Abstract

Coal mine goafs are distributed widely across many parts of the world and their stability is a major cause for concern, particularly when designing new infrastructure. To reduce risk, the coal mine goafs are often stabilized using cement grout and such operations can be very expensive and difficult to verify. This paper uses the finite element method to examine the relative influence of a number of key factors controlling the stability and surface deformations of shallow, horizontal coal mine goafs overlain by sedimentary rock. Representative ranges in the stiffness and strength characteristics of coal and rock are examined and each material is assumed to satisfy the Hoek–Brown failure criterion. The analyses show that, for a typical maximum coal extraction rate of 40%, the critical goaf span varies linearly with the depth of the coal seam (for the maximum depth investigated of 45 m) and increases with the competency of the overlying rock. A relationship combining the rock quality and the ratio of the critical goaf span to the depth of the coal seam is proposed to enable assessment of abandoned coal mines with marginal stability. This relationship is shown to be consistent with observations made in two coal mining case histories.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

There is an abundance of abandoned small coal mine workings around the world and those mined over the last number of centuries are currently of major concern to developers, where suitable land is in short supply. For example, in the Shanxi province in China, Lee (2016) reports of plans to move 650,000 residents from unsafe old mining regions. The small coal mine workings are distributed randomly and typically have a relatively shallow embedment of less than 50 m. These mines were hand excavated for many centuries and typically have a low extraction ratio of about 40% (Xu et al. 2015). Although the spans of the coal mine goafs are often less that those derived from the general room and pillar method (Bell et al. 1988), their randomness makes prediction and evaluation of their effects on overlying ground deformations uncertain (Bell et al. 2000). Considerable expenses have been incurred to deal with the potential influence of small coal mine goafs on overlying property (Shi et al. 2017). However, many of the measures employed have exhibited a lack of understanding of the relative effect of the factors influencing the ground deformation.

The primary factors controlling the stability of small coal mine goafs are recognized as being the depth to the coal seam and the seam thickness, the characteristics of the overlying rock and the hydrogeology (National Coal Board, NCB 1975). Further reviews related to subsidence and the impact of subsidence above both room & pillar and longwall mine workings are described by Bell et al. (2000) and many others. These highlight the importance of the properties of the rock in determining ground deformations associated with room and pillar mine workings as well as the geometry of the coal extraction area and depth below the surface. Large scale subsidence in shallow workings with low extraction volumes usually arises due to void migration as a result of roof rock falls, which can culminate in the creation of crown-holes and chimney types collapses emerging at the surface. Such failures can occur shortly after mining operations are completed or can take many years to develop due to effects of progressive failure. Feng and Wu (2015) conclude that the uncertainties related to the random nature and the variability in goaf conditions pose the greatest challenges for developments above abandoned small coal mine workings.

This paper presents the results from numerical studies with the primary aim of providing guidelines to developers on the potential for instability above existing coal mine goafs. The study focuses, in particular, on the effects of the properties of the rock above a horizontal coal seam (or seam with a relatively low dip angle) and the depth to this seam for a constant (typical) extraction volume of 40%. More detailed numerical analyses aimed at simulation of the development of movements are presented in Li et al. (2015), Weng et al. (2018) and elsewhere. Zhou et al. (2016) consider steeply dipping coal mine seams.

2 Numerical Approach

The Finite Element (FE) method was employed to perform the parametric study presented in this paper. To obtain a conservative estimate of the potential for instability, coal extraction was assumed to be performed in long lengths of a given span width and was hence modelled using a 2D plane strain approach. Additional 2D axisymmetric analyses were performed for single openings with a radius equal to half the span width. Most analyses did not include the presence of groundwater or water pressures but some were performed to examine the effect of a high water table.

The general arrangement of the 2D plane strain FE meshes employed is illustrated on Fig. 1, which shows typical in situ small coal workings with goaf spans of 4 m and 8 m and a constant extraction ratio of 40%. The meshes comprised about 3000 triangular elements with a higher concentration of elements in areas with high stress gradients, such as the corners of the goafs. A suite of analyses was performed using the 60 m wide mesh shown in Fig. 1, assuming span widths (s) of 3 m, 4 m, 8 m, 12 m and 24 m and for depths to the top of the coal seams (h) of 15 m, 25 m, 35 m and 45 m. These analyses adopted a constant coal seam thickness of 3 m and also assumed that the vertical boundaries of the mesh were free to move in the vertical direction; this latter condition essentially models a width of coal mine workings much larger than the mesh width of 60 m. To aid interpretation, further analyses were performed using the same geometry as indicated in Fig. 1 but containing a single goaf span at the centre of the mesh. These single goaf analyses were performed assuming 2D axisymmetric conditions.

