Abstract

Fucosylated oligosaccharides have an important role in maintaining a healthy immune system and homeostatic gut microflora. This study employed a commercial β-galactosidase in the production of fucose-containing galacto-oligosaccharides (fGOS) from lactose and fucose. The production was optimized using experiment design and optimal conditions for a batch production in 3-liter scale. The reaction product was analyzed and the produced galactose-fucose disaccharides were purified. The structures of these disaccharides were determined using NMR and it was verified that one major product with the structure Galβ1–3Fuc and two minor products with the structures Galβ1–4Fuc and Galβ1–2Fuc were formed. Additionally, the product composition was defined in more detail using several different analytical methods. It was concluded that the final product contained 42% total monosaccharides, 40% disaccharides and 18% of larger oligosaccharides. 290 μmol of fGOS was produced per gram of reaction mixture and 37% of the added fucose was bound to fGOS. The fraction of fGOS from total oligosaccharides was determined as 44%. This fGOS product could be used as a new putative route to deliver fucose to the intestine.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

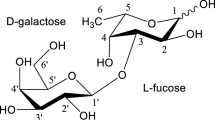

Over the last years knowledge has accumulated that gut microbiota and gut health are heavily modulated by a range of different oligosaccharides. In particular, fucosylated oligosaccharides have an important role as they can maintain homeostatic gut microbiota and a healthy immune system. One source of these beneficial oligosaccharides is human milk oligosaccharides (HMOs), which are a key component in human milk that is generally accepted as the ideal food for infants. Although it is not fully known which of these benefits derive from HMOs, they are known to have a variety of important functions both in the infant and for the microbiota of the infant. Human milk has, on average, 8 g/L HMOs, and their concentration is in the same range as that of protein. HMOs are composed of five monosaccharide building blocks – d-glucose, d-galactose (Gal), N-acetyl-d-glucosamine, l-fucose (Fuc) and sialic acid (N-acetylneuraminic acid). The smallest HMOs are trisaccharides, either fucosyllactose or sialyllactose. There are over 200 HMO structures identified to date. The proportion of fucosylated HMOs in term breast milk has been reported to be 35–50%, depending on the mother’s genetic background. HMOs are not metabolized by the infant, but by the microbiota of the infant’s GI tract. Especially different species of Bifidobacteria are experts in utilizing these oligosaccharides, and HMOs are thus perceived as prebiotics, improving the growth of beneficial microbes [1,2,3].

Another source of fucosylated glycans can be found on the surface of human epithelial cells that express ABH blood group antigens and Lewis antigens. Many bacteria and viruses use these antigens for lectin-mediated adhesion [4]. The process of epithelial fucosylation has been shown to be a response to the colonization of the gut by certain commensal bacteria. Fucosylation is strongest in tissues that are in close contact with highest density of microbes [5,6,7]. The fucosylated epithelial glycans function as energy source for certain commensal bacteria. Bacteroides thetaiotamicron and Bacteroides fragilis, two symbionts, produce fucosidases that cleave α1–2-fucose from mucosal glycans. These two strains can also induce host fucosylation and thus ensure a good carbon source for their own growth [5, 6]. As the fucosidase enzyme is secreted, the fucose is freed into the gut lumen and is available also for other microbes to use. Bacteria using fucose as carbon source can produce metabolites useful to the host and host microbiome, such as short chain fatty acids. Bifidobacteria feeding on fucose have been shown to produce 1,2-propanediol, which in turn can be used by Eubacterium hallii to produce propionate. Intestinal free fucose is also known to cause changes in bacterial gene expression. It has been shown to suppress the virulence of pathogens such as Enterococcus faecalis and enterohemorragic Escherichia coli [5,6,7].

Free fucose in the intestines may function as a signal molecule to warn about the invasion of mucin-hydrolyzing microbes and breakage of mucosal barrier. Intestinal epithelial cells respond to this by up-regulation and secretion of cytokines and thus preparing for an invasion of pathogens. This signaling mechanism seems to be used by commensal probiotic bacteria as a means to educate the host’s mucosal immune system without producing pathological symptoms [5,6,7].

Fucosylated glycans can protect against infections caused by pathogenic or opportunistic micro-organisms. Epithelial α1–2-fucose acts as an inhibitor against several pathogens, such as Salmonella typhimurium. However, some pathogens, such as Helicobacter pylori and noroviruses also use α1–2-fucosylated glycans as means to adhere to the cell surface and initiate infections. As these microbes bind to α1–2-fucosyl units, it is also possible to prevent the adhesion and infections of these pathogens by supplying exogenous glycans. [5, 6]. Fucosylated HMOs share common structural motives with these antigens and can thus act as decoys and prevent the adhesion of certain pathogens. Instead, the pathogens bind to the soluble HMOs and are washed away. The most consistent data on antiadhesive and antimicrobial effects has been reported for α1–2-fucosylated HMOs and their protection against Campylobacter jejuni and noroviruses. The content of 2′-fucosylated oligosaccharides in milk has been associated with lower risk of diarrhea in breastfed infants [1, 8,9,10].

