Abstract

Numerous studies have attempted to correlate geotechnical properties and to produce semi-empirical methods for estimating geotechnical parameters when sufficient field or laboratory measurements are not available. In the case of Greek soil formations, several studies have been presented that relate in situ tests (standard penetration test, cross-hole, seismocone) and laboratory tests for cohesive soils. Statistical analysis of the data resulted in the formulation of empirical correlations between various soil parameters, often with reasonably high correlation coefficients. However, these relationships refer mainly to cohesive soils, because the majority of tests were carried out in such formations. In this paper, the correlation of the particle size and the peak friction angle for a wide range of Greek soil formations is investigated. A simple, but rational approach for estimating the friction angle is presented, which allows prediction of the shear strength of soil formations. Since this investigation covered a wide range of soils and the number of test results is significant, the obtained empirical correlations can be considered as reliable for Greek soils.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

The effective cohesion (c′) and friction angle \(\left( {\Phi ^{{\prime }} } \right)\) are two inherent properties required for shear strength of a soil mass in any geotechnical analysis. Cohesion is present only in cases of cemented soils, partially saturated soils and heavily overconsolidated clays, and, as mentioned by Kulhawy and Mayne (1990), it gradually decays with time. On the contrary, in uncemented soils (including clays) the shear strength is mainly frictional and depends on the peak friction angle (Ameratunga et al. 2016).

Several authors have presented correlations for estimating the peak friction angle \(\left( {\Phi _{\text{p}}^{\prime } } \right)\) in an effort to provide a tool to predict the shear strength of cohesionless soils. Initially, the effective friction angle (measured in triaxial compression tests) was correlated with the particle size and the relative density (Terzaghi and Peck 1967; Schmertmann 1978). Subsequent approaches correlated the peak friction angle with one or more soil index parameters, such as the soil type, the relative density, the unit weight and the void ratio (Kulhawy and Mayne 1990).

Further research indicated that the peak friction angle of the granular soils increases with the angularity of the grains, surface roughness and relative density. Based on these results BS 8002 (1994) suggests that the peak effective friction angle \(\left( {\Phi _{\text{p}}^{\prime } } \right)\) of a granular soil can be estimated using Eq. (1).

where kA, kB and kC account for the angularity of the grains (0°– 4°), grain size distribution (0°– 4°), and relative density expressed in terms of blow counts from the standard penetration test (0°– 9°), respectively.

At the same time, Salgado (2008) stipulates that for triaxial compression loading, the peak friction angle of granular soils can be estimated by Eq. (2) which includes the dilatancy angle.

where \(\left( {\Phi _{\text{p}}^{\prime } } \right)\) is the peak friction angle under triaxial compression loading, and \(\left( {\Phi _{\text{CV}}^{\prime } } \right)\) is the critical state friction angle, ψ is the dilatancy angle component.

In fine-grained soils, there is a clear trend of decreasing peak friction angle \(\left( {\Phi _{\text{p}}^{\prime } } \right)\) with increasing plasticity index (PI). Sorensen and Okkels (2013) analyzed an extensive database of normally consolidated, reconstituted, and undisturbed natural clays from the Danish Geotechnical Institute, along with the data from Kenney (1959), Brooker and Ireland (1965), Bjerrum and Simons (1960) and Terzaghi et al. (1996). The results indicate that the best estimate of the peak effective friction angle for fine-grained soils is given by Eq. (3).

where PI is the plasticity index.

For overconsolidated clays, Sorensen and Okkels (2013) suggest that the best estimates of the peak friction angle can be given by the Eqs. (4) and (5).

From the aforementioned literature review it is clear that the estimation of the peak friction angle is a difficult task, as it depends on multiple unknown variables. Several studies attempt to develop semi-empirical methods for estimating geotechnical parameters when laboratory measurements or field data are sparse or not available. The majority of these formulations apply to cohesive soils, and establish a direct correlation between the undrained shear strength and the CPT cone resistance (Zein 2017).

In Greece, several studies have been presented to relate in situ tests (standard penetration test, cross-hole, seismocone) and laboratory testing results (Anagnostopoulos 1974; Zervogiannis et al. 1987; Bouckovalas et al. 1989; Koukis et al. 1997; Zervogiannis and Kalteziotis 1988; Anagnostopoulos and Koukis 2003) but they are mostly limited to cohesive soils. Therefore, a simple but rational approach for evaluating the peak friction of a wide range of soil formations is considered to be desirable for practical engineering applications.

