Abstract

One of the most important stages in the design and construction of underground spaces is the evaluation of ground conditions and the risks of tunneling, and in particular the squeezing potential of rock mass. Generally, tunneling is difficult and time-consuming under squeezing conditions. For this reason, it is very important to identify and estimate the squeezing conditions of rock mass in selecting a suitable excavation method and proper support system. In this study, the squeezing conditions of rock mass are investigated in the Kerman water conveyance tunnel. This tunnel transfers water from the Safa river dam to Kerman city for supply of drinking water. Firstly, geological zones, characteristics of rock mass, intact rock and classification of rock mass are presented and then, the estimation of the squeezing potential along Kerman water conveyance tunnel is investigated. Estimating of this phenomenon was done using empirical, semi-empirical, analytical theory approaches and a new probabilistic method called the Bayesian network. The results showed that the tunneling has a squeezing problem, especially in the ET-21 zone, which is due to the existence of the tectonic and faulted area along with weak rock properties.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Time-dependent large displacement, occurring around the tunnel and other underground spaces, is generally defined as squeezing in rock mass (Barla 1995). The Squeezing phenomenon happens during a tunneling in rock and is essentially associated with creep caused by exceeding a limiting shear stress. Deformation may terminate during construction or continue over a long time period. Squeezing problems are particularly common in relatively deep tunnels in weak rocks. However, significant convergences can also occur in shallow tunnels within very weak or over-stressed rock masses due to effects of tectonic or topographic (Shrestha and Broch 2008; Hudson 2009; Hoek and Marinos 2010). In addition, significant time-dependent behavior and squeezing is also observed in some cases (Malan 1998, 1999). Squeezing is a unique problem faced by rock engineers while tunnels excavated through rock masses of very poor quality under high rock cover. Squeezing in rock occurs mainly in marl, argillaceous and phyllitic schist, and materials containing considerable amount of clay or mica such as fault shales (Shalabi 2005).

Tunneling under squeezing rock conditions often imposes high costs and long delays. Therefore, analysis and recognition of squeezing potential before the commencement of the project is very important for planning time, cost, and selecting a suitable excavation method and support system to reduce the adverse effects on the project (Barla 2001). The effects of rock squeezing, as the redistribution of stress and deformation in a plastic zone around a deep tunnel, were first identified by Wiesmann (1912) during the construction of the Simplon tunnel in Switzerland.

Many researchers attempted to evaluate ground squeezing using different approaches (Ghaboussi and Gioda 1977; Gioda 1981; Sulem et al. 1987; Pan and Dong 1991; Deere et al. 1969; Aydan et al. 1993). Terzaghi (1946) and Deere et al. (1969) used rock mass classification system (empirical approach) to predict rock load. Then, Semple et al. (1973) carried out the experimental approach to evaluate the soil creep parameters. Kallhawy (1974) and Ghaboussi and Gioda (1977) implemented the analytical approach to assess ground squeezing by using different creep models. Also, Mesri et al. (1981) by performing experimental tests on soil samples, evaluated soil creep. Jethwa et al. (1984), Singh et al. (1992, 2002) and Hoek and Marinos (2000) proposed several methods to “quantify” squeezing potential based on the concept of comparing the rock mass strength with the induced stress. Aydan et al. (1993) and Singh et al. (2007) stated a slightly modified approach by which they compare the strains to define squeezing potential. The magnitude of the tunnel convergence is related to rock load (height of rock load), and the rate of deformation depend largely upon geological conditions, in situ stress, ground water condition, and geotechnical properties of rock mass. Recently, the squeezing phenomenon was addressed and extensively investigated (Singh et al. 2007; Hasanpour et al. 2014; Agan 2016; Saeed and Maarefvand 2014; Farrokh et al. 2006; Hoek and Guevara 2009; Asghar et al. 2017; Ajalloeian et al. 2017; Khanlari et al. 2012).

