Abstract

Soft soils are well known for their low strength and high compressibility. Several techniques, including reinforcement, are commonly used to increase the strength and decrease the deformation of this kind of soil. This paper presents the results of an investigation into the effects of fiber on the consolidation and shear strength behavior of a clay soil reinforced with nylon fibers. A series of one dimensional consolidation and triaxial tests were conducted on samples of unreinforced and reinforced clay with different percentages of randomly distributed nylon fibers. The results show that the preconsolidation pressure decreases and the coefficient of swelling and compression generally increase with increasing the fiber content. Furthermore, the addition of the fiber leads to a significant increase in shear strength and friction angle of the natural soil.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

It is generally accepted that there is a distinction between oriented and aligned and randomly distributed reinforcing elements in reinforced soils. In the former case, the inclusions are placed in the soil at strategic locations, whereas in the latter, reinforcement elements, usually fibers, are mixed with the soil and may be placed within the problematic shear zone. In comparison with oriented or systematically reinforced soils, fiber reinforced soils with random distribution of fibers exhibit some advantages. One of the main advantages of using randomly distributed fibers is the maintenance of strength isotropy and the absence of potential planes of weakness that can develop in soils with oriented reinforcement (Gray and Maher 1982; Maher 1988). Although the concept of randomly reinforced soil is relatively new in geotechnical engineering but the reinforcement of clay soils with natural fibers has been practiced from the time of Pharaohs. Recently soil reinforcement with short, discrete, randomly oriented fibers is getting more attention from many researchers around the world. Many investigators have used fiber to improve various properties of sandy soil (e.g., Gray and Ohashi 1983; Maher and Gray 1990; Al-Rafeai 1991; Consoli et al. 2009; Yetimoglu and Salbas 2003 and Ahmad et al. 2010). These investigations have indicated that the strength of reinforced soil increases with increase in fiber content, aspect ratio and friction between soil and fiber.

Although the majority of the published literature on randomly oriented fiber focus on reinforcement of cohesionless or granular soils, results from a limited number of studies have indicated that cohesive soils can also be reinforced and such reinforced soils can be beneficial in practice (e.g., Andersland and Khattak 1979; Freitag 1986; Maher and Ho 1994; Consoli et al. 2002; Mesbah et al. 2004; Kumar et al. 2006; Tang et al. 2007 and Attom et al. 2009). It is resulted from the above studies that addition of fibers can affect the behavior of the reinforced soil in different ways. The size and quantity of fibers are very important factors governing the mechanical behavior of randomly reinforced soil. However, it should be noted that natural fibers are biodegradable and may not last for many years. Nylon fibers are not affected by the presence of salts in soils, biological degradation and ultraviolet degradation. Kumar and Tabor (2003) indicated that the tensile strength of nylon fiber is greater than many of the other materials such as paper and rubber from used tires. Andersland and Khattak (1979) conducted triaxial tests on kaolinite clay reinforced with paper pulp (cellulose) fibers. The samples were consolidated from a slurry mix and tested under two different cell pressures. On the basis of the tests results it was concluded that the addition of fibers increased both the stiffness and undrained strength of clay. Andersland and Khattak (1979) used the results of triaxaial tests on mixture of kaolinite/fiber to calculate the safety factor of an excavated slope in consolidated fibrous paper mill sludge with properties very similar to the fiber/kaolinite mixture and achieved very good agreement with field data.

Many widespread benefits and applications could arise if suitable reinforcements and construction technique can be adapted to use cohesive fill particularly in areas where cohesionless fill is in short supply. Numerous testing programs have been conducted to determine the effects of discrete fibers on the behavior of soils, usually focusing only on the short-term behavior and total strength of mixture of soil and fiber. Therefore, there is limited data for the long-term effects of fiber reinforcement within a clay soil fabric and there is a need for a data base in order to better understand and evaluate the potential improvements in the mechanical behavior of cohesive soils when reinforced with randomly distributed fibers.

