Abstract

The galactosylation of furostanosides and spirostanosides were investigated by using β-galactosidase from Lactobacillus bulgaricus L3 as a catalyst and lactose as a sugar donor. Four novel galactosylated furostanoside products (compounds 1–4) from compound F, compound G, compound I, and compound H were obtained and their structures were identified by HR-ESI-MS, 1D and 2D NMR spectra. The result showed that galactosyl moiety was found to be added to the 6-OH of the 26-O-glucosyl in these four furostanoside substrates.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Steroidal saponins are important bioactive ingredients of Chinese traditional medicine, which are mainly composed of two groups, furostanosides (the F ring was open with 26-O-glucosyl) and spirostanosides (the F ring was closed). They possess various biological activities such as inhibition of platelet-aggregation, anti-bacteria, cytotoxicity and anti-dementia. The sugar chain was thought to have a considerable effect on their biological and pharmacological activities, such as some spirostanosides from the rhizome of Paris polyphylla were shown to cause strong platelet aggregation and being cytotox [1, 2]. On the contrary, timosaponin BII (furostanosides) was shown to have much stronger improving learning and memory abilities than spirostanosides from rhizome of Anemarrhena asphodeloides [3]. Modification of the sugar chain may offer some new drugs with novel or stronger pharmacological activities. Glycosylation is a method to synthesize promising drugs, which are more stable and soluble in the living body. The glycosylations by enzymes are more selective and environment-friendly than that by chemical synthesis [4, 5].

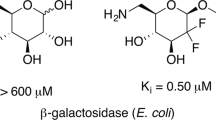

β-galactosidases (EC 3.2.1.23) are widely distributed in microorganisms (including fungi, bacteria and yeast), animals and plants. These enzymes show great prospect for the industrial applications owing to their hydrolytic and glycosylated activities. For example, the hydrolytic activity has been applied to hydrolyze lactose in milk to reduce lactose intolerance, and the transglycosylation activity has been used to synthesize prebiotic galacto-oligosaccharides from lactose [6–9]. Recently, β-galactosidases research has gained more momentum due to their broad acceptor specificity in transglycosylation. That is, these enzymes are able to transfer galactosyl moiety to various compounds in the presence of lactose or simple galactosides as the glycosyl donor. This results in the production of a series of promising galactose-containing chemicals, including diverse oligosaccharides [7], alkyl-glycoside [10, 11], glycoconjugates [12, 13] and others [14] that play important roles in the industries of food additives, cosmetics and medicines [15–17]. There are some β-galactosidases from Aspergillusoryzae [18, 19] and Bacillus circulans [20] that can transform the specified substrates into galactosylated products. Because the transglycosylation product of the β-galactosidase can be hydrolyzed by the enzyme itself, the yield is modest. The transglycosylation yield is closely related to the conditions that they reacted in. There are many researches about enhancing yields through the two-phase aqueous-organic system [21] or optimizing the conditions by response surface methodology [18].

Up to date, glycosylation of steroidal saponins was mainly focused on glucosylation [22, 23]. The galactosylation of steroidal saponins has not been reported so far. In this paper, for the first time, the β-galactosidase from Lactobacillus bulgaricus L3 was used in the galactosylation of steroidal saponins with the cheap lactose as a sugar donor. The enzyme catalyst was easily accessible and showed powerful synthetic ability according to the previous research [15, 24, 25].

This paper mainly presented the preliminary regularity results of galactosylations of steroidal saponins by the enzyme.

Experimental

Materials and general methods

Acetonitrile (chromatographic grade) was purchased from Fisher Scientific Co. Ltd. Other reagents were all analytical grade and commercially available. Steroidal saponins were prepared by our laboratory. Lactose was purchased from Shanghai Hengxin Chemical Reagent Co. Ltd.