The initial stage of the calculations involved setting up of the in situ stresses in the ground (taking the in situ earth pressure coefficient, K0 = 0.33). The coal within the excavated goaf span was then replaced by air and the redistribution of stresses and associated deformations calculated.

2.1 Rock Modelling

Prediction of the response at the surface due to excavation from a coal seam requires an accurate representation of the strength of coal and the overlying rock. Rock masses have variable joints and fractures and the strength along such discontinuities usually controls the response of the entire rock mass (e.g. Goodman 1989). Marinos and Hoek (2000) developed the ‘Geological Strength Index’ (GSI) as a measure of rock mass properties based on its structure and discontinuity strength. The GSI varies from a value of 100 for an intact rock mass to zero for a ‘soil-like’ rock containing numerous closely spaced fractures with very low strength.

Hoek and Brown (1980, 1988) developed the Hoek–Browne (H–B) failure criterion for rock masses, which is an empirical relationship that extrapolates the strength of intact rock to that of rock masses. Hoek et al. (2002) present the latest extended version of the H–B model, which uses the GSI directly in the formulation. This criterion, which has been applied successfully to rock masses for many years (Benz et al. 2008), adopts the following relationship between the major principal effective stress (σ′1), minor principal effective stress (σ′3) and uniaxial compressive strength of the intact rock material (σci):

where

As indicated in Eqs. (2) and (3), the material constants a and s are related to the GSI and the disturbance factor (D); the value of D varies from 0 for an undisturbed in situ rock mass to 1 for a rock mass that has been grossly disturbed by man-made interventions such as blasting and excavation.

The value of mb in Eq. (1) is related to another material constant (mi) via the following relationship:

These formulations are used in the H-B model in the Plaxis FE program (Brinkgreve et al. 2016), which was used for this study. This program assumes linear elastic rock response up to yield where the yield function is a re-configured form of Eq. (1) i.e. the model is elastic perfectly plastic with a strength given by the H–B criterion. The tensile strength of the rock mass (σt) has an important effect on the predicted response to the excavation of mine openings and can be derived from Eq. (1) as:

2.2 Rock Properties

An important component of this study was the selection of appropriate properties for the coal and, in particular, for the overlying rock. Five categories of rock, from grade 1 to grade 5, were examined. Typical values of the unconfined compressive strength for intact material (σci) and the GSI for these categories are summarized in Table 1. These values were assessed from recommendations of Hoek and Brown (1988) and Hoek et al. (2002). The empirical factor (mi) for the intact rock was assumed to be 12, which is the mean value of commonly quoted factors of 9 for mudstone and 15 for sandstone. The disturbance factor (D) was set equal to zero for the rock as the coal was hand-excavated (Hoek et al. 2002) and the Young’s modulus (E) was calculated as 200 σci, which is a typical multiple of σci for sedimentary rocks (Goodman 1989).

Fractures (or cleats) in coal usually occur in two sets that are generally mutually perpendicular and also perpendicular to the bedding (e.g. Laubach et al. 1998). Coal is often classified in terms of its brightness with the brightest coal having cleats at a typical spacing of a few millimetres and dull clays being hard and blocky (with widely spaced cleats). Medhurst and Brown (1998) report on triaxial tests on coal samples of between 60 and 300 mm in diameter to investigate the effects of cleating on the mass strength and developed the H–B parameters as indicated in Table 2. As for the rock samples the Young’s modulus was calculated as 200 σci.

Tensile strengths derived using Eq. (5) are summarized in Tables 1 and 2 for the selected H–B parameters. While the predicted ratio of the compressive to tensile strengths for the coal of 16–38 are within the expected range for intact rock (e.g. Sheorey 1997), corresponding ratios for the rock reduce from about 25 for very good quality rock to about 2000 for poor quality rock, reflecting the deterioration of tensile strength with reducing GSI.

It should be noted that the H–B model does not capture on-going development of voids due to progressive failure arising from strain softening of the rock material. The analyses presented here therefore provide an indication of the initial movements and collapse potential above a mine opening and do not model time dependent deterioration of the mine. More detailed analyses of goaf stability described by Weng et al. (2018) show that a combination of tension weakening (represented as a reduction in GSI and hence rock modulus) with a double yield model to simulate the mechanical behavior of caved rock compaction provides a better description of the development of subsidence than strain-softening models using the Mohr–Coulomb failure criterion, such as reported by Li et al. (2015).