The focus of the present study is on the effects of fibers on improving the mechanical behavior of cohesive soils. Cohesive soil reinforced with nylon fibers as the primary reinforcement could be beneficial engineering material as it is possible to use nylon fibers as an alternative low cost material for soil reinforcement. In order to better understand the effects of using nylon fibers as soil reinforcement an experimental program was undertaken to investigate the effect of nylon fibers on improving the mechanical behavior of a cohesive soil. The main objective of this study is to investigate the contribution of nylon fibers to the consolidation and shear strength behavior of a clay soil. The results of this study can be used for design of suitable mixtures of reinforced soil, for analysis of short- and long-term stability of such reinforced soils and for field applications concerning soils that have properties similar to fiber-clay mixture.

2 Experimental Study

2.1 Soil Properties

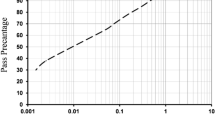

The soil used in the testing program was a fine grained soil comprising 10% sand, 56% silt and 34% clay. Laboratory tests to determine specific gravity, liquid limit (LL), plastic limit (PL), shrinkage limit (SL), grain size distribution and Standard Proctor compaction were determined according to the ASTM standards. Table 1 summarizes the various index and engineering properties of the soil. The soil can be classified as clay with low plasticity (CL) according to the Unified Classification System (USCS).

2.2 Fiber Properties

Nylon fibers were used as the reinforcement in this work. Nylon fibers have resistance against corrosion or deterioration in the soil. Plastic fibers with different lengths were obtained by threading long filaments of a plastic sheet. The fibers were threaded into pieces and starched to specified length and width. The dimensions of fiber that was used were 4.0 mm length, 2.0 mm width and 0.4 mm thickness. Fibers with the small length (4.0 mm) are usually termed short fiber (Gray and Al-Rafeai 1986). The short fibers are usually used for soils with small dimensions. Andersland and Khattak (1979) used fibers with length of 1.6 mm for reinforcing clay soil in CU triaxial tests. The fiber strength characteristics were determined through tensile strength tests. The physical and mechanical properties of the fiber used in this work are shown in Table 2.

2.3 Sample Preparation

Saturated samples were prepared for the conventional consolidation and triaxial compression tests. In order to prepare the samples, the slurry technique was considered as used by other researchers such as Marto (1996) and Andersland and Khattak (1979). When saturated samples are tested in triaxial apparatus by applying back pressure, the procedure may take a long time for clay soils particularly if the dimensions of the sample are large. This could make triaxial testing of soils time demanding and costly. As a result, some researchers such as Marto (1996) and Andersland and Khattak (1979) have suggested and used the slurry technique for preparation of soil samples. This technique of sample preparation provides reasonably homogenous and reproducible samples with near saturation conditions. Unreinforced samples and fiber-reinforced samples with different percentages of fiber content (10, 20 or 30%) were mixed with distilled water to a water content above the liquid limit (LL) to form a slurry. The exact amount of water was weighed and slowly added to the mixture of soil and fiber. The resultant slurry was mixed by hand steer for about 1 h until a smooth liquid resulted. The percentage of fiber was measured after 15 min of mixing by taking a sample. This was regularly done to ensure an even distribution of fiber at the time of sampling. A number of cylindrical tubes with 150 mm diameter and 300 mm height (referred to as consolidation tubes) were filled with slurry for consolidation. The slurry was then consolidated by loading, using a hydraulic jack, to the maximum consolidation pressure of 80 kPa, while drainage was allowed from the top and bottom of the tube. Consolidation was generally completed within about 7 days. After consolidation the samples were extruded into 38 mm diameter thin walled stainless steel tube and also the conventional consolidation mould. They were waxed at both ends to retain the initial water content. The samples were then stored in a controlled temperature of 20°C ± 1 before being used for testing.