The aim of this work is develop tools to estimate the peak effective friction angle based on soil mass properties. Data for this research were collected from a number of major roadwork projects throughout Greece. The laboratory results were obtained by standard testing procedures applied to different geological formations, from Neogene to Quaternary in age.

2 Data and Methods

A database of soil parameters was established, using testing results obtained from site investigation projects mostly conducted for public works. A limited amount of data derived from private projects was also included. Measurements were conducted by private geotechnical investigation and design firms throughout the Greek continental territory and some Greek islands. In total, the testing results include 2200 soil samples, collected from 80 different sites, 480 boreholes and 20 excavated pits.

Most of samples comprise allochthonous soils derived from riverine, marine, lacustrine, marsh and colluvium. In addition, a number of samples were taken both from soft bedrock outcrops (marls, marly sandstones, sandstones and mudstones) and weathered bedrock, which commonly underlays alluvial or colluvial formations.

The samples were collected from the ground surface up to a maximum depth of 50 m. Undisturbed borings were made using push and rotary samplers. More specifically, the Shelby tube sampling method was used to collect undisturbed samples of soft, fine-grained (cohesive) soils, while rotary core samplers were utilized to sample coarse grained materials. In dense coarse grained formations such as soft schist, sandstone and sandy soils with a relatively high clay content, fairly undisturbed soil specimens were obtained through trimming, taken with a large diameter sampler (90–114 mm). Disturbed soil samples were collected from soils with high gravel content, as the other sampling methods were ineffective. The loose coarse grained material was screened by a #4 sieve, and the passing material was used for specimen preparation. The packing density and water content of the in situ material were approximated in the prepared specimens.

For preserving and transporting the samples, standard practices corresponding with the various sampling devices were followed. In any case, the ends of the drive samplers, and sample liners used by rotary drilling methods, were sealed by wax and properly marked with all pertinent data. Sample extruders were used to remove the samples from the sampling tubes.

The unified soil classification system was used to describe the texture and grain size of the samples, while ASTM standards were followed for the geotechnical testing. The database, apart from the index test results for soil classification (ASTM D2487), includes the strength parameters derived from shear testing (ASTM D6528).

The direct shear test (DSS) conducted under the in situ void ratio of the soil, was used to evaluate the shear stress–strain response and strength parameters of the soil formations. As stated by Boylan and Long (2009) the DSS test has advantages over triaxial compression testing because in the former, the sample assembly is simple and the in situ failure mechanism is better represented than in the latter testing procedure. Moreover, shear tests require a shorter testing time than triaxial testing. In addition, the measured values in a triaxial test may be affected by higher order uncertainties than shear testing.

In the present work, the testing procedure for direct shear testing followed the ASTM D6528 standard (undrained direct simple shear testing of cohesive soils). Generally three or more specimens were tested for each soil sample, each under a different normal load, in order to determine shear resistance and strength properties. The normal load range applied was compatible with the depth of the sample. The specimens, obtained mainly from the core of the samples, were trimmed by hand into the rings for direct shear testing. It is worth noting that in order to meet the minimum grain size in the DSS test, particles with size greater than 5% of the shear cell diameter were manually removed, while at the same time, an effort was made to retain the packing and moisture content of the fines.

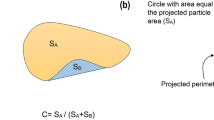

Moreover, considering that the engineering properties of the soils are primarily controlled by size and packing conditions of the particles, the coarse to fines weight ratio (c/f ratio) was estimated for each sample. This is defined as the ratio of the percent weight of the soil consisting of grains over 74 µm in size, to the percent weight of the soil consisting of grains smaller than 74 µm. This value is the direct product of wet sieving analysis of the soil samples, and it is estimated by a simple division of two values which are determined by weighing. Hence, it is an inherently accurate, impartial and cost effective index, which is assumed advantageous in evaluating the shear strength parameters.

It should be mentioned, however, that the grain size, as determined by wet sieving, differs from the naturally occurring grain size due to the partial loosening or dissolution of segregated smaller particles during this procedure. In order to avoid misinterpretations and discrepancies in measurements this research was conducted using wet sieving results.