3 Numerical Observations

The 2D plane strain analyses were performed for the full range of goaf spans (s) and depths of coal seams (h) referred to earlier and for all five rock types with properties given in Table 1. Initial calculations using the properties of the four categories of coal indicated in Table 2 showed that there was virtually no dependence of the computed deformation patterns in the rock on the selected coal category. This observation is consistent with work of Hill (2005) who observed that stability is controlled by the overlying rock and the goaf span when the width to height ratio of coal pillars is greater than about 2. The analyses were therefore performed for a single category of coal, namely that of the ‘mid-brightness’.

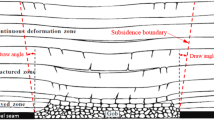

The computations (all of which involved a 40% extraction rate) indicated that a stable condition could not be achieved in Grade 5 rocks for the minimum assumed goaf span of 3 m while all goaf spans up to the maximum assumed value of 24 m were stable for the Grade 1 and 2 rocks. For the other two categories of rock considered (Grade 3 and 4), surface settlements were relatively small when conditions were stable. However, extremely large settlements occur when the goaf span increases above a critical value. The mechanisms are evident in the examples shown in Fig. 2 which shows the shear strains surrounding single and multiple goafs for stable conditions in Grade 2 rock in Fig. 2a, c and unstable conditions in Grade 4 rock in Fig. 2b, d. In the stable condition, the weight of the overburden is transmitted by arching across the span. An illustration of the arching mechanism is provided on Fig. 3 which plots contours of vertical stress in the vicinity of the openings. Failure and collapse of the roof material into the underlying void will occur (the degree of which depends on the fracture properties of the rock) but these minor failures have little impact on immediate ground settlements. As shown on Fig. 2b, d, when the rock is of lower strength and the goaf span is at or above a critical value, large deformations occur at the ground surface as the failure mechanism within the rock extends to the surface. The mechanism indicated in Fig. 2b, d is comparable to that suggested in NCB (1975) for the same s/h ratio. It is also noted that while little interaction of the shear strains in the rock above the goafs are apparent on Fig. 2c, the deformations at ground level are higher for cases of multiple goafs due to elastic interaction of the displacement fields.

This interaction is illustrated on Fig. 4a, which, for Grade 4 rock, plots the ratio of the surface settlement due to multiple goafs of a given span (as shown on Fig. 1) to the settlement arising from a single opening of that span. Ratios significantly higher than unity, and hence significant interaction, occur at low spans as the number of mine openings is greater (given the constant extraction ratio). The ratio reduces as the depth to the coal seam increases and, as seen in Fig. 4b, there is a relatively unique dependence of settlement (and the plotted settlement ratio) on the goaf span to mine depth ratio (s/h).

The variation of surface settlement with the goaf span (s) is plotted on Fig. 5 for Grade 3 and 4 rocks. Settlements are evidently larger in the Grade 4 rock. These show a small rate of increase as the goaf span widens up to a critical span width, above which very large settlements occur and eventually the failure mechanism extends to the surface occurs. The critical span dimension increases as the depth to the coal seam increases and as the quality of the rock improves.

4 Discussion

An interesting outcome of the finite element analyses is the prediction of a relatively steep sided failure mechanism as indicated in Fig. 2b, d. As a consequence, very little interaction of the failure modes associated with each goaf is predicted, provided that the extraction ratio does not exceed 40% (which is a practical maximum for most shallow coal mines).

Critical span widths (scrit) were derived from output such as shown Fig. 5 and are defined here as the span at which the rate of change of the slope of the span-settlement relationship was a maximum. The ‘turning points’ could be inferred by inspection and, for the example given in Fig. 5a, scrit values of 8.7 m, 10.4 m, 12.2 m and 14.2 m are identified for respective coal seam depths (h) of depths of 15 m, 25 m, 35 m and 45 m.

The scrit values deduced for Grade 3 and 4 rocks are plotted against the coal seam depth (h) on Fig. 6. A clear linear variation of scrit with h is in evidence for each rock type (15 m < h < 45 m). Furthermore, the slope of the trend lines is identical, indicating the key importance of the scrit/h ratio in the assessment of marginal stability. It is also clear from Fig. 6 that, for all coal seam depths, the scrit value for the Grade 3 rock is approximately 4 m higher than for Grade 4 rock. It is worth recalling that no failure was predicted for any span with Grade 1 or 2 rock and no mining could be conducted safely with Grade 5 rock.