2.4 Experimental Testing

One dimensional consolidation (oedometer) and consolidated undrained (CU) triaxial tests were conducted on the samples prepared. The consolidation characteristics of the unreinforced soil and fiber-reinforced soils with difference fiber contents were studied through a series of standard oedometer tests under zero lateral strain conditions.

In order to study the effect of fiber on shear strength of clay, a number of consolidated undrained (CU) triaxial tests were performed on the unreinforced samples and samples reinforced with different percentages of fiber inclusions. Each sample was isotropically consolidated to an effective confining pressure ranging from 200 to 400 kPa. During the consolidation test, the plot of the sample volume change against time was plotted. The consolidation stage was considered to be completed when there was no further volume change occurring. In this work the time for consolidation was about 20 to 24 hours. The triaxial tests were performed with initial pore pressure equal to zero under constant cell pressures of 200, 300 and 400 kPa at a constant rate of axial strain. An axial rate of 7 mm/h was selected giving a strain rate of 0.15% per minute as suggested by Bishop and Henkel (1969) and Smith and Smith (1990). The slow rate was chosen to ensure the equilibrium of pore water pressure throughout the sample during the test. The undrained triaxial test also allowed the pore pressure response of the soil samples to be studied. Verification tests were performed by repeating the tests in order to examine the repeatability of the experiments.

3 Results

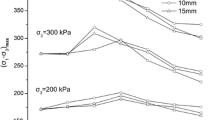

The results of the one dimensional consolidation tests are shown as ν-ln p′ plots in Fig. 1 where v is specific volume (\( v = 1+ {\text{e}} \)) and p′ is the applied pressure. The intersection of the two linear segments of the curve is used to determine the preconsolidation pressure \( \left( {p^{\prime}_{c} } \right) \) as defined by Cui and Delage (1996) and the results are shown in Table 3. The slopes C s in the elastic zone (zone before preconsolidation pressure) and C c in the elastoplastic zone (zone after preconsolidation pressure) were determined and the values are shown in Table 3. A total of 12 consolidated undrained (CU) triaxial shear tests with constant cell pressure were conducted on samples of unreinforced soil and soil reinforced with 10, 20 and 30% fiber. The tests were conducted at three different cell pressures of 200, 300 and 400 kPa. Figures 2, 3 and 4 show the variations of the deviator stress σ 1–σ 3 and pore water pressure u w with axial strain ε 1 at different cell pressures for the unreinforced and reinforced samples.

The results of the tests on the unreinforced soil and soils reinforced with different percentages of fiber under cell pressure of 200 kPa are shown in Fig. 2. The deviator stress increased until 15% axial strain for the unreinforced soil but for the reinforced samples the tests continued up to axial strain more than 20% (Fig. 2a). It is resulted by comparing the strengths at 15% axial strain for the unreinforced and reinforced samples that nearly 35, 67 and 72% increase in strength was attained by reinforcing the soil with 10, 20 and 30% fiber respectively. It is obvious from this figure that the strength curves due to 20 and 30% fiber are close to each other and the increase in strength for the soil with 30% fiber is only about 5% in comparison with the soil with 20% fiber. These results show that at a given confining pressure, increasing the amount of fiber increases the strength of the soil. Figure 2b shows the variation of pore water pressure against axial strain. It is shown that the pore water pressure increased by reinforcing the soil. The increase in the pore water pressure at 15% axial strain was nearly 55% by reinforcing the sample with 10% fiber. It is resulted that the fiber increases the porosity of the soil and the water can be collected in the pores. It can be seen that by increasing the axial strain the variation of pore water pressure becomes relatively small and at around 20% axial strain the pore water pressure remains almost constant. Figure 3 shows the results of shear tests on the unreinforced and reinforced samples under cell pressure of 300 kPa. The tests were continued up to about 20% axial strain. The deviator stress increased with increasing the fiber content. The increase of strength at 20% axial strain is about 21, 49.5 and 58.6% by reinforcing the samples with 10, 20 and 30% fiber respectively. The variation of pore water pressure with axial strain for the unreinforced sample and the samples with different percentages of fiber is shown in Fig. 3b. The amount of increase in pore water pressure is more compared with the sample tested under confining pressure of 200 kPa. Figure 4 shows the results of shear tests at confining pressure of 400 kPa. The tests were continued up to axial strain of 20%. The samples under this confining pressure showed more variations of strength and pore water pressure than the confining pressures 200 and 300 kPa. The increase in pore water pressure is 54, 65.8 and 92% by reinforcing the sample with 10, 20 and 30% of fiber respectively. It can be concluded that by increasing cell pressure the stress–strain and pore water pressure slowly evolved and the initial slope of the curves became steeper at higher cell pressures.

