Abstract

The straw return method has been increasingly implemented in rice production in Northeast China. In-depth studies on the characteristics of rice straw decomposition are of great importance for achieving sustainable agricultural development. In this study, the nylon mesh bagging method was used to study the patterns of rice straw decomposition and nutrient release during a 5-year period of rice growth. The results showed that straw decomposition occurred mainly during the first 3 years after straw return, with the cumulative amount of decomposition reaching 77.0%, and that the rate of straw decomposition decreased linearly with time. The release of carbon, nitrogen, cellulose and hemicellulose occurred mainly during the first and second years after straw return. Moreover, the release of phosphorus and potassium occurred mainly during the first month after straw return, and lignin was released at various rates throughout the entire study period. These results indicated that straw returned to the soil acts both as a source of phosphorus and potassium in the short term and as a source of nitrogen and carbon in the long term during the rice growing season in Northeast China.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Northeast China is located in the area of northeastern Asia and represents an important source of rice production. In the three provinces of Northeast China (Heilongjiang, Jilin and Liaoning) in 2015, the rice production area was 4454.4 thousand hectares, and the rice yield was 33.0 million tons. On the basis of a grain/straw ratio of 1/1.2, rice produced 39.6 million tons of straw in 2016 (China 2016). The open-field burning of rice straw eliminated 22.4% of the straw production (Liang et al. 2006) in 2015 but produced approximately 15.1 million tons of pollutants in the three provinces of Northeast China. The nutrient loss caused by straw burning can reach 80% for nitrogen (N; Raison 1979), 25% for phosphorus (P; Nigussie and Kissi 2011), 21% for 33 potassium (K; Ponnamperuma 1984) and 4–60% for sulfur (S; Lefroy et al. 1994). However, chopping straw followed by its direct return to the field can solve the problem of environmental pollution caused by straw burning and returns the various nutrients contained within the straw directly to the soil, thereby increasing the availability of soil nutrients (Mandal et al. 2004; Tirol-Padre et al. 2005; Yadvinder-Singh et al. 2004; Yadvinder et al. 2010) and improving soil structure (Abera et al. 2012; Hansen et al. 2010). Hence, investigations into the characteristics of rice straw decomposition are of important practical significance for sustainable rice production. Crop straw exhibits a common decomposition pattern of “first fast and then slow” (Ferreira et al. 2016; Pal and Broadbent 1975; Smith and Douglas 1971) and is impacted by environmental factors such as climate and soil conditions. Fores et al. (1988) studied the pattern of rice straw decomposition during the dry season in the Ebro Delta (northeastern Spain), and their results showed that, at 139 days after decomposition, the residue mass and residue N