Abstract

The specific energy (SE) is the most important parameter to estimate the energy consumption in tunnel boring machines (TBMs). It is defined as the amount of required energy to excavate a unit volume of rock mass which used to predict the performance of TBMs. Several models are used to estimate the SE based on different parameters such as the rock mass properties, disc cutter dimensions and cutting geometry. The aim of this work is to propose new relations between the SE and the strain energy of rock mass (W) using the geological mappings of rock mass and TBM operational parameters from Amir-Kabir Water Transferring Tunnel of Iran. W is an appropriate criterion to estimate SE because it is a function of different parameters such as rock mass behavior, pre and post failure properties and peak and residual strains. In this study, to increase the correlation coefficient of relation between the mentioned parameters, the rock mass is classified in two methods, in the first method according to the geological strength index (GSI) all data is classified in three classes such as weak, fair and good and in the second method using the drop to deformation modulus ratio (η) the classification of data is performed in three classes such as η < 0.05, 0.05 ≤ η < 10 and η ≥ 10. The results show that there are direct relations between both parameters. It is suggested to estimate SE in all rock mass classes using the proposed relations based on GSI classification.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

The specific energy of excavation (SE) is defined as the energy consumption for the drilling unit volume of rock mass. The concept of the SE has been presented first time by Teale (1965) in the petroleum industry and is an index for evaluation of the drilling processes and excavating result in rock masses. SE can be determined by the collected data from performance of a drilling machine or a TBM. Boyd (1987) calculated rate of penetration based on SE of rock mass (Ramezanzadeh et al. 2004). Correlation of this parameter to the mechanical properties of the rock mass makes it very attractive for researchers (Acaroglu et al. 2008). Some researchers such as Muirhead and Glossop (1968) achieved a good correlation between this parameter and uniaxial compressive strength (UCS). Altindag (2003) found that there is a meaningful relationship, between the SE and the fragility of rock mass (Altindag 2003). Bieniawski et al. (2006) found correlation between Rock Mass Excitability (RME) and SE. Acaroglu et al. (2008) proposed a method by using fuzzy logic procedure in the process of rock cutting to predict SE requirement of constant cross-section disc cutters. Atici and Ersoy (2009) estimated the effect of brittleness and destruction energy on SE. Zhang et al. (2012) introduced the mechanical analysis of the shield excavating process into the nonlinear multiple regression of the on-site data and achieved a diagnosis model of the SE. Wang et al. (2012) developed new SE equations with change in disc cutter radius.

The aim of this study is to predict the specific energy of TBM, SE, using the strain energy of rock mass, W. For this reason estimation of SE is conducted in three methods. In the first method prediction of SE is done without considering the post peak behavior of rock mass. In the next step, the classification of post peak behavior of rock mass is considered using two indexes including the Geological Strength Index, GSI, and the Drop to Deformation modulus ratio, η, and finally the relations between both parameters (SE and W) in any classes are estimated.

The proposed method to estimate the SE in detail is mentioned in the following section.

2 The Proposed Methods to Estimate SE

As mentioned above, the required energy to excavate a unit volume of rock mass is named SE, that is dependent on the operational parameters of TBM (Wang et al. 2012). So SE is a function of two components such as the rolling (torque) and the axial (thrust) forces of the cutterhead (Zhang et al. 2012).

Teale (1965) proposed the SE as the following expression (Teale 1965):

where SE is the specific energy for drilling (MJ/m3), F is the total thrust (KN), A is the drilling face area (m2), N is the rate of cutter head revolution (rps), T is the cutter head torque (KN m), and u is the average of penetration rate (m/s).

Equation (1) has two terms, the first representing the SE of the cutter head thrust from static loading, Whereas the second part is the SE of rotation incurred by the rotating cutter head.

SE is also used for estimation and comparison of cutting efficiency (production rates) of mechanized systems and one of the most important factors to define their optimum cutting geometries (optimum ratio of depth of cut to line spacing) for a given rock sample (Bilgin et al. 2013). SE is estimated according to Eq. 2 (Roxborough and Phillips 1975):

where SE is specific energy (MJ/m3), FC is cutting force acting on the tool (KN), and Q is yield or rock volume cut in unit cutting length (m3/km).

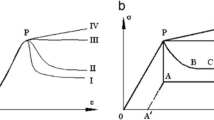

According to Eq. 3, as seen in Fig. 1 the SE is equal to integral of complete stress–strain curve in uniaxial compression test (Atici and Ersoy 2009):

where \({\text{SE}}\) is the specific energy (MJ/m3); \(\sigma\) is the stress (MPa); ε is the strain.In the next section concept of the W theory is explained in detail.