4 Discussion

The consolidation properties of clay-fiber mixtures were investigated through one dimensional consolidation tests. The mixture of soil and fiber can be considered as a composite because of the small length of fiber and large percentage of fiber (10, 20 and 30%) that was used in preparing the samples. Based on the results of the oedometer tests on the samples of unreinforced and reinforced clay it is concluded that the preconsolidation pressure decreases and the values of C c and C s generally increase with increasing the fiber content of the soil as shown in Table 3. For the soils with 10 and 20% fiber the values of C c are nearly the same and C s slightly decreases from 10 to 20%. This may be due to less uniform distribution of fibers in the sample with 20% fiber. By adding fiber to the soil (or increasing the fiber content) some soil particles are replaced with fibers and they occupy the pores between the soil particles which results in increase in void ratio of the soil mass. As a result, the soil becomes more compressible. Therefore both the clay and fiber in the mixture control the porosity. A soil that is more compressible has a lower preconsolidation pressure than a less compressible soil. Also, since the fibers are more compressible than the soil particles the compressibility of the soil and values of C c and C s increase with increasing the fiber content (except for 20% the values of C c is nearly the same). During one-dimensional consolidation, the stiffness of the soil decreases with increasing the fiber content. This is in contrast with the observed increase in stiffness during triaxial shearing where the stiffness and strength increase by increasing the fiber content. The main reason could be that some fibers work in tension during shearing whereas there is no tension during consolidation. These results are supported by the finding of Fukue et al. (1986) who studied the consolidation behavior of sand-bentonite-clay mixtures and showed that as the clay content increases the compression index and therefore compressibility of sample increases In practical field applications, the clay soil can be treated with a suitable agent such as lime before adding the fiber. Adding lime reduces plasticity of clay which allows the fibers to be more easily mixed into the soil.

The results of the triaxial tests on the reinforced and unreinforced samples show that the increase of strength continued up to and beyond 20% axial strain. The stress–strain curves did not indicate a clear peak of shear stress until the end of the test. The maximum deviator stress increased as the confining pressure increased. The tests were usually terminated at about 20% axial strain and at this stage the samples were bulging appreciably. The failure stress in the experiments was taken corresponding to axial strain of 20% (Head 1986; Bowles 1987). The pore water pressure increased steadily during shearing and also with increasing the confining pressure. Typical deviator stress-axial strain and pore-water pressure-axial strain curves (for cell pressures of 200, 300 and 400 kPa) for the unreinforced samples and samples reinforced with different fiber contents are shown in Figs. 2, 3 and 4. It can be observed from these figures that the initial slopes of stress–strain curves of the reinforced soils are steeper in comparison with the unreinforced soil. The stiffness of the soil is increased by increasing the amount of fiber and confining pressure. The results show that the stress–strain behavior was markedly affected by the fiber inclusions and the effect increased by increasing fiber content. It can be concluded that the fibers have a significant influence on the mechanical behavior of the soil and the strength and stiffness of the soil increases with increasing the fiber content. The results indicate that there is a direct relationship between the strength and the amount of fiber in soil mass, at least in the range of the experimental work carried out in this study. These results are consistent with those reported by Ranjan et al. (1996) who indicated that the amount of increase in strength induced by reinforcement with short fibers depends on many factor such as fiber content and confining pressure. The pore water pressure also increased with increasing the fiber content during undrained shearing. The pore water pressures generated within the soil during the CU tests, are related to the tendency of the soil to contract or dilate during shearing. The excess pore pressures are higher for the reinforced soils than the unreinforced soil (Figs. 2b–4b) particularly at cell pressures of 300 and 400 kPa. This higher pore water pressure generated can be related to the effect of fibers on the soil during deformation. Li (2005) explained this increase in pore water pressure on the fibers distributing stresses within soil mass and therefore increasing the tendency for contractive deformations within the mixture of soil fabric. The tendency to contract or dilate is indicated by the slope of the plot of excess pore water pressure in the post peak portion of the curve, whereby a positive slope indicates contractive behavior and a negative slope indicates dilatancy behavior. The values of the excess pore pressure in this work are generally positive and this indicates the tendency towards contractive behavior. Therefore, since positive pore pressure is associated to the tendency for volumetric contraction it may be concluded that fibers restrain the dilatancy of the mixture of soil and fiber as discussed by researchers such as Peters et al. (2010). This also provides an evidence that the deformation behavior of a soil might indicates how the fabric affects the soil behavior. The results of variation of pore water pressure in this test program are in agreement with the findings of Ahmad et al. 2010 and Li (2005).

