Abstract

The aim of this work was to obtain polyaniline (Pani) and poly(ortho-methoxyaniline) (Poma) by chemical synthesis and to evaluate their corrosion protection properties on carbon steel (CS) and copper (Cu) in an aggressive media such as sodium chloride. The syntheses of the polymers were carried out by chemical oxidation of the monomers by (NH4)2S2O8 in nitric acid solutions. Under these conditions, the polymers were obtained in the oxidized form, dissolved in 1-methyl-2-pyrrolidone and casted by solvent evaporation onto the metallic substrates (carbon steel and copper) for corrosion evaluation. The morphology of the polymers was evaluated by scanning electron microscopy (SEM) and atomic force microscopy (AFM). The electrochemical behavior was determined by open circuit potential (OCP) measurements and polarization curves (PC). The best results were obtained with Pani because this polymer film participates in the formation of an oxide film at the polymer–metal interface, a phenomenon which is not observed with Poma. This oxide film increases the barrier effect that the polymeric film has by itself.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

Carbon steel (CS) and copper (Cu) are materials widely used in technological and industrial applications [1, 2]. However, CS presents a limited resistance to corrosion; seawater and acid solutions are the most aggressive agents for this metal [3, 4]. On the other hand, Cu has a good resistance to corrosion but is attacked by oxidant acids and salts of heavy metals [5–7].

Conductive polymers are broadly studied because they are applicable in many areas [8–13]. Pani and their derivatives are the most widely studied of these polymers because of good environmental stability, reversibility of the doped/undoped process [13] and corrosion protection for metals [14–16]. They act as a physical barrier between the metal and the electrolytic medium. However, when these conducting polymers have polar groups in their structure, they can act as macromolecular inhibitors, shifting the potential of the substrate such that the corrosion rate is reduced [17, 18]. These polymers can also induce the formation of a homogeneous oxide layer between the metal and the polymer layer [19–23].

Tallman et al. [24] reported cathodic and anodic polarization curves of both uncoated and Pani-coated metal, immersed in 3.5% NaCl. The polarization curve for Pani-coated steel showed a smaller corrosion current density and a more noble potential than that observed with bare steel. On the other hand, Santos et al. [25] studied the corrosion protection for different types of steel coated with Pani in chloride ion-containing solutions. They found that the corrosion potential shifted to more positive values when the steel was coated with the polymer (0.1 V for carbon steel and 0.297 V for stainless steel). Additionally, the inhibition efficiency for the corrosion processes, as evaluated by weight loss, was almost 100% for both types of steel used.

Brusic et al. [26] have reported that thin films of Pani, chemically synthesized (emeraldine) and deposited on copper by spin-drying, were able to reduce the corrosion current density in water saturated with air from 10.0 to 0.3 mA cm−2, resulting in a lower corrosion rate, relative to the uncoated metal. These results demonstrated that Pani in the emeraldine oxidation state is able to protect metals such as copper against corrosion.

Widera et al. [10] studied the influence of anions on the electrodeposition, properties and overoxidation of Poma by means of an electrochemical quartz microbalance in the presence of HCl and HClO4 acids. The effect of anions during polymerization was explained in terms of the interactions of anions with neutral or oxidized monomer and the trapping of hydrated anions in the polymer films. Also, the degradation of the polymer films was considered, taking into account the presence of water molecules in the polymer films. Scanning electro microscopy (SEM) was used to detect the changes in polymer morphology caused by degradation. But, to our knowledge, the ability of this polymer to protector material metals from corrosion has not been studied.

The aim of this work was to evaluate the protective properties of Poma and Pani coatings in the corrosion of steel and copper in 3.5% NaCl. Moreover, referred to the corrosion of CS and Cu, the effects of the morphology of the deposited film and of the capacity of the polymer to promote the formation of a homogeneous oxide layer in the metal–polymer interface were also studied.

2 Experimental

2.1 Materials

Aniline (Merck) and o-methoxyaniline (Aldrich) were distilled prior to use. HNO3, NaCl, (NH4)2S2O4 and NH4OH (Merck) were used as received.

