Abstract

The entrance of Tianshan tunnel was constructed in residual slope accumulation of gravelly soil while the massif at the entrance was considered as a potential landslide mass. In this context, landslide is very likely to occur to cause engineering accidents under the effects of tunneling construction disturbance and rainfall infiltration. By analyzing the engineering geological and hydrogeological conditions of the tunnel, the researchers discussed the original construction scheme of the tunnel entrance and decided to optimize the construction technology of the tunnel entrance. During the construction design, the stability of side and face-upward slope of the entrance was calculated first, which reaches a conclusion that the side and face-upward slope probably landslide towards the free face induced by rainstorms. Next, the potential landslide mass at side and face-upward slope of the tunnel entrance was optimized and governed by using the method of lengthening umbrella arches and increasing reverse pressure by filling soil. Finally, the “three-bench seven-step” method was utilized to replace the center diagram method and the reasonability of the excavation method was verified by comparison and analysis using three-dimensional numerical simulation. Thus, the construction efficiency can be improved on the precondition of guaranteeing the safety.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

It is inevitable to build numerous tunneling engineering while the highway engineering passes through mountain ridges. With the constant improvement of the tunnel construction level and management idea, numerous worldwide problems in tunneling field have been solved (Ding et al. 2014; Guo and Yin 2014; Ellingsen et al. 2015, 2017). Nevertheless, scientific researchers and front-line construction technicians are still faced with multiple problems in tunneling, and entrance construction technology at shallow-buried section with unfavorable geological conditions is one of the problems (Špačková et al. 2013; Alija et al. 2013; Ieronymaki et al. 2016). Tunnel entrances and exits show complex geological condition and intense stratum weathering, so the tunneling is in a great risk including collapse, great deformation, and lining cracking. These make construction staff be not able to construct the tunnel for a long time and heavily delay the construction schedule (Lisa et al. 2013; Yazdani-Chamzini et al. 2013; Boonyarak and Ng 2014; Tafraouti et al. 2016).

By studying the Tianshan tunnel, the geological and hydrogeological conditions of the tunneling were analyzed aiming at shallow-buried tunnel entrance in residual slope accumulation of gravelly soil. Moreover, the original construction scheme of the tunnel entrance was demonstrated and the optimized construction technology for the shallow-buried tunnel entrance in residual slope accumulation of gravelly soil was proposed. During the optimization design, the stability of the side and face-upward slope of the tunnel entrance was first calculated, which draws a conclusion that the side and face-upward slope are likely to landslide towards the free face induced by rainstorms. Next, the potential landslide mass at side and face-upward slope of the tunnel entrance were optimized and governed by using the method of lengthening umbrella arches and increasing reverse pressure by filling soil. Finally, the “three-bench seven-step” method was employed to replace center diagram (CD) method and the reasonability of the “three-bench seven-step” method was verified through comparison and analysis using three-dimensional numerical simulation. By using the method, the construction efficiency can be improved on the precondition of guaranteeing the safety.

2 Engineering Overview

Tianshan tunnel is a long motorway tunnel with separated up and down lines and totally four lanes. The left line of the tunnel buried 210 m underground at most in the length of 1765.732 m starts from ZK61+205 and ends at ZK62+970.732, showing a one-way upslope with the longitudinal gradient of + 2.260 and + 1.728%. The right line of the tunnel has a maximum buried depth of 214 m and a length of 1765 m. It starts from YK61+210 and ends at YK62+975, and shows a one-way upslope with the longitudinal gradient of + 2.250 and + 1.770%. The spacing between the left and right lines of the tunnel is 25 m and the tunnel portals of the left and right lines are designed as bamboo-cutting and gable wall types.

2.1 Engineering Geological Conditions

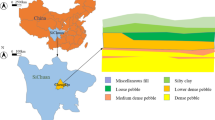

The tunnel is constructed in the corroded hilly area with significant topographic relief. The elevation of the summit of the traversed area is in the range of 384–426 m and the mountain valleys with open terrain extended approximately along the east–west direction are distributed in the southern and northern sides of the area. The elevations of the valley bottoms in the northern and southern sides are 164 and 210 m, respectively. Moreover, the natural ground elevation of the traversed section of the tunnel is in the range of 194.5–423.8 m. The lower part of the entrance slope is close to the slope toe with the aspect around 337° and the slope angle of 20°–25° while the mid-upper part of the slope is steep with the slope angle of 40°–50°. The northwestern side of the gully towards south–south-west of the tunnel exit shows a deep slope with the angle of 30°–45°.

