cell influences the results, e.g., slow recovery of the initial properties is expected after each stop and start, which can give a misinterpretation of the FC performance.

Several processes may affect the response of an FC, therefore steady-state techniques are not really suitable to obtain parameters separately. Transient techniques such as electrochemical impedance spectroscopy (EIS) and pulsed or current interruption (CI) may allow separation of the parameters of the different processes occurring simultaneously according to their time and frequency characteristics, and are more suitable for real time parameter estimation.

Jaouen [4, 5] has studied ORR and mass transport limitation using EIS and CI. Different models have been developed to predict the potential relaxation after applying a steady-state current density j st . It was found that, at small current densities (when mass transport limitation is negligible), the equation

is valid, and parameters such as Ai 0 , A dl C dl and the Tafel slope can be obtained directly from the potential relaxation. A dl is the area of double layer formation, A is the area of reaction, C dl is the double layer capacitance, i 0 is the exchange current density, ε1, ε2 are the volume fraction of polymer in the agglomerate and the electrode porosity, respectively and L is the electrode thickness.

Gomadam and Weidner [6] studied porous electrodes in different configurations and calculated their theoretical responses, applying small perturbations (EIS) and dc polarization. With the help of an appropriate algorithm, the different resistances (ionic, electronic and charge transfer) and double layer capacitance can be separated. It was found that from the ratio IL/V (where I is the measured current, V is the applied potential and L is the distance between anode and cathode) either the charge transfer resistance or the sum of ionic and electronic resistances can be calculated when the applied current is low, i.e., charge transfer is hindered or when it is high, i.e., the electrochemical process is transport-limited. However, for the majority of practical situations these criteria are not met. In these cases the separation algorithms are complex and these parameters can be obtained from a set of data, only. The current interruption technique has been successfully applied to predict valve-regulated lead acid (VRLA) battery resistances and time constants by Srinivasan et al. [7]. They considered four different processes, i.e., the relaxations of electronic resistance of the separator, the resistance of the porous electrode, which is the sum of the electronic and ionic resistances, as well as the kinetic and mass transport resistances. They assumed that during charging and discharging the time constant of the charge transfer relaxation was determined by the ratio of the double-layer and the reaction areas. During charging this ratio increases with the charging level, while during discharge the ratio remains more or less constant. The specific capacitance and the exchange current density were unchanged during charge and discharge.

Therefore, the different parameter estimation techniques can be distinguished according to the type of problem regarding their utilization for real time and precise parameter estimation:

-

(1)

Laboratory condition is needed: CV, LSV, EIS

-

(2)

FC loses power during the measurement: performance curves

-

(3)

Not sensitive enough to separate the different electrochemical properties: Lifetest, cell resistance

In the following a real-time measurement system and method will be presented for the estimation of the most important electrochemical properties which eliminates the previously mentioned drawbacks. A factorial measurement technique will be applied to determine the precision and applicability of the method under different operating condition. The method will be considered suitable if there are no significant correlations between the operating conditions and the estimated parameters.

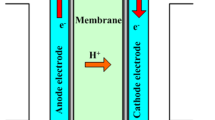

1.2 Real time measurement system

Only few applications allow fuel cells to operate under a permanent load. Moreover, the fuel cell voltage continuously varies with time and the required power, therefore a voltage converter should be applied. For practical reason FCs also need a voltage regulator to convert its voltage to a more usable form. Larminie and Dicks [8] showed a very basic voltage regulation device, the ‘step-down’ switching regulator (Fig. 1). This rather simple circuit contains a diode, a switch and an inductor and as well as the fuel cell. It converts the voltage of FC (V FC ) to a corresponding output voltage (V out ) required by the load. The inductor stores energy while it operates the load at the ‘on’ state. When the switch is turned off the stored energy keeps the current flowing through the load. The ‘on’ and ‘off’ times determine the voltage regulation by the following equation:

While the output voltage depends on the duration ‘on’ and ‘off’, the frequency of the switching also influences the output and its usability. The output has a ripple during the switch on and off periods. The ripple is smaller at higher frequencies, while each turn-off and turn-on involves the loss of energy. Consequently, the frequency should not be too high. The main advantage of this voltage regulator is that while keeping the current flow at the load side, it always interrupts the current at the FC side, which allows the study of potential relaxations and the estimation of the most important electrochemical parameters.