Estimation of the destruction specific energy (SEs) out of the stress–strain curve of a rock sample under unconfined compression test (Atici and Ersoy 2009)

3 Strain Energy Theory

The area under complete stress–strain curve is called strain energy of rock mass (W). W is affected by rock mass behavior, pre and post failure properties, peak strain and residual strain. Based on Hoek–Brown’s proposal, rock mass behavior is considered strain softening, because it can accommodate purely brittle behavior and elastic perfectly plastic behavior (Alejano et al. 2009, 2010; Hoek and Brown 1997). In this research, estimation of the W is carried out based on Dehkordi’s proposal (Dehkordi et al. 2011). In this method, pre and post peak behavior of rock mass is assumed linear and the modified Hoek and Brown’s criteria is used to estimate principle stresses (Hoek 1994, 2000; Hoek et al. 1998, 2002; Hoek and Diederichs 2006; Hoek and Karakas 2008). The drop modulus is estimated using Alejano’s equations (Alejano and Alonso 2005; Alejano et al. 2009, 2010). The value of peak strain is evaluated based on Sakurai’s suggestions (Sakurai 1993, 1997). For estimation of residual parameters of rock mass, \(GSI_{res}\) is estimated using Cai’s method (Cai et al. 2004, 2007). These concepts are shown in Fig. 2.

Dehkordi et al. (2011, 2013) proposed a method to estimate the stored strain energy of pre failure and the residual strain energy of post failure according to Eqs. 4, 5 respectively (Dehkordi et al. 2015a). The W is equal to summation of the residual and stored energies (Eq. 6).

where \({\text{W}}_{\text{pre}}\) and \({\text{W}}_{\text{post}}\) are stored and residual strain energy in pre- and post-failure, respectively and W is the total strain energy.

The most important parameters to estimate the residual and stored energies of rock mass are peak and residual strength and strain parameters. According to the Dehkordi et al. (2011), peak and residual properties of rock masses were respectively estimated based on the Hoek–Brown failure criterion-2002 edition and Cai et al. (2007) proposals. Cai et al. (2007), proposed estimating the residual strength of rock masses by adjusting peak GSI to the residual GSI value by using of two major controlling factors in the GSI system including residual block volume Vrb and residual joint condition factor Jrc. In order to obtain Peak failure criterion can be used of GSIpeak in Hoek and Brown equations and the residual failure criterion is similarly obtained by changing the value of the peak geotechnical quality GSIpeak to that of the residual geotechnical quality GSIres.

The guidelines given by Cai et al., (2007) used to estimate GSIres is mentioned in Table 1. Once this GSIres value has been obtained, a standard technique (for instance, RocLab freeware) can be used to obtain the residual parameters mres and sres (together with the non-changing σci) that define the Hoek–Brown residual failure criterion.

As mentioned above, peak and residual strains are important factors to estimate the strain energy. Peak strain is obtained using Sakurai’s suggestion. Sakurai (1983, 1997) has suggested that the stability of tunnels can be assessed by using of the strain in the rock mass surrounding the tunnel. The maximum strain is defined by the ratio of tunnel closure (δi) to tunnel diameter (do). Sakurai proposed the following equation to estimate the percentage strain:

where σcm is the rock mass strength and A, B are constants.

Sakurai (1997) has proposed three warning levels of risk in tunnels according:

where \(\upvarepsilon_{\text{c}}\) is critical strain and \({\text{E}}_{\text{rm}}\) is deformation modulus of rock mass.

Equations 8, 10 are shown short and long term of stability of tunnels (Sakurai 1997). In this paper, Eq. 8 was used to estimate the critical strain related to peak strength of rock mass.

The proposed method by Dehkordi et al. (2011), to estimate the residual strain, which is highly dependent on the post failure behavior of rock mass, is described in the next section.

4 Post Failure Behavior of Rock Mass Modes

Hoek and Brown (1997) suggested guidelines to estimate the post failure behavior types of rock mass according to rock mass quality. These guidelines are based on rock types (Hoek and Brown 1997):

-

(a)

For very good quality hard rock masses, with a high GSI value (\(GSI > 75\)), the rock mass behavior is elastic brittle and dilation angle is \(\frac{\uptheta}{4}\) (where \(\uptheta\) is the friction angle).

-

(b)

For averagely jointed rock (\(25 < GSI < 75\)), the strain softening is assumed and dilation angle is \(\frac{\uptheta}{8}\).

-

(c)

For very weak rock (\(GSI < 25\)), the rock mass behaves in an elastic perfectly plastic manner and no dilation are assumed (according to Fig. 3).