The NMR spectra were recorded on a Varian UNITY INOVA 600 spectrometer (150 MHz for 13C-NMR and 600 MHz for 1H-NMR) (Paloalto, USA) in pyridine-d 5. UPLC analyses were performed on Waters Acquity UPLC™ system with an Acquity UPLC HSS T3 column (100 × 2.1 mm, 1.8 μm) (Waters Corporation, USA). The ESI-MS spectra were recorded on Synapt Q/TOF MS (Waters Corporation, USA). HPLC analyses were performed on Waters 2695 Alliance Separations Module with a Venusil XBP C18 column (4.6 × 250 mm, ODS, 5 μm) (Bonna-Agela, China) and a PL-ELS 2100 evaporative light scattering detector (ELSD) (Polymer Laboratories, UK). Semi-preparative HPLC was carried out using the NP7000 module (Hanbon Co. Ltd, China.) equipped with a Shodex RID 101 detector (Showa Denko Group, Japan) and a Vensiul C18 column (8.0 × 250 mm, ODS, 5 μm) (Bonna-Agela, China).

β-Galactosidase preparation

The β-galactosidase gene from L. bulgaricus L3 (GenBank No. EU734748) had been cloned into pET-21b and transformed into E. coli BL21 (DE3) in the previous work.11 The recombinant E. coli was grown in LB medium containing ampicillin (50 μg/mL) at 37 °C, and the enzyme was induced to be expressed by adding isopropyl-1-thio-β-D-galactoside (IPTG) when the cell density reached 0.6 ~ 1.0 at 600 nm. After continuous cultivation for 3–5 h, cells were harvested and disrupted by ultrasonic treatment. The lysate was centrifuged and the enzyme was purified from the suspension by Ni2+ chelation chromatography (Qiagen, Germany).

The assay for β-galactosidase activity

The activity of β-galactosidase was determined by adding enzyme solution (50 μL) to 450 uL of 2 mmol/L ONPG (O-nitrophenyl-β-D-galactopyranoside) at 37 °C for 10 min. The reaction was stopped by adding 1 mL of 0.5 mol/L Na2CO3. After centrifugation of the mixture, the supernatant was measured at 420 nm. One unit of enzyme activity (U) is defined as the amount of enzyme that produces 1 μmol o-nitrophenol per minute under the assay conditions [15].

Transglycosylation conditions of the β-galactosidase

All the reactions were done in a series of solutions of compound F (1 mg/mL) with lactose (0.4 mol/L) and β-galactosidase (1 U/mL) to a volume of 500 ul. The optimum pH was determined in phosphate buffer (PB) in the presence of β-galactosidase over a range of pH from 5.5 to 8.5 at 45 °C for 24 h. The optimum temperature was determined at the optimum pH with different temperatures ranging from 20 to 55 °C for 24 h. The effect of time course on the yield of product was detected at optimum temperature and pH with reaction time ranging from 1 to 36 h. All of the reactions were stopped by adding 300 μL of acetone, and then the increase of the product was measured by HPLC.

Enzymatic galactosylation of various steroidal saponins

The lactose was dissolved in 50 mmol/L PB to reach a concentration of 0.4 mol/L, and then the enzyme was diluted to 10 U/mL by the 50 mmol/L PB. The furostanoside and spirostanoside substrates were dissolved or suspended in 50 mmol/L PB (phosphate buffer, pH 7.0) to reach a concentration of 20 mg/mL. A mixture of enzyme, lactose and substrate (1:8:1, v/v/v) in 50 mmol/L PB to a volume of 500 ul was incubated in water bath at 45 °C for 24–30 h. The reactions were stopped by adding water-saturated n-butanol, and then the n-butanol layer was concentrated to dry. The reaction mixtures of furostanosides and spirostanosides were dissolved by acetonitrile-water (v/v, 30:70) and methanol, respectively, and then detected by UPLC-MS. The structures of these substrates were listed in Table 1.