The Mohr circles of failure at different confining pressures together with the failure envelopes for the unreinforced soil and the soil reinforced with 30% fiber are shown in Fig. 5 in term of effective stresses. The failure envelopes pass through the origin, indicating zero apparent cohesion, c = c′ = 0. For the unreinforced soil, the values of friction angles in terms of total and effective stresses (φ and φ′) are 17 and 27° respectively (Table 3). For the reinforced soil with 10, 20 and 30% fibers the friction angles are 18, 21 and 23° in terms of total stresses and 36, 40 and 44° in terms of effective stresses. By adding 10–30% fiber to clay, the voids created by fiber are occupied by clay particles and thus the friction angle of the mixture is enhanced. This may be attributed to the contribution of both clay and fiber in clay-fiber composite with increasing the percentage of fiber from 10 to 30% in the mixture. At this stage the resistance of clay is attributed to the friction mobilized between clay-fiber, fiber–fiber and clay–clay. This phenomenon causes the friction angle to increase.

This increase in the pore water pressure decreases the effective stress within the soil mass. Typical stress paths in the space of deviator stress, \( q\left( {\sigma_{1} - \sigma_{3} } \right) \) and mean net stress, \( p^{\prime}\left( {\frac{{\sigma_{1} + 2\sigma_{3} }}{3}}- u_{w}\right) \) or deviator stress and mean stress, \( p\left( {\frac{{\sigma_{1} + 2\sigma_{3} }}{3}} \right) \) are shown in Fig. 6. The horizontal distance between the effective stress and total stress represents the value of pore water pressure at the desired stress point. The total stress paths (TSP) are straight lines with gradient of 3 vertical to 1 horizontal. Positive pore pressure was produced which caused the effective stress path (ESP) to rise to the left along a curved path. In general, the shape of the stress paths for unreinforced and reinforced samples indicates an increase in pore pressure with deformation (or a tendency towards a contractive volumetric deformation). At critical state, the paths reached the peak value where the samples continued plastic deformation with no change in applied stress or pore pressure. The results of (effective) stress paths show that the critical state line for a given fiber content appears to be a straight line (in the p′:q space) given by the following equation:

where M is the slope of critical state line.