β-Galactosidases are hydrolytic enzymes belonging to the group of glycoside hydrolases. They catalyze the hydrolysis of lactose by glycosyl transfer to water. Under certain conditions, they exhibit a transglycosylation activity forming galacto-oligosaccharides (GOS). The regioselectivity of the enzymes varies leading to different linkages of GOS. β-Galactosidases can be used to produce GOS mixtures from lactose. The composition of GOS varies according to the enzymes used. The linkage between the sugar units can be β1–2, β1–3, β1–4 or β1–6 and the degree of polymerization (DP) usually ranges from two to five. The structure can be either linear or branched [11,12,13,14].

GOS are among the most promising prebiotic oligosaccharides. The human intestine lacks enzymes able to hydrolyse β-glycosidic linkages other than lactose, making these molecules immune to digestion in the small intestine. GOS can subsequently be utilized by the intestinal microbiota leading to a prebiotic effect [2, 11]. Commercial GOS preparations commonly contain about 20% glucose, 20% lactose and 10–20% other disaccharides in addition to tri-, tetra- and pentasaccharides. GOS are used as prebiotics especially in infant foods. Currently Vivinal-GOS is the most used GOS product worldwide. It is a GOS mixture produced by the bacterial β-galactosidase preparation, Biolacta, containing one or more GH42 β-galactosidases from Bacillus circulans. According to literature, Biolacta can catalyze the formation of β1–4 linkages and, to a lesser extent β1–6 linkages. Other β-galactosidases are also commercially available, and those from Aspergillus oryzae and Streptococcus thermophilus are also used in the production of GOS [14,15,16,17,18]. Although β-galactosidases are quite specific for the donor being a galactosyl-moiety, the acceptors can vary in structure. Glucose, galactose, fructose, fucose and N-acetyl- d-glucosamine are known to function as acceptors for different β-galactosidses [2, 11,12,13].

In this work, the aim was to produce fucose-containing galacto-oligosaccharides (fGOS) that could serve as a carrier of fucose into the intestines of infants. We used a commercial β-galactosidase enzyme to produce fGOS and optimized the production. The mass balance of the product was determined using a variety of analytical methods. Additionally, three fucose-containing disaccharides were purified and their structure was determined using NMR.

Materials and methods

Chemicals

A commercial enzyme preparation Biolacta N5 containing β-D-galactosidase from Bacillus circulans was obtained from Amano Enzyme (Nagoya, Japan). L-Fucose was purchased from Hofman International (Calgary, AB, Canada) and lactose (Infantose) from DMV International (Amersfoort, The Netherlands). Oligosaccharide standards (DP2-DP7 malto-oligosaccharides) were obtained from Elicityl (Crolles, France) and Vivinal-GOS from FrieslandCampina (Amersfoort, The Netherlands). All other chemicals were purchased either from VWR (Radnor, PA, USA) or Sigma-Aldrich (St. Louis, MO, USA).

Enzymatic production of fGOS

The enzymatic reaction using Biolacta N5 with fucose and lactose as substrates was performed at 55 °C. pH was adjusted to 6.0 using 10 mM ammonium acetate buffer. Unless otherwise noted, the reactions were performed in a hybridization incubator (Model 1000, Robbins Scientific, San Diego, CA, USA). Sugar solutions were prepared in DI-H2O and pasteurized at 80 °C for 15 min prior to the addition of enzyme. The enzyme was dissolved in a small amount of water, added to a pre-tempered sugar solution and gently mixed. Samples were immediately placed on a 100 °C heating block for 5 min to terminate enzyme reactions and stored at −20 °C.

Optimization

The enzymatic production of fGOS was optimized using Modde 8.0 (Umetrics, Umeå, Sweden). The optimization was made using a full central composite circumscribed (CCC) design with 27 experiments including center point and eight star points. The factors to be optimized were initial fucose concentration (200–800 μmol/g, star points 50 μmol/g and 950 μmol/g, center point 500 μmol/g), initial lactose concentration (200–800 μmol/g, star points 50 μmol/g and 950 μmol/g, center point 500 μmol/g), enzyme activity (2–8 U/g, star points 0.5 and 9.5 U/g, center point 5 U/g) and reaction time (5–19 h, star points 1.5 and 22.5 h, center point 12 h). The results were evaluated using statistical coefficients: coefficient of determination (R2), coefficient of model prediction (Q2), P value and P for the lack of fit. The optimum values were predicted using a prediction tool provided by Modde. All experiments and analytics were done without parallels, except for the center point at which three parallel experiments were done. The modelling then uses the variation at the center point to estimate the reliability of the results.

A kinetic experiment was performed under the optimized conditions where the changes in reaction composition were followed for 38 h.

Scale-up reaction

A scale-up reaction was performed at a 3.75 kg scale (approximately 3 L). The reaction conditions were 130 g fucose and 325 g lactose per kg of reaction mixture (792 mmol and 949 mmol, respectively) buffered to pH 6.0 using 10 mM ammonium acetate buffer. The reaction was carried out in a 4-L metal pot with a lid. Proper mixing was assured by the use of a hydrofoil impeller with three blades. Temperature was adjusted by a water bath. After pasteurization and tempering to 55 °C, 7 U of Biolacta N5 enzyme was added per gram of reaction mixture and the reaction was carried out for 17 h. The reaction was stopped by raising the temperature of the bath to 100 °C. Once the temperature of the reaction mixture had been over 95 °C for 5 min, it was cooled to 4 °C.

Analytics

The exact weight of each approximately 1 g sample was recorded and the samples were diluted to 5 ml with DI-H2O in a volumetric flask. This solution was used to make further dilutions when needed. A commercial galacto-oligosaccharide product with known composition, Vivinal-GOS was used as a reference in all the analytical steps.

