Abstract

The permeability of the rock specimen during the process of deformation and failure is a dynamic evolution, and it relates with the growth and coalesces of micro-cracks within the rock. Although extensive researches have been conducted on the relationship between the stress–strain and the permeability, the deformation of the specimen should be taken into account for the evaluation of the permeability. In this study, experiments on the hydro-mechanical coupling of sandstone are carried out. Change of the permeability with the axial, lateral and volumetric strains is investigated. The experimental results show that the change of the permeability during the process of deformation and failure has apparent phases, and the evolution of the permeability is closely correlated with the strain. According to the experimental data, two kinds of empirical equations are fitted to better describe the relationship between the permeability and the strain. One is the polynomial equation used to simulate the phase of compression of rock specimens, the other is exponential equation used to simulate the rest of deformation phases. The obtained equations are just the empirical ones for the sandstone and are not for the universal application.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

The permeability is an important physical property of rock. The experimental and theoretical investigations show that the permeability of rock changes with the growth and coalesce of micro-cracks within the rock (Bai et al. 1999a; Heiland and Raab 2001; Shao et al. 2005; Wang et al. 2012). It is one of the most significant phenomena and should be taken into account in many engineering applications, such as storage of nuclear wastes, stability of rock slopes and hydraulic dams. The permeability of rock also shows strong correlation with the burial depth, stress state and rock properties.

It is well understood that the compressive loading may lead to the reduction of permeability as a result of closure of pores. Conversely, the growth and coalesce of micro-cracks during the process of loading may result in the enhancement of the permeability. That is, the permeability of rock is a dynamic evolution process during the complete stress–strain cycle. In order to establish the correlation between the stress–strain and the permeability, many experiments have been made (e.g. Zoback and Byerlee 1975; Bai et al. 1999b; Suri et al. 1997). The relationship between the stress–strain and the rock failure mechanism have also been investigated by many researchers (e.g. Barton et al. 1985; Li et al. 1994; Zhu and Wong 1997; David et al. 2001; Heiland 2003; Olivella et al. 2004; Millard et al. 2005; Shao et al. 2005). These investigations show that the stress–strain has an obvious effect on the permeability, and some kinds of functions may be used to describe the relationship between the strain and the permeability (Gangi 1978; Tsang and Witherspoon 1981; Hicks et al. 1996; Shan et al. 2000; Zhang et al. 2004).

Although extensive researches have been carried out on stress–strain and permeability behavior of rock, the relationship between the strain and the permeability, particularly it remains unclear for the behavior at the phase of post-peak (Zhang et al. 2007). The relationship between the lateral strain and the permeability as well as that between the volumetric strain and the permeability still needs to be investigated.

In order to use experimental data in the engineering practice, it is necessary to develop an empirical equation. At present, some orthogonal polynomial equations are used for the fitting of the relationship between the strain and the permeability (Li et al. 1994). Though the fitting precision is good, it is not enough to reflect the variation mechanism of the permeability at the phase of post-peak. Some experimental researches show that the permeability and dilatant volumetric change are not unique functions of differential stress and that the permeability changes with differential stress are not uniquely dependent upon dilatant volumetric changes (Zoback and Byerlee 1975). Therefore, it is necessary to establish the strain-permeability equations to describe the change laws of permeability in the complete process of rock failure.

2 Experimental Principles and Methods

The coupling experiments during the complete process of stress and strain are carried out by MTS815.02 rock mechanics electric servo-controlled testing system, which is capable of uniaxial compression, triaxial compression and pore water-pressure experiments, etc., and it is one of the most advanced laboratory experimental equipments on mechanical properties of rock. The experimental principle of fluid flow is shown in Fig. 1.

In Fig. 1 σ1 is the axial pressure, σ3 is the confining pressure, p1 denotes the water pressure at the upper end, and p2 denotes the water pressure at the lower end of specimen. At the upper and lower ends of the specimen there is a permeable panel, which is a steel plate with many evenly distributed small holes, and its function is to make the water pressure act evenly at the end of the whole specimen. The plastic insulation tape and the thermal shrinkage plastic wrap are used to seal the rock specimen.

The experimental methods are as follows: first, load a certain axial pressure σ1, confining pressure σ3 and pore pressure p1 (always let p1 be less than σ3), and then lower the pore pressure p2 at the bottom of the rock specimen, the pressure difference ∆p (∆p = p1− p2) at both ends of the specimen is formed, which makes the water flow through the specimen. The ∆p decreases continuously during the process of experiment with the increase of the micro-cracks within the rock specimen. Its rate of decrease relates with the rock structure, specimen length, cross-section of the specimen, fluid viscosity, stress state, etc.