In this research, the squeezing potential of the Kerman water conveyance tunnel, which is the largest water transfer tunnel in the Middle East, were studied. This tunnel is 38 km long and transfer water from Safarood dam in the city of Rabor to the center of Kerman province. Due to the necessity of implementation of the tunnel and the presence of several of the faults in the tunnel route, the evaluation of the squeezing condition during the tunnel is essential. Ultimately, the squeezing potential in critical geological units is estimated using the methods presented in this study.

2 Project Description and Geology of Kerman Water Conveyance Tunnel

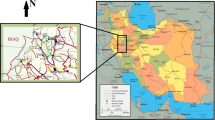

The Kerman water conveyance tunnel, located in southeast of Iran. This tunnel provides a part of requirement water of Kerman city. This study reflects the findings of the 38 km long tunnel that constructed by the TBM. The geometry of the tunnel shape is circular and the maximum overburden point of this tunnel is 940 m in the central area of the tunnel route. The parameters of tunnel properties have been shown in Table 1. The geological study includes the field and laboratory investigations. Based on the results, the tunnel alignment of lot1 and lot2 was divided 21 lithology types. This paper presents the geological study of the lot1 that was critical.

2.1 Geology of Tunnel

Based on the results of the samples and boreholes carried out, the tunnel path passes through collection of sedimentary rocks consisting of sandstone and limestone, and volcanic rocks which are also composed of volcanic lavas, tuff and volcanic ash along with symbolic combination of diorite to granite and granodiorite as shown in Fig. 1.

The investigation of the types of lithology in the tunnel route of lot 1 and lot 2 was carried out. According to geological and geotechnical investigation (borehole, core logging and laboratory testing), the rock mass has been identified to consist of 21 lithography types in both lot1 and lot2. The types of lithology identified are shown in Fig. 1. The boundaries of types of lithography are according to the stratigraphy and in many cases for the geomechanical features; the lithography was the main factor in separation and classification (Fig. 2).

Considering previous studies (Saeed and Maarefvand 2014) and field surveys in the study area, there are several major and minor faults in this complex region, which mainly have east–west and northwest-southeast trend. In the tunnel path, seven main faults and a number of sub-faults was identified. Main faults include Madehkuh fault, Sarzeh fault, and Lalehzar fault. These faults created crushed zones around them with different thicknesses. The crushed zones along with the weak rock mass, indicated major problems in the excavation process. These problems include falling rock and water flow into the tunnel.

3 Engineering Geology

In the Kerman project, various investigations were carried out at different periods of time for estimation of intact rock and rock mass characteristic, rock mass classification, and assessment of geological hazards.

To complete the engineering geological studies and create a connection between surficial studies and condition of rock masses in the tunnel depth, 16 boreholes were drilled. To estimate the geotechnical parameters of intact rock and rock mass, laboratory and field tests such as triaxial and uniaxial compressive strength, direct shear, Brazilian and point load tests, in situ permeability, and Schmidt hammer tests were carried out. The geological formations outcropped in the project area mainly consist of sandstone and limestone with layers of interbedded igneous rocks such as diorite to granite and granodiorite. Four types of rock masses were critical along the tunnel alignment:

-

Type 1: Lithology is mainly Granite and Andesite and Scarce Ignimbrite with blocky to Massive structure (rock symbol is ET-10).

-

Type 2: Poorly lithified Sandstone and Conglomerate are dominant rock type which their Structure were Blocky (rock symbol is ET-11).

-

Type 3: Lithified sandstone and Conglomerate and Massive to blocky are Lithology and Structure, respectively (rock symbol is ET-12).

-

Type 4: Fault zone which has laminated to very blocky structure (rock symbol is ET-21).

Overall, the rock masses of ET-21 zone are strongly faulted and mixed. Obviously, the study of the structural features and discontinuities within the rock mass can have an important effect on the rock. As shown in Table 2, quantitative description of rock discontinuities, e.g. persistence, orientation and spacing were carried out according to the suggested method of ISRM (Brown 1981). For this aim, the scan-line survey method of the ISRM (Brown 1981) description criteria was applied. It should be noted that the depth and position of the tunnel are below ground water level.