The analyses suggest the following simple relationship can be employed to assess if an abandoned coal mine has marginal stability, where G is the rock grade and the mine extraction ratio does not exceed 40%:

Equation (6) is illustrated graphically on Fig. 7, and indicates that scrit can be interpreted as the span for which the arching mechanism seen on Fig. 2a, c can no longer develop as it emerges to the surface. The dimension ‘d’ (= 4(5 − G)) reflects the additional degree of arching possible in more competent rock.

Graphical illustration of Eq. 6

Further FE parametric studies, which included modifications to the rock properties, 2D axisymmetric analyses and the inclusion of groundwater provided additional insights to assist application or modification of Eq. (6). These showed:

-

(1)

As anticipated from inspection of the H-B failure criterion, the value of d depends most significantly on the specified σci and GSI parameters in very weak rock. For example, increasing the unconfined compressive strength (σci) of very poor quality Grade 5 rock from 1 to 10 MPa (which is clearly not realistic) enabled stable goafs to be excavated (with d = 2.2 m) while increasing σci in better quality Grade 4 rock from 5 to 25 MPa only increased scrit by about 2.5 m.

-

(2)

The critical span width (or diameter) for goafs which are approximately circular in plan is approximately 50% higher than for the long ‘tunnel-type’ excavations considered in derivation of Eq. (6).

-

(3)

When a water table at ground level is assumed, the critical span width reduces by between 0.5 and 2 m as h increases from 15 to 45 m in the set of analyses considered in Fig. 5.

5 Case Histories

Two small coal mine goaf projects were chosen in this paper to examine the potential of Eq. (6) for assessment of the stability of old coal mine workings.

Project #1 is in Jincheng city in the Shamxi province, China, where extensive coal mining has taken place over the past century. Large areas of shallow buried goafs envelope the city and their presence is the major consideration for developers for the rapidly growing city. The particular area in Jincheng examined here is at a construction site where a coal seam exists at around 25 m depth. The geo-investigation report sourced from the Taiyuan Design Research Institution for the Coal Industry presents the stratigraphy and the various rock properties at the site, which were established through a combination of geophysical and conventional geotechnical methods. A summary of the profile is provided in Fig. 8a. The coal is classified as of high brightness (Class C2) and the mine goafs are about 6 m wide. The overlying 16 m thickness of sandstone and mudstone layers is of fair to good quality, with an interpreted grade of 2.5. No water inflow to the mine goafs was observed and the water table is anticipated to be below 80 m depth.

Project #2 is located in Zibo city, Shandong province, China. The coal seam at this site (Class C3–C4) is at about 45 m depth and goaf spans were estimated to be about 6–8 m wide. The stratigraphy and rock properties were obtained from geo-investigation provided by the Shandong provincial Geo-mineral Engineering Exploration Institute, and are summarized in Fig. 8b. Boreholes showed poor core recovery and based on the rock core strengths, core logs and the rock descriptions provided in the same report, the 33 m thick rock strata overlying the goafs was assessed to be of very poor to poor quality with a Grade (G) of 4.5. No water was encountered in the boreholes.

Equation (6) is represented on Fig. 9 as a variation of scrit with rock grade for various thicknesses of rock cover (h). The goaf width (s) and rock cover (h) for both projects are indicated on this figure and show that there are no concerns for Project #1 but stability is a significant concern for Project #2 for which the estimated goaf span is 7 m and the critical goaf span is 5 m. These inferences are entirely consistent with the observations at the respective sites.

Comparison of configurations at Projects #1 and #2 with Eq. 6

Extensive coring was performed in advance of construction in Project #1 at Jincheng and revealed no evidence of mining induced deterioration of overlying rock properties. However, despite confirmation of good quality rock and an absence of any evidence of subsidence, mine goafs were grouted at large expense and resulted in a 1 year delay to the construction programme; the grouting volumes injected were consistent with an extraction rate of 30%. FE analyses following the same methodology as described above showed that grouting provides no benefit for the goaf span width and rock grade at this site. In contrast and also in keeping with Fig. 9, major ground deformations and evidence of localized collapse for Project #2 at Zibo are reported in the geo-investigation reports. Grouting of mine goafs was, in this instance, performed to stabilize the site and allow construction of apartment blocks. Stabilisation of old goafs using grout is described by Wang et al. (2018).

6 Conclusion

A parametric study using the finite element method is described to assist the assessment of the stability of horizontal shallow coal mine goafs. It is shown that for a typical maximum coal extraction ratio of 40% and using an appropriate model and representative parameters for the rock and coal strata, the critical span width (scrit) for a goaf is related to the capacity of the overlying rock to arch. This capacity is deduced to be primarily a function of the depth of rock above the coal seam as well as the rock quality. A simple expression to determine scrit is developed which can be used to provide an estimate of the likelihood of marginal stability above shallow coal mine goafs at a given site. This expression is demonstrated to be consistent with observations in two mining case histories.