Figure 7 shows typical effective stress paths and critical state lines for natural soil and soil with 30% fiber. The envelop for reinforced soil is located above the one for the unreinforced soil. This increase in strength is due to a combination of an increase in the peak deviator stress, as well as the decrease in effective stress (due to increase in pore pressure) caused by the fibers, resulting in a greater shift (to the left) in p′ value. The results also show that as the effective confining pressure increases, the effect of the fibers on the soil strength increases. It is resulted by comparing the effective stress paths of the unreinforced soil and the soil with 30% fiber that the pore water pressure increases and effective stress decreases with increasing the amount of fiber especially at high confining pressures. It is concluded from the results that the value of M is dependent on the percentage of fiber. The values of M for natural soil and soil with 30% fiber are 0.98 and 1.70 respectively. Therefore, the greater the fiber content, the higher is the value of M. The relationship between M and φ′ (effective friction angle) in compression test is gives as:

By considering the value of M in the above equation the values of φ′ can be obtained. The values of φ′ were calculated for natural soil and soil with 30% fiber as 25 and 41.5° that are nearly the same as the results in Table 3.

The fiber surface is bonded to many clay particles and this contributes to the bond strength and frictional resistance between the fiber and soil mixture. The distributed discrete fibers act as a spatial three-dimensional network to interlock soil grains, cause grains to form a unitary coherent matrix and restrict the displacement. In the clay soil the fibers are strongly bonded to the soil particles. This bonding provides resistance against sliding and hence the fibers can bear tensile stresses.

It is generally known that inclusion of fibers with tensile capacity into soils increases the strength of soils. The tensile strength of a fiber is limited to the adhesion/friction developed along the length of fiber and is a function of the length of fiber. The fibers that were used in this study had a short length and they were like strips with smaller width and thickness compared to length. According to the literature, researcher have often used relatively long fibers with small percentages (such as 0.5, 1, 2 and 5%) for reinforcing soils and the outcome has generally been an increase in strength. It can be said the addition of fibers to clay in the present work leads to a composite soil. The strength of composite soil is usually increased by adding a large percent of reinforcing material as shown by many researchers such as Leelanitkul (1989); Tan et al. (1994); Kumar and Wood (1999) and Wood and Kumar (2000). It is believed that no significant tensile strength could be developed in these fibers. It can be concluded that the interaction of these fibers with soil is not through additional tensile strength that can be developed along the length of long fiber, but through the addition of a stronger substance to the soil. This is evident from the test results as a larger amount of fiber (30%) was required to be used in a soil to make a composite with nearly equal volumes of soil and fiber. This composite nature can lead to a modest change in the properties of the soil. As it was indicated the addition of fibers increases the void ratio of composite but with increasing the void ratio the shear strength increases. These findings are consistent with results that were presented by Vallejo and Mawby (2000). They indicated that for the mixture of granular material and clay the peak of shear strength increases with increasing the porosity. Therefore, in this composite the clay and fiber in the mixtures both control not only the porosity but the shear behavior as well.

In order to evaluate the effects of fibers on the strength of soil during undraind shearing, a strength ratio parameter, R f , is introduced (similar to the parameter defined by Haeri et al. (2000) and Zhang et al. (2006) for granular soils reinforced with non-random reinforcing elements) as:

where \( (\sigma_{1} - \sigma_{3} )_{{r_{f} }} \) is deviator stress of reinforced soil at failure and \( (\sigma_{1} - \sigma_{3} )_{f} \) is deviator stress of natural unreinforced soil at failure. Using this definition the strength ratios for different confining pressures and different fiber contents are calculated as shown in Fig. 8. The results indicate that the strength ratio decreases with increasing the confining pressure for the clay with 10% fiber content but the rate of variation decreases by increasing the fiber content such that for the soil reinforced with 30% fiber, the variation of the strength ratio is almost negligible. It is concluded that in general, the value R f decreases with increasing cell pressure. Up on application of the confining pressure the fibers tend to go temporarily into compression. This compressional prestress has to be overcome by sufficient shear distribution and accompanying tensile elongation in the fibers before any shear strength increase would occur.