3.1 Rock Mass Classification

Some rock mass classifications such as Rock Quality Designation (RQD), Rock Mass Rating (RMR), Quality system (Q), Geological Strength Index (GSI) have been performed on the engineering geological units of the Kerman water conveyance tunnel. The rock mass properties were determined using result of these systems. RMR system was initially developed by Bieniawski (1974) on the basis of his experiences in shallow tunnels also the version 1989 of RMR (Bieniawski 1989) has been presented. The GSI, is a new rock mass classification system that was developed by Hoek (1994). The Q-system was developed as a rock tunneling quality index by the Norwegian Geotechnical Institute (NGI) (Barton et al. 1974) and the last update was released in 2004.

As shown in Table 3, values of rock mass classifications (RQD, Q, RMR, and GSI) show that faulted zone have a lower quality compared to other formations. Based on Q and RMR classifications, the faulted zone classify into poor and very poor classes.

4 Evaluation of Squeezing Phenomena

To determine the squeezing conditions and the potential of this phenomenon, several qualitative and quantitative methods such as empirical, semi-empirical, and theoretical–analytical are presented by researchers. Beside these methods, probabilistic method of Bayesian network also have been proposed.

The empirical methods are based on the rock mass classification system. The two main approaches of these methods are proposed by Singh et al. (1992) and Goel et al. (1995). In the semi-empirical methods, the expected deformation of the tunnel is defined in a hydrostatic stress field. The common starting point to quantify the squeezing potential of the rock in this method is the use of ‘‘competency factor’’ defined as the ratio of uniaxial compressive strength rc/rcm, of rock/rock mass to the overburden stress, cH. Three common semi-empirical methods are Jethwa et al. (1984), Aydan et al. (1993) and Hoek and Marinos (2000) approaches (Barla 2001; Singh et al. 2007). Theoretical–analytical method is based on the strength and deformation parameters of the rock mass. In this method, recognition of the rock stress–strain behavior is necessary. The two major methods in this group are Barla (1995) and ISRM approaches (Singh and Goel 1999).

4.1 Empirical Approach

In empirical methods, the analysis is purely based on experience and comparison. Various types of empirical approaches have been proposed by different authors for the assessment of the potential squeezing phenomenon. Depending on the indicators used, the approaches can be grouped into the following three categories:

-

(a)

Strength-stress ratio approach

-

(b)

Strain estimation approach; and

-

(c)

Rock mass classification approach.

Singh et al. (1992) approach is based on 39 case studies, in which data on rock mass quality (Q) and overburden (H) are collected and then, the following equation is used for predicting squeezing conditions:

where H is overburden (m) and Q is rock mass quality. For squeezing condition:

Goel et al. (1995) have proposed the following simple empirical approach, which is based on the rock mass number (Qn):

where H is overburden (m) and B is tunnel span or diameter (m). For squeezing condition: \(\text{H} \gg (275\,\text{N}^{0.33} )\text{B}^{ - 0.1}\).

In this approach, different squeezing behaviors of the rock mass are classified in five categories including self-supporting, non-squeezing, mild squeezing, moderate squeezing, and high squeezing. The limit between squeezing and non-squeezing conditions obtained when H less than \((275\,\text{N}^{0.33} )\;\text{B}^{ - 0.1}\) (Barla 2001; Singh and Goel 1999). Table 4 shows the evaluated squeezing conditions of rock masses according to Singh et al. (1992) approach. As can be seen, all zones except ET-12, have the potential of squeezing. Table 5 shows the results of the squeezing potential evaluation of the rock masses in Kerman water conveyance tunnel based on Goel et al. (1995) approach. As shown in the table, according to the critical height of overburden, the squeezing potential for all zones have predictable.

4.2 Semi-empirical Methods

The most popular semi-analytical approaches used for the analysis of a tunnel squeezing phenomenon are proposed by Jethwa et al. (1984), Aydan et al. (1993) and Hoek and Marinos (2000). These approaches are described and used for the analysis of the present work.