Preparative enzymatic reactions and purification of products

To get enough products to clarify the galactosylation regularity, compound F (500 mg), compound G (300 mg), compound I (60 mg), and compound H (60 mg) were separately incubated in four flasks with 0.4 mol/L of lactose (100, 30, 15, or 20 mL) and undiluted β-galactosidase (2.8, 1, 1.3 or 1 mL), respecively, in water bath at 45 °C for 24–30 h. After the reaction, these mixtures were separately loaded on four SP825 macroreticular resin columns and firstly all eluted with water to remove the enzyme, and then eluted with acetone-water (v/v, 25:75, 15:85, 50:50, or 50:50, respectively) to get the substrate and products. The fractions eluted by acetone-water were separately concentrated to dry under reduced pressure. These four residues were then purified by Semi-preparative HPLC with 23, 19, 26, or 16 % acetonitrile-water, (v/v, 23:77, 19:81, 26:74, or 16:84, respectively). The conditions above were showed in Table 2.

Results and discussion

Optimization of transglycosylation conditions of the β-galactosidase toward steroidal saponins using compound F as an acceptor

Compound F was found to be glycosylated by the β-galactosidase from L.bulgaricus L3. It was selected as an acceptor of steroidal saponin to investigate the optimal transglycosylation conditions of the enzyme. Figure 1a showed that the enzyme activity was decreased at pH higher or lower than 7, which meant that the optimum pH was 7. The temperature-related activity curve showed that the optimum temperature was 45 °C, and the activity was lower than 60 % of the maximum activity when the temperature was below 30 °C (Fig. 1b). The time course of the enzyme was studied by measuring the production of the predominant product: the maximum yield of the product was achieved at 30 h, but after 30 h yield was decreased. The optimum reaction time was found to be 30 h (Fig. 1c).

Acceptor specificity of the β-galactosidase on various steroidal saponins

The galactosylation of nine furostanosides (the F ring was open with 26-O-glucosyl, such as compound A-I) and eight spirostanosides (the F ring was closed) were investigated by using β-galactosidase from L.bulgaricus L3 as a catalyst. Through the detection by UPLC-MS (ultra high-performance liquid chromatography and hybrid time-of-flight mass spectrometry), it showed that none of the spirostanosides was converted, but all of the furostanosides were transformed into novel products with a molecular weight of at least 162 Da or more (Fig. 2). However, for most of furostanoside transformation products, only one product was predominant. The structures of these furostanoside substrates were different: some of them had the same aglycone unit but different sugar chains at C-3; some of them had different aglycone units but could also be converted by enzyme. For example, the structures of compound G, I, H and compound F were different except they were all furostanosides with a C-26-sugar chain, but all of them could be converted by enzyme. Therefore, it can be inferred that the galactosylation position was at C-26-O-sugar chain. And the composition of C-3 sugar chain may affect the quantity of the galactosylated products, there was only one product in the biotransformation products of compound D, E with a terminal (1 → 4) rhamnose moiety but two products in the biotransformation products of compound C with a terminal (1 → 2) rhamnose moiety. The substrates with shorter or no sugar chain at C-3 position (compound A, F, H, I) were converted to more galactosylated products than the substrates with long sugar chain at C-3 position (compound B, E, G). Through the results above (showed in Fig. 2), it was confirmed that the galactosyl moiety was preferred to be added to C-26-sugar chain, and the C-3 sugar chain may affect the quantity of galactosylated site of the substrate. Considering the structure of every substrate, four substrates (compound F, compound G, compound I and compound H) with different aglycone units and C-3 sugar chains, were chosen for large-scale transglycosylation study to obtain the products and thereby confirm the exactly galactosylation position.

Purification and structural identification of the transglycosylation products

For each transformation product of compound F, compound G, compound I, and compound H, only one product peak could be seen in HPLC (high-performance liquid chromatography)-ELSD (evaporative light scattering detector) (Fig. 3), while more product peaks were found in UPLC-MS (Fig. 2). It was because the sensitivity of MS was much higher than that of ELSD, but the response of ELSD was more positively correlated to the quality of compound. It indicated that β-galactosidase had considerable selectivity in the galactosylation of furostanosides. The yields of the products were different due to different structures of their substrates.

