Abstract

Rapid urbanization and expansion of metropolitans in the developing world is pressing the need of tall structures with multiple basements. In several such projects, open land is available around excavation site and unsupported deep excavations by maintaining appropriate side slopes offer economical solution. In this research, subsoil stratigraphy of Lahore district was established to be comprising of a top clay stratum 1.5–8 m thick, followed by a sand layer. Considering subsoil data from several geotechnical investigation reports, the effect of four key parameters viz., cohesion of clay layer, friction angle of sand layer, thickness of clay layer at the top and slope inclination of underlying sand layer on safety factor of open excavations was studied. Six hundred twenty-five slope stability analyses were conducted by considering different geometries and soil properties. Based on the results of these analyses, a regression model was suggested to estimate safety factor of open excavations in similar stratigraphy which would be useful in feasibility studies and preliminary design of deep excavations. It was established that the clay layer cohesion was the most dominant contributor to safety factor.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

With the ever-increasing population of our planet the space around us is getting congested and limited. Consequently its dwellers are forced to construct vertical; both above and below the ground surface. Such trend of high-rise construction is somehow comparable in both developed and under-developed countries. Although the rules, regulations and safety management systems are better implemented in developed countries but safety in construction is given least importance in the developing world (Qazi et al. 2006). Enforcement of safety regulations in Pakistan is not widespread and some relevant regulations are both outdated and irrelevant to daily construction operations (Mohamed et al. 2009).

There is a growing demand of deep excavations with the increase in trend of high-rise buildings in Pakistan and the metropolis of Lahore is no exception. In urbanized areas of the city, earth retaining structures like retaining walls, anchor piles, soldier piles, etc. are often the solutions to ensure stability of deep excavations. These earth retaining techniques are costly solutions and demand highly skilled staff and equipment. However, with expansion of the city, many of the newly planned buildings exist in areas where sufficient open land is available around the excavation site. In such areas, unsupported excavations offer an economical solution to the slope stability concerns. However, no statutory laws or regulations currently exist in the country ensuring the safety of such deep unsupported excavations; rendering them a serious threat for the workers involved.

Many of the developed countries have laid down strict regulations to avoid slope failure damages. Occupational Safety and Health Administration (OSHA), a subsidiary of US Department of Labor, presents comprehensive guidelines for the execution of open excavations (OSHA 1979). Nevertheless, such well-defined guidelines are not in practice in construction industry of Pakistan.

The decision to use open excavations shall only be made on the basis of adequate subsoil knowledge and appropriate slope stability analyses (Puller 2003). Vertical cuts may be provided in clays to a limited depth. The theoretical safe depths for homogenous clay cut slope with vertical sides varies from 1.52 m (5ft) to 24.38 m (80ft) for very soft to hard clay consistencies respectively (Ratay 1996).

The main aspire of this research was to study the available factor of safety against slope failure for various geometries of open excavations with different soil properties for Lahore district. The results may possibly be applied to a construction site where similar stratigraphy exists. The findings of this study could be useful in the formulation of labor safety laws regarding construction of deep excavations in Pakistan.

2 Methodology

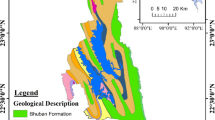

For this study thirty-one different geotechnical investigation reports of various projects scattered across Lahore district were reviewed to establish general subsurface profile (Fig. 1). Thus the data collected was factual representation of soil profiles and geotechnical parameters of the study area.

Data from the geotechnical investigation reports consisted of bore hole depth, soil type, depth of ground water table, thickness of each soil layer, unit weights, and undrained cohesion and friction angle of clay and sand layers respectively.

2.1 Soil Properties

The typical soil profile of Lahore district consists of lean clay/silty clay layers at the top followed by silty sand/fine sand deposits (Hayat and Chaudhary 2000; Hayat 2003; University of Punjab 1987). In this study, most critical soil conditions were considered for the analyses. Thus, the top layer was considered purely of cohesive nature (i.e. friction angle, Φ = 0) and the underlying sand layer to be purely frictional (i.e. cohesion intercept, c = 0).

Five distinct values of undrained cohesion representing soft (25 kPa), medium (56 kPa), stiff (87 kPa), and very stiff (119 and 150 kPa) consistency of clay layers were considered to study the effect of cohesion on safety factor. As shown in Fig. 2, the consistency of clay stratum in the study area varied from soft (≈25 kPa) to very stiff (≈150 kPa), thus the selected values well represented the whole study area. Geotechnical investigation reports depicted the variation of friction angle of sand (Φ sand ) between 26° and 34°. The cohesion values and friction angles selected for slope stability analyses are shown in Table 1.