In view of the location of geotectonics, the tunnel area is located on the intersection between two second-level tectonic units: lower Yangtze plate of Yangtze paraplatform and Mufushan depression. The area has developed folds and faults. The early structures in the basements of Mesoproterozoic erathem are closed congruous folds stretched approximately along south-north direction and distributed in a limit scope. After long-term stable platform development, the super-thick overlying sedimentary covers are formed on the basements and lifted as the lands under the effect of Indosinian movement. In the early phase of Yanshan movement (folds shaping), folds are formalized and a series of east–west folds and accompanying brittle fractures. During the Himalayan movement happening in the later phase of Yanshan movement, numerous north–north-east fractures and terrestrial red deposit basins are developed.

According to the areal geology, geological survey and drilling, the strata of the tunnel are successively displayed as Quaternary residual silty clay with gravels and gravelly soil (Qel+dl); underlying dolomite of Qingxudong formation (∈1q) and siltstone, silty shale, calcareous shale, carbonaceous shale and carbonaceous siltstone of Wulipai formation (∈1w) in lower series of Cambrian System; and residual slope accumulation of gravelly soil covering the tunnel entrance.

2.2 Hydrogeological Conditions

The groundwater in the tunnel area can be divided into pore water in unconsolidated Quaternary formation, fracture water in bedrock and karst fracture water. Where, the pore water in unconsolidated Quaternary formation is preserved in the pores of loose unconsolidated formation of residual slope accumulation of silty clay with gravels and gravelly soil. The aquifer with a thin overall thickness is unstably distributed mostly in the slight slope area of traversed massif of the tunnel, which exerts an insignificant effect on tunneling. The fracture water in bedrock is influenced by the weathering effect and the weathering fracture zones provide storage space for groundwater. However, restricted by the development degree of fractures, open characteristic and fillings, fracture water in bedrock is low water yield, which also has an insignificant influence on the tunneling. Additionally, karst fracture water is hosted in the soluble karst fractures and pipeline caves in the tunnel entrance, which is mainly supplied by the atmospheric precipitation, so the water yield has a close relationship with atmospheric precipitation. However, it cannot be excluded that there are slightly developed karst caves distributed in partial sections where accumulated water and mud are accumulated, so water inrush or mud burst probably occurs during the tunneling in rainy season.

3 Original Construction Technology Scheme of Tunnel Entrance

3.1 The Construction Scheme of Side and Face-Upward Slope of the Tunnel Entrance

The ratio of the face-upward slope of tunnel entrance is 1:0.5 and the face-upward slope of tunnel entrance is reinforced by using anchor, net and shotcrete method. Mortar anchors with the diameter of 22 mm and the length of 3.5 m are applied and the interval the anchors, arranged in a quincunx shape, is 1.5 m × 1.5 m. The φ6 mesh reinforcement with the mesh size of 20 cm × 20 cm is used and the 8-cm thick C20 concrete is sprayed on the slope. Moreover, the original technological construction scheme at the side and face-upward slope of the tunnel entrance is shown in Fig. 1.

3.2 Original Scheme for Governing Potential Landslides of the Side and Face-Upward Slope

Aiming at the potential landslide risk of side and face-upward massif during the Tianshan tunneling, two selective governance schemes can be used: strengthening the sliding massif by grouting through the steel floral tube on the surface and establishing the slide-resistant piles in the tunnel entrance.