The brittle and perfectly plastic behaviors are special cases of the strain softening behavior because the strain softening behavior can accommodate brittle and perfectly plastic behaviors (Alejano et al. 2009). One of the most important parameters to identify the strain softening behavior of rock mass is the drop modulus (M) which is the slope of the post failure section of stress–strain curve. The amount of the mentioned parameters is an index to determine the post failure of rock mass, if this modulus approaches to zero, perfectly plastic behavior is obtained and inversely the brittle behavior is observed if it approaches to infinity.

Based on the previous researches, it is cleared that the drop modulus of rock mass is highly related to rock mass quality (Cai et al. 2007; Hoek and Brown 1997) and the confinement stress level (Alejano and Alonso 2005; Wawersik 1970). Based on these observations, Alejano et al. (2009) proposed the next equations to estimate the drop modulus of the rock mass by using the deformation’s modulus, Erm, GSI peak , intact rock strength, \(\upsigma_{\text{ci}} ,\) confinement stress, \(\sigma_{3}\) and \({\text{s}}^{\text{peak}}\).

The residual strain is estimated according to the following equations:

where M is the drop modulus, \(\upvarepsilon_{{1{\text{peak}}}}\) is the strain in peak point, and \({\Delta \varepsilon }\) shows the post peak strain (changing the strain from peak to residual strength).

Dehkordi et al. proposed a new classification of rock mass based on the η ratio to predict the post failure behavior of rock mass. The η ratio is equal to the absolute value of the drop to deformation modulus ratio and obtained from following equation:

The classification of post peak behavior of rock mass based on η ratio is as below (Dehkordi et al. 2015b):

-

1.

if \(\eta < 0.05\), the rock mass behaved in plastic manner

-

2.

if \(0.05 \le \eta < 10\), the post peak behavior is strain softening

-

3.

if \(\eta > 10\), the post peak behavior is brittle

As mentioned above, there are two indexes to estimate the post failure properties of rock mass including the η ratio and the GSI.

In this study the classification of Amir-Kabir Water Transferring Tunnel is adapted according to both of mentioned indexes.

5 Projects Description and Geology

Amir-Kabir Water Transferring Tunnel of Iran is a water transferring tunnel with 16 m3/s water flow capacity from Amir-Kabir dam to Tehran. Location of tunnel is shown in Fig. 4.

Location of Amir-Kabir tunnel (Lot-2) (SCE 2009)

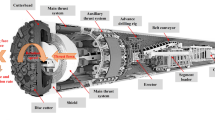

Total length of tunnel is 30 km and it is divided into two sections. The Lot2 with 13.45 km in length and 4.66 m in diameter is excavated with a double shield TBM Herrenknecht model S323. The basic specifications of utilized TBM are shown in Table 2.

The tunnel alignment contains a series of asymmetric faults and folded formations. The lithology of this area consists of a sequence of Karaj formations and a variety of pyroclastic rocks, often interbedded with sedimentary rocks. The rock mass types of tunnel are gray tuff, siltstone, sandstone, monzodiorite and monzogabbro. The engineering geological profile of the tunnel is shown in Fig. 5.

Engineering geological profile of Amir-Kabir tunnel (Lot-2) (SCE 2009)

In general, by considering the repeated units in different parts of the tunnel route, 20 engineering geological units were distinguished. Geological and geomechanical properties of rock mass types are mentioned in Table 3 (SCE 2009).

In the next section SE of TBM is estimated based on W with considering both indexes of post failure behavior of rock mass.

6 Estimation of SE Using W

The main purpose of this section is to predict SE of TBM using W. For this reason, 83 sections in different zones of Amir-Kabir Water Transferring Tunnel of Iran were considered and estimation of SE was conducted using of recorded actual information in TBM operational data sheets of mentioned tunnel. One of the operational data sheets was shown in Fig. 6.

A recorded TBM operational data sheet from Amir-Kabir tunnel (SCE 2009)

The minimum and maximum of W varies between 0.04 and 4.51, depending on the quality of rock mass and confinement stress. The regression analysis is used to investigate the kind of relation between SE and W without considering the post failure behavior of rock mass.

As illustrated in Fig. 7, there is a direct relation between both parameters and a new logarithmic equation with R2 = 0.668 (Eq. 17) is proposed to predict SE based on W.

where SE is the Specific Energy of TBM (MJ/m3), and W is the Strain Energy of rock mass (MJ/m3).

It is cleared that the correlation coefficient between both parameters is low, so to increase it, the classification of rock mass according to the post failure behavior of rock mass is considered.