2.2 Geometry of Open Excavations

The model configuration for the slope stability analyses is shown in Fig. 3. The maximum depth of open excavation (H) considered for analysis was 12.5 m (41ft); being maximum feasible depth of open cuts in Lahore. Static ground water table was typically not encountered at this depth.

The effects of clay and sand layer thickness on slope stability of open excavations were considered by thickness ratio (TR) defined as;

Five distinct thickness ratios for which safety factors were computed are 0.136, 0.333, 0.613, 1.041, 1.778. Practical experience of excavation in sands shows that the side slopes are generally kept between 1:0.75 (v:h) to 1:1.75. Five different configurations viz., 1:0.75, 1:1, 1:1.25, 1:1.5 and 1:1.75 were analyzed to explore the effect of slope inclination on safety factor. Hereinafter slope inclination of sand layer is expressed in terms of parameter ‘n’, representing horizontal component of slope with respect to the vertical component.

2.3 Analysis Approach

Twenty-five different geometries were considered for analyses by taking different combinations of thickness ratio (TR) and slope inclination (n). Each configuration was independently modeled and slope stability analysis was run using SLOPE/W computer program for twenty-five discrete combinations of soil properties. Thus, a total of six hundred twenty-five (625) analyses were performed for a wide range of geometrical configurations (Fig. 4) as well as soil properties (Fig. 5). A typical sequence of slope stability analyses performed in this study is explained in Fig. 6.

2.4 SLOPE/W Stability Analysis

Determination of critical safety factor was done through SLOPE/W computer program. Figure 7 shows a typical model configuration used for slope stability analyses. Slope geometry and soil properties were varied for subsequent analyses. SLOPE/W analyzed a number of trial slip surfaces, determined their corresponding safety factors, and reported the minimum of these as the critical safety factor. However, the actual sliding mass corresponding to this critical failure plane was sometimes very small; and the movement of such small soil mass may not be a real concern for the overall stability of cut slope. Hence, all test results were visually examined to consider slip surfaces with least safety factor, and causing considerable soil mass to fail, as the critical slip surfaces. A typical failure plane along with factor of safety contours is shown in Fig. 8.

3 Development of Regression Model

Multiple regression analysis was performed to explore possible correlations and the effects of four explanatory variables (i.e. c clay , Φ sand , TR and n) on the response variable FOS (factor of safety).

3.1 Selection of Best-Fit Regression Model

For the selection of a multiple regression model a number of regressions, comprising different combinations of independent variables, may be performed on a given data set. The best-fit regression is then selected as the multiple regression model (Bera et al. 2005). It is not necessary for the model to include all the independent variables. The selection of appropriate model mainly depends on individual’s judgment. It includes incorporation of relevant theory and knowledge of the subject under study, and careful examination of scatter plots and regression diagnostics (Dielman 2001).

In the model under consideration, first of all the maximum model was defined; that is the model containing all explanatory variables which could possibly be present in the final model. This included all the interaction terms that might affect the response variable (i.e. FOS). Eighty-six interaction terms were developed by considering different combinations of explanatory variables with different exponential powers. The maximum model thus defined contained a total of eighty-six different explanatory variables.

This large number of explanatory variables may or may not be relevant for making predictions about the response variable. Thus, it is useful to reduce the model to contain only the variables which provide important information about response variable. Stepwise regression method was employed to select the most significant and relevant out of the available eighty-six explanatory variables. Thus the finally selected regression model for the determination of safety factor can now be presented as;

Figure 9 shows the goodness of regression model by plotting the safety factor predicted by regression model versus safety factor obtained through SLOPE/W analyses.

3.2 Assessment of Regression Model

A measure of how well the multiple regression line fits the data is assessed through a statistic called multiple coefficient of determination (R 2) which ranges from 0 to 1. However, the value of R 2 sometimes keeps on increasing with the addition of explanatory variables even if the additional explanatory variables are non-desirable and adding to the redundancy of the model. Therefore in multiple regression, an alternate and useful measure of goodness of fit is adjusted R 2 (R 2 adj ). Generally, an R 2 value greater than 0.95 indicates the regression line reasonably fits the data (Aiken and West 1991; Haan 1994). Table 2 shows that R 2 adj of model is greater than 0.95 thus proposed regression model reasonably fits the data.