The samples were grouped into four categories as shown below and geotechnical analysis and correlations were conducted for each individual category:

-

(1)

Normally consolidated, fine-grained soils.

-

(2)

Over consolidated, fine-grained soils.

-

(3)

Loose granular soils.

-

(4)

Dense granular soils.

For each soil group, descriptive statistics of the estimated geotechnical parameters and their frequency distributions are presented in Tables 1, 2, 3 and 4. Also, histograms of the testing results are shown in Figs. 1, 2, 3 and 4. They present the frequency distributions of representative geotechnical parameters and allow the inspection of the measured data for their underlying distribution.

In this work, a soil formation was classified as fine-grained, if the samples taken from this formation contained 50 percent or more fines. As shown in Tables 1 and 2, the average percent of fine particles encountered in the fine grained soil samples is more than 50%. As a result, the data presented in tables and figures with respect to the ratio value c/f, refer to soil formations which meet the classification requirements according to USCS and ASTM standards.

The histograms presented in Figs. 1, 2, 3 and 4 indicate that the statistical distributions of soil parameters are different for the different soil groups identified in this study. As a result, uncertainty arises when applying a unique correlation for estimating the peak friction angle of soils for all soil groups. The majority of soil properties are not normally distributed, while the coarse to fines weight (c/f) ratio follows a log normal distribution in all soil groups. It is clear from published literature that increasing plasticity leads to a reduction in the peak friction angle (Ameratunga et al. 2016). Results from the tested samples, however, indicate that the peak friction angle is only loosely related to their plasticity index.

Consequently, considering that the engineering properties of the soils are primarily controlled by the size and packing conditions of the particles, the use of the c/f ratio is assumed advantageous in evaluating shear strength parameters. Hence, an analysis was carried out to establish a direct relationship between the peak friction angle (ф′p) and the c/f soil ratio that might be used to predict the shear characteristics of a soil.

3 Analysis of the Results

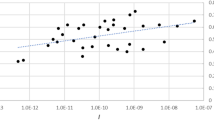

The peak friction angle and the c/f ratio were correlated and the various relationships that were derived from the regression analysis are presented in Table 5. The significance of these relationships was assessed by using the coefficient of determination (R2). R2 values equal to 0.929 and 0.872 were obtained for the normally and overconsolidated fine grained soils respectively, while lower correlation coefficients, 0.480 for loose and 0.543 for dense soils, were obtained for the granular soil samples.

The best fit trend lines and their mathematical expressions, along with the resulting coefficient of determination for the different soil formations, are shown in Fig. 5.

The validity of the suggested correlations was assessed using different (control) samples, collected at the same sites as the samples used for formulating the correlations. The control samples were tested using the same laboratory equipment and personnel. In order to circumvent any effects of systematic variation in laboratory testing, irregular or extreme values of peak friction angle were not excluded from the validation group. Also, for comparison, the suitability of Sorensen and Okkels (2013) correlations to fit the measured values of the peak friction angles was also evaluated.

The proposed correlations were evaluated on the basis of the following criteria:

-

(a)

The predicted values of peak friction angles were cross plotted against the values derived from shear testing (Fig. 6). These scatter diagrams were constructed to provide evidence regarding the relationship between predicted and measured values. Irregular or extreme values are evident in most of the diagrams. The z-score method was used to detect outliers. Any data point with a z-score greater than ± 3 was considered an outlier (Dithinde et al. 2016).

The number of points which may be considered potential outliers are limited in fine grained soils (none in normally consolidated, and 7 out of 530 points in the data set of over consolidated soils). However, the number of outliers increases in the granular soils dataset. 40 out of 332 points (12%) in the loose granular soils and 56 out of 387 points (15%) in the dense granular soils can be classified as outliers.

-

(b)

The overall suitability of the derived correlation equations to fit measured values was evaluated taking into account the mean value and the standard deviation of the control data. The error associated with the predicted values and the Pearson’s coefficient are also presented in Table 6.

Table 6 Suitability of correlations between peak friction angle and c/f ratio to fit the measured values of peak friction angle -

(c)

The root mean square error (RMSE) of the predicted values was calculated for each group of soils (Table 6). RMSE is the square root of the average squared difference between the calculated (using the empirical equation) and the corresponding values determined from shear testing. RMSE was determined using Eq. (6).

where n is the number of data points, φpcal is calculated from the empirical equation, φpmeas is determined directly from shear laboratory tests.