TLC

Samples were diluted to approximately 2 g/L concentration and 1 μl was pipetted to a SilicaGel 60 aluminium TLC plate (Merck, Kenilworth, NJ, USA). A solution of l-fucose, glucose, galactose and lactose, 2 g/L each, was used as retention standard. The samples were dried and the plate was developed twice in a chromatographic chamber using butanol - acetic acid - H2O 2:1:1 solution as mobile phase. After drying, the samples were stained with Orchinol solution (2 g/L Orchinol in solution of 75% EtOH and 10% H2SO4 in DI-water) and the color was developed in an oven at 95 °C for 3 min.

Gel chromatography

Analytical gel chromatography was performed using Bio-Gel P-2, extra fine (Bio-Rad, Hercules, CA, USA) in a 0.8 × 60 cm column equipped with a Bio-Rad deashing pre-column and an RI-detector (RID-10A, Shimadzu, Kyoto, Japan). Samples were filtered through 0.2 μm HPLC-filters and 20 μl was injected to the column. Two parallel injections were made. Milli-Q water was used as the eluent at a flow rate of 0.2 ml/min at 75 °C. Malto-oligosaccharides, 1 g/L each from DP 1 to DP 6 were used as standard.

Preparative scale gel- chromatography was performed with the same resin using a column with the dimensions of 2.5 × 100 cm. A solution containing 400 mg of sugars was diluted to 2.5 ml with water and filtered through 0.2 μm filter unit. The solution was injected to the column and eluted with deionized water at 0.25 ml/min flow rate at room temperature using Äkta instrument (GE Healthcare, Chicago, IL, USA). After a void volume of 200 ml, 40 fractions of 5 ml each were collected.

HPAEC-PAD

Monosaccharides were analyzed by high performance anion exchange chromatography equipped with pulsed amperometric detector (HPAEC-PAD) on a Dionex ICS-3000 system (Sunnyvale, CA, USA) equipped with a Dionex CarboPac PA20 column (3 × 150 mm) and an ICS-3000 ED pulsed amperometric detector. Samples were diluted and an internal xylose standard (final concentration 10 mg/L) was added to each sample into the first dilution. Duplicate analyses were made from separate dilutions. Samples were filtered through 0.2 μm filters and 20 μl was injected to the column at room temperature. Water was used as eluent. Monosaccharides were quantified based on external monosaccharide standards. All samples were analyzed in duplicates from separate dilutions.

Oligosaccharides were analyzed by the same HPAEC-PAD setup using Dionex CarboPac PA1 column (4 × 250 mm). 20 μl of filtered samples were injected to the column that was kept at 30 °C. 100 mM NaOH (A) and 1 M NaOAc in 100 mM NaOH (B) were used as eluents. The separations were performed at a flow rate of 0.8 ml/min. The starting conditions were 99.8% A and 0.2% B followed by a 20 min gradient to 99% A and 1% B, and a 43 min gradient to 85% A and 15% B. The column was washed with 100% B for 7 min and equilibrated to starting conditions for 12 min between runs. Chromeleon 7.2 software (Thermo Scientific, Waltham, MA, USA) was used for data processing.

LC-MS of free sugars

The samples were purified with Supelclean ENVI-18 solid phase extraction columns (Supelco, Sigma-Aldrich, Bellefronte, PA, USA). The column (100 mg bed weight) was washed twice with 95% acetonitrile, then equilibrated twice with 2% acetonitrile. Sample was loaded to the column in 2% acetonitrile and the flow through was collected. Appropriate dilutions were prepared to a final acetonitrile concentration of 50% and filtered through a 0.2 μm filter.

An HPLC (1200 Infinity, Agilent, Santa Clara, CA, USA) equipped with XBridge Amide Column (3.5 μm particle size, 2.1 × 150 mm, Waters, Milford, MA, USA) was used. Buffers were A) 70/30 Milli-Q H2O/Acetonitrile supplemented with 0.1% NH4OH and B) 80/20 Acetonitrile/Milli-Q H2O supplemented with 0.1% NH4OH. The gradient used was 0% to 60% buffer A in 15 min, then 60% to 0% buffer A in 3 min. The column was equilibrated with buffer B for 12 min between injections. Injection volumes between 1 μl and 20 μl were used. A sugar solution containing fucose, glucose and lactose, 50 ppm each was used as standard in 10 μl injection volume. The sugars were detected using Q-TOF MS (6530, Agilent, Santa Clara, CA, USA) in the negative ion mode with following settings: Source gas temperature 300 °C, drying gas 10 L/min, nebulizer 20 psig, capillary voltage 3000 V. The peaks were identified by masses and the changes in concentrations of different sugars were estimated by the proportional changes in the areas of extracted ion count peaks. MassHunter software version 7.0 (Agilent, Santa Clara, CA, USA) was used for all data processing.

Carbohydrate 2-AB labeling

2-aminobenzamide (2-AB) labeling of purified oligosaccharides was performed following the protocol of Bigge et al. [19]. 400 and 800 nmol of total sugars were labeled. Excess label was removed by paper chromatography. Two layers of filter papers (Whatman chromatography paper, grade 3MM CHR, GE Healthcare, Chicago, IL, USA) inserted in an empty syringe were washed twice with 30% acetic acid, twice with DI-H2O and twice with acetonitrile and equilibrated twice with 95% acetonitrile. The labeling reaction was loaded in 95% acetonitrile and the sample tube was washed three times with 95% acetonitrile and loaded to the syringe. The syringe was washed eight times with 95% acetonitrile. The sample was eluted with DI-H2O and dried at 65 °C under air flow.