The semi-empirical approaches illustrated for predicting squeezing. However, they also provide some tools for estimating the expected deformation around the tunnel by using closed-form analytical solutions for a circular tunnel in a hydrostatic stress field. The common starting point of all these methods for quantifying the squeezing potential of rock is the use of the ‘‘competency factor’’, which is defined as the ratio of the uniaxial compressive strength of rock/rock mass to overburden stress.

4.2.1 Jethwa et al

Jethwa et al. (1984) defined Eq. 4 for determining the degree of squeezing on the basis of rock mass uniaxial compressive strength and a tunnel depth below the earth surface:

where \(\upsigma_{{\text{cm}}}\) is rock mass uniaxial compressive strength, \(\text{P}_{0}\) is in situ stress, \(\upgamma\) is rock mass unit weight, and H is tunnel overburden.

The classifications of squeezing potential according to Jethwa et al. (1984) approach are given in Tables 6 and 7.

4.2.2 Aydan et al

Aydan et al. (1993) approach suggested a method based on the experiences obtained from Japanese tunnels. These researchers proposed a relationship between the strength of the intact rock (\(\upsigma_{{\text{ci}}}\)) and the overburden pressure (\({\upgamma}{\text{H}}\)), assuming that the uniaxial compressive strength of the intact rock (\(\upsigma_{{\text{ci}}}\)) and of the rock mass (\(\upsigma_{{\text{cm}}}\)) are the same. The normalized strain levels, \(\eta_{p}\), \(\eta_{s}\), and \(\eta_{f}\) are defined by the following equations:

where \(\upvarepsilon_{\text{p}}\), \(\upvarepsilon_{\text{s}}\) and \(\upvarepsilon_{\text{f}}\) are the strain values after yield point and \(\upvarepsilon_{\text{e}}\) is the elastic strain limit obtained from the laboratory tests. Based on a closed-form analytical solution, they developed for computing the strain level \(\upvarepsilon_{\uptheta}^{\text{e}}\) around a circular tunnel in a hydrostatic stress field. Aydan et al. (1993) proposed five different degrees of squeezing behaviors (Table 8). Table 9 shows the results of evaluation of Kerman water conveyance tunnel squeezing conditions based on this method. At the beginning, the values of parameters \(\eta_{p}\), \(\eta_{s}\), \(\eta_{f}\), \(\upvarepsilon_{\uptheta}^{\text{e}}\) and \(\upvarepsilon_{\uptheta}^{\text{a}}\) were calculated in each zone and then the squeezing potential was evaluated. Results of the evaluations show that the rock mass of ET-21 has very heavy squeezing condition (VHS) and for other zones squeezing potential not predicted.

4.2.3 Hoek and Marinos

Hoek and Marinos (2000) used the ratio of the rock mass uniaxial compressive strength \(\upsigma_{{\text{cm}}}\) to the in situ stress \(\text{p}_{0}\) as an indicator of potential of tunnel squeezing problem. In particular, Hoek and Marinos (2000) by studying a number of tunnels in Venezuela, Taiwan, and India, proposed the Eq. 7. This equation can be used for assessment of tunneling problems under squeezing conditions. According to this equation, for the case which tunnel strain (%) is equal or less than 1, no squeezing occurs.

where \(\upvarepsilon_{\text{t}}\) is the tunnel strain in percentage, \(\text{P}_{\text{i}}\) is the support pressure (MPa), \(\upsigma_{{\text{cm}}}\) is the rock mass uniaxial compressive strength (MPa) and \(\text{P}_{0}\) is the in situ stress (MPa).

Table 11 represents the results of the squeezing evaluation according to this method. According to results of Hoek and Marinos approach (Table 10), three parts of the tunnel length are under the non-squeezing condition and only 3.1% of the ET-21 section are posed to severe squeezing conditions.

Under these conditions, re-excavation of the tunnel and heavy support installation are necessary (Table 11).

