Abstract

Stone columns are found to be effective and economical ground improvement technique in soft grounds. Understanding its behaviour when they are installed in stratified soils, in particular when the upper layer consists of weak soil, will be of great practical significance. This paper presents results from a series of laboratory plate load tests carried out in unit cell tanks to investigate the behaviour of stone columns in layered soils, consisting of weak soft clay overlying a relatively stronger silty soil, for various thicknesses of the top layer. Tests were carried out with two types of loading (1) the entire area in the unit cell tank loaded, to estimate the stiffness of improved ground and (2) only the stone column loaded, to estimate the limiting axial capacity. Laboratory tests were carried out on a column of 90 mm diameter surrounded by layered soil, for an area ratio of 15%. It is found that the depth of top weak layer thickness has a significant influence on the stiffness, load bearing capacity and bulging behavior of stone columns.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

The increased cost of conventional foundations and numerous environmental constraints greatly encourage the in situ improvement of weak soil deposits. Amongst the various techniques for improving in situ ground conditions, reinforcing the ground with stone columns or granular piles is one of the most versatile and cost effective technique. Stone columns provide the primary functions of reinforcement and drainage by improving the strength and deformation properties of the soft soil. Stone columns increase the unit weight of soil (due to densification of surrounding soil during construction), dissipate quickly the excess pore pressures generated and act as strong and stiff elements and carry higher shear stresses (Madhav and Miura 1994). They are installed in a wide variety of soils, ranging from loose sands to soft compressible clays. Stone columns have been and are being used in many difficult foundation sites throughout the world to increase the bearing capacity, to reduce the total and differential settlements, to increase the rate of consolidation, to improve slope stability of embankments and also to improve the resistance to liquefaction (Alamgir et al. 1996). Applications of stone columns include support to embankments, liquid storage tanks, raft foundations and other low rise structures.

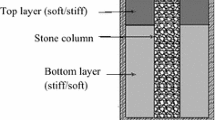

It is well established that stone columns derive their load carrying capacity from the lateral confining pressure from the surrounding soils (Greenwood 1970; Hughes et al. 1975; Barksdale and Bachus 1983). The passive resistance of the surrounding soil dictates the column performance under load. Generally the column bulging will be greatest close to the top of the column where the overburden pressures are lowest. When stone columns are installed in very soft soils or in layered soils where the top layer is very soft, they may not derive significant load capacity owing to low lateral confinement, which leads to excessive bulging. In reality, most naturally occurring soils are formed in discrete layers or are often heterogeneous. Footings are most likely to be founded on heterogeneous or multi-layered soils. Understanding the behaviour of stone columns when they are installed in stratified soils, in particular when the upper layer consists of weak layer, will be of great practical significance. Not much experimental work has been reported in literature to study the behaviour of stone columns in stratified soils. In the present study, the performance of stone columns in layered soil, which consists of weak soft clay overlying a relatively stronger silty soil, is being studied for various thicknesses of top weak layer. Series of laboratory model tests were performed in a circular unit cell tank with the stone column at the centre and the layered soil surrounding it, to investigate the effect of top soft layer thickness on the strength, stiffness and bulging characteristics of stone columns in a layered soil bed.

2 Experimental Programme

Unit-cell idealization is used in the present study to simplify the design of the apparatus needed to assess the behavior of an interior column in a large group of columns. For an infinitely large group of stone columns subjected to a uniform loading applied over the area (Fig. 1a), tributary area of each interior column may be considered as a unit cell as shown in Fig. 1b. Due to symmetry of load and geometry, lateral deformations cannot occur across the boundaries of the unit cell, and the shear stresses on the outside boundaries of the unit cell must be zero (Barksdale and Bachus 1983). Following these assumptions a uniform loading applied over the top of the unit cell must remain within the unit cell. The unit cell can be physically modeled as a cylindrical shaped container having a frictionless, rigid exterior wall symmetrically located around the stone column (Fig. 1c). Charles and Watts (1983), Ambily and Gandhi (2007), Gniel and Bouazza (2009), Shivashankar et al. (2010) have used this concept of unit cell in their model testing to predict the behavior of stone column in a large group.