LC-MS of labeled sugars

Samples were suspended in 90% acetonitrile/10% 100 mM ammonium formate and filtered through 0.2 μm filters. Same setup of LC-MS was used as for free sugars. Buffers were A) 100 mM ammonium formate and B) 100% acetonitrile. The gradient used was 10% to 30% buffer A in 35 min and 30% to 10% buffer A in 1 min. The column was equilibrated for 9 min using 10% buffer A between samples. The samples were analyzed in triplicates from two different labeling reactions using different injection volumes. Quantification was made using Agilent’s Diode Array Detector (DAD, G4212 with 10 mm cell V(o) 1 μl) at 254 nm. Peaks were identified using MS-detector in the positive ion mode using the same settings as for negative ion mode.

Purification of Gal-Fuc disaccharides

The novel galactose-fucose disaccharides were purified using the same HPLC instrument and eluents as for free sugars. The gradient was optimized for the separation of disaccharides and was as follows: 5 min with 100% buffer B, gradient of 0% to 20% buffer A in 5 min, gradient of 20% to 60% buffer A in 1 min, 5 min of 60% buffer A, gradient of 60% to 0% buffer A in 2 min, equilibration with 100% buffer B for 7 min. Several injections were made and the two fractions containing m/z 325 product (fraction 1 from 5.4 to 7.2 min and fraction 2 from 7.4 to 7.9 min) were collected and pooled. The fractions were dried at 45 °C under airflow.

NMR for structural analysis

The pooled fractions of the galactose-fucose disaccharides were dried under airflow at 45 °C. The samples were dissolved in 600 μl of Deuterium oxide containing 0.05% 3-(trimethylsilyl)propionic-2,2,3,3,d4 acid (Aldrich, St. Louis, MO, USA). All NMR experiments were carried out at 22 °C on a 600 MHz Bruker Avance III NMR spectrometer equipped with a QCI H-P/C/N-D cryoprobe. Chemical shifts were referenced to external acetone (2.225 ppm and 31.55 ppm for 1H and 13C, respectively).

In 1D 1H spectra, the water signal was suppressed by 4 s volume selective presaturation (so called 1D NOESY presaturation). Pulsed field gradient versions of DQFCOSY, TOCSY, HSQC, HMBC and HSQCTOCSY were used for 2D NMR. In TOCSY, DIPSI2 spinlock was 120 ms. The one-bond 1H-13C coupling constant in HSQC was estimated to be 150 Hz and 8 Hz was used for the multiple bond coupling constant in HMBC. Adiabatic 13C decoupling was employed during HSQC acquisition time.

Results

Optimizing the enzymatic production of fGOS

In order to produce fGOS a reaction between fucose and lactose using different commercial β-galactosidase enzymes was performed (data not shown). Based on these preliminary tests, Biolacta N5 composed of β-galactosidases from Bacillus circulans was chosen for further experiments. Reaction conditions were chosen based on the enzyme’s optimal conditions for stability and hydrolytic activity [20]. In order to ensure compatibility with analytical methods, 10 mM ammonium acetate was chosen as the buffer.

The production of fGOS was first tested under different conditions to screen for the range of optimization of principal components (data not shown). Based on these primary results, the effects of enzyme activity, reaction time and fucose and lactose concentrations were investigated using a Central Composite Circumscribed (CCC) experimental design. Lactose concentration optimization was done at high concentrations as this leads to lowered water activity and higher transgalactosylation reaction rates [12]. High fucose concentrations were used to make sure that the enzyme has free fucose available to be used as a galatosyl-acceptor. Temperature and pH were not optimized in this study as they have been extensively studied, and their effect can be predicted based on previous results [12]. The reaction products were analyzed using HPAEC-PAD for final fucose, and LC-MS for the ratio between fGOS and total oligosaccharides (OS). The factors and responses used in the model are presented in the Online Resource (Table S1). The response surface plots for fGOS production and fucose utilization are presented in Fig. 1.

Response surface plots for CCC experimental design of fGOS production. A and c: fGOS produced (μmol/g fucose). B and d: used fucose (% of fucose added to the reaction). Responses are plotted against intial fucose and lactose concentrations (μmol/g) (a and b) and enzyme activity (U per gram of reaction mixture) and incubation time (hours) (c and d). The remaining factors are at their center points

In order to estimate how good the model is, R2, Q2 and P-values were extracted from the data. R2 value indicates how well the model corresponds to the observations and Q2 indicates how well the model is able to predict experimental results. P-values predict how valid the model is. For fGOS produced the R2 value was 0.942 the Q2 value was 0.758 and the P value was less than 0.001. The P value for the lack of fit was 0.057. These statistical coefficients suggest that the model was highly significant and capable of predicting conversion at a certainty level of 76%. For percentage of used fucose, the R2 value was 0.919 the Q2 value was 0.681 and the P value was less than 0.001. The P value for the lack of fit was 0.074. These statistical coefficients suggest that the model was highly significant and capable of predicting conversion at a certainty level of 68%. For the fraction of fGOS from total OS produced the R2 value was 0.725 the Q2 value was −0.104 and the P value was 0.024. The P value for the lack of fit was 0.001 (data not shown). These statistical coefficients suggest that the model was not significant.