The lower the RMSE value, the better the correlation. This method has been adopted by several authors (Alvarez Grima and Babuska 1999; Finol et al. 2001; Ozer et al. 2008; Onyejekwe et al. 2015) to evaluate the suitability of correlation formulas to fit measured values. As reported by Chang and Phantachang (2016), errors in this procedure are squared before they are averaged, thus participating with a heavier weight in the respective correlation equations.

The use of RMSE is considered advantageous in evaluating these correlations, since it would expose the potential to produce large errors which are undesirable. However, RMSE values do not consider precision (Onyejekwe et al. 2015).

-

(d)

The ranking distance of the predicted to measured friction angle ratio (RD), (Cherubini and Orr 2000; Orr and Cherubini 2003), was also used to evaluate the performance of the empirical equations for the different groups of soil (Table 6). RD was calculated using Eq. (7) (Cherubini and Orr 2000), where K is the ratio of the estimated to the laboratory determined peak friction angle.

where μ and s represent the mean and standard deviation of the series of analyzed data respectively.

The correlation is considered better when the RD values are lower.

4 Results and Discussion

The scatter diagram in Fig. 6a shows that the points which represent the normally consolidated soils are grouped into a clear linear shape, indicating that the predicted peak friction angles are directly related to the laboratory measured values. The validation diagram constructed for the overconsolidated fine grained soils follows a similar pattern, although the points are spread randomly within a wider zone around the perfect fit line (Fig. 6b). Both correlations exhibit very low RMSE values, equal to 2.54 for normally consolidated and 3.31 for overconsolidated soils. Therefore, the recommended correlation equations are considered appropriate to predict the peak friction angle for fine-grained soils. It should be noted that in overconsolidated soils the inter-granular bonds are able to withstand a higher shear strength compared to normally consolidated soils. However, when the applied loads are increased during shearing, the stresses at certain interparticle contacts are assumed to reach the bond strength, and a mechanical bond degradation (de-bonding) process is initiated (Smith et al. 1992; Lagioia and Nova 1995).

Therefore, the low values of ф′p (5°–10°) for over consolidated fine-grained soils can be attributed to the effect of initial microstructure and structure degradation that involves damage to interparticle bonds and changes in particle arrangement (Amorosi and Rampello 2007).

The correlations for granular soils show a greater variability and subsequent uncertainty when predicting peak friction angles. Figure 6c, d indicate that a number of points may be identified as potential outliers. Although the plotted points show an overall linear trend, the points are more scattered in comparison to the samples of fine-grained soils. This results in a general underestimation of predicted values of peak friction angle for the loose and the dense granular soils. The respective RMSE values, which lie between 4.74 for loose and 5.56 for dense granular soil, are higher than those for fine-grained soils.

Furthermore, the estimated Pearson coefficient is slightly higher for the fine-grained compared to the granular soils; both indicate a marked degree of correlation based on the guidelines suggested by Franzblau (1958).

Statistics of the ratio of the estimated to the measured peak friction angle (denoted by K), give a slightly lower mean value for loose and coarse-grained soils when compared to fine grained soils. In terms of the proximity of the average K to 1 (accuracy), the proposed correlations gave a reasonable prediction, with a K value ranging between 1.08 and 1.02 for the normally consolidated soils and between 0.98 and 0.97 for loose and dense granular soils, respectively (Table 6).

In terms of precision (standard deviation of K ratio), the correlations for granular soils gave the best prediction. S(K) values were equal to 0.112 for loose and 0.118 for dense granular soils. Contrarily, the corresponding value for normal consolidated fine-grained soils is equal to 0.235 for both normal and overconsolidated samples. The low RD values for both fine-grained and granular soils (Table 6) indicate that all calculation methods have both high accuracy and high precision.

The inferior correlation results obtained for the granular soils compared to the fine-grained soils (based on Pearson’s coefficient and RMSE values) can be attributed to the following:

According to ASTM D6528, the specifications for direct shear testing require that all soil particles pass through the #4 sieve. Removal of large grains generates a grain size distribution which is different than the grain size distribution of the undisturbed or natural soil. Hence, considerable variation is expected for samples with a high gravel content that does not pass through the #4 sieve, when compared to samples with a lower gravel content.