In this study, the lateral displacement transducer (LVDT) is adopted, and it can measure the change of lateral strain with time.

According to the test data automatically collected by the computer, the permeability k can be gotten based on the following assumptions:

-

1.

The fluid is considered as the continuum medium;

-

2.

The effect of gas in the experiment is ignored;

-

3.

The fluid flow can be described by the Darcy’s law.

Thus, the density of the fluid can be expressed as:

where V is the volume of fluid; is the quality of fluid.

When the fluid is compressed, the volume of fluid will be changed, and its bulk modulus K can be defined as:

where p is the fluid pressure. The negative sign in the equation denotes the volume of fluid decreases when the fluid is compressed.

The mass of the fluid (m = ρV) is considered to be constant, thus the density and volume of the fluid is the inverse ratio: (m = ρV) is constant, thus the density and volume of the fluid is the inverse ratio:

Substituting the Eq. (3) into the Eq. (2) yields the bulk modulus K:

Assuming that B is the volume of the container and A is the cross-section of the rock sample, then,

where t is the time; q is the mass flow; v is the flow velocity.

According to Eqs. (5) and (6), Eq. (4) can be changed as:

Based on the pressure balance principle from the Fig. 1,

Assuming that \( \xi = \frac{{p_{2} - p_{1} }}{H} \) is the pressure gradient and H is the height of the rock specimen, thus, the flow velocity v in the Eq. (8) can be expressed as:

According to the Darcy’s law, the flow velocity v and the pressure gradient ξ are as follows:

where μ is the dynamic viscosity.

Substituting Eq. (10) into Eq. (9) gives:

Let ξ 0 and ξ f be the initial and final pressure gradients of pore, respectively, and t f be the final time of date collection by the integral, Eq. (11) may be changed as:

Thus, the permeability k of rock specimen is obtained:

where p 10 − p 20 and p 1f − p 2f is the initial and the final pressure differences, respectively.

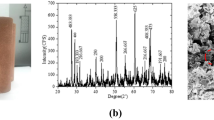

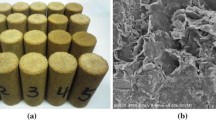

3 Experimental Parameters

The rock specimens are chosen from Nanjing, China. The controlled parameters are as follows:

-

1.

The water is used as the medium of fluid. Its density ρ = 1,000 (kg m−3), the dynamic viscosity μ = 1.01 × 10−3 (Pa s), and the coefficient of compressibility 1/K = 0.556 × 10−9 (Pa−1).

-

2.

The confining pressure is 5 MPa; and the initial hydraulic pressure difference is 4.8 MPa.

-

3.

The physical and mechanical parameters of the specimens are as shown in Table 1.

Table 1 Physical and mechanical parameters of sandstone

4 Experimental Results

Based on the test data automatically collected by the computer, the permeability of the rock specimens during the complete process from loading to failure can be obtained by use of Eq. (13).

Table 2 is the experiment results of hydro-mechanical coupling.

4.1 Relationships Between Axial Strain and Permeability

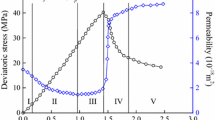

The permeability evolution of rock specimens under the complete stress–strain process shows a quite logical feature and can be divided into several phases (Martin and Chandler 1994). According to the relationship between the axial strain and the permeability, the evolution of permeability can be divided into the following four phases.

At the first phase of compression, the initial micro-cracks and pores within the rock specimens are compressed to closure, and the permeability gradually decreases with the increase of the stress and strain. At the second phase of elastic deformation, the micro-cracks and pores within the rock are compacted to the minimum, and change of the permeability is very small. Although the cracks can be further compressed, the compressibility is far less than that at the first phase. This phase can be considered to be linear elastic deformation; and the permeability at this phase can be approximated to be a constant. At the third phase of rapid increase of permeability, the cracks begin to dramatically grow and coalesce, at the same time, new cracks are formed and the connectivity of the crack network is enhanced. These make the permeability reach the maximum at this phase and show the “jumping” phenomenon. At the fourth phase of residual stress, continuous straining results in frictional sliding on fractures, under the effect of confining pressure, the permeability decreases. Generally, the permeability of rock specimens is more complex at the phase of post-peak, and the change of permeability mainly depends on the porosity and confining pressure (Fig. 2).

4.2 Relationship Between Lateral Strain and Permeability

The lateral deformation of the rock specimens reflects the yielding, weakening and failure characteristics during the process of their axial compression and failure. At present, there are some researches on the lateral deformation of the rock (Heiland 2003), but few on the post-peak lateral deformation. Figure 3 shows the curves of the complete lateral strain during the process of axial compressive failure, where the lateral deformation is set to be positive.