The optimal conditions using the optimizer in Modde were determined as 800 μmol of fucose, 950 μmol of lactose and 7 U of enzyme per gram of reaction mixture and 22 h reaction time.

In order to investigate the effect of reaction time on fGOS production, an experiment was made under the optimized conditions and the reaction was followed for 38 h. Fucose, glucose and galactose concentrations were determined using HPAEC-PAD and fGOS/OS ratio using LC-MS. The results showed that during the first 10 h the reaction proceeded rapidly, but after 14 h the amount of free fucose and fGOS/OS ratio stayed constant (data not shown). It could be noticed that high lactose concentration in the mixture protects the fGOS from degradation, but once most of the lactose has been hydrolyzed, oligosaccharides, including fGOS will start to degrade. Thus, high lactose concentration is needed to get good fGOS production although this leads to a lower fGOS /OS ratio.

Scale-up production

Once the optimum for fGOS production and the correct reaction time had been determined, a scale-up reaction was done at 3.75 kg with a reaction time of 17 h.

In order to analyze reactions products, preparative gel-chromatography followed by TLC analysis was conducted. First, a preparative scale gel chromatography was performed to fractionate sugars into fractions based on degree of polymerization. The fractions were analyzed on TLC and selected fractions were also analyzed using LC-MS to identify the products (see Fig. 2). Products of both GOS and fGOS could be detected up to DP 7.

TLC analysis of product fractionated with preparative scale gel-chromatography. 5 ml fractions were collected and analyzed on TLC. Selected fractions were analyzed on LC-MS with negative ion mode and the results of the mass analysis are marked below. All m/z values that had intensity at least 5% of the most intense peak were acknowledged. Those with 5–10% of the most intense peak are marked in brackets. The m/z values correspond to the following sugars: 163 – fucose; 179 – hexose; 325 – hexose + fucose; 341 – hexose disaccharide; 487 – trisaccharide with fucose and two hexoses; 503 – hexose trisaccharide; 649 – tetrasaccharide with fucose and three hexoses; 665 – hexose tetrasaccharide; 811 – pentasaccharide with fucose and four hexoses; 827 – hexose pentasaccharide; 973; hexasaccharide with fucose and five hexoses; 989 – hexose hexasaccharide; 1135 – heptasaccharide with fucose and six hexoses; 1151 – hexose heptasaccharide

Structure of galactose-fucose disaccharides

Gal-Fuc disaccharides were purified using LC. The dried fractions were suspended in 50% acetonitrile in water and the purity was analyzed using LC-MS. Figure 3 shows that there was a small amount of lactose or a disaccharide of equivalent mass in the purified fraction (m/z 341). The peak at the retention time of 5.4–7.2 min (Fig. 3a) was formed of two distinct sugars and could not be resolved.

Purity of fucose-galactose disaccharides checked by LC-MS. (a) – peak 1 eluting at 5.4–7.2 min. (b) – peak 2 eluting at 7.4–7.9 min. Continuous line – extracted ion chromatogram of m/z 325 corresponding to Gal-Fuc disaccharide. Dotted line - extracted ion chromatogram of m/z 341 corresponding to hexose disaccharide. No other structures were detected on the LC-MS.

The structures of the disaccharides were determined by NMR spectroscopy. In brief, most of the proton signals were first assigned starting from the anomeric signals and the signals of the fucose methyl groups. After that the corresponding 13C signals and most of the remaining 1H signals were assigned from HSQC and HSQCTOCSY spectra and the locations of the glycosidic bonds were initially obtained from the downfield shifts of the fucose 13C signals at the site of glycosylation. Finally the linkage position was confirmed by the 3-bond HMBC signals over the glycosidic bond, if possible.

As already suggested by the relatively broad LC peak in Fig. 3, the first disaccharide sample contained two disaccharides. The anomeric and methyl regions of the 1H spectrum of this sample are shown in Fig. 4a. In both of these saccharides, the H1-H2 coupling constant is about 7.5 Hz (data not shown) confirming that the galactose is in β configuration. The 1H and 13C chemical shifts of both disaccharides are given in Online Resource (Tables S2 and S3, respectively). When compared to the 13C chemical shifts of fucose monosaccharide also given in Online Resource (Table S3), it is evident that for the more abundant disaccharide, fucose C3 signals have shifted to the lower field, while for the other saccharide the same has happened to the C4 signals. This is also evident from the HSQC spectrum (Online Resource Fig. S1), where these four signals form a group separate from the rest of the signals. Thus the structures of the two saccharides are Galβ1–3Fuc and Galβ1–4Fuc. This was further confirmed by HMBC signals observed between galactose H1 and fucose C3 and C4 (data not shown). Based on peak integrations, the ratio between the concentrations of the structures Galβ1–3Fuc and Galβ1–4Fuc was about 2:1.