Also, there is a marked discrepancy between the measured size of soil grains (based on wet sieving), and the natural state of the grain size of the specimens used for shear testing. A quantity of large grains is formed of segregates which partly disperse during wet sieving, giving a nominal grain size that is smaller than the natural size found in the field (undisturbed samples). Following this specification, the result may not provide representative parameters of the tested soil samples. Hence, considerable variation was produced in shear testing results for samples with a high gravel content, even though their c/f ratio was similar or identical.

The aforementioned problems are exacerbated in the group of dense granular soils, because they mainly contains material from weathered soft or semi-hard to moderately hard rocks or very stiff, fissured and flaky clays that do not totally disperse their segregates during wet sieving. Also, in many cases this group of soils contains segregates cemented by calcite material.

Finally, it should be mentioned that based on the deviation statistics of the predicted and measured values as well the RMSE and RD index values, the c/f ratio correlations for predicting peak friction angles in fine-grained soils is advantageous compared to the relationships proposed by Sorensen and Okkels (2013) (Table 6).

5 Conclusions

The relationship between the grain size and the peak friction angle for different USCS soil types was investigated and empirical equations were developed between the effective peak friction angle and the coarse to fines weight ratio (c/f). A large database was used for this analysis and the statistical results were compared against a control subset of the tested samples which was not utilized in the statistical derivations.

The empirical relationship between the effective peak friction angle and the coarse to fines weight ratio for the fine-grained soils, is expressed by polynomial equations. The proposed equations for normally consolidated soils exhibit higher coefficients of determination than those for overconsolidated soils. Comparative results also show that the c/f ratio correlations for predicting effective peak friction angles in fine-grained soils are advantageous compared to the relationships proposed by Sorensen and Okkels (2013).

Furthermore, a linear relationship between the effective peak friction angle and the natural logarithmic value of the coarse to fines weight ratio was determined through this investigation for granular soils. This relationship, however, shows a higher variability and, therefore, higher uncertainty, when predicting peak friction angles. As a result, the relationships generated for predicting the effective peak friction angle in dense granular soils, although acceptable, should be supported by additional data.

References

Alvarez Grima M, Babuska R (1999) Fuzzy model for the prediction of unconfined compressive strength of rock samples. J Rock Mech Min Sci 36(3):339–349

Ameratunga J, Sivakugan N, Das BM (2016) Correlations of soil and rock properties in geotechnical Engineering. Springer. Developments in Geotechnical Engineering. Das BM (ed), Henderson; Nagaratnam S (ed), Townsville. ISBN 978-81-322-2627-7 ISBN 978-81-322-2629-1 (eBook). https://doi.org/10.1007/978-81-322-2629-1

Amorosi A, Rampello S (2007) An experimental investigation into the mechanical behaviour of a structured stiff clay. Géotechnique 57(2):153–166

Anagnostopoulos A (1974) Evaluation of the undrained shear strength from static cone penetration test in a soft silty clay in Patras, Greece. Proc Eur Symp Penetr Test Stockh 2(2):13–14

Anagnostopoulos A, Koukis G, Sabatakakis N, Tsiambaos G (2003) Empirical correlations of soil parameters based on cone penetration tests (CPT) for Greek soils. Geotech Geol Eng 21:377–387

ASTM D2487 (2004) Standard test method for classification of soils for engineering purposes. American Society for Testing and Materials, West Conshohocken

ASTM D6528-07 (2007) Standard test method for consolidated undrained direct simple shear testing of cohesive soils. ASTM International, West Conshohocken

Bjerrum L, Simons NE (1960) Comparison of shear strength characteristics of normally consolidated clays. Proc ASCE Res Conf Shear Strength Cohesive Soils. Boulder, Colorado, pp 711–726

Bouckovalas G, Kalteziotis N, Sabatakakis N, Zervogiannis H (1989) Shear wave velocity in a very soft clay–measurements and correlations. Proceedings of the twelfth international conference on soil mechanics and foundation engineering, Rio de Janeiro, 13–18 August, pp 191–194

Boylan N, Long M (2009) Development of a direct simple shear apparatus for peat soils. ASTM Geotech Test J 32(2):126–138