All experiments were carried out on 90 mm diameter stone columns surrounded by layered soil in cylindrical tanks of 780 mm high and diameter 237 mm to represent the required unit cell area of soft soil around each column assuming equilateral triangular pattern of installation of columns, for an area ratio (Ar) of 15%, which corresponds to spacing of 2.5D, where D is the diameter of the stone column (area ratio quantifies the amount of soil replaced by stones, which is defined as the ratio of stone column area to the unit cell area). Tests were conducted in layered soil beds for top weak layer thicknesses (t) of 1D, 2D, 3D and 4D. Tests were also conducted in homogeneous soil beds consisting of only soft clay and silty soil.

Three series of tests were conducted by varying the top weak layer thickness. The first series of tests was performed on the layered soil beds without stone column. A second series of tests was performed on layered soil beds treated with stone columns by loading the entire unit cell area. In the field, the entire plan area of the stone column treated ground will be subjected to loading from the superstructure. The same was simulated in the laboratory in this series of tests by loading the whole area of the unit cell. These tests are used to study the stiffness of the improved ground. The third series of tests was performed on layered soil beds treated with stone columns by loading the column area alone. These tests are used to find the limiting axial capacity of the stone column. The overall experimental programme is given in Table 1.

A typical test arrangement is shown in Fig. 2. All the experiments were conducted on floating stone columns in layered soil beds in unit cell tanks so that L/D ratio (length of the column/diameter of the column) is a minimum of 6, which is required to develop the full limiting axial stress on the column (McKelvey et al. 2004). The total height of the layered soil bed placed in the tank was 8 times the diameter of the column. Vertical stress was applied either over the entire tank area or only over the stone column. The load was applied through a proving ring at a constant displacement rate 0.0625 mm/min. This rate of displacement is chosen to avoid any possible squeezing out of soil from the annular space between the inside of unit cell cylindrical tank and the loading plate and also to prevent build-up of excess pore water pressures. A 30 mm thick sand layer was placed at the top to serve as a blanket for the case where the entire area is loaded. The load was applied through a 12 mm thick mild steel plate.

2.1 Properties of Materials Used

The soil used for bottom layer is of ML classification, obtained from Kavoor near Mangalore, India. The soil used for top layer is marine clay of MH classification, obtained from New Mangalore Port Trust (NMPT) premises near Mangalore, India. Particle size distribution of the soils is shown in Fig. 3. Other properties of the soils are given in Table 2. Based on the preliminary tests on the silty soil, water content of 40% and dry unit weight of 12.8 kN/m3 were selected for the bottom layer and the corresponding shear strength was found to be 38 kPa. Water content of 45% and dry unit weight of 12.7 kN/m3 were selected for the top soft layer and the corresponding shear strength was found to be 19 kPa. Aggregates varying from 2 to 10 mm particle size have been used to form the stone column. In field, the diameter of stone columns normally ranges from 600 to 900 mm and the size of stones used in the range of 2–75 mm (IS 15284-2003). Hence, in field, the ratio of stone column diameter to the maximum particle size will be in the range of 8–12. The maximum size of the aggregate used in the model tests is such that this ratio is in this range. The maximum and minimum dry unit weights of the aggregate are 16.5 and 14.1 kN/m3, respectively. The sand used (for preparing sand bed in case of entire area loading) is clean river sand of size less than 4.75 mm. The grain size distribution curve of the sand used is also shown in Fig. 3.

2.2 Preparation of Layered Soil Bed and Construction of Stone Column

The inner surface of tank wall was covered with a very thin polythene sheet over a thin coat of grease that was applied to reduce the friction between clay and the tank wall. Soil was filled in the tank in layers with measured quantity by weight. Each layer was subjected to uniform compaction with a tamper to achieve 50 mm height and the corresponding unit weight. Stone column was constructed by replacement method. Thin open-ended seamless steel pipes of 90 mm outer diameter and wall thickness 2 mm were used to construct the stone column. After the bottom layer was prepared for a depth of twice the diameter of the column, the steel pipe was placed at the centre of the soil bed and construction of layered soil bed and stone column were carried out simultaneously. Outer surface of the pipe was lubricated by applying a thin layer of grease for easy withdrawal without any significant disturbance to the surrounding soil. Stones were charged into the hole in layers in measured quantities to achieve a compacted height of 50 mm. The pipe was then raised in stages ensuring a minimum of 5 mm penetration below the top level of the placed gravel. To achieve a uniform unit weight, compaction was done with a 2 kg circular steel tamper with 10 blows of 100 mm drop to each layer. This light compaction effort was adopted to ensure that there is no significant lateral bulging of the column which creates disturbance to the surrounding soft soil. Unit weight of stone columns was estimated with the quantity of aggregate consumed for the construction and the volume of the stone column. The corresponding unit weight of stone column was found to be 16 kN/m3. The procedure was repeated until the column was completed to the full height.