Anomeric and methyl regions of the 600 MHz 1H NMR spectra of the disaccharide samples in D2O. The structures of the two disaccharides in the first sample (panel a) were Galβ1–3Fuc and Galβ1–4Fuc, while the disaccharide in the second sample (panel b) was Galβ1–2Fuc. Unknown signals not originating from the disaccharide are indicated by an asterisk (*)

The second sample contained only one disaccharide. The anomeric and methyl regions of its 1H spectrum are shown in Fig. 4b. Due to severe signal overlap, all signals of the α-fucose moiety could not be assigned. However, the β-fucose signals were fully assigned and the 1H and 13C chemical shifts of all assigned signals are given in Online Resource (Tables S2 and S3, respectively). Clear glycosylation shifts of the fucose C2 signals (both anomers) compared to those of monosaccharide fucose could again be observed. Thus, the structure of this third disaccharide is Galβ1–2Fuc. Based on peak integrations, this structure was present in about the same concentration as structure Galβ1–4Fuc.

Product characterization

The mass balance of the scale-up product was analyzed using several different methods. The total sugar content was calculated based on sugars added to the reaction mixture, and was 455 mg/g. First the monosaccharide composition of the oligosaccharide mixtures were defined using HPAEC-PAD for monosaccharides. The concentrations of monosaccharides were 81.8 mg fucose, 8.7 mg galactose and 106.5 mg glucose per gram of product mixture. Based on the amount of initial fucose and lactose, 37% initial fucose was bound to oligosaccharides.

Next, the distribution of sugars among different degrees of polymerization was analyzed using analytical gel-chromatography. Peaks up to DP 6 could be separated nicely with the conditions used. A mixture of malto-oligosaccharides from DP 1 to DP 6 at 1 g/L concentration each were used as standard, as the RI-detector response goes down with longer sugar chains. According to these results, the DP distribution was as follows (in mg sugar per gram of product mixture): DP 1: 191 mg/g (42.1% of total sugars), DP 2: 182 mg/g (40.1%), DP 3: 60.9 mg/g (13.4%), DP 4: 16.9 mg/g (3.7%) and DP 5: 3.4 mg/g (0.8%). DP 6 products were below detection limit. The relative amount of monosaccharides (DP 1) was in line with the results for monosaccharides from HPAEC-PAD, according to which the monosaccharide concentration of the mixture is 197 mg per gram of product mixture (43.3% of total sugars).

As gel chromatography does not separate between fGOS and GOS, HPAEC-PAD was used to determine the amounts of different DP fGOS and GOS separately. In order to achieve this, the fractions from preparative gel-chromatography analyzed with TLC and LC-MS were used as standards to identify different DP sugars from HPAEC-chromatogram. Additionally, HPAEC-PAD chromatograms of Vivinal-GOS DP-fractions were used to identify GOS peaks to identify peaks belonging to fGOS. After the peaks had been identified, a sample of fGOS was analyzed using two different concentrations and peaks were annotated based on their retention times.

In order to quantify the sugars by HPAEC-PAD, malto-oligosaccharides DP 1–4 were used as standards at 100 μg/ml concentration. Although the response factor of PAD-detector cannot be predicted based on the structure of the sugar, it is generally accepted that the response factor decreases as the retention time increases [21,22,23]. Thus, a correlation between retention times and peak areas of the malto-oligosaccharides was used to estimate the concentration of different sugars in the fGOS mixture. Based on the results from HPAEC-PAD, the distribution of sugars was as follows (% of total sugars): DP 1: 43.8%, DP 2: 35.7% of which 28.9% contained fucose, DP 3: 14.1%, DP 4: 5.1% and DP 5 and higher 1.2%. The peaks of higher DP than 2 were not separated well enough to distinguish between fGOS and GOS and thus the fGOS to total oligosaccharide ratio could only be defined from DP 2.

Another method of quantification of different oligosaccharides, 2-AB labeling was also studied. As each molecule of reducing sugar binds one molecule of 2-AB, this method should be quantitative for other than monosaccharides, which are lost during the purification process. 2-AB can be detected with DAD using 254 nm. MS at positive ion mode was used for peak identification. DP 2 peaks were nicely separated and fGOS to total OS ratio was defined as 29.5% within DP 2 products. With DP 3 peaks there was some overlapping and more so with DP 4 peaks. Additionally, DP 4 peaks were already close to detection limit, and DP 5 could not be detected at all.

Discussion

In this study, fucose-containing galacto-oligosaccharides were produced using the commercial β-galactosidase preparation Biolacta N5. The production was optimized and the fGOS product was analyzed using several different quantification and characterization methods.

This is, to our knowledge, the first report of the structure of an l-fucose-containing disaccharide produced by β-galactosidases. Fucose-containing hetero-oligosaccharides have previously been produced from fucose and lactose using whole cells of Bifidobacterium longum and crude cell extracts of Leuconostoc mesenteroides, Lactobacillus ruminis and Lactobacillus bulgaricus [24, 25]. The structure of these oligosaccharides produced by L. bulgaricus has been studied and it was concluded that five structures had been produced, two with sequence Gal-Fuc and three with Gal-Gal-Fuc. However, a more detailed structure of these sugars has not been reported.