In this method, the tunnel strain is calculated for \(\text{P}_{\text{i}} = 0\). The method also shows that the ET-21 zone has very severe squeezing behavior. Experiences show that the ratio of a tunnel wall deformation to tunnel radius should kept constant (about 2%), to prevent serious instability (Hoek 2007). In order to obtain the required maintenance for the controlled axial strain in the tunnel wall at the critical region, a graph has been provided (Fig. 3). This graph is plotted using the Hoek–Marinos equation and putting various support pressures and gains in proportion to the axial strain. Based on this graph, minimum support pressure necessary to keep the ratio of wall deformation to tunnel radius less than 2% is 6.3 MPa.

4.3 Theoretical–Analytical Approach

Theoretically, the squeezing condition around a tunnel opening is encountered when tangential stress is bigger than rock strength. Barton et al. (1974) suggest that the ratio of maximum tangential stress (calculated from elastic theory) to unconfined compression strength (\(\upsigma_{\uptheta} /\upsigma_{\text{c}}\)) can be used to define squeezing rock pressure. Singh et al. (1992) suggest that a necessary condition for squeezing rock conditions is (Eq. 8):

where \(\upsigma_{\uptheta}\) is the tangential stress and \(\text{q}_{\text{c}}\) is the uniaxial crushing strength of the rock mass.

4.3.1 Barla Approach

Barla (1995), by working on case studies of various tunnels in Venezuela, Taiwan, and India, suggested Eq. 9 and a classification for squeezing behavior (Table 12)

where \(\upsigma_{{\text{cm}}}\) is rock mass uniaxial compressive strength, \(\text{P}_{0}\) is in situ stress.

Evaluation of squeezing behavior according to Barla (1995) is shown in Table 13. Barla’s results show that ET-10, ET-11 and ET-12 are under mild-squeezing conditions and ET-21 is under High-squeezing condition.

4.3.2 ISRM Approach

ISRM suggested Eq. 6 and classifies squeezing rock condition as shown in Table 12. ISRM’s results of the squeezing evaluation of the Kerman water conveyance tunnel are presented in Table 13. As shown in the table, ET-10, ET-11, ET-12 and ET-21 are under High-squeezing condition.

According to both methods, all zones have squeezing conditions, but these conditions are more severe for ET-21 compared to other zones. In these rock masses, the predicted squeezing degrees of Barla approach are less than the values predicted by ISRM.

4.4 Bayesian Networks Method

In this research, the phenomenon of squeezing was assessed by Bayesian networks (BNs). BNs were introduced by Pearl (1985) to more easily deal with conditional dependency relationships between the (observable or unobservable) random variables of a statistical model, and they have been shown to have advantages to deal with inference, classification, and decision making problems (Aguilera et al. 2011). Recently, this method has been used in civil engineering and geotechnical applications (Landuyt et al. 2013; Cain et al. 2003; Batchelor and Cain 1999; Jimenez-Rodriguez and Sitar 2006; Huang et al. 2012; Medina-Cetina and Nadim 2008; Song et al. 2012; Schubert et al. 2012; Peng et al. 2014; Zhang et al. 2011; Sousa and Einstein 2012).

Five main parameters that might influence on squeezing phenomenon are identified: tunnel depth (H), Rock Tunneling Quality Index (Q), tunnel span or diameter (B or D), support stiffness (K), and stress strength ratio (SSR). According to research that conducted by Feng and Jimenez (2015), it can be noted that the error rate of the BN, approximately 9.64%, which is considered acceptable for practical engineering and which, in any case, is lower than error rates computed with other traditional methods (Fig. 4).

Error rate in different methods of evaluating the squeezing phenomenon (Feng and Jimenez 2015)

Table 14 includes the conditional probability tables for all parameters. This table shows the qualitative values of each parameter along with their quantitative values.

The network property vector is defined in which the values indicate the probability of each parameter being discussed. By inserting the qualitative values obtained from Table 14 in Table 15, the probability of each parameter obtained with regarding to the possibility of occurrence or non-occurrence of fracturing. By placing in Eq. 11, it is possible to calculate the probability of occurrence of the squeezing phenomenon in the considered project (Singh et al. 2007).