3.2.1 Strengthening the Sliding Massif by Grouting Through the Steel Floral Tube on the Surface

In two sides of the outer contour within the width of 13 and 10 m area above dome roof of Tianshan tunnel, the deep-grouting is conducted by using φ108 steel floral tubes. The cave roof within the culvert at the tunnel entrance is reinforced by using the grouting technology based onφ108 steel floral tube. Moreover, the left cave of the Tianshan tunnel entrance from ZK61+215 to ZK61+428 shows the length of 213 m, so it is necessary to arrange 43 rows of tubes (eight tubes in each row and the tubes are 30 m long on average) and inject 5 m3 of cement paste into each tube. The right cave of the tunnel entrance from YK61+220 to YK61+415 has the length of 195 m. It is necessary to set 40 rows of tubes (eight tubes in each row and the average length of the tubes is 30 m) and inject 5 m3 of cement paste into each tube. The grouting reinforcement process of the roof surrounding rocks is displayed in Fig. 2.

3.2.2 Designing the Slide-Resistant Piles on the Tunnel Entrance

To prevent the slippage and collapse of massif, 50 tubes (2 rows) of slide-resistant piles (φ120 cm) were established within the open tunnel. The slide-resistant piles are anchored to the rock mass and the anchorage length was not shorter than half of the total length of the pile. The thickness of the sliding layer was 16 m according to data acquired through geological exploration, so the length of each slide-resistant pile was not shorter than 32 m.

3.3 Original Method for Tunneling

The CD tunneling method was used to excavate the Tianshan tunnel entrance in the previous stage. The method has a few characteristics including low construction risk, complex construction procedures, small-medium construction machinery, good stability of working face, great construction difficulty and large technological difficulty (Li and Li 2014). It is necessary to follow the principles of new Austrian tunneling method (NATM) including advanced tube, timely grouting, short advance, strong support, quick sealing and frequent measurement in the construction using CD method. Moreover, the principle was considered as the core guidance concept during the construction of tunnel entrance (Fukushima et al. 2014). The primary support structure system composed of advanced support system, spray, net, steel arch, steel foot pipe (anchor) and spray of the CD method is the key point and precondition of successfully completing the construction.

4 Optimization of Construction Technology of the Tunnel Entrance

Considering complex geological conditions of shallow-buried tunnel entrance and the strata containing residual slope accumulation of gravelly soil, experts analyzed the original technological construction scheme on site. The result showed that the original construction scheme exhibited certain irrationality and large risk, so it was necessary to optimize the original construction technology. The main optimization points include three aspects: to calculate the stability of the side and face-upward slope at the tunnel entrance; to modify the governance scheme on the potential landslide of side and face-upward slope at the tunnel entrance into lengthening umbrella arches and increasing reverse pressure by filling soil; and to replace the original tunneling method with three-bench seven-step method.

4.1 Calculation of the Stability of the Side and Face-Upward Slope at the Tunnel Entrance

4.1.1 Calculation Method

The transfer coefficient method is applied to calculate the stability of the side and face-upward slope at the tunnel entrance, which is also called imbalanced trust force method (ITFM), sliding method of broken line and residual trust method (RTM). The method is a practical method for analyzing the stability of the landslide created by engineering technicians (Blödorn et al. 2015). The method shows simple calculation process and can provide and design thrust for governing landslides, so it is widely used in the water resource and railway departments, which is also considered as a recommended calculation method in codes. When the sliding surface is expressed as a broken line, the stability of the landslides can be analyzed by using sliding method of broken line. The calculation of the transfer coefficient method is shown in Fig. 3.

The sliding force of the ith block can be expressed as follows:

where Wi1 and Wi2 separately refer to the natural weights above and below the water line of the ith block, while θ and α represent the ground inclination of the ith calculation block and the average inclination of groundwater flowline of the ith calculation block, respectively. Generally, α is the average of the inclinations of saturation line and sliding surface, and negative values are used under anti-inclined state. Moreover, Di refers to seepage pressure.Sliding-resistance force of ith block is calculated as follows:

where ci and φi refer to the standard value of bonding strength of the rock and soil mass at the sliding surface of the i th calculation block and that of internal friction angle of the slip soil of the i th calculation block.