3.3 Significance of Multiple Regression Coefficients

Significance of multiple regression coefficients of Eq. 1 as a whole was tested using F-test. F-test indicates the suitability of the assumed model for predicting data. The null hypothesis considers all the partial regression coefficients equal to zero, whereas, at least one of the values is non-zero in the alternate hypothesis. If the significance level F is 0.05 (or less) then model is considered as “significant”. It means that there is only 5 in 100 (or less) chance that there really is no relationship among the response variable and the predictors (Devore and Farnum 1999; Draper and Smith 1966). Table 2 shows that the significance F of model is 0, thus proving the suggested model to be significant.

3.4 Significance of Partial Multiple Regression Coefficients

To evaluate the contribution of individual variables in explaining the response variable, t-statistic test is performed. Table 3 presents summary of the t-statistics of the coefficients. The significance of each partial multiple regression coefficient is evaluated by comparing its absolute t-value with the corresponding critical t-value. If the observed t-result is less than critical t-value then statistically, the coefficient is same as zero.

The decision rule for the rejection of the null hypothesis is satisfied, i.e. all the explanatory variables help explain the variation in safety factor.

3.5 Limitations of the Suggested Model

The suggested regression model is only capable of predicting safety factor of geometry presented in Fig. 3, i.e. top clay stratum with a vertical cut and sloping sand layer underneath. Slope faces having other geometrical configurations such as clay face being inclined or having benches cannot be analyzed using this model. Likewise, the applicability of this model is limited to open excavations having cohesion of clay layer (c clay ), friction angle of sand layer (Φ sand ), slope inclination of sand layer (n) and thickness ratio of soil layers (TR) in the range of 25 ≤ c clay ≤ 150 kPa, 26o ≤ Φ sand ≤ 34o, 0.75 ≤ n ≤ 1.75, and 0.136 ≤ TR ≤ 1.778, respectively.

The model does not account for the effects of dynamic forces on stability of open excavations. Hence, additional considerations will be required for application of this model to seismically active regions or areas nearby ground vibration sources.

4 Discussions

The results of all six hundred twenty-five analyses are summarized in Eq. 1. Using preliminary soil data only, this equation can be of practical importance for quick estimate of safety factor of slopes with similar configurations. It also enables to study the effects of individual predictor variables (c clay , Φ sand , n and TR) on the safety factor of any geometry of open cuts.

Safety factor of a slope is directly dependent on shear strength of soil. It is an obvious fact that the safety factor of a slope will increase with an increase in shear strength of the soil (Duncan et al. 1987; Terzaghi 1943). To integrate this verity in the current study, safety factor was determined by increasing cohesion and keeping the other three parameters viz. n, TR and Φ sand , constant. Figure 10 shows a plot of c clay versus FOS while keeping other three parameters viz. n, TR and Φ sand fixed at their minimum and maximum values.

It can be elucidated that increase in safety factor with increasing c clay is dependent on the values of other three parameters viz., Φ sand , TR and n. When Φ sand , TR and n have their minimum values, percentage increase in safety factor for every 10 kPa increase in c clay is 4 %. However, when values of other three parameters (i.e. Φ sand , TR and n) increase to their maximum values, percentage increase in safety factor becomes 14 %. Similar analysis conducted for Φ sand , TR and n shows that percentage increase in safety factor ranges from 1.7 to 4 % for every 1° increase in Φ sand and 15 to 34 % for unit increase in ‘n’.

It was observed that the trend is not identical for thickness ratio and depends largely on soil properties. Thickness ratio (TR) depicts the effect of changing soil layer thickness on safety factor (Fig. 11).

Weak soils show a decreasing trend of safety factor (19 % decrease per unit increase in TR) whereas, a considerable increase of about 56 % is observed in favorable soil conditions. Increase in TR is an indicative of added clay thickness. Both the disturbing and resisting moment increases with TR. Disturbing moment increases due to the increased overburden of clay layer; while the increase in resisting moment is because a larger part of failure envelope passes through the clay layer. Since clay layer is the most significant contributor towards safety factor (discussed in Sect. 4.1); larger part of failure envelope passing through clay layer would therefore improve shear resistance and enhance safety factor. In case of weak soil conditions, increased disturbing moment caused by high overburden dominates the increase in resisting moment, thereby reducing safety factor. However, for favorable soil conditions increase in resisting moment with TR eclipse the increase in disturbing moment, as highlighted in Fig. 12. With increasing TR from Fig. 12a–d, a progressively larger portion of failure envelope passes through clay layer. A larger contribution from clay layer therefore, causes the safety factor to increase from Fig. 12a–d.