For instance, an example is given to learn how to use Eq. 11 for the ET-10 zone. In this geological zone the values of the parameters are: Q = 11 (average), H = 900–1000 (very deep), SSR = 0.35 (low), D = 5.27 (small) and K = 318 MPa (moderate).

By placing in Eq. 11, the probability of occurrence of squeezing is obtained in the form of a relation.

According to the results, the probability of squeezing for the ET-10 region is 80%, which indicates a high probability for the occurrence of this phenomenon. Table 16 shows the probability of squeezing for each zone. As can be seen, for the ET-10 and ET-21 zones, a high percentage of squeezing is estimated.

5 Result and Discussion

Knowledge of earth conditions, both geologically and geotechnically is one of the most important parameters in choosing the method of excavation and designing a support system for underground spaces. In general, a tunnel has a tendency toward squeezing condition when it is excavated in a rock mass with weak properties or faulted zone and with a high overburden. Therefore, due to the fact that the Kerman water conveyance tunnel passes through several numbers of faults with a high overburden, the squeezing condition is investigated using different methods, which is presented in Table 17. By examining various empirical, semi-empirical and theoretical–analytical methods, along with the BN method, possibility of squeezing occurrence acquired in 4 geological zones. By converting qualitative outputs to quantitative, comparisons of methods and condition of squeezing zones have been investigated. According to Table 17, the probability of occurrence of squeezing in each geological zone can be obtained by assigning the probable percentage to each the outputs according to the scouring state in each method. By converting the probability of the output data from Table 17 to Fig. 4, it is possible to analyze the prediction methods of the squeezing phenomenon. On each side of the graph, various methods of squeezing prediction have been named, and the values written from the center toward the polygon environment which shows the probability of occurrence of the squeezing phenomenon. The graph of each geologic region shows a closed graph, which increases the probability of occurrence of squeezing phenomena in that area as much as it is closer to the polygonal environment or, in other words, has more area. Therefore, the probability of occurrence of squeezing phenomena is high in the two regions of ET-21 and ET-10, respectively. The convergence rate of the tunnel environment cannot be properly achieved prior to an operation of tunneling. Regarding to the Hoek-Marinos method, input parameters are obtained through in situ tests, in this state, determining the tunnel deformation using this method can be determined correctly. The deformation of the tunnel wall in the most critical zone, regardless of the support system, was found to be more than 6%, indicating that there is a serious squeezing in the tunnel. To reduce this value to about 2%, the approximate pressure of the support system is close to 6.13 MPa (see Fig. 3).

6 Conclusion

This paper aims to evaluate the phenomenon of squeezing along the path of the tunnel in various methods. Considering the methods for estimating the squeezing potential, two major factors in the occurrence of squeezing phenomena are the following: deep tunnels and existence of weak rock mass in surrounding of the tunnel. The Kerman water conveyance tunnel passes through five zones with different geological conditions. Based on the results obtained (Table 17), except Singh’s method for the ET-12 zone, which gained no-squeezing condition, this phenomena was predicted for the rest of the zones with different intensities. The highest intensity of squeezing occurs in the ET-21 geologic zone. This zone is a faulted area which the highest burden of this zone reaches 585 m. In addition, a statistical method called Bayesian networks was used for prediction of squeezing. In this method, the ET-21 zone was introduced as a critical zone (Fig. 5).

References

Agan C (2016) Prediction of squeezing potential of rock masses around the Suruc water tunnel. Bull Eng Geol Environ 75:451–468

Aguilera PA, Fernández A, Fernández R et al (2011) Bayesian networks in environmental modelling. Environ Model Softw 26:1376–1388

Ajalloeian R, Moghaddam B, Azimian A (2017) Prediction of rock mass squeezing of T4 tunnel in Iran. Geotech Geol Eng 35:747–763

Asghar R, Lohrasb F, Mohammad D (2017) Squeezing rock conditions at phyllite-slate zone in Golab water conveyance tunnel, Iran: a case study. J Cent South Univ 24:2475–2485

Aydan Ö, Akagi T, Kawamoto T (1993) The squeezing potential of rocks around tunnels; theory and prediction. Rock Mech Rock Eng 26:137–163