2.3 Test Procedure

The load-deformation behavior of the column/treated soil has been studied by applying vertical load with the help of a loading frame. To load the stone column area alone, a loading plate of diameter equal to the diameter of the column was placed over the stone column. The load was applied through a proving ring at a constant displacement rate. Settlements were monitored for equal intervals of loads up to failure. In the case where load is applied over the entire area, a 30 mm thick sand layer was placed over the entire surface. A steel plate of 12 mm thickness and a diameter of 10 mm less than the inside diameter of the test tank was placed over the sand blanket. The loading was applied in a similar way until the settlement exceeded 10 mm. When the entire area is loaded, because of the confining effect from the boundary of the unit cell, failure does not take place even for a settlement of up to or beyond 10 mm. The load settlement curves as can be seen from Figs. 4 and 5 are almost linear except in initial settlement of up to 1 mm. In other words, stiffness is constant beyond 1 mm settlement. Hence for comparison purpose a settlement of 10 mm was chosen for all the tests, where entire unit cell area was loaded. This corresponds to about 4% of the loading plate diameter and 1.3% strain. After completion of each test, the shape of the stone column was established by pouring concentrated slurry of cement into the stone column and allowing it to set for about a day. After the slurry got hardened, the surrounding clay was removed carefully and the deformed shape of stone column was obtained and quantified.

3 Results and Discussions

3.1 Behavior of Untreated Ground

Figure 4 shows typical load-settlement behavior of untreated ground, for different top layer thicknesses (from 1D to 4D). The load carrying capacity (for 10 mm settlement) of untreated ground decreases with the increase in top soft soil layer thickness. The decrease in load carrying capacity is 15, 24, 30 and 37% for a layer thickness of 1D, 2D, 3Dand 4D, respectively to that of load carrying capacity of only silty soil (bottom layer soil). Degree of reduction in load carrying capacity of untreated ground due to the presence of top soft layer is expressed in Table 3 in terms of load carrying capacity ratio (LCR) which is defined as ratio of load carrying capacity of layered ground to that of homogeneous ground (silty soil). It can be seen from Table 3, the LCR is found to decrease with increase in top soft layer thickness.

3.2 Behavior of Composite Ground (Entire Area Loaded)

As discussed earlier, the loading of entire area of unit cell tank represents an actual field condition for the interior columns of a large group of stone columns. These tests were used to evaluate the improvement in the stiffness and reduction in settlement of the treated ground with stone columns compared to that of untreated ground. Figure 5 shows typical load-settlement behavior of improved ground with 90 mm diameter stone column, for different top layer thicknesses (from 1D to 4D), for an area ratio of 15%. The load carrying capacity (for 10 mm settlement) of treated ground with stone columns with top layer thickness of 0D (only silty soil), 1D, 2D, 3D, 4D and 8D (only weak soil) are increased by 54, 31, 26, 25, 25 and 25%, respectively compared to that of respective untreated grounds.

For the homogeneous ground consisting of single type of soil, the improvement with stone column depends upon the shear strength of the surrounding soil. In case of soft silty soil (qu = 38 kPa), the improvement is 54% of that of untreated ground. Where as in case of soft clay (qu = 19 kPa), the improvement observed is only 25%. This is due to the poor lateral confinement offered by the soft clay. In case of layered soils, the improvement largely depends up on the top weak layer thickness. As the top layer thickness increases, the improvement with the stone column decreases. Significant reduction in improvement is observed even when the top layer thickness is 1D (around 20%). Predominant bulging is observed in the top 2D depth of stone column when they are installed in layered soil, where the top soft layer thickness is 2D or more. Hence, when the top layer thickness is more than 2D, the improvement with stone column is found to be nearly constant. In other words, the effect of bottom stronger layer is insignificant when the top layer thickness is more than 2D.

To evaluate the improvement in stiffness of treated ground, stiffness ratio (β), defined as the ratio of load intensity of treated ground to that of untreated ground of corresponding layer thickness, for the same settlement, was calculated and compared. Figure 6 shows the variation of stiffness ratio (corresponding to 10 mm settlement) with normalized thickness of top soft layer (t/D). The stiffness ratio is decreasing significantly with the thickness of top soft layer up to 2D and thereafter it is found to be nearly constant.