Brooker EW, Ireland HO (1965) Earth pressure at rest related to stress history. Can Geotech J 2(1):1–15

BS 8002 (1994) Code of practice for earth retaining structures. British Standards Institution, London

Chang WJ, Phantachang T (2016) Effects of gravel content on shear resistance of gravelly soils. Eng Geol 207:78–90

Cherubini C, Orr TLL (2000) A rational procedure for comparing measured and calculated values in geotechnics. In: Yokohama IS, Nakase A, Tsuchida T (eds). Proceedings of the international symposium on coastal geotechnical engineering in practice, vol 1. AA Balkema, Rotterdam, pp. 261–265

Dithinde M, Phoon KK, Ching J, Zhang LM and Retief JV (2016) Statistical characterisation of model uncertainty. Chapter 5, Reliability of geotechnical structures in ISO2394. CRC Press, Leiden

Finol J, Guo YK, Jing XD (2001) A rule based fuzzy model for the prediction of petrophysical rock parameters. J Pet Sci Eng 29(2):97–113

Franzblau A (1958) A primer for statistics for non-statistician. Harcourt Brace & World, New York

Kenney TC (1959) “Discussion of geotechnical properties of glacial lake clays,” by T.H. Wu. J Soil Mech Found Div ASCE 85(SM3): 67–79

Koukis G, Tsiambaos G and Sabatakakis N (1997) Correlations of mechanical characteristics and classification of soil units of Patras city. In: Proceedings of 3rd Hellenic congress in geotechnical Engin., Patras, pp. 121–127 (in Greek)

Kulhawy FH and Mayne PW (1990) Manual on estimating soil properties for foundation design, Report EL-6800, Research Project No. 1493-6, Electric Power Research Institute (EPRI), Palo Alto

Lagioia R, Nova R (1995) An experimental and theoretical study of the behaviour of a calcarenite in triaxial compression. Géotechnique 45(4):633–648

Onyejekwe S, Kang X, Ge L (2015) Assessment of empirical equations for the compression index of fine-grained soils in Missouri. Bull Eng Geol Environ 74(3):705–716

Orr TLL, Cherubini C (2003) Use of the ranking distance a san index for assuming the accuracy and precision of the equations for the bearing capacity of piles and at-rest earth pressure coefficient. Can Geotech J 40(6):1200–1207

Ozer M, Isik NS, Orhan M (2008) Statistical and neural network assessment of the compression index of clay-bearing soils. Bull Eng Geol Environ 67:537–545

Salgado R (2008) The engineering of foundation. McGraw Hill, New York, p 882

Schmertmann JH (1978) Guidelines for cone penetration test performance and design, Report FHWA-TS-78-209. Department of Transportation, Washington, D.C., p 145

Smith PR, Jardine RJ, Hight DW (1992) The yielding of Bothkennar clay. Géotechnique 42(2):257–274

Sorensen KK, Okkels N (2013) Correlation between drained shear strength and plasticity index of undisturbed overconsolidated clays. In: Proceedings of the 18th international conference on soil mechanics and geotechnical engineering, vol. 1, Paris, Presses des Ponts, pp. 423–428

Terzaghi K, Peck RB (1967) Soil mechanics in engineering practice, 2nd edn. Wiley, New York

Terzaghi K, Peck RB, Mesri G (1996) Soil mechanics in engineering practice, 3rd edn. Wiley, New York

Zein AKM (2017) Estimation of undrained shear strength of fine grained soils from cone penetration resistance. Geo-Engineering 8:9. https://doi.org/10.1186/s40703-017-0046-y

Zervogiannis H, Bouckovalas G, Christoulas St (1987) Correlation of mechanical characteristics and classification of soil deposits. Bulletin of Central Public Works Laboratory, vol. 4, pp. 255–265 (in Greek)

Zervogiannis H, Kalteziotis N (1988) Experience and relationships from penetration testing in Greece. In: Proceedings of 1st international symposium on penetration testing, ISOPT-1, vol. 2, Orlando, 1063–1071

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Rights and permissions

About this article

Cite this article

Arvanitidis, C., Steiakakis, E. & Agioutantis, Z. Peak Friction Angle of Soils as a Function of Grain Size. Geotech Geol Eng 37, 1155–1167 (2019). https://doi.org/10.1007/s10706-018-0675-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10706-018-0675-8