The results of this study indicated that the addition of nylon fiber to clay soil can improve its mechanical behavior. The fiber may be used in practice to stabilize the subgrades of roads and highways, to increase the stability of highway embankments In practice, mixing of clay soil with fiber in the field could be a problem because of high plasticity of clay soil. It is possible to reduce plasticity of clay by mixing it with lime which will allow the fibers to be more easily mixed into the soil. In this process the decrease in plasticity from the cation exchange of the calcium from lime with the clay minerals allows the fiber to be adequately mixed with clay soil. There is still contention about whether this stabilization technique is applicable to the field implementation. Freed (1990) and Grogan and Johnson (1994) showed that fibers can be successfully mixed with high-plasticity soil stabilized with lime and the mixing could be easy and the uniformity is possible. Since nylon fibers are not affected by the presence of salts in soil and are not biodegradable it can be resulted that no pollution is caused by this technique of soil reinforcement.

5 Conclusion

The effects of fiber reinforcement on clayey soil were studied by using results obtained from a series of one dimensional consolidation and CU triaxial tests. The following conclusions can be drawn from the results of this study.

The inclusion of fiber with small length and high percentage to clay soil resulted a composite material and the behavior this composite is dependent on both the soil and the fiber.

The inclusion of fibers has a significant effect on the consolidation characteristics of randomly reinforced clay soil. During consolidation, the mechanical properties of reinforced soil change with increasing the fiber content.

Reinforcement using fibers was found to restrain the volumetric dilation of soil and this leads to an increase of the excess pore water pressure in undrained conditions.

Failure envelopes determined from CU triaxial tests indicate an increase in the effective shear strength of the soil with presence of fibers.

The stiffness and shear strength of soil increase with increasing the fiber content. The friction angles in term of total stresses and effective stresses (ϕ and ϕ′) also increase with fiber content. For an increase in fiber content, the increase in ϕ′ is greater than the increase in ϕ. The slope of critical state line M is dependent of fiber content of reinforced soil.

References

Ahmad F, Bateni F, Azmi M (2010) Performance evaluation of silty sand reinforced with fibers. Geotext Geomembr 28:93–99

Al-Rafeai TO (1991) Behavior of granular soils reinforced with discrete randomly oriented inclusions. Geotext Geomembr 10:319–333

Andersland OB, Khattak AS (1979) Shear strength of kaolinite/fiber soil mixtures. In: Proceedings of international conference on soil reinforcement, vol 1. Paris, France, pp 11–16

Attom MF, Al-Akhras N M, Malkawi AIH (2009) Effect of fibers on the mechanical properties of clayey soil. In: Proceedings of the institute of civil engineers, geotechnical engineering, vol 162(GES), pp 277–282

Bishop AW, Henkel DJ (1969) The measurement of soil properties in the triaxial test. William Clowes and Sons limited, London

Bowles JE (1987) Foundation analysis and design. McGraw Hill International Book Company, New York

Consoli NC, Montardo JP, Prietto PDM, Pasa GS (2002) Engineering behavior of a sand reinforced with plastic waste. J Geotech Geoenviron Eng ASCE 128(6):462–472

Consoli NC, Vendruscolo MA, Fonini A, Dalla Rosa F (2009) Fiber reinforcement effects on sand considering a wide cementation range. Geotext Geomembr 27:196–203

Cui YJ, Delage P (1996) Yielding and plastic behavior of an unsaturated compacted silt. Géotechnique 46(2):291–331

Freed WW (1990) Innovative method of stabilizing clay utilized on centre development project. Texas Contractor, pp 12–14

Freitag DR (1986) Soil randomly reinforced with fibers. J Geotech Eng ASCE 112(8):823–826

Fukue M, Okusa S, Nakamura, T (1986) Consolidation of sand-clay mixtures. Consolidation of soils: testing and evolution ASTM STP892, pp 627–641

Gray DH, Al-Rafeai T (1986) Behavior of fabric versus fiber reinforced sand. J Geotech Eng ASCE 112(8):804–820

Gray DH, Maher MH (1982) Admixture stabilization of sand with discrete randomly distributed fibers. In: Proceeding of the XIIth international conference on soil mechanics and foundation engineering. Riode Janeiro, Brazil vol 1, pp 1363–1366