According to our idea the ‘on’ and ‘off’ states give an opportunity to apply transient techniques without the interruption of its normal operation, and enables us to record and analyze FC’s behaviour while the system relaxes from one state to an other.

1.3 Data evaluation strategy

It is evident that only two real time methods can be taken into account, i.e., current interruption (CI) or current pulse technique, which are described in [4–6] (see Table 1).

In the case of pulse techniques [6] galvanostatic current is applied for the t on state of the voltage regulator. However, the static current cannot be held easily since the step-down regulator simultaneously charges the resistor as well. The potential relaxation under t off is more suitable for the parameter estimation. According to Weber et al. [9], the rate of the HOR is ten times higher than that of the ORR, thus the hydrogen anode relaxation has no significant effect on the mid time potential relaxation. It may be significant only at short times (t < 10 μs), which is not registered by the potentiostat. Consequently, Jaouen’s CI model [4] which uses “medium time” relaxation domain (t > 100 ms) was used, and parameters were estimated by fitting Eq. 2 to the data.

2 Experimental

2.1 Fuel cell preparation

The fuel cell was prepared using a standard E-TEK electrode (single sided ELAT 20 wt% Pt/C, 0.4 mg cm−2) for the anode. The cathode was prepared by using a pulsed electrodeposition technique [10], where platinum was deposited directly on the surface of the carbon electrode. The anode and cathode were hot pressed by 140 atm at 130 oC with the membrane (Nafion 112) for 3 min. The area of the fuel cell was 0.5 cm2. The fuel cell hardware was made by Fuel Cell Technologies.

2.2 Measurement configuration

The measurements were carried out on a Fuel Cell Technology test station using it in two ways. The performance curves were registered by its embedded program. The cell temperature was 75 oC, the reactant gases flow according to cell performance (1.5 stoic for H2 and 2 stoic for O2). The cell was operated at ambient pressure. The dew point of gases was 5°C below the controlled temperature. The effect of the voltage regulator was simulated with pulsed current at different frequencies, duty ratios and current values. The main parameters were controlled by the FC station in the same way as during the performance curve measurements. However, it was disconnected electronically and an EG&G 273 potentiostat was connected to apply pulsed current and measure the voltage response. The measurement was controlled with the CorrWare software’s galvanic square-wave mode. A reference electrode was not used during the measurements.

2.3 Measurement strategy

It is intended to determine the correlation between the operating conditions and the estimated parameters by using the fewest possible measurements. It is assumed that the essential cell parameters (e.g., the activity of the catalyst, double layer capacitance, porosity) remain unchanged during the measurement. The measurement and the data evaluation are considered satisfactory, if the correlation between the measured and operating parameters is weak. Consequently, the different conditions of the voltage regulator (frequency, duty ratio and average current) must be examined. The variation of every possible combination of the measurement is not only time consuming, but if the measurement time is too long the inner properties of the FC might change. Therefore, a screening measurement technique was chosen requiring 23 * 2 (2 levels, 3 factors and 2 replications) = 16 treatments. In this case the overall measurement takes only 20 min and yields the same information as the tedious and time-consuming separate measurements of every possible relationship. The measurement design is originated from a 2p factorial ANOVA (Analysis of Variance) [11]. The principle of both the measurement and the evaluation is the variation of 3 parameters (called factors) at two levels (two different values), with two replications (every combination was measured twice) (see Table 2.). The different combinations of the parameters are chosen randomly. An automatic measurement program was designed whose details are summarized in Table 3. All the combinations were measured in a single run (Fig. 2). Three operating conditions were varied:

-

Frequency (turn-on and turn-off): factor A

-

Applied current: factor B

-

Duty ratio \( \frac{{t_{{on}} }} {{t_{{on}}\,+\,t_{{off}} }} \): factor C

Every protocol (T1-T8) was set up in the following way:

-

(1)

Relaxation at the open-circuit potential for 60 s;

-

(2)

Application of a constant current under galvanostatic conditions for 30 s;

-

(3)

Application of pulsed current as described in Table 2. The average of the current was equal to the galvanostatic current applied in step 2.

The consecutive steps of the measurement are illustrated in Fig. 2.