References

Bell FG, Cripps JC, Culshaw MG, Lovell MA (1988) A review of ground movements due to civil and mining engineering operations. Geol Soc Lond Eng Geol Spec Publ 5(1):3–31. https://doi.org/10.1144/GSI.ENG.1988.005.01.01

Bell FG, Stacey TR, Genske DD (2000) Mining subsidence and its effect on the environment: some differing examples. Environ Geol 40(1–2):135–152. https://doi.org/10.1007/s002540000140

Benz T, Schwab R, Kauther RA, Vermeer PA (2008) A Hoek–Brown criterion with intrinsic material strength factorization. Int J Rock Mech Min Sci 45(2):210–222. https://doi.org/10.1016/j.ijrmms

Brinkgreve RBJ, Kumarswamy S, Swolfs WM (2016) PLAXIS 2016. Plaxis BV, Delft

Feng A, Wu S (2015) Verification analysis of small coalmine goaf surface residual subsidence. Science paper online. (in Chinese)

Goodman R (1989) Introduction to rock mechanics, 2nd edn. Wiley, Hoboken

Hill D (2005) Coal pillar design criteria for surface protection. In: Proceeding of the 2005 coal operators’ conference, pp 31–38

Hoek E, Brown ET (1980) Empirical strength criterion for rock masses. J Geotech Eng Div. https://doi.org/10.1016/0148-9062(81)90766-X

Hoek E, Brown ET (1988) The Hoek–Brown failure criterion—a 1988 update. In: Proceedings of 15th Canadian rock mechanics symposium, pp 31–39

Hoek E, Carranza C, Corkum B (2002) Hoek–Brown failure criterion—2002 edition. In: NARMS-TAC conference, Tornoto, pp 267–273. https://doi.org/10.2026/0148-9062(74)91782-3

Laubach SE, Marrett RA, Olson IE, Scott AR (1998) Characteristics and origins of coal cleat: a review. Int J Coal Geol 35(1–4):175–207. https://doi.org/10.1016/S0166-5162(97)00012-8

Lee J (2016) China’s sinking coal mining towns. The Guardian. www.theguardian.com/global-development-professionals-network. Accessed 9 Sept 2016

Li WF, Bai JB, Peng S, Wang XY, Xu Y (2015) Numerical modeling for yield pillar design: a case study. Rock Mech Rock Eng 48:305–318

Marinos P, Hoek E (2000) GSI: a geologically friendly tool for rock mass strength estimation. In: Proceedings of the GeoEng2000 conference, Melbourne, pp 1422–1442

Medhurst TP, Brown ET (1998) A study of the mechanical behavior of coal for pillar design. Int J Rock Mech Min Sci 35(8):1087–1105

Sheorey PR (1997) Empirical rock failure criteria. AA Balkema, Rotterdam

Shi C, Chen Y, Xu Z et al (2017) Code for coal mine treatment of buildings in coal mine goaf, GB 51180-2016. China Plane Press, Shanghai (in Chinese)

National coal board (1975) Subsidence engineer’s handbook. National coal board, London

Wang C, Lu Y, Cui B, Guo H, Zhang Z (2018) Stability evaluation of old goaf treated with grouting under building load. Geotech Geol Eng 36(4):2553–2564

Weng L, Luan H, Luan Y (2018) A numerical approach considering mining-induced fracture weakening and goaf compaction on surface subsidence. Geotech Geol Eng. https://doi.org/10.1007/s10706-018-0608-6

Xu Y, Wu X, Li F et al (2015) Code for investigation of geotechnical engineering in the coal mine goaf. GB 51044-2014. China Plane Press, Shanghai (in Chinese)

Zhou S, Wu K, Zhou D, Li L, Xu Y (2016) Experimental study on displacement field of strata overlying goaf with sloping coal seam. Geotech Geol Eng 34(4):1847–1856

Acknowledgements

The first author would like to acknowledge the assistance provided by The University of Western Australia during this research. This research did not receive any specific grant from funding agencies in the public, commercial, or not-for-profit sectors.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Zhang, F., Lehane, B. A Numerical Study to Assist Assessment of the Stability of Shallow Coal Mine Goafs. Geotech Geol Eng 37, 2837–2846 (2019). https://doi.org/10.1007/s10706-018-00799-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10706-018-00799-5