Gray DH, Ohashi H (1983) Mechanics of fiber reinforcement in sand. J Geotecl Eng ASCE 109(3):335–353

Grogan WP, Johnson WG (1994) Stabilization of high plasticity clay and silty sand by inclusion of discrete fibrillated polypropylene fibers for use in pavement subgrades. Rep. No. CPAR-GL-94-2, US Army Corpse of Engineers, Waterways Experiment Station

Haeri SM, Noorzad RN, Oskoorouchi AM (2000) Effect of geotextile reinforcement on the mechanical behavior of sand. Geotext Geomembr 18:385–402

Head KH (1986) Manual of soil laboratory testing. Pentech Press, London

Kumar S, Tabor E (2003) Strength characteristics of silty clay reinforced with randomly oriented nylon fiber. Electronic J Geotech Eng 8

Kumar GV, Wood DM (1999) Fall cone and compression tests on clay-gravel. Géotechnique 49(6):727–739

Kumar A, Walia BS, Bajaj A (2006) Compressive strength of fiber reinforced highly compressible clay. J Constr Build Mater 20:1063–1068

Leelanitkul S (1989) Improving properties of active clay by sand admixtures. In: Proceedings of foundation engineering: current principles and practices conference, ASCE. New York, USA, pp 381–391

Li C (2005) Mechanical response of Fiber-Reinforced soil. PhD Dissertation, The University of Texas at Austin, USA

Maher MH (1988) Static and dynamic response of sands reinforced with discrete randomly distributed fibers. PhD thesis, University of Michigan, USA

Maher MH, Gray DH (1990) Static response of sand reinforced with randomly distributed fibers. J Geotech Eng ASCE 116(11):1661–1677

Maher MH, Ho YC (1994) Mechanical properties of kaolinite/fiber soil composition. J Geotech Eng ASCE 120(8):1381–1393

Marto A (1996) Volumetric compression of a silt under periodic loading. PhD thesis, University of Bradford, Bradford, UK

Mesbah A, Morel JC, Walker P, Ghavami Kh (2004) Development of a direct tensile test for compacted earth blocks reinforced with natural fibers. J Mater Civil Eng ASCE 16:95–98

Peters JF, Ernest S, Bovney IV (2010) Percolation threshold of sand-clay binary mixtures. J Geotech Geoenviron Eng ASCE 136(2):310–318

Ranjan G, Vasan RM, Charan HD (1996) Probalilistic analysis of randomly distributed fiber-reinforced soil. J Geotech Eng. ASCE 122(6):419–428

Smith GN, Smith IGN (1990) Elements of soil mechanics. Blackwell Science Inc., Oxford

Tan TS, GohTC Karunaratne GP, Lee SL (1994) Shear strength of very soft clay-sand mixtures. Geotech Testing J 17(1):27–34

Tang C, Shi B, Gao W, Chen F, Cai, Y (2007) Strength and mechanical behavior of short polypropylene-fiber reinforced and cement stabilized clayey soil. Geotext Geomembr 25:194–202

Vallejo LE, Mawby R (2000) Porosity influence on the shear strength of granular material-clay mixtures. Eng Geol 58:125–136

Wood DM, Kumar GV (2000) Experimental observations of behaviour of heterogeneous soils. Mech Cohes Frict Mater 5:373–398

Yetimoglu T, Salbas O (2003) A study on shear strength of sands reinforced with randomly distributed fiber. Geotext Geomembr 21:103–110

Zhang MX, Javadi AA, Min V (2006) Triaxial tests of sand reinforced with 3D inclusions. Geotext Geomembr 24:201–209

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Estabragh, A.R., Bordbar, A.T. & Javadi, A.A. Mechanical Behavior of a Clay Soil Reinforced with Nylon Fibers. Geotech Geol Eng 29, 899–908 (2011). https://doi.org/10.1007/s10706-011-9427-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10706-011-9427-8