After the preparation and purification, four galactosylation products (compounds 1–4) of compound F, compound G, compound I, and compound H were obtained in 52, 27.4, 14.5, and 9.7 mg, respectively, and their corresponding yields were 10.4, 9.2, 24.2 and 16.2 %. The structure of compound 1 was identified by HR-ESI-MS, 1D and 2D NMR spectra, and the structures of other three compounds (2–4) were identified by HR-ESI-MS, 1D NMR spectra and the comparison with the NMR data of compound 1.

The Liebermann–Burchard and Ehrlich reagent tests for compounds 1–4 were positive, which indicated that they were furostanosides.

Compound 1 was a white amorphous powder. Its molecular formula C51H86O24 was determined by HR-ESI-MS ion [M + K]+ at m/z 1121.5226 (calcd for C51H86O24K, 1121.5146) (Fig. 4). The HR-ESI-MS ion peaks at m/z 1065.5444 [M + H–H2O]+, 903.4923 [M + H–H2O–162]+, 741.4410 [M + H–H2O–162 × 2]+, 579.3846 [M + H–H2O–162 × 3]+, and 417.3340 [M + H–H2O–162 × 4]+ indicated that it was a compound F -glycosylation-derivative. One more hexose in 1 was confirmed by the anomeric H-atom signal at δ 5.03 besides the three anomeric H-atom signals of compound F at δ 4.91, δ 5.27and δ 4.70 in 1H NMR. 1 had almost identical structure with compound F [26] except for the sugar chain at C-26 by comparing their 13C NMR data, which suggested that the hexose was attached at the 26-O-glucosyl of BII. All proton signals were delineated based on the anomeric proton of the sugar unit by analyzing the 1H-1H COSY spectrum, and then the carbon signals were assigned through the analysis of cross-peaks in the HSQC spectrum. Thus, the proton and carbon signals of the glucose and galacose of C-26 sugar chain of 1 were fully assigned. By combined analysis of the 1H-NMR, 13C-NMR, HSQC, 1H-1H COSY, and HMBC, all their proton and carbon signals were assigned as shown in Table 3. In HMBC spectrum, the correlation between δ 5.03 (H-1′′′′) and δ 70.1 (C-6′′′) suggested the galatosyl was attached at 6-OH of the C-26 sugar chain. Therefore, the structure of 1 was determined as 26-O-β-D-galactopyranosyl-(1 → 6)-β-D-glucopyranosyl-(25S)-5β-furost-3β, 22α, 26-triol- 3-O-β-D-glucopyranosyl-(1 → 2)-β-D-galacotopyranoside.

Compound 2 was obtained as a white amorphous powder. It showed a molecular formula of C62H102O34 corresponding to an [M + K]+ ion peak at m/z 1429.5918 in the HR-ESI-MS (calcd for C62H102O34K, 1429.5890) (Fig. 4). The fraction ion peaks at m/z 1373.6229 [M + H–H2O]+, 1211.5663 [M + H–H2O–162]+, 1079.5201 [M + H–H2O–162–132]+, 917.4653 [M + H–H2O–162–132–162]+, 755.4108 [M + H–H2O–162–132–162 × 2]+, 593.3661 [M + H–H2O–162–132–162 × 3]+, and 431.3120 [M + H–H2O–162–132–162 × 4]+ indicated that 2 had one more hexose than its substrate compound G. 2 had the same structure units of aglycone and sugar chain at C-3 as compound G [27], but significant differences in the signals from sugar chain at C-26 by comparing their carbon signals. However, the structure of sugar chain at C-26 was identified as the same as 1 by comparing their 13C-NMR data (Table 3). Accordingly, the structure of 2 was identified as 26-O-β-D-galactopyranosyl-(1 → 6)-β-D-glucopyranosyl-(25S)-5α-furost-3β, 22α, 26-triol-12-one-3-O-β-D-glucopyranosyl-(1 → 2)-[O-β-D-xylopyranosyl-(1 → 3)]-β-D-glucopyranosyl-(1 → 4)-β-D-galacotopyranoside.