As β-galactosidase from B. circulans has a broad product spectrum with different linkages produced, it was expected that the enzyme would produce differently linked galactosyl-β-l-fucoses. The product mixture was shown to contain three different Galβ-l-fucoses with Galβ1–3Fuc dominating, accounting for about 70% of the amount of all Gal-Fuc disaccharides. The two other structures were Galβ1–2Fuc (10%) and Galβ1–4Fuc (20%). It is generally believed that Biolacta N5 has a preference to the formation of β1–4-linkages and to a lesser extent β1–6-linkages [16]. As the structures of l-fucose differs from glucose in positions C4 and C6, it is likely that the steric differences favor the production of Galβ1–3Fuc when compared with Gal-Glc disaccharides. Recently, the composition of Vivinal-GOS was studied in detail and all possible Gal-Glc disaccharides (β1–2, β1–3, β1–4 and β1–6) were found as well as Galβ1–4Gal. Nine different trisaccharides were found as well as 15 tetrasaccharide and 15 pentasaccharide structures [26]. In our study the main fucose-containing disaccharide was Galβ1–3Fuc, and thus it is likely that the majority of fucose-containing trisaccharides also has this linkage. It seems sterically possible to get four or five different trisaccharides from each disaccharide with the addition of a galactosyl-moiety and thus it is possible that the trisaccharide pool is a mixture of 10–15 different fucose-containing trisaccharides as well as approximately 10 GOS structures. Naturally, the number of different structures increases with the degree of polymerization, as can be seen in the literature.

In human milk the fucose moiety is attached to the non-reducing end with an α-linkage. In the fGOS product fucose is at the reducing end of the sugar and galactose is linked to fucose via β-linkage. It is not known how this linkage affects the biological activity of the product. It would seem likely that for the antiadhesive effect to take place, it is important to get the L-fucose into the intestine without it being degraded on the way. As humans lack the ability to hydrolyze β-glycosidic linkages other than present in lactose [27], it seems likely that Gal-Fuc disaccharide with β-linkage would survive the digestive enzymes. The addition of fGOS to infant formula could thus be a method of delivering fucose into the intestines of the infant for bacteria to utilize. As these oligosaccharides would most likely be utilized by bifidobacteria and possible also other bacteria in the intestines, some of the fucose would be used by these bifidobacteria and some would be released into the medium, depending on the strain in question. As free fucose functions as a signal molecule warning the intestinal epithelial cells of possible invasion and breakage of mucosal barrier, adding fGOS to formula could strengthen the mucosal immune system of the infant. Additionally free fucose is shown to suppress the virulence of certain pathogens [5,6,7].

Production optimization was done using an experiment model and optimal conditions and responses at these conditions were estimated using a prediction tool in Modde. A scale up reaction at 3.75 kg scale was done using the optimal conditions. At the end of the reaction, the mixture contained a total of 42% monosaccharides, 40% disaccharides and 18% of larger oligosaccharides. There were some challenges in product quantification. As the product is a mixture of dozens of different sugars, the complete separation of all peaks using liquid chromatography turned out to be a difficult task. Another problem is the lack of standards to identify and quantitate different sugars. For these reasons a combination of several methods consisting of gel chromatography, TLC, LC-MS and HPAEC-PAD was used. As the full separation of sugars larger than DP 2 could not be achieved, the ratio between fGOS and GOS could only be determined for disaccharides as 0.3. When the ratio of total fGOS to GOS was defined based on free monosaccharides, the result was 0.44. It seems that the ratio of fGOS to GOS increases with larger oligosaccharides. It could be that the enzyme prefers fGOS over GOS due to the effect of smaller fucose on the steric hindrances.

According to the model, the amount of fGOS produced was estimated to be 220 ± 35 μmol per gram of reaction mixture. In the scale-up experiment the result was 290 μmol/g reaction mixture. Also the amount of added fucose bound to fGOS was higher, 37%, than predicted, 30 ± 5.2%. It can be said that the results were slightly better than predicted.

Conclusions

In this work a commercial β-galactosidase from Bacillus circulans was used to produce fucose-containing galacto-oligosaccharides from fucose and lactose. The production was optimized and the product was analyzed. NMR studies revealed three novel fucose-containing disaccharides, galactose linked to fucose through β1–3-, β1–4- or β1–2-linkage. The fGOS oligosaccharide mixture contained 40% monosaccharides, 40% disaccharides and 20% oligosaccharides. 30% of the disaccharides and 44% of all oligosaccharides contained fucose.

References

Bode, L.: Recent advances on structure, metabolism, and function of human milk oligosaccharides. J. Nutr. 136, 2127–2130 (2006)

Oliveira, D.L., Wilbey, R.A., Grandison, A.S., Roseiro, L.B.: Milk oligosaccharides: a review. Int. J. Dairy Technol. 68, 305–321 (2015)

Ninonuevo, M.R., Park, Y., Yin, H., Zhang, J., Ward, R.E., Clowers, B.H., German, J.B., Freeman, S.L., Killeen, K., Grimm, R., Lebrilla, C.B.: A strategy for annotating the human milk glycome. J. Agric. Food Chem. 54, 7471–7480 (2006)

Cooling, L.: Blood groups in infection and host susceptibility. Clin. Microbiol. Rev. 28, 801–870 (2015)

Goto, Y., Uematsu, S., Kiyono, H.: Epithelial glycosylation in gut homeostasis and inflammation. Nature Immunol. 17, 1244–1251 (2016)

Pickard, J.M., Chervonsky, A.V.: Intestinal fucose as a mediator of host-microbe symbiosis. J. Immunol. 194, 5588–5593 (2015)

Chow, W.L., Lee, Y.K.: Free fucose is a danger signal to human intestinal epithelial cells. Br. J. Nutr. 99, 449–454 (2008)