2.2 Polymer synthesis

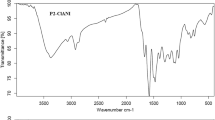

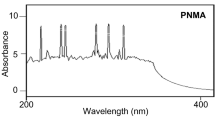

The polymers were synthesized by chemical oxidative polymerization as described in previous work [10–16, 19, 23–25]. Briefly, 0.042 M aniline and o-methoxy aniline were dissolved in 1 M HNO3. The solutions were kept at 0 ± 0.1° C under nitrogen. Next, a 0.063 M (NH4)2 S2O8 solution was slowly added with vigorous stirring over a 2 h period. The precipitate formed was washed with acetone until the initially pale violet filtrate became colourless. The polymers obtained were converted to emeraldine base by adding an excess of 0.1 M NH4OH for 16 h. The emeraldine base powders were dried at room temperature. To characterize the polymers obtained, the UV/Visible spectra were recorded in a Shimadzu 1603 spectrophotometer. The spectrum corresponding to Pani dissolved in 1-methyl-2-pyrrolidinone (NMP) showed two absorption bands at wavelengths between 328 nm and 346 nm, and 610 nm and 643 nm, which is characteristic of Pani in its emeraldine base form. Moreover, a small difference in the absorption at 600 nm was observed for the polymers Pani and Poma, which can be attributed to the delocalization of the electron pairs on oxygen of the methoxy group [12]. These results are in agreement with results previously reported [20].

2.3 Electrode preparation

Bare carbon steel and copper were obtained by cutting a 1.5 cm thick plate into pieces with dimensions of 2.0 by 2.0 cm. Prior to use, these samples were finished using 100–600 grip SiC paper and rinsed with acetone before applying the Pani and Poma coating on one of the 1 cm2 faces aisled with epoxy resin. The polymers (50%wt) were dissolved in NMP and a volume (100 μL) of these solutions was disposed onto the electrodes, which were placed horizontally in a hot plate, at a temperature of 85–90 ± 0.1 °C. A morphological analysis and determination of film thickness were conducted using scanning electron microscopy (SEM) with a JEOL 5410 microscope, which was coupled to a energy dispersive spectrometer (EDS) for surface analysis, or by atomic force microscopy (AFM) in a Nanoscope IIIa, Digital Instruments. The samples were polished with Al2O3 up to 0.05 μm and metallized with Au–Pd prior to observation.

2.4 Immersion assays

Metals coated with the synthetic polymers were immersed for one month in a 3.5% NaCl solution. After this period of time the concentrations of the ions in solution were determined by an UV–visible analysis using the 1–10-phenantroline method for carbon steel and diethyldithiocarbamate method for copper [27].

2.5 Electrochemical methods

The open corrosion potential measurements were performed in a conventional three-compartment cell containing 0.1 M NaCl solutions saturated with air. Saturated calomel was used as a reference electrode. The potentiostatic polarization curves were carried out under the same conditions described above, using Pt as a counter electrode. The exposed work area of all samples was 1 cm2 for both carbon steel and copper.

To determine the polarization resistance (Rp), the potential of the working electrode was ramped ±25 mV around the open circuit potential at a scan rate of 0.1 m Vs−1. The polarization resistance was determined by the slope of the potential versus current lines.

3 Results and discussion

Table 1 shows the weight loss expressed as mg L−1 of corrosion products found in solution after a month of immersion in 3.5% NaCl aqueous solution, for carbon steel and copper, both uncoated and coated with Pani and Poma. As shown by the lower metal concentration released in the coated relative to the corresponding uncoated metal, both polymers have protective properties. Pani is effective for the protection of both CS and copper, while the use of Poma results in a major metal dissolution. Upon synthesis both the Pani and Poma coatings were obtained in the oxidized state. Next, they were neutralized and converted to the inactive form (E Inact B ). The difference observed in the protective effect of the different polymer coatings could be attributed to the different porosity of the deprotonated films. A more compact film, obtained with the polymers in the inactive state, could inhibit the corrosion of the metal better, since the compact film is an obstacle to the movement of chloride ions through the coating. This possibility is tested by examining the oxidation states of these compounds, as shown in Scheme 1.

On the other hand, it is possible that, on the surface of the substrate, the polymer in the inactive state could be reduced to an active state together, with the formation of CS or Cu oxides (see below). The formation of these oxide–polymer systems requires an adherent film, to maintain the protective effect of the films. Figure 1 shows the cross-sections of the CS/Pani and CS/Poma films observed in the SEM micrograph. The polymers adhere well to the substrate surface, evidenced by the close contact between the substrate and film. The thickness remains relatively unchanged, and close to 3.0 μm. Similar results were observed in the copper system with both polymers.