It can be seen that the change tendency of the relationship between the lateral strain and the permeability is basically the same as that between the axial strain and permeability, and it also undergoes four different phases. The lateral elastic strain is much smaller than the axial elastic strain, and the lateral deformation is earlier and faster to deviate from the linear elastic state than the axial deformation. Accordingly, the increase of deformation of the rock specimens is relatively faster, and the generated lateral strain is much smaller than the axial strain when the permeability reaches the peak. Therefore, the lateral strain can be more sensitive than the axial strain to reflect the change of permeability of the rock specimens.

4.3 Relationships Between Volumetric Strain and Permeability

Based on the results, the evolution of permeability and volumetric strain is compared, as shown in Fig. 4.

It is clear that the evolution of permeability is closely correlated with the volumetric strain. Four phases of evolution can be identified. At the first phase of deviatoric loading, there is a decrease of permeability due to progressive closure of the initial micro-cracks and the corresponding volumetric strain is compressive. At the second phase, the permeability nearly remains constant and the volumetric strain continues to be compressed with smaller rate. This phase corresponds to the elastic deformation phase of materials. At the third phase, the growth of micro-cracks occurs, leading to the progressive volumetric dilation due to the opening of micro-cracks. There is a significant increase of permeability at this phase in relation with the volumetric dilation, which is the same with the works of Schulze et al. (2001) and Zhang et al. (2007). After the post-peak, influenced mainly by the confining pressure, the permeability decreases, but does not appear linearly.

5 Fitting of Curves

According to the experimental data, empirical equations for the relationship between the permeability and the strain of sandstone are fitted based on the following procedures:

-

1.

In order to obtain the fitting equations, the Newtonian difference method is used to interpolate the certain number of key and test points.

-

2.

The orthogonal polynomial methods are employed on the basis of the least-squares to approximate a certain number of key and test points.

-

3.

The exponential equations are used to fit a certain number of key points and obtain the equation.

Through the mathematical fitting, two kinds of empirical equations for the relationship between the permeability and strain are obtained: (1) polynomial equations can better describe the initial phase of elastic compression; (2) exponential equations include two types of the exponential decay and the exponential rise. The former describe the phases of permeability stability and post-peak, and the latter describe the phase of the permeability with dramatic increase. The fitting equations are given below.

The initial phase of elastic compression:

The correlation coefficient, R2 = 0.97675.

The second phase of permeability stability:

The correlation coefficient, R2 = 0.9495.

The third phase of the permeability with dramatic increases:

The correlation coefficient, R2 = 0.9757.

The fourth phase of post-peak:

The correlation coefficient, R2 = 0.9125.

Therefore, the polynomial equations by fitting can be expressed as y = a + bx − cx 2 + dx 3, which better describes the initial phase of elasticity compression. The exponential equations can be expressed as y = A 1 × exp (∓ x/t 1) + y, which describes the other deformation phases. The coefficients are different for different confining pressures and seepage pressure differences.

6 Conclusions

The deformation and fluid flow failure of sandstone under the hydro-mechanical coupling is essentially a dynamic evolution process, that is, the initiation, growth and coalesce of micro-cracks and failure of sandstone. The permeability evolution of rock specimens under the complete stress–strain process shows a quite logical feature and can be divided into four phases, and the permeability has different changes at various phases. According to the investigation on the features of axial stain-permeability, lateral strain-permeability and volumetric strain-permeability curves, it is seen that the evolution of permeability is closely correlated with the strain.

The permeability-strain equation provides another indispensable governing equation for analyzing the hydro-mechanical coupling of sandstone. Because the evolution of permeability is closely correlated with the strain, the empirical equations can be obtained by the method of mathematical fitting. Finally, two kinds of equations are obtained, which can better describe the process of the fluid flow and failure of sandstone. One is the polynomial equation to describe the compression phase of the rock specimens, and the other is the exponential equation to describe the other phases of deformation.

In this work, the obtained equations are just the empirical equations for the sandstone. They are not for the universal application, and their coefficients are different for various test conditions and rock samples. It should be noted that the proposed equations are suitable for the sandstone.