The duration of the current switch on and switch off periods was determined by the frequency and the duty ratio, while the amplitude of the pulse was calculated on the basis of the average current and the duty ratio. For example, parameters of protocol T8 were calculated in the following way. The frequency of T8 is 5 Hz, so the time elapsed between each period is 0.2 s. The duty ratio is 50%, therefore t on and t off is equal to 0.1 s. The galvanostatic current is 0.025 A, therefore the pulsed current should be equal to 0.05 A, in order to drive the same amount of charge through the FC.

The randomly set parameters are shown in Table 3.

3 Results and discussion

Typical results of the measurements by following the protocols described in the Experimental part are shown in Figs. 3–5. The pulse operation [see (b) figures of Figs. 3–5] was started immediately after the galvanostatic operation [(a) figures]. In each figure (b) few cycles of the total treatment are also presented in a magnified form for the sake of better visibility. The decreasing and increasing voltage curves correspond to the switched on state (t on ) and the relaxation (t off ), respectively.

The evaluation was started with the selection of a region where the pulsed state became steady, i.e., the minimum and the maximum of the potential did not change substantially. Then, a pulse was selected from this region, and the ohmic drop was calculated by subtracting the first point of the selected (increasing) pulse from the last point of the previous (decreasing) pulse. The time difference and the sampling rate were 0.004 s. The beginning of the pulse was taken as zero time. The data were fitted by using Eq. 2 and Origin 6.1’s non-linear least square fitting modules. The coefficient of determination was higher than 99.8%. The Tafel slope, A dl C dl and Ai 0 parameters were calculated from the fitted curves (Fig. 6). Since the porosity and the volume fraction of the electrode were not known, therefore A dl C dl and Ai 0 could not be derived, but \( Ai_{0} {\left( {1 - \varepsilon _{1} } \right)}{\left( {1 - \varepsilon _{2} } \right)}L \equiv \beta Ai_{0} \) and \( A_{{dl}} C_{{dl}} {\left( {1 - \varepsilon _{1} } \right)}{\left( {1 - \varepsilon _{2} } \right)}L \equiv \beta A_{{dl}} C_{{dl}} \) could be determined. The ratio \( {{Ai_{0} }}/{{A_{{dl}} C_{{dl}} }} \) was also calculated since it is a characteristic value of the rate of depolarization. The calculated time constant \( \frac{{\alpha F}} {{RT}}\frac{{Ai_{0} }} {{A_{{dl}} C_{{dl}} }} \) may refer to micro-scale reactions and structural changes [7].

The calculated data of the different protocols were summarized in Table 4.

Finally, a factorial analysis was carried out. The factorial analysis is based on the separation of the effect of the factors and the comparison of the extent of differences between the so-called “between-samples” and the “within-samples” variations. (see Appendix A). In our situation there are five random variables; namely Ai 0 /A dl C dl , RT/αF, R Ω , βA dl C dl , βAi 0 . The effects of the factors (frequency (A), static current (B) and duty ratio (C)) can be estimated with the following equation.

where i, j, k = 1, 2 denote the two different levels of the factors and l = 1, 2 denotes the replications, ε is the effect of any random processes, i.e., the error of the measurements. This model considers the individual effects of the factors and the interactions between the factors (AB, AC, BC, ABC). The treatment sum of squares SSTr was calculated for each factor by using Yate’s method [11], and it was compared with the error sum of squares SSE. In this way, the measurement error can be separated from the model error. The effect of model error was diminished by using randomly applied protocols. However, this procedure does not give information about the goodness of the applied electrochemical model. The results of the factor analysis at 99% confidence level are summarized in Table 5. The cases when the effect of the parameters have been found significant, i.e., the factor is likely to influence the parameter, are displayed in bold in Table 5.

It has been found that

-

Interaction effects are not significant;

-

The measurement of the ohmic drop is independent of the operating conditions;

-

The value of the Tafel slope is sensitive to the frequency;

-

The double-layer capacitance and the exchange current are affected by the duty ratio, but independent of other operating conditions;

-

The parameter Ai 0 /A dl C dl and consequently the relaxation time is substantially affected by the applied current, while the values of the other quantities are varied to a much smaller extent.