Compound 3 was obtained as a white amorphous powder. It showed a molecular formula of C39H60O15 corresponding to an [M + K]+ ion peak at m/z 807.3558 in the HR-ESI-MS (calcd for C39H60O15K, 807.3569) (Fig. 4). The characteristic fraction ion peaks at m/z 751.3909 [M + H–H2O]+, 589.3388 [M + H–H2O–162]+, and 427.2852 [M + H–H2O–162 × 2]+ showed one more hexose was existed in 3 than the substrate compound I. By comparing the 13C NMR data of 3 (Table 3) with that of compound I [28], both of them have the same aglycone structure except the C-26 sugar chain. The C-26 sugar chain data of 3 was the same as that of 1 (Table 3). The result indicated that the structure of 3 was 26-O-β-D-galactopyranosyl-(1 → 6)-β-D-glucopyranosyl-(25R)-furost-4-en-22α, 26-diol-3, 12-dione.

Compound 4 was obtained as a white amorphous powder. The HR-ESI-MS of 4 exhibited the [M + K]+ ion peak at m/z 877.3822 (calcd for C39H66O19K, 877.3835) (Fig. 4), which is consistent with the molecular formula C39H66O19. The characteristic fragment ion peaks at m/z 821.4182 [M + H–H2O]+, 659.3668 [M + H–H2O–162]+, and 497.3153 [M + H–H2O–162 × 2]+, and the 13C NMR data (Table 3) comparison with its substrates compound H (supplementary file) and 1 further confirmed that the galactosyl moiety was added to the C6-OH of C-26-glucosyl. Thus, the structure of 4 was elucidated as 26-O-β-D-galactopyranosyl-(1 → 6)-β-D-glucopyranosyl-(25R)-furost-1β, 2β, 3β, 4β, 5β, 6β, 22α, 26-octanol.

All of the transformation products in UPLC-MS showed that there was one predominant product. Thus, the structures of four predominant products (1–4) were identified by the methods of HR-ESI-MS and NMR. Compounds 1–4 were identified as new compounds. The structures of compounds 1–4 indicated that the galactosylation position of the predominant product in each transformation product was at 6-OH of 26-O-glucosyl of the substrate. It suggested that in this galactosylation study, the galactosyl moiety was preferred to being added to the 6-OH of the 26-O-glucosyl by β-galactosidase from L. bulgaricus L3.

Up to now the glycosylation by glycosyltransferase could not be scaled-up because of the source of enzyme and the activated sugar donor. β-galactosidase was a common enzyme, and lactose, which was common and cheap, was used as non-activated sugar donor in this study. And galactosylation of steroidal saponins was firstly investigated, which provide a new method to glycosylation.

Conclusion

This paper provided a novel enzymatic method for the glycosylation of steroidal saponins. The reaction was processed in only one convenient step through the β-galactosidase from L. bulgaricus L3, which utilized cheap lactose as donor substrate in the presence of the steroidal saponins as acceptors. All of the tested furostanosides could be glycosylated by the enzyme. Among them, four kinds of galactosyl moiety derivatives were purified and identified to be novel compounds. Since steroidal saponins with different sugar chains always have different pharmacological activities, the galactosylation of steroidal saponins may offer a new way to generate the compounds with novel or improved properties.