4.1 Dependence of Safety Factor on Predictor Variables

Each of four predictor variables contribute to change in safety factor. However, due to incomparable units, it is difficult to determine the most significant contributor. Therefore, values of all variables normalized with respect to corresponding maximum values are plotted against safety factor as shown in Fig. 13. C clay , having the steepest slope turns out to be the most significant contributor among predictor variables. Thus, even a small increase in cohesion causes considerable improvement in safety factor.

Figure 13 also shows that the safety factor is least sensitive to changes in n and Φ sand . Therefore, it can be comprehended that cohesion of top clay layer plays a more significant role in overall stability of model excavation.

5 Conclusions

A regression model for quick estimate safety factor of open excavations is proposed. It is emphasized that the suggested regression model can confidently be applied for estimating safety factor of similar open excavations in Lahore district or other areas where similar stratigraphy prevails.

The individual effects of each of four predictor variables (c clay , Φ sand , n and TR) on safety factor was analyzed. It was observed that all else being equal, safety factor increases by 4–14 %, 1.7–4 % and 15–34 % for every 10 kPa increase in c clay , 1° increase in Φ sand and unit increase in n respectively. In case of TR; a decreasing safety factor trend for debile conditions changes to an increasing trend for strong soil conditions. Normalized values of predictor variables plotted against safety factor show that c clay is the most significant contributor to safety factor.

The suggested regression model can facilitate engineers in preliminary design of deep excavation. Findings of this study is a step forward towards execution of safe open cuts and the results can be utilized in formulation of pertinent labor safety laws in Pakistan.

References

Aiken LS, West SG (1991) Multiple regression: testing and interpreting interactions. Sage Publications Inc., California

Bera AK, Ghosh A, Ghosh A (2005) Regression model for bearing capacity of a square footing on reinforced pond ash. Geotext Geomembr 23(3):261–285. doi:10.1016/j.geotexmem.2004.09.002

Devore JL, Farnum NR (1999) Statistics for engineers and scientists. International Thomson Publishing, Inc., USA

Dielman TE (2001) Applied regression analysis for business and economics. Thomson Learning, Inc., Duxbury

Draper NR, Smith H (1966) Applied regression analysis. Wiley, New York

Duncan JM, Buchignani AL, DeWet M (1987) An engineering manual for slope stability studies. Department of Civil Engineering, Geotechnical Engineering, Virginia Polytechnic Institute and State University, Blacksburg

Haan TC (1994) Multiple linear regression. Statistical method in hydrology. Affiliated, East-West Press Pvt. Ltd., New Delhi

Hayat K (2003) Geotechnical zonation and their relation to geology of Pakistan. University of Punjab, Lahore

Hayat K, Chaudhary MN (2000) Geotechnical properties, stratigraphy and fluvial facies of Lahore soils. In: Paper presented at the 3rd South Asia Geological Congress Lahore, Pakistan

Mohamed S, Ali TH, Tam WYV (2009) National culture and safe work behaviour of construction workers in Pakistan. Saf Sci 47(1):29–35. doi:10.1016/j.ssci.2008.01.003

OSHA OSaHA (1979) Safety and Health Regulations for Construction (Standards 29–CFR) 1926 Subpart P App B Sloping and Benching. U.S. Department of Labor, Occupational Safety and Health Administration, 200 Constitution Avenue, Washington DC, 20210, USA

Puller M (2003) Deep excavations: a practical manual, 2nd edn. Thomos Telford Publishing, Thomas Telford Services, Ltd., 1 Heron Quay, London

Qazi AU, Ye L, Choudhry RM (2006) Demand and awareness of construction safety practices in Pakistan. In: Dongping Fang RM, Hinze JW (eds) CIB W99 international conference on global unity for safety & health in construction. Tsinghua University Press, Beijing, pp 470–475

Ratay RT (1996) Handbook of temporary structures in construction, 2nd edn. McGraw Hill, New York

Terzaghi K (1943) Theoretical soil mechanics. Wiley, New York

University of Punjab (1987) Geotechnical aspects of Lahore soils. The Geological Bulletin of the Punjab University, vol 24. Lahore, Pakistan

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Irfan, M., Akbar, A., Aziz, M. et al. A Parametric Study on Stability of Open Excavations in Alluvial Soils of Lahore District, Pakistan. Geotech Geol Eng 31, 729–738 (2013). https://doi.org/10.1007/s10706-013-9623-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10706-013-9623-9