References

Bai M, Meng F, Elswroth D et al (1999a) Numerical modelling of coupled flow and deformation in fractured rock specimens. Int J Numer Anal Methods Geomech 23:141–160

Bai M, Meng F, Elswroth D et al (1999b) Analysis of stress-dependent permeability in nonorthogonal flow and deformation fields. Rock Mech Rock Eng 32(3):195–219

Barton N, Bandis S, Bakhtar K (1985) Strength, deformation and conductivity coupling of rock joints. Int J Rock Mech Min Sci Geomech Abstr 22(3):121–140

David C, Menendez B, Zhu W, Wong TF (2001) Mechanical compaction, microstructures and permeability evolution in sandstones. Phys Chem Earth (A) 26(1–2):45–51

Gangi AF (1978) Variation of whole and fractured porous rock permeability with confining pressure. Int J Rock Mech Min Sci Geomech Abstr 15(4):249–257

Heiland J (2003) Laboratory testing of coupled hydro-mechanical processes during rock deformation. Hydrogeol J 11(1):122–141

Heiland J, Raab S (2001) Experimental investigation of the influence of differential stress on permeability of a Lower Permian (Rotliegend) sandstone deformed in the brittle deformation field. Phys Chem Earth 26(1–2):33–38

Hicks TW, Pine RJ, Willis Richards J (1996) A hydro-thermo-mechanical numerical model for HDR geothermal reservoir evaluation. Int J Rock Mech Min Sci Geomech Abstr 33(5):499–511

Li SP, Li YS, Wu ZY (1994) Permeability-strain equations corresponding to the complete stress–strain path of Yinzhuang sandstone. Int J Rock Mech Min Sci Geomech Abstr 31:383–391

Martin JB, Chandler NA (1994) The progressive fracture of Lac du Bonnet granite. Int J Rock Mech Min Sci Geomech Abstr 31:643–659

Millard A, Rejeb A Chijimatsu M et al (2005) Numerical study of the THM effects on the near field safety of a hypothetical nuclear waste repository—BMT1 of the DECOVALEX III project”. Part 2/Effects of THM coupling in continuous and homogeneous rocks. Int J Rock Mech Min Sci Geomech Abstr 42:731–744

Olivella S, Gens A, Gonzalez C (2004) THM analysis of a heating test in a fractured tuff. Elsevier Geo-Engineering Book Series: coupled thermo–hydro–mechanical–chemical processes in geo-systems-fundamentals. Model Exp Appl 2:181–186

Schulze O, Popp T, Kern H (2001) Development of damage and permeability in deforming rock salt. Eng Geol 61:163–180

Shan RL, Jiang YS, Li BQ (2000) Obtaining dynamic complete stress-strain curves for rock using the Split Hopkinson Pressure Bar technique. Int J Rock Mech Min Sci 37(2):983–992

Shao JF, Zhou H, Chau KT (2005) Coupling between anisotropic damage and permeability variation in brittle rocks. Int J Numer Anal Methods Geomech 29:1231–1247

Suri P, Azeemuddin M, Zaman M, Kukreti AR, Roegiers JC (1997) Stress dependent permeability measurement using the oscillating pulse technique. J Petrol Sci Eng 17:247–264

Tsang YW, Witherspoon PA (1981) Hydro mechanical behavior of a deformable rock fracture subject to normal stress. J Geophys Res 86(B10):9187–9298

Wang HL, Chu WJ, He M (2012) Anisotropic permeability evolution model of rock in the process of deformation and failure. J Hydrodyn 24(1):25–31

Zhang J, Roegiers JC, Spetzler HA (2004) Influences of stress on permeability around a borehole in fractured porous media. Int J Rock Mech Min Sci 41(3):454–464

Zhang J, Standifird WB, Roegiers JC, Zhang Y (2007) Stress-dependent fluid flow and permeability in fractured media: from lab experiments to engineering applications. Rock Mech Rock Eng 40(1):3–21

Zhu W, Wong TF (1997) The transition from brittle faulting to cataclastic flow: permeability evolution. J Geophys Res 102(B2):3027–3041

Zoback MD, Byerlee JD (1975) The effect of microcrack dilatancy on the permeability of Westerly granite. J Geophys Res 80:752–755

Acknowledgments

This work is financially supported by the National Basic Research Program of China (973 Program) (Grant No. 2011CB013504), the State Key Laboratory for GeoMechanics and Deep Underground Engineering, China University of Mining & Technology (SKLGDUEK1108), the Natural Science Foundation of China (Grant Nos. 51009052, 11172090, 11272113), the Natural Science Foundation of Jiangsu Province (Grant No. BK2012809) and the National Key Technology R & D Program of China (Grant No. 2012BAK03B04).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wang, H., Xu, W. Relationship Between Permeability and Strain of Sandstone During the Process of Deformation and Failure. Geotech Geol Eng 31, 347–353 (2013). https://doi.org/10.1007/s10706-012-9588-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10706-012-9588-0