The seepage pressure Di which is the product of saturated area, weight of water and hydraulic slope i ≈ sinαi is calculated. The seepage pressure shows the same direction as the waterflow and has an included angle αi with the horizontal direction, which can be calculated as follows:

Assuming that \( h_{w} = \frac{{h_{a} + h_{b} }}{2} \), then

where γW, γ and γ’ refer to volume weight of water as well as natural volume weight and buoyant unit weight of rock and soil masses, respectively. Moreover, Viu and Vid represent the volumes per width of the parts above and below water line of the rock and soil mass, respectively. In addition, Li denotes the length of sliding surface of the ith calculation block. The significances of the other symbols are the same as the above aforementioned.

Thus, the residual sliding force of the nth block can be expressed as follows:

where Ψ and K separately refer to the thrust transfer coefficient and the minimum safety coefficient of prevention engineering. For different levels of prevention engineering, the minimum safety coefficient of prevention engineering can be determined based on different load combinations.

When the sliding thrust of the last block is Pn = 0, K is the stability coefficient of landslides and is expressed by using Fs.

4.1.2 Calculation of Stability of Side and Face-Upward Slope

According to the investigation resources, the stability of side and face-upward slope was calculated by selecting three typical calculation sections. By comprehensively determining values based on test and experience, the physical and mechanical calculation parameters of the stability of the side and face-upward slope are obtained, as shown in Table 1.

Two working conditions are applied for the calculation: the safety coefficients on the conditions of self-weight (natural) and self-weight plus rainstorm (saturated) are designed as 1.25 and 1.15, respectively. By using transfer coefficient method, the stability and residual sliding force of the three sections can be calculated, as shown in Table 2.

By analyzing the calculation results of the stability, it can be seen that the stability coefficient of unstable slope is 1.044–1.109 under the natural stage, which is in the understable to basically stable states. Moreover, the stability coefficient of the slope is 0.968–0.982 under the rainstorm state, which is in an unstable state. The covering layer above the slope is very likely to landslide towards the free face induced by rainstorms and especially under the condition of rainstorms, the deformation of side slope aggravates. Landslide directly influences the construction safety of the tunnel and also safety in future operation stage. To guarantee the construction safety of the tunnel, it is necessary to optimize the tunneling construction scheme and take proper measures to prevent landslides.

4.2 Optimization and Governance of Potential Landslide Mass at the Side and Face-Upward Slope of the Tunnel Entrance

The original measures for governing the landslides at the side and face-upward slope of the tunnel entrance are relatively irrational, which is displayed as follows: firstly, the reinforcement measure of grouting and reinforcing the landslides from surface steel floral tube belongs to an active support. Under the permeation, filling, compaction and separation effects of slurry on the rock and soil masses, the mechanical strength parameters of rock and soil masses can be improved after the solidification of the slurry so as to promote the whole stability of landslides. Grouting reinforcement is mainly suitable for reinforcing the strata with hard surface layer and soft soil in the mid and deep-layers. However, Tianshan tunnel entrance is mainly constructed in residual slope accumulation of gravelly soil with soft surface layer, so it is hard to ensure the reinforcement effect through grouting. Secondly, in terms of establishing the slide-resistant piles at entrance, the piles exhibit their advantages including flexibly selecting the locations (single or multiple rows, being used alone or combining with other engineering), having convenient constructions, safe and reliable. Moreover, the arrangement of pile-resistant piles can be modified at any time according to the occurrence conditions of sliding surfaces (zones) revealed by the borehole drilling so as to satisfy the practical needs. Nevertheless, the slide-resistant piles need to be constructed step by step, which takes a long working term, and they cost high.

Considering this, the following measures for optimizing and governing the potential landslides at side and face-upward slope of the tunnel entrance were put forward: lengthening umbrella arch and increasing reverse pressures by filling soil. The major points lie in that the primary basement of the umbrella arch was constructed after completing the construction of large pipe shed of the tunnel while 8 cm of umbrella arches were separately added in the left and right tunnels. Next, open tunnels were constructed and reverse pressures were applied by filling soil on the top of umbrella arch and open tunnel. Where, the basement at the umbrella arch was still soft clay, so it was necessary to establish three rows of φ42 small grouting pipes on the bottom of the umbrella arches so as to reinforce the basement. The advantage of the method lies in that it is the most economical and effective scheme to lose weight by excavating the primary sliding and pulling section of the landslide and to increase the reverse pressure at the sliding-resistant section and the leading edge. Lengthening umbrella arches and increasing the reverse pressure by filling soil conforms to the principle (early entering and late exiting) of tunneling and avoids the excessive excavation and construction on massif. Thus, the plants around the tunnel entrance can be well preserved to maintain the previous ecological landforms at low costs.