The reduction in settlement of the treated ground is evaluated based on another parameter, known as settlement reduction ratio (SRR), which is defined as the ratio of the settlement of treated ground to that of untreated ground (corresponding to the same top soft layer thickness) for the same surcharge loading. Lower SRR values represent the stiffer ground. Figure 7 shows the variation of SRR with the load intensities for different top soft layer thickness. The reduction in settlement is found to be more significant for stone column treated ground in homogeneous soil bed (i.e. with out top soft layer). The SRR values reduce significantly (hence settlements) with the decrease in the thickness of top soft layer, for all load intensities. This is due to the excessive bulging of stone columns in soil beds with the increase in top soft layer thickness. The reduction in settlement is found to be marginal (only 20–30%). This is due to the excessive bulging of stone column in the upper layers due to the poor lateral confinement offered by the surrounding soft soil. Hence, it can be concluded that the performance of stone columns in layered soils where the top layer is soft, is found to be poor and hence it needs proper reinforcement to reduce the excessive bulging and to improve its performance.

3.3 Limiting Axial Stress of Stone Column in Layered Soil (Column Alone Loaded)

Model tests were carried out with load applied just on the column area to find the limiting axial stress of the stone column. Figure 8 shows a typical relationship between axial load intensity on column and settlement for 90 mm diameter stone column, for an area ratio of 15%, for different top weak layer thicknesses. Figure 9 shows the variation of limiting axial stress with the normalized top soft layer thickness. The limiting axial stress of stone column decreases substantially with the increase in thickness of top soft layer. Even for 1D layer thickness, the decrease in limiting axial stress is around 50% compared to that of limiting axial stress of stone column in silty soil bed. For layer thickness of 4D, the limiting axial stress is same as that of stone column treated weak clayey ground. The limiting axial stress of the column, with 1D, 2D, 3D, 4D and 8D top weak layer thicknesses are decreased by 47, 57, 63, 73 and 73%, respectively compared to that of stone column in homogeneous silty soil. The limiting axial stress of stone column decreases with the increase in thickness of top soft layer. This is due to the decreasing confinement from the surrounding soil with the increase in top layer thickness and increasing the bulging tendency of stone columns and hence the limiting capacity.

3.4 Bulging Behavior of Stone Column in Layered Soil

After the load test, the deformed shape of the stone column was established by pouring concentrated slurry of cement into the stone column and allowing it to set for about a day. After the slurry gets hardened, the surrounding soil was carefully removed and the deformed shape was obtained. The diameter of the deformed stone column or bulge diameter was measured at different depths from the top of the column. The length of the deformed portion of the column was also measured. In case of homogeneous soil beds, the bulging mode of failure was clearly seen in tests where the column alone was loaded. Maximum bulging in this case was observed at a depth of 0.5–0.8 times the diameter of the column from the top. In case of stone columns in layered soils, the entire bulging was noticed in the top weak layer zone only. No significant bulging was noticed when the entire tank area was loaded. In case of entire area loaded, some load will be shared to the surrounding soil, due to which (surcharge loading on the surrounding soil) the passive resistance against the lateral bulging of stone column will be high compared to the case where column alone is loaded and hence less bulging. Another reason for less bulging is that the settlement level up to which the tests are conducted is only 10 mm. In case of column area loading, the tests were carried out up to failure (around 40 mm) and hence significant bulging was noticed. Typical photographs of extruded stone columns are shown in Fig. 10.

Figure 11 shows the non-dimensionalised bulge profiles (bulging expressed as percentage of the diameter of stone column) for 90 mm diameter stone columns in layered soil beds subjected to column area loading. The profiles show the variation of the non-dimensionalised bulge with normalized depth (H/D), where H is the total length of the stone column and D is the diameter of the stone column. It can be seen that, in case of homogeneous soil beds, bulging of stone column was predominant in weaker soil, due to lesser lateral confinement offered by that soil. The maximum bulging in silty soil was found to be 10.6% and it increased to 23.2% in weak clayey soil. The maximum bulging was found to occur at a depth of 1D from the top. The total length of the stone column subjected to bulging was observed to be 2–3 times the diameter of the column. In case of stone columns installed in layered soils, the entire bulging was observed in the top weak layer only. This may be due to the poor lateral confinement offered by the top weak soil. The maximum bulging for 90 mm diameter stone column was found to be 11.2, 20.6, 22.6 and 23.3% for 1D, 2D, 3D and 4D top weak layer thicknesses.