Barla G (1995) Squeezing rocks in tunnels. ISRM News J 2:44–49

Barla G (2001) Tunnelling under squeezing rock conditions. Eurosummer-School Tunn Mech Innsbruck 169–268

Barton N, Lien R, Lunde J (1974) Engineering classification of rock masses for the design of tunnel support. Rock Mech 6:189–236

Batchelor C, Cain J (1999) Application of belief networks to water management studies. Agric Water Manag 40:51–57

Bieniawski ZT (1974) Geomechanics classification of rock masses and application in tunneling. In: Proceedings of 3rd international congress on rock mechanics, pp 27–32

Bieniawski ZT (1989) Engineering rock mass classifications: a complete manual for engineers and geologists in mining, civil, and petroleum engineering. Wiley, New York

Brown ET (1981) Rock characterization, testing & monitoring: ISRM suggested methods. Pergamon Press, New York

Cain JD, Jinapala K, Makin IW et al (2003) Participatory decision support for agricultural management. A case study from Sri Lanka. Agric Syst 76:457–482

Deere DU, Peck RB, Monsees JE, Schmidt B (1969) Design of tunnel liners and support systems

Farrokh E, Mortazavi A, Shamsi G (2006) Evaluation of ground convergence and squeezing potential in the TBM driven Ghomroud tunnel project. Tunn Undergr Space Technol 21:504–510

Feng X, Jimenez R (2015) Predicting tunnel squeezing with incomplete data using Bayesian networks. Eng Geol 195:214–224

Ghaboussi J, Gioda G (1977) On the time-dependent effects in advancing tunnels. Int J Numer Anal Methods Geomech 1:249–269

Gioda G (1981) A finite element solution of non-linear creep problems in rocks. Int J Rock Mech Min Sci Geomech Abstr 18(1):35–46

Goel RK, Jethwa JL, Paithankar AG (1995) Tunnelling through the young Himalayas—a case history of the Maneri–Uttarkashi power tunnel. Eng Geol 39:31–44

Hasanpour R, Rostami J, Ünver B (2014) 3D finite difference model for simulation of double shield TBM tunneling in squeezing grounds. Tunn Undergr Space Technol 40:109–126

Hoek E (1994) Strength of rock and rock masses. ISRM News J 2:4–16

Hoek E (2007) Rock mass properties. Pract rock Eng. www.rocscience.com/learning/hoek-s-corner

Hoek E, Guevara R (2009) Overcoming squeezing in the Yacambú-Quibor tunnel, Venezuela. Rock Mech Rock Eng 42:389–418

Hoek E, Marinos P (2000) Predicting tunnel squeezing problems in weak heterogeneous rock masses. Tunnels Tunn Int 32:45–51

Hoek E, Marinos P (2010) Tunnelling in overstressed rocks. Rock engineering in difficult ground conditions—soft rocks and karst. Taylor&Francis, London

Huang HW, Zhang J, Zhang LM (2012) Bayesian network for characterizing model uncertainty of liquefaction potential evaluation models. KSCE J Civ Eng 16:714–722

Hudson JA (2009) Stresses in rock masses: a review of key points. In: ISRM Regional Symposium-EUROCK 2009. International Society for Rock Mechanics

Jethwa JL, Singh B, Singh B (1984) 28 Estimation of ultimate rock pressure for tunnel linings under squeezing rock conditions—a new approach. In: Design and performance of underground excavations: ISRM symposium—Cambridge, UK, 3–6 September 1984. Thomas Telford Publishing, pp 231–238

Jimenez-Rodriguez R, Sitar N (2006) Inference of discontinuity trace length distributions using statistical graphical models. Int J Rock Mech Min Sci 43:877–893

Kallhawy FH (1974) Finite element modeling criteria for underground opening in rock. Int J Rock Mech Min Sci Geomech Abstr 11:465–472

Khanlari G, Meybodi RG, Mokhtari E (2012) Engineering geological study of the second part of water supply Karaj to Tehran tunnel with emphasis on squeezing problems. Eng Geol 144–145:9–17. https://doi.org/10.1016/j.enggeo.2012.06.001