The multi-step construction of umbrella arches is shown in Fig. 4 while lengthening umbrella arches on site is displayed in Fig. 5.

Construction of lengthened umbrella arches on site. a Installing the joist steel on the lengthened umbrella arches, b installing template on the lengthened umbrella arches, c completing the concrete-grouting on the lengthened umbrella arches, d increasing reverse pressure by filling soil on the lengthened umbrella arches

4.3 Optimized Tunneling Construction Method

The CD method was initially applied for tunneling in the early stage to guarantee that timely dropping and sealing as well as load-bearing capacity of the initial support. However, due to small construction area by using the CD method, it is necessary to take small-type machinery or human excavation and transportation works with multiple portions and complex working procedures. Moreover, the earlier procedures constrain the subsequent procedures in various aspects and there are large disturbance among different portions, which is harmful for field construction and performance and causes a slow construction progress. Additionally, numerous materials are consumed during the temporary supports which are difficult to be constructed and removed, and the removal influences the stability of surrounding rocks. Moreover, the blasting vibration and slungshot easily damage the temporary supports in the blasting.

Through argument and analysis, it is determined to replace CD method with three-bench seven-step method. As one of the mining construction methods widely used in IV and V-level surrounding rock tunnels, the three-bench seven-step method shows several advantages. Firstly, the large construction space is convenient for the mechanized construction on numerous parallel working faces. Parts of soft rocks and soil sections can be directly excavated by using excavators, which shows high efficiency; Secondly, it is convenient for flexibly and timely transferring the construction procedure and adjusting the construction method while the geological conditions are changed. Thirdly, the method is suitable for the forms with different spans and multiple sections and it is convenient to conduct the initial support procedure. Fourthly, on the basis of the bench excavation, the core soil is preserved to carry out left–right staggered excavation, which is favorable for the stability of the excavated working faces. Fifthly, when surrounding rocks are seriously deformed, it is necessary to adjust the closure time as soon as possible on the precondition of guaranteeing the safety and satisfying the clearance requirements. Sixthly, compared with CD method, the most significant advantage of the three-bench seven-step method is that it can avoid plenty of removal works.

To guarantee the construction safety, the construction safety of tunneling by separately using CD and three-bench seven-step methods is compared by applying three-dimensional numerical simulation. Midas is employed to establish the three-dimensional calculation model, and meshes are generated, as shown in Fig. 6.

The physical and mechanical indexes of various surrounding rocks of the tunnel provided by the investigation unit are shown in Table 3.

The vertical and horizontal displacements of strata caused by the constructions by using CD and three-bench seven-step excavation methods are shown in Figs. 7 and 8.

The calculation values of dome roof settlements and clearance convergence caused by using CD and three-bench seven-step methods are displayed in Table 4.

As shown in the calculation result of three-dimensional numerical simulation, the maximums of dome roof settlement in the construction by using CD and three-bench seven-step methods were 9.55 and 8.12 mm respectively, which were smaller than the controlling value (10.42 mm) in the code. The maximum horizontal convergence values of the tunnel were about 5 and 6 mm respectively, which were also below the controlling value (26.04 mm). Obviously, the settlement of dome roof and the horizontal convergence caused by using three-bench seven-step method were both larger than those by using CD method while the displacements were both within the limited value in the code. Thus, to improve the construction efficiency, it is appropriate to replace the CD method with the three-bench seven-step method under the safe displacement.

5 Conclusions

By studying the construction technology of shallow-buried tunnel entrance constructed in residual slope accumulation of gravelly soil of Tianshan tunnel, the following conclusions can be obtained:

- (1)

By calculating the stability of side and face-upward slope of the tunnel, it is suggested that the stability coefficient of unstable slope is 1.044–1.109 under the natural stage, which is in the understable to basically stable states. Moreover, the stability coefficient of the slope is 0.968–0.982 under the rainstorm state, which is in an unstable state. To guarantee the construction safety of the tunnel, it is necessary to optimize the tunneling construction scheme and take proper measures for landslide prevention.