7 Estimation of SE with Considering the Post Failure Behavior of Rock Mass

As mentioned above there is two indexes to identify the post failure behavior of rock mass such as GSI and η ratio.

7.1 Estimation of SE with Considering GSI

The classification of rock mass formations with considering the Hoek’s proposal is performed as shown in Table 4 and the statistical analysis to estimate SE using W is performed in any class.

As seen in Figs. 8, 9, and 10, the relation between SE and W in any class is direct, and the proposed equations (Eqs. 18–20) are shown in Table 5.

Where SE is the Specific Energy of TBM (MJ/m3), and W is the Strain Energy of rock mass (MJ/m3).

7.2 Estimation of SE with Considering η Ratio

As mentioned above η ratio is an index to distinguish post failure behavior of rock mass. So the classification of rock mass with considering it, is performed as shown in Table 6.

As seen in Figs. 11, 12, and 13, the relation between SE and W in any class is direct, and the proposed equations (Eqs. 21–23) are shown in Table 7.

8 Conclusion

In this study the post failure behavior of rock mass was assumed strain-softening behavior, because it can clarify both brittle and plastic behaviors. The results of model showed that increasing the quality of rock mass and decreasing the minimum principal stress can cause to increase the drop modulus because the rock mass behavior changes from elastic plastic to elastic brittle and drop modulus intended to infinite and it can be true inversely.

In this research, the prediction of the specific energy of TBM in Amir-Kabir Water Transferring Tunnel of Iran was performed using the strain energy of rock mass and it was predicted in three methods such as without considering the post peak behavior of rock mass, using the Geological Strength Index, and using the Drop to Deformation modulus ratio.

At the first method, estimation of SE using W without considering the post failure behavior of rock mass was carried out in Amir-Kabir Water Transferring Tunnel of Iran and a new logarithmic equation (Eq. 17) with R2 = 0.668 was proposed to predict SE based on W. Because of high variation of SE and low correlation coefficient of the mentioned equation, the classification of all data was performed with considering the post failure behavior of rock mass using GSI and η ratio.

At the next step, the classification of rock mass was conducted based on GSI and all data was classified in three classes such as plastic (\({\text{GSI}} < 25\)), strain softening \((25 < GSI < 75)\) and brittle \(\left( {{\text{GSI}} > 75} \right)\) and the best correspondence between SE and W was proposed using the statistical analysis in any class. Based on the statistical analysis, the maximum correlation between both parameters was achieved using Eqs. 18–20 to estimate the SE.

Finally using η ratio, the classification of data was performed in three classes such as \(\upeta < 0.05\), \(0.05 \le\upeta < 10\) and \(\upeta \ge 10\). Also a statistical analysis was performed to estimate SE using W in any class. The results show that there were direct relations between both parameters and the best equations with highest correlation coefficient were achieved and Eqs. 21–23 were proposed to estimate SE.

The results showed a strong correlation between the mentioned parameters using the classification of post peak behavior of rock mass based on GSI, because the correlation coefficients of the mentioned equations (Eqs. 18–20) were higher than other equations. So it was proposed to estimate SE using W considering post failure behavior of rock mass based on GSI classification.

References

Acaroglu O, Ozdemir L, Asbury B (2008) A fuzzy logic model to predict specific energy requirement for TBM performance prediction. Tunn Undergr Space Technol 23:600–608

Zhang Q et al (2012) Modeling specific energy for shield machine by non-linear multiple regression method and mechanical analysis. In: Proceedings of the 2011 2nd international congress on computer applications and computational science. Springer, Berlin, pp 75–80

Alejano L, Alonso E (2005) Considerations of the dilatancy angle in rocks and rock masses. Int J Rock Mech Min Sci 42:481–507

Alejano L, Rodriguez-Dono A, Alonso E, Fdez-Manin G (2009) Ground reaction curves for tunnels excavated in different quality rock masses showing several types of post-failure behaviour. Tunn Undergr Space Technol 24:689–705

Alejano L, Alonso E, Rodriguez-Dono A, Fernandez-Manin G (2010) Application of the convergence-confinement method to tunnels in rock masses exhibiting Hoek–Brown strain-softening behaviour. Int J Rock Mech Min Sci 47:150–160

Altindag R (2003) Correlation of specific energy with rock brittleness concepts on rock cutting. J S Afr Inst Min Metall 103:163–171

Atici U, Ersoy A (2009) Correlation of specific energy of cutting saws and drilling bits with rock brittleness and destruction energy. J Mater Process Technol 209:2602–2612

Bieniawski Z, Tamames B, Fernandez J, Hernandez M (2006) Rock mass excavability (RME) indicator: new way to selecting the optimum tunnel construction method. In: ITA-AITES World Tunnel Congress & 32nd ITA General Assembly, Seoul.