The ohmic drop or cell resistance is the sum of the potential drop in the separator, in the current collector (and other resistive parts), and the potential loss in the porous electrodes, because the time difference between the first point and the last point of the current interruption is in the ms range. After the immediate voltage drop due to the resistance of the separator, the relaxation is governed by the non-uniform potential distribution over the porous electrode [12]. The cell resistance measured is somewhat larger than that calculated from the performance curve (Fig. 7 and Table 6). The ohmic losses at the membrane and the porous electrode might be separated accurately if the short time transients were also recorded.

The sensitivity of the ratio Ai 0 /A dl C dl to the applied current is likely due to the higher non-uniform potential distribution that was built up at higher current densities. This deviation is due to the simplified nature of the original model [4] where the porous electrode relaxation has been neglected. Eq. 2 gives an adequate description of the potential relaxation in the range of 10–100 ms, i.e., when the potential profile becomes uniform and the discharge of the double layer is dominant.

The effect of the duty-ratio on the exchange current density and the double layer capacitance is likely to be a measurement error, while a shorter duty ratio cuts off the mid time relaxation.

The influence of the frequency on Tafel slope cannot be interpreted by the previously mentioned reasons, because the duty ratio and the current have no effects on it. The values of the Tafel slope calculated from the CI curves are substantially smaller than those derived from the performance curves. Therefore, this effect might be in connection with the changes of the surface coverage related to the adsorbed species and the double layer composition which are periodically varied during the potential excursion between ca. 0.45 V and 0.75 V with the frequencies from 1 Hz to 5 Hz.

Figure 7 shows the measured performance curves of the prepared single MEA (membrane electrode assembly). The result of the non-linear fitting of Eq. 1 and the obtained parameters are summarized in Table 6.

It is worth mentioning that the uniqueness of the parameters is not guaranteed [13] even with a good fit. In some cases the best fit may supply electrochemical parameters, which are obviously erroneous, e.g., a negative resistance value. Therefore, in our procedure the range of parameters was also considered, i.e., the parameter values which cannot be valid were a priori rejected by the computer program.

4 Conclusion

Periodical modulation technique has been applied by using a step-down voltage converter in combination with a PEMFC in order to estimate the most important electrochemical parameters characterizing the functioning of a PEMFC. In this way the PEMFC can be investigated without interrupting the current flow at the load side, while a knowledge of the potential relaxation functions at the PEMFC side allows the derivation of the quantities and their changes with time when an appropriate algorithm is used.

The effectiveness and reliability of this approach have been tested by using a factor analysis method (ANOVA). It was found that the quantities derived, such as Tafel-slope, double-layer capacitance, the exchange current density and the cell resistance, can be determined with a very good statistics. Therefore, the method and the algorithm elaborated for this purpose is suitable for real-time monitoring and the regulation of the functioning fuel cell.

The correlations found so far, e.g., between the double layer capacitance and the duty ratio, or between the exchange current density and the duty ratio, can be diminished by using higher frequency data acquisition; however, it makes the measurement somewhat more expensive. Since the electrochemical parameters are independent of the interaction effects of the applied parameters, the higher frequency data acquisition is not really necessary. Further improvements in the measurement technique is in progress which involves data collection at higher frequencies and refinement of the algorithm taking into account the short-time transients and the non-linear phenomena such as the non-uniform potential distribution of the porous electrode and the double layer effect.

References

Kim J, Lee S, Srinivasan S (1995) J Electrochem Soc 142:2670

Zhai Y, Zhang H, Liu G, Hu J, Yi B (2007) J Electrochem Soc 154:B72

Jiang R, Rong C, Chu D (2007) J Electrochem Soc 154:B13

Jaouen F, Lindbergh G, Wiezell K (2003) J Electrochem Soc 150:A1711

Jaouen F, Lindbergh G (2003) J Electrochem Soc 150:A1699

Gomadam PM, Weidner JW, Zawodzinski TA, Saab AP (2003) J Electrochem Soc 150:E371

Srinivasan V, Wang GQ, Wang CY (2003) J Electrochem Soc 150:A316

Larminie J, Dicks A (2003) Fuel cell systems explained, 2nd edn. Wiley, Chichester, England, p 335

Weber AZ, Darling R, Newman J (2004) J Electrochem Soc 151:A1715

Kim H, Popov BN (2004) Electrochem Solid State Lett 7:A71

Devore J L (2004) Probability and statistics, 6th edn. Brooks/Cole Belmont, CA, USA, p 476