Due to the difference observed in the protective properties, the topography of the coatings studied was analyzed by AFM. Figure 2 shows the AFM images obtained for Pani and Poma deposited on Carbon Steel, in which it is possible to observe the differences between polymers. Pani-coated CS has a more homogeneous surface, with some places in where the height is lower than the average depth. The roughness of the coating, expressed as root mean square roughness (RMS), was 3.84 nm. On the other hand, Poma-coated CS has a more heterogeneous surface with islands and particles. The roughness of this sample was 4.87 nm, indicating a slightly rougher surface than Pani. In addition, Pani forms a smoother film, which could be a reason why Pani works more efficiently as a protective coating than Poma. The depth of the films, measured as the difference between the highest and lowest regions, was 13 nm and 30 nm for the Pani and Poma samples, respectively. These parameters confirm that the Pani film is smoother than the Poma film, explaining the superior protective effect, since this film acts as a barrier to chloride ions, inhibiting the penetration of the electrolyte into the substrate.

Figure 3 shows the open circuit potential of the coated and uncoated samples in 0.1 M NaCl solutions saturated with air as function of time for (A) carbon steel and (B) copper. When the metals are covered with the polymer films, potentials are shifted towards more noble values compared with the corresponding bare metals, indicating that these systems have a greater resistance to corrosion. In the case of the uncoated carbon steel (Fig. 3A), the variations in potential corresponds to a system found in an active dissolution process. When this metal is covered with the polymers after an initial decrease in potential, an increase in these values is observed. This increase is greater for CS/Pani than CS/POMA This process can be attributed to the formation of an oxide film [19–23]. This oxide film is formed at the same time as the reduction process of the polymeric film from the inactive state to the active-protonated form, as observed in Eqs. 1–3 and in the global reaction in Eq. 4. Both processes result in the production of a final film (oxide and polymer) with a more positive potential than the bare metal, indicative of the protective effect of the film.

where, the different polymeric species have the corresponding structures shown in Scheme 1 and M, and M(OH)2 are the bare metal and the hydroxide species, respectively.

The reaction shown in Eq. 1, corresponds to the oxidation of the CS, reaction, which lowers the pH of the metal–polymer interface. This change in acidity allows protonation of the polymer, which can be reduced as shown in Eq. 3. Finally, the global reaction considers the oxidation of Iron, and the protonation and oxidation of the polymer, to form the oxide-polymer protective layer, as shown in Fig. 4.

The OCP measurements for copper-polymer systems are shown in Fig. 3B. An increase in the open circuit potential with respect to the uncoated metal is observed at long times (80 min). The initial increase observed in all cases can be attributed to passive oxide formation, which is characteristic of the more noble metals. This phenomenon is more pronounced for Pani, which indicates that the polymeric film is participating in the oxide formation. This behaviour is in agreement with the reports by other authors [15] and the results shown with CS. The observations can be interpreted using the same reactions shown in Eq. 1–3.

The OCP results suggest that the protective properties of these polymers, but mostly Pani, are due to both a barrier effect and to the formation of a passive oxide. For Poma it seems that a barrier effect is the only mechanism, because, as shown in Fig. 3A, an increase in open circuit potential is not observed. An increased potential would be attributed to the formation of an oxide film, since the oxidation of the Poma film would require a more positive potential, which cannot be achieved by the oxidation of metal and the formation of the oxide film.

Similar results were observed with copper (Fig. 3B). In this case, thicker polymer coatings were studied. Table 2 shows the OCP measurements for polymer coatings of 3.0 and 18.0 μm thickness, where a direct relationship between the OCP and the thickness is observed, supporting the idea of a barrier effect in these systems. For CS, Pani shows a higher potential, due to the additional formation of the oxide film.

The corrosion current density (CCD) values obtained from Rp are summarized in Table 3. The corrosion current values of the coated carbon steel samples are smaller than those for the bare metal, the Pani coating being the most protective. This is in agreement with the roughness values observed in the AFM images and the weight loss experience. The current densities are closer to 10−7 A cm−2, indicating passivity of the system as a result of the protective effect of the oxide-polymer systems formed over the metal. Copper shows CCD values lower than CS due to the more noble character of this metal.

Figure 5 shows the anodic polarization curves for the different systems studied. For both CS and Cu, Pani is a better coating but it is important to note that a localized corrosion phenomena was not observed at higher potentials for either polymers or metals. Moreover, the bare metals show active dissolution, which is not seen with the polymer coating. It is important to note that when the film was removed from the metallic surface after polarization at a potential value close to 0.4 V, that localized corrosion was not evident.