Bode, L.: Human milk oligosaccharides: every baby needs a sugar mama. Glycobiology. 22, 1147–1162 (2012)

Barile, D., Rastall, R.A.: Human milk and related oligosaccharides as prebiotics. Curr. Opin. Biotechnol. 24, 214–219 (2013)

Hickey, R.M.: The role of oligosaccharides from human milk and other sources in prevention of pathogen adhesion. Int. Dairy J. 22, 141–146 (2012)

Lu, L.L., Xiao, M., Li, Z.Y., Li, Y.M., Wang, F.S.: A novel transglycosylating β-galactosidase from Enterobacter Cloacae B5. Process Biochem. 44, 232–236 (2009)

Gosling, A., Stevens, G.W., Barber, A.R., Kentish, S.E., Gras, S.L.: Recent advances refining galactooligosaccharide production from lactose. Food Chem. 121, 307–318 (2010)

Gänzle, M.G.: Enzymatic synthesis of galacto-oligosaccharides and other lactose derivatives (hetero-oligosaccharides) from lactose. Int. Dairy J. 22, 116–122 (2012)

Li, W., Sun, Y., Ye, H., Zeng, X.: Synthesis of oligosaccharides with lactose and N-acetylglucosamine as substrates by using β-d-galactosidase from Bacillus Circulans. Eur. Food Res. Technol. 231, 55–63 (2010)

Ito, Y., Sasaki, T.: Bioscience, biotechnology, and biochemistry cloning and characterization of the gene encoding a novel β-galactosidase from Bacillus Circulans. Biosci. Biotechnol. Biochem. 618, 1270–1276 (1997)

Zeuner, B., Jers, C., Mikkelsen, J.D., Meyer, A.S.: Methods for improving enzymatic trans-glycosylation for synthesis of human milk oligosaccharide biomimetics. J. Agric. Food Chem. 62, 9615–9631 (2014)

Sakai, K., Katsumi, R., Ohi, H., Usui, T., Ishido, Y.: Enzymatic syntheses of N-Acetyllactosamine and N-Acetylallolactosamine by the use of β-D-galactosidases. J. Carbohydr. Chem. 11, 553–565 (1992)

Farkas, E., Thiem, J., Ajisaka, K.: Enzymatic synthesis of fucose-containing disaccharides employing the partially purified α-L-fucosidase from Penicillium multicolor. Carbohydr. Res. 328, 293–299 (2000)

Bigge, J.C., Patel, T.P., Bruce, J.A., Goulding, P.N., Charles, S.M., Parekh, R.B.: Nonselective and efficient fluorescent labeling of glycans using 2-amino benzamide and anthranilic acid. Anal. Biochem. 230, 229–238 (1995)

Mozaffar, Z., Nakanishi, K., Matsuno, R., Kamikubo, T.: Purification and properties of β-galactosidases from Bacillus circulans. Agric. Biol. Chem. 48, 3053–3061 (1984)

Kunz, C., Rudloff, S., Hintelmann, A., Pohlentz, G., Egge, H.: High-pH anion-exchange chromatography with pulsed amperometric detection and molar response factors of human milk oligosaccharides. J. Chromatogr. B Biomed. Appl. 685, 211–221 (1996)

Borromei, C., Cavazza, A., Merusi, C., Corradini, C.: Characterization and quantitation of short-chain fructooligosaccharides and inulooligosaccharides in fermented milks by high-performance anion-exchange chromatography with pulsed amperometric detection. J. Sep. Sci. 32, 3635–3642 (2009)

Corradini, C., Cavazza, A., Bignardi, C.: High-performance anion-exchange chromatography coupled with pulsed electrochemical detection as a powerful tool to evaluate carbohydrates of food interest: principles and applications. Int. J. Carbohydr. Chem. 2012, 1–13 (2012)

Schwab, C., Lee, V., Sørensen, K.I., Gänzle, M.G.: Production of galactooligosaccharides and heterooligosaccharides with disrupted cell extracts and whole cells of lactic acid bacteria and bifidobacteria. Int. Dairy J. 21, 748–754 (2011)

Black, B.A., Lee, V.S.Y., Zhao, Y.Y., Hu, Y., Curtis, J.M., Ga, M.G.: Structural identification of novel oligosaccharides produced by lactobacillus bulgaricus and lactobacillus plantarum. J. Agric. Food Chem. 60, 4886–4894 (2012)

Van Leeuwen, S.S., Kuipers, B.J.H., Dijkhuizen, L., Kamerling, J.P.: 1H NMR analysis of the lactose/β-galactosidase-derived galacto-oligosaccharide components of Vivinal GOS up to DP5. Carbohydr. Res. 400, 59–73 (2014)

Boehm, G., Stahl, B.: Oligosaccharides from milk. J. Nutr. 137, 847S–849S (2007)

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflicts of interest

The authors declare that they have no conflicts of interest.

Ethical approval

This article does not contain any studies with human participants or animals performed by any of the authors.

Electronic supplementary material

ESM 1

(PDF 386 kb)

Rights and permissions

About this article

Cite this article

Usvalampi, A., Maaheimo, H., Tossavainen, O. et al. Enzymatic synthesis of fucose-containing galacto-oligosaccharides using β-galactosidase and identification of novel disaccharide structures. Glycoconj J 35, 31–40 (2018). https://doi.org/10.1007/s10719-017-9794-3

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10719-017-9794-3