Bilgin N, Copur H, Balci C (2013) Mechanical excavation in mining and civil industries. CRC Press, Boca Raton

Boyd R (1987) Performance an experimental development of the mobile miner at Mount Isa. In: Proceedings Rapid Excavation and Tunneling Conference, pp 747–768.

Cai M, Kaiser P, Uno H, Tasaka Y, Minami M (2004) Estimation of rock mass deformation modulus and strength of jointed hard rock masses using the GSI system. Int J Rock Mech Min Sci 41:3–19

Cai M, Kaiser P, Tasaka Y, Minami M (2007) Determination of residual strength parameters of jointed rock masses using the GSI system. Int J Rock Mech Min Sci 44:247–265

Dehkordi MS, Shahriar K, Maarefvand P, Gharouninik M (2011) Application of the strain energy to estimate the rock load in non-squeezing ground condition. Arch Min Sci 56:551–566

Dehkordi MS, Lazemi H, Shahriar K (2015a) Application of the strain energy ratio and the equivalent thrust per cutter to predict the penetration rate of TBM, case study: Karaj-Tehran water conveyance tunnel of Iran Arabian. J Geosci 8:4833–4842

Dehkordi MS, Lazemi H, Shahriar K, Dehkordi MS (2015b) Estimation of the rock load in non-squeezing ground condition using the post failure properties of rock mass. Geotech Geol Eng 33:1115–1128

Hoek E (1994) Strength of rock and rock masses ISRM News Journal 2:4–16

Hoek E (2000) Practical rock engineering. Course note by Evert Hoek, Rocscience.

Hoek E, Brown E (1997) Practical estimates of rock mass strength. Int J Rock Mech Min Sci 34:1165–1186

Hoek E, Diederichs MS (2006) Empirical estimation of rock mass modulus. Int J Rock Mech Min Sci 43:203–215

Hoek E, Karakas A (2008) Practical rock engineering. Environ Eng Geosci 14:55–58

Hoek E, Marinos P, Benissi M (1998) Applicability of the geological strength index (GSI) classification for very weak and sheared rock masses. The case of the Athens Schist Formation. Bull Eng Geol Environ 57:151–160

Hoek E, Carranza-Torres C, Corkum B (2002) Hoek–Brown failure criterion-2002 edition. In: Proceedings of NARMS-Tac, pp 267–273

Muirhead IR, Glossop LG (1968) Hard rock tunnelling machines. Trans Inst Min Metall 77:A1–A48.

Ramezanzadeh A, Rostami J, Kastner R (2004) Performance prediction models for hard rock tunnel boring machines. In: Proceedings of sixth Iranian tunneling conference, Tehran, Iran

Roxborough FF, Phillips HR (1975) Rock excavation by disc cutter. Int J Rock Mech Min Sci Geomech Abstr 12:361–366

Sakurai S (1993) Back analysis in rock engineering. Comprehensive rock engineering. J Excav Support Monit 4:543569

Sakurai S (1997) Lessons learned from field measurements in tunnelling. Tunn Undergr Space Technol 12:453–460

Sakurai S, Takeuchi K (1983) Back analysis of measured displacements of tunnels Rock. Mech Rock Eng 16:173–180

Sahel Consulting Engineers (SCE) (2009) Engineering geology report of Karaj–Tehran water conveyance tunnel (lot 2)

Teale R (1965) The concept of specific energy in rock drilling. Int J Rock Mech Min Sci Geomech Abstr 1:57–73

Wang L, Kang Y, Cai Z, Zhang Q, Zhao Y, Zhao H, Su P (2012) The energy method to predict disc cutter wear extent for hard rock TBMs. Tunn Undergr Space Technol 28:183–191

Wawersik WRFC (1970) A study of brittle rock fracture in laboratory compression experiments. Int J Rock Mech Min Sci Geomech Abstr 7:561–575

Acknowledgements

The authors are indebted to all staff, including consulting engineers, contractors, and employers, especially Sahel Consulting Engineers (SCE), for providing us with data, as well as all individuals who helped to us to prepare this paper.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Mirahmadi, M., Tabaei, M. & Dehkordi, M.S. Estimation of the Specific Energy of TBM Using the Strain Energy of Rock Mass, Case Study: Amir-Kabir Water Transferring Tunnel of Iran. Geotech Geol Eng 35, 1991–2002 (2017). https://doi.org/10.1007/s10706-017-0222-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10706-017-0222-z