Landuyt D, Broekx S, D’hondt R et al (2013) A review of Bayesian belief networks in ecosystem service modelling. Environ Model Softw 46:1–11

Malan FRP (1998) Ultra-deep mining: the increased potential for squeezing conditions. J S Afr Inst Min Metall 98:353–363

Malan DF (1999) Time-dependent behaviour of deep level tabular excavations in hard rock. Rock Mech Rock Eng 32:123–155

Medina-Cetina Z, Nadim F (2008) Stochastic design of an early warning system. Georisk 2:223–236

Mesri G, Febres-Cordero E, Dr Shields, Castro A (1981) Shear stress–strain–time behaviour of clays. Geotechnique 31:537–552

Pan YW, Dong JJ (1991) Time-dependent tunnel convergence—II. Advance rate and tunnel-support interaction. Int J Rock Mech Min Sci Geomech Abstr 28(6):477–488

Pearl J (1985) Bayesian networks: a model of self-activated memory for evidential reasoning. In: Proceedings of the 7th conference of the cognitive science society, pp 329–334

Peng M, Li XY, Li DQ et al (2014) Slope safety evaluation by integrating multi-source monitoring information. Struct Saf 49:65–74

Saeed MS, Maarefvand P (2014) Engineering geological study of NWCT tunnel in Iran with emphasis on squeezing problems. Indian Geotech J 44:357–369

Schubert M, Høj NP, Ragnøy A, Buvik H (2012) Risk assessment of road tunnels using Bayesian networks. Procedia Soc Behav Sci 48:2697–2706

Semple RM, Hendron AJ, Mesri G (1973) The effect of time-dependent properties of altered rock on tunnel support requirements

Shalabi FI (2005) FE analysis of time-dependent behavior of tunneling in squeezing ground using two different creep models. Tunn Undergr Space Technol 20:271–279

Shrestha GL, Broch E (2008) Influences of the valley morphology and rock mass strength on tunnel convergence: with a case study of Khimti 1 headrace tunnel in Nepal. Tunn Undergr Space Technol 23:638–650

Singh B, Goel RK (1999) Rock mass classification: a practical approach in civil engineering. Elsevier, Amsterdam

Singh B, Jethwa JL, Dube AK, Singh B (1992) Correlation between observed support pressure and rock mass quality. Tunn Undergr Space Technol 7:59–74

Singh M, Rao KS, Ramamurthy T (2002) Strength and deformational behaviour of a jointed rock mass. Rock Mech Rock Eng 35:45–64

Singh M, Singh B, Choudhari J (2007) Critical strain and squeezing of rock mass in tunnels. Tunn Undergr Space Technol 22:343–350

Song Y, Gong J, Gao S et al (2012) Susceptibility assessment of earthquake-induced landslides using Bayesian network: a case study in Beichuan, China. Comput Geosci 42:189–199

Sousa RL, Einstein HH (2012) Risk analysis during tunnel construction using Bayesian Networks: Porto Metro case study. Tunn Undergr Space Technol 27:86–100

Sulem J, Panet M, Guenot A (1987) An analytical solution for time-dependent displacements in a circular tunnel. Int J Rock Mech Min Sci Geomech Abstr 24(3):155–164

Terzaghi K (1946) Rock defects and loads on tunnel supports

Wiesmann E (1912) Mountain pressure. Switz J Struct 60:15

Zhang LM, Xu Y, Jia JS, Zhao C (2011) Diagnosis of embankment dam distresses using Bayesian networks. Part I. Global-level characteristics based on a dam distress database. Can Geotech J 48:1630–1644

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Azizi, F., Koopialipoor, M. & Khoshrou, H. Estimation of Rock Mass Squeezing Potential in Tunnel Route (Case Study: Kerman Water Conveyance Tunnel). Geotech Geol Eng 37, 1671–1685 (2019). https://doi.org/10.1007/s10706-018-0714-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10706-018-0714-5