When this surface was analysed by cross-section SEM and EDS, the presence of a thin oxide film became evident. Figure 6 shows a micrograph of the carbon steel/oxide/Pani system and the corresponding EDS analysis in the zones corresponding to the metal (zone A), oxide (zone B) and polymer (zone C). According to the EDS analysis, Fe, corresponding to carbon steel, is found in zone A. In zone B, the EDS measurement shows an increase in the oxygen band, which is indicative of the formation of a thin oxide film at the metal/polymer interface. Zone C corresponds to the polymer in which the band corresponding to carbon is greatly increased. Similar results were obtained for the other systems assayed.

4 Conclusions

We have demonstrated that Pani and Poma polymer coatings can protect carbon steel and copper against corrosion. Of these polymers, Pani synthesized in HNO3 media in the inactive form presented the best behaviour for both metals. This behaviour can be explained by the formation of a homogeneous oxide film at the metal–polymer interface, which is due to the reduction of the polymer. On the other hand, the use of Poma results in a less compact and rougher film. There is also no evidence of the formation of an oxide film, likely explaining why it is less effective as a protective agent than Pani.

References

Graedel TE, Frankenthal RP (1990) J Electrochem Soc 137:2385

Feliu S, Morcillo M, Feliu S Jr (1993) Corr Sci 34:403

Morcillo M, Almeida E, Rosales B, Uruchurtu J, Marrocos M (1998) Corrosión y Protección de Metales en las Atmósferas de Iberoamérica, CYTED, Madrid, España

Johansson E, Leygraf C, Rendahl B (1998) Brit Corr J 33:59

Odnevall Wallinder I, Verbiest P, He W, Leygraf C (2000) Corr Sci 42:1471

Jeffrey R, Melchers RE (2002) Brit Corr J 37:99

Corvo F, Mendoza AR, Autie M, Betancourt N (1997) Corr Sci 39:815

Nekrasov A, Ivanov V, Vannikov A (2001) Electrochim Acta 46:3301

Bernard M, Joiret S, Hugot-Le Goff A, Viet Phong P (2001) J Electrochem Soc 148:B12

Widera J, Skompska M, Jackowska K (2001) Electrochim Acta 46:4125

Lu JL, Liu NJ, Wang XH, Li J, Jing XB, Wang FS (2003) Synth Met 135–136:237

Vera R, Romero H, Ahumada E (2003) J Chil Chem Soc 48:35

Spinks GM, Dominis AJ, Wallace GG (2003) Corrosion 59:22

Spinks GM, Dominis AJ, Wallace GG, Tallman DE (2002) J Solid State Electrochem 6:85

Kinlen PJ, Silverman DC, Jeffreys CR (1997) Synth Met 85:1327

Tallman DE, Spinks G, Dominis A, Wallace G (2002) J Solid State Electrochem 6:73

Camalet JL, Lacroix JC, Aeiyach S, Lacaze PC (1998) J Electroanal Chem 445:124

Wessling B (2003) Synth Met 135–136:265

Fahlman M, Jasty S, Epstein AJ (1997) Synth Met 85:1323

Epstein AJ, Smallfield J, Guan H, Fahlman M (1999) Synth Met 102:1374

Meneguzzi A, Ferreira CA, Pham MC, Delamar M, Lacaze PC (1999) Electrochim Acta 44:2149

Gasparac R, Martin C (2001) J Electrochem Soc 148:138

Choi S, Park S (2002) J Electrochem Soc 149:E26

Tallman DE, Pae Y, Blerwagen GP (1999) Corrosion, 55:779

Santos JR, Mattoso LH, Motheo AJ (1998) Electrochim Acta 43:309

Brusic V, Angelopoulus M, Graham T (1997) J Electrochem Soc 144:436

Fries J, Getrost H, (1977) in: Darmstadt M (ed) Organic reagents for trace analysis, pp 141–143

Acknowledgements

The authors thank the Dirección de Investigación de la Pontificia Universidad Católica de Valparaíso, Chile, for financial support through Project No 125.763.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Vera, R., Schrebler, R., Cury, P. et al. Corrosion protection of carbon steel and copper by polyaniline and poly(ortho-methoxyaniline) films in sodium chloride medium. Electrochemical and morphological study. J Appl Electrochem 37, 519–525 (2007). https://doi.org/10.1007/s10800-006-9284-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10800-006-9284-y