Ong IJ, Newman J (1999) J Electrochem Soc 146:4360

Sgura I, Bozzini B (2005) Non-linear Mech 40:557

Acknowledgement

Financial support by the National Office of Research and Technology (OMFB-00356/2007) and the Hungarian Scientific Research Fund (OTKA T031762)(G.I.) are acknowledged. Dr. Branko Popov and the University of South Carolina (USA, SC) are greatfully acknowledged for providing an opportunity for experimental work. Dr. Jong-Won Lee and Seh Kyu Park are also acknowledged for their practical advice.

Author information

Authors and Affiliations

Corresponding author

Appendix A: Factorial ANOVA

Appendix A: Factorial ANOVA

The analysis of variance, or briefly ANOVA, refers broadly to a collection of experimental situation and statistical procedures for the analysis of quantitative responses from experimental units. It involves the analysis either of data sampled from more than two numerical distributions (populations) or of data from experiments in which more than two treatments have been used. The characteristics that differentiate the treatments one from another are called factors, and the different treatments are referred to as levels of the factors. The evaluation of ANOVA is based on the following statistical definitions:

Confidence interval and confidence level is used to calculate and report an entire interval of plausible values of an event A. A confidence level of 95% implies that 95% of all samples are in an interval that includes any parameters being estimated and only 5% of all samples can be found outside (Fig. A.1). The higher the confidence level, the goodness of the estimation is obviously better.

Hypothesis testing is a method for deciding which of two (or more) contradictory claims about the parameter is correct. The main question to be answered is that the different populations are originated from the same random variable or not.

The hypothesis test procedure is specified by the test statistics and the confidence level. The test statistics is dependent on a parameter estimated (true average, deviation), the sample size and the preliminary known parameters, respectively. If the distribution is normal and the standard deviation (σ) is known, the test statistic is:

where \(\bar{\hbox{X}}\) is the average values of the samples, μ is the mean value and n is the number of the selected samples. Z is the probability of the deviation of the calculated average (\( {\text{\ifmmode\expandafter\bar\else\expandafter\=\fi{X}}} \)) and its expected value (μ).

Test statistics for comparing two population variances is based on the F-distribution, that is

where \( \ifmmode\expandafter\bar\else\expandafter\=\fi{\sigma }^{2}_{{{\text{A,B}}}} = {\sum\limits_{i = 1}^{{\text{P,Q}}} {\frac{{{\left( {x_{i} - \ifmmode\expandafter\bar\else\expandafter\=\fi{x}_{{{\text{A,B}}}} } \right)}}} {{\sigma _{{{\text{A,B}}}} }}} } \), and P, Q are the number of populations A and B, respectively, and σ is the standard deviation of the populations.

Mean squares: The samples standard deviations will generally differ somewhat even when the corresponding σ values are identical. The analysis of the structural effects of the different factors can be done to compare the between-samples variation with the within-samples variation (Fig. A.2). This can be done efficiently by using mean squares instead.

where K is the number of the population and L is the number of the measurement (observation) in each population. SST is the total sum of squares, SSTr is the treatment sum of squares (between-samples) and SSE is the error sum of squares (within-samples). SST = SSE + SSTr is always valid. If the factors have no effects, the values of the individual sample mean values should be close to one another and therefore close to the grand mean, resulting in a relatively small value of SSTr. However, if the μI values are quite different, because of the effects of the factors, the average of the populations should substantially differ from the average of all samples. The probability of the deviation follows the F-distribution and can be estimated by

Using the confidence level, the probability of the difference can be qualitatively estimated. If the ratio \( \frac{{{\text{SSTr}} \cdot {\text{K(L}} - 1)}} {{{\text{MSE}} \cdot {\text{(L}} - 1)}} \) is higher than F value at 95% (or else) confidence level, the parameter is affected by the factor used. Otherwise the factor has no significant effect on the parameter investigated.

Rights and permissions

About this article

Cite this article

Kriston, Á., Inzelt, G. Estimation of the characteristic parameters of proton exchange membrane fuel cells under normal operating conditions. J Appl Electrochem 38, 415–424 (2008). https://doi.org/10.1007/s10800-007-9454-6

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10800-007-9454-6