- (2)

Aiming at the governance of potential landslides at the side and face-upward slope of the tunnel entrance, the grouting reinforcement is mainly used for reinforcing the strata with hard surface layer and soft soil in the mid- and deep-layers. However, Tianshan tunnel entrance is located at residual slope accumulation of gravelly soil with soft surface layer, so it is hard to ensure the reinforcement effect through grouting. Moreover, the slide-resistant piles need to be constructed step by step, which take a long working term and they cost high, so it is also unsatisfactory. However, the method of lengthening umbrella arches and increasing the reverse pressure by filling soil conforms to the principle (early entering and late exiting) of tunneling and avoids the excessive excavation and construction of massif. Thus, the plants around the tunnel entrance are well preserved to maintain the previous ecological landforms at low costs.

- (3)

The three-bench seven-step and CD methods can be both used to control the deformation of surrounding rocks of the tunnel entrance. The former effectively avoids plenty of removal works, so it can significantly improve the construction efficiency and save construction costs.

References

Alija S, Torrijo FJ, Quinta-Ferreira M (2013) Geological engineering problems associated with tunnel construction in karst rock masses: the case of Gavarres tunnel (Spain). Eng Geol 157:103–111

Blödorn R, Tamura MT, Henke RA (2015) Study of the drilling process used in the hole-drilling Method through thrust force measurement and tool wear analysis. In: 23rd ABCM international congress of mechanical engineering. Rio de Janeiro, pp 1–8

Boonyarak T, Ng CWW (2014) Effects of construction sequence and cover depth on crossing-tunnel interaction. Can Geotech J 52(7):851–867

Ding L, Zhang L, Wu X (2014) Safety management in tunnel construction: case study of Wuhan metro construction in China. Saf Sci 62:8–15

Ellingsen DG, Ulvestad B, Bakke B (2015) Serum pneumoproteins in tunnel construction workers. Int Arch Occup Environ Health 88(7):943–951

Ellingsen DG, Seljeflot I, Thomassen Y (2017) Biomarkers of endothelial activation and thrombosis in tunnel construction workers exposed to airborne contaminants. Int Arch Occup Environ Health 90(4):309–317

Fukushima H, Domon T, Nishimura K (2014) Biaxial loading test on shotcrete for urban NATM tunnel. In: ISRM international symposium-8th Asian rock mechanics symposium. International society for rock mechanics

Guo X, Yin F (2014) Optimization study on construction step of shallow buried highway and small spacing tunnel. Civil Eng Technol 3(3):46–51

Ieronymaki ES, Whittle AJ, Sureda DS (2016) Interpretation of free-field ground movements caused by mechanized tunnel construction. J Geotech Geoenviron E ng 143(4):04016114

Li ZQ, Li Z (2014) Study on the blasting excavation method of urban shallow tunnel. Appl Mech Mater 580:1051–1055

Lisa H, Gunnar G, Asa F (2013) A statistical grouting decision method based on water pressure tests for the tunnel construction stage—a case study. Tunn Undergr Space Technol 33:54–62

Špačková O, Šejnoha J, Straub D (2013) Probabilistic assessment of tunnel construction performance based on data. Tunn Undergr Space Technol 37:62–78

Tafraouti N, Benamar R, Lamdouar N (2016) Study of the interaction between two parallel tunnels in the case where the second tunnel is excavated after the construction of the first tunnel. Int J Appl Eng Res 11(21):10624–10633

Yazdani-Chamzini A, Yakhchali SH, Mahmoodian M (2013) Risk ranking of tunnel construction projects by using the electre technique under a fuzzy environment. Int J Manag Sci Eng Manag 8(1):1–14

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Lu, L., Liang, S., Luo, S. et al. Optimization of the Construction Technology of Shallow-Buried Tunnel Entrance Constructed in Residual Slope Accumulation of Gravelly Soil. Geotech Geol Eng 36, 2391–2401 (2018). https://doi.org/10.1007/s10706-018-0470-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10706-018-0470-6