References

Fu, Y.L., Yu, Z.Y., Tang, X.M., Zhao, Y., Yuan, X.L., Wang, S., Ma, B.P., Cong, Y.W.: Pennogenin glycosides with spirostanol structure are strong platelet agonists: structural requirement for activity and mode of platelet agonist synergism. J. Thromb. Haemost. 6, 524–533 (2008)

Zhao, Y., Kang, L.P., Liu, Y.X., Liang, Y.G., Tan, D.W., Yu, Z.Y., Cong, Y.W., Ma, B.P.: Steroidal Saponins from the Rhizome of Paris polyphylla and their cytotoxic activities. Planta Med. 75, 356–362 (2009)

Li, T.J., Qiu, Y., Yang, P.Y., Rui, Y.C., Chen, W.S.: Timosaponin B-II improves memory and learning dysfunction induced by cerebral ischemia in rats. Neurosci. Lett. 421, 147–151 (2007)

Desmet, T., Soetaert, W., Bojarová, P., Křen, V., Dijkhuizen, L., Eastwick-Field, V., Schiller, A.: Enzymatic glycosylation of small molecules: challenging substrates require tailored catalysts. Chem. Eur. J. 18, 10786–10801 (2012)

Crout, D.H.G., MacManus, D.A., Critchley, P.: Stereoselective galactosyl transfer to cis-cyclohexa-3, 5-diene-1, 2-diol. J. Chem. Soc. Chem. Commun. 6, 376–378 (1991)

Park, A.R., Oh, D.K.: Galacto-oligosaccharide production using microbial β-galactosidase: current state and perspectives. Appl. Microbiol. Biotechnol. 85, 1279–1286 (2010)

Oliveira, C., Guimarães, P.M., Domingues, L.: Recombinant microbial systems for improved β-galactosidase production and biotechnological applications. Biotechnol. Adv. 29, 600–609 (2011)

Crout, D.H.G., MacManus, D.A., Critchley, P.: Enzymatic synthesis of glycosides using the β-galactosidase of Escherichia coli: regio-and stereo-chemical studies. J. Chem. Soc. Perkin Trans. 1(7), 1865–1868 (1990)

Gais, H.J., Zeissler, A., Maidonis, P.: Diastereoselective D-galactopyranosyl transfer to meso diols catalyzed by β-galactosidases. Tetrahedron Lett. 29, 5743–5744 (1988)

Van Rantwijk, F., Woudenberg-van Oosterom, M., Sheldon, R.A.: Glycosidase-catalysed synthesis of alkyl glycosides. J. Mol. Catal. B Enzym. 6, 511–532 (1999)

Yang, Y.B., Wang, M., Liang, Y., Liang, J.Y.: Transgalactosylation of isotaxiresinol by beta-galactosidase. J. China. Pharmaceut. Univers. 33, 526–528 (2002)

Shimizu, R., Shimabayashi, H., Moriwaki, M.: Enzymatic production of highly soluble myricitrin glycosides using β-galactosidase. Biosci. Biotechnol. Biochem. 70, 940–948 (2006)

Kim, G.E., Lee, J.H., Jung, S.H., Seo, E.S., Jin, S.D., Kim, G.J., Cha, J., Kim, E.J., Park, K.D., Kim, D.: Enzymatic synthesis and characterization of hydroquinone galactoside using Kluyveromyces lactis lactase. J. Agric. Food Chem. 58, 9492–9497 (2010)

Fang, Y., Xu, W., Wu, J., Xu, Z.K.: Enzymatic transglycosylation of PEG brushes by β-galactosidase. Chem. Commun. 48, 11208–11210 (2012)

Lu, L.L., Xu, S.Z., Jin, L., Zhang, D.Y., Li, Y.M., Xiao, M.: Synthesis of galactosyl sucralose by β-galactosidase from Lactobacillus bulgaricus L3. Food Chem. 134, 269–275 (2012)

Majumder, A.B., Singh, B., Gupta, M.N.: Diastereoselective synthesis of (R)-(alkyl)-β-d-galactopyranoside by using β-galactosidase (Aspergillus oryzae) in low-water media. Bioorg. Med. Chem. Lett. 18, 124–128 (2008)