4 Conclusions

Experimental investigations were carried out to study the behaviour of stone columns when they are installed in stratified soils, in particular when the upper layer consists of weak soil, which will be of great practical significance. Based on experimental investigations, the following conclusions are drawn:

-

(1)

In case of homogeneous grounds, the improvement of soft soil with stone columns largely depends on the strength of the surrounding soil. Improvement in the relatively stronger silty soil is higher compared to that in soft clay. This is due to the low confinement of soft clay.

-

(2)

In case of entire area loading, the stiffness and load carrying capacity of stone column treated layered ground decreases with the increase in the top weak layer thickness. The improvement with stone columns in layered soils is found to be constant when the top layer thickness is more than 2D. Hence, for a layer thickness more than 2D, the presence of stronger bottom layer is insignificant.

-

(3)

The reduction in settlement when the stone columns are installed in layered soil, where top layer is weak, is found to be marginal (only 20–30%). This is due to the excessive bulging of stone column in the upper layers due to the poor lateral confinement offered by the surrounding soft soil. Hence, it can be concluded that the performance of stone columns in layered soils where the top layer is weak, is found to be poor and hence it needs proper reinforcement to reduce the excessive bulging and to improve its performance.

-

(4)

In case of column area loading, the top weak layer has substantial effect on the limiting axial stress of stone column in layered ground. Even for 1D layer thickness, the decrease in limiting axial stress is around 50% compared to that of limiting axial stress of stone column in silty soil bed. For layer thickness of 4D, the limiting axial stress is same as that of stone column in soft clayey ground.

-

(5)

In case of homogeneous soil beds, maximum bulging was observed at a depth of one times the diameter of the column from the top. The total length of the stone column subjected to bulging was observed to be 2–3 times the diameter of the column. In case of stone columns in layered soils, the entire bulging was noticed mostly in the top weak layer zone. Substantial increase in bulging was observed when the top layer thickness is equal to or more than 2D.

References

Alamgir M, Miura N, Poorooshasb HB, Madhav MR (1996) Deformation analysis of soft ground reinforced by columnar inclusions. Comput Geotech 18(4):267–290

Ambily AP, Gandhi SR (2007) Behavior of stone columns based on experimental and FEM analysis. J Geotech geoenviron Eng ASCE 133(4):405–415

Barksdale RD, Bachus RC (1983) Design and construction of stone columns, vol. 1, report no. FHWA/RD-83/026, National technical information service, Springfield, Virginia

Charles JA, Watts KA (1983) Compressibility of soft clay reinforced with granular columns. In: Proceedings of the 8th European conference on soil mechanics and foundation Engineering, Helsinki, pp 347–352

Gniel J, Bouazza A (2009) Improvement of soft soils using geogrid encased stone columns. J Geotext Geomembr 27:167–175

Greenwood DA (1970) Mechanical improvement of soils below ground surfaces. In: Proceedings of the ground Engineering conference, Institution of Civil Engineers, London, pp 11–22

Hughes JMO, Withers NJ, Greenwood DA (1975) A field trial of the reinforcing effect of a stone column in soil. Geotechnique 25(1):31–44

Indian Standards (IS) (2003) Indian standard code of practice for design and construction for ground improvement guidelines. Part 1: stone columns, IS 15284 (part 1), New Delhi, India

Madhav MR, Miura N (1994) Soil improvement—panel report on stone columns. In: Proceedings of the 13th international conference on soil mechanics and foundation Engineering, New Delhi, India, pp 163–164

McKelvey D, Sivakumar V, Bell A, Graham J (2004) Modeling vibrated stone columns in soft clay. In: Proceedings of the Institute of Civil Engineers, Geotechnical Engineering, vol 157, Issue GE3, pp 137–149

Shivashankar R, Babu MRD, Nayak S, Manjunath R (2010) Stone columns with vertical circumferential nails: laboratory model study. Geotech Geol Eng 28(4):695–706

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Shivashankar, R., Dheerendra Babu, M.R., Nayak, S. et al. Experimental Studies on Behaviour of Stone Columns in Layered Soils. Geotech Geol Eng 29, 749–757 (2011). https://doi.org/10.1007/s10706-011-9414-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10706-011-9414-0