Takayama, S., Shimazaki, M., Qiao, L., Wong, C.H.: Synthesis of lactosamine derivatives usingβ-galactosidase from Bacillus circulans. Bioorg. Med. Chem. Lett. 6, 1123–1126 (1996)

Ismail, A., Linder, M., Ghoul, M.: Optimization of butylgalactoside synthesis by β-galactosidase from Aspergillus oryzae. Enzym. Microb. Technol. 25, 208–213 (1999)

Santiago, R.D., Fernández-Mayoralas, A., García-Junceda, E.: Enzymatic synthesis of disaccharides by β-galactosidase-catalyzed glycosylation of a glycocluster. J. Mol. Catal. B Enzym. 11, 71–79 (2000)

Giacomini, C., Irazoqui, G., Gonzalez, P., Batista-Viera, F., Brena, M.B.: Enzymatic synthesis of galactosyl–xylose by Aspergillusoryzae β-galactosidase. J. Mol. Catal. B Enzym. 159, 19–20 (2002)

Nakano, H., Shizuma, M., Murakami, H., Kiryu, T., Kiso, T.: One-pot synthesis of glycosyl poly (arbutin) by enzymatic glycosylation followed by polymerization with peroxidase. J. Mol. Catal. B Enzym. 33, 1–8 (2005)

Wang, Y.Z., Feng, B., Huang, H.Z., Kang, L.P., Cong, Y., Zhou, W.B., Zou, P., Cong, Y.W., Song, X.B., Ma, B.P.: Glucosylation of steroidal saponins by syclodextrin glucanotransferase. Planta Med. 76, 1–8 (2010)

Zhou, W.B., Feng, B., Huang, H.Z., Qin, Y.J., Wang, Y.Z., Kang, L.P., Zhao, Y., Wang, X.N., Cai, Y., Tan, D.W., Ma, B.P.: Enzymatic synthesis of α-glucosyl-timosaponin BII catalyzed by the extremely thermophilic enzyme: Toruzyme 3.0 L. Carbohydr. Res. 345, 1752–1759 (2010)

Lu, L.L., Gu, G.F., Xiao, M., Wang, F.S.: Separation and structure analysis of trisaccharide isomers produced from lactose by Lactobacillus bulgaricus L3 β-galactosidase. Food Chem. 121, 1283–1288 (2010)

Lu, L.L., Xu, S.Z., Zhao, R.F., Zhang, D.Y., Li, Z.Y., Li, Y.M., Xiao, M.: Synthesis of galactooligosaccharides by CBD fusion β-galactosidase immobilized on cellulose. Bioresour. Technol. 116, 327–333 (2012)

Ma, B.P., Dong, J.X., Wang, B.J., Yan, X.Z.: New Spirostanol Glycosides from Anemarrhena asphodeloides. Acta Pharm. Sin. 31, 271–277 (1996)

Jin, J.M., Zhang, Y.J., Yang, C.R.: Spirostanol and furostanol glycosides from the fresh tubers of Polianthes tuberosa. J. Nat. Prod. 67, 5–9 (2004)

Kang, L.P., Wu, K.L., Yu, H.S., Pang, X., Liu, J., Han, L.F., Zhang, J., Zhao, Y., Xiong, C.Q., Song, X.B., Liu, C., Cong, Y.W., Ma, B.P.: Steroidal saponins from Tribulus terrestris. Phytochemistry 107, 182–189 (2014)

Acknowledgments

This project is supported by the National Natural Science Foundation of China (No. 30973632) and Major State Basic Research Development Program of China (973 Program) (No. 2012CB822102).

Author information

Authors and Affiliations

Corresponding authors

Additional information

Jie Zhang and Lili Lu are co-first author

Rights and permissions

About this article

Cite this article

Zhang, J., Lu, L., Lu, L. et al. Galactosylation of steroidal saponins by β-galactosidase from Lactobacillus bulgaricus L3. Glycoconj J 33, 53–62 (2016). https://doi.org/10.1007/s10719-015-9632-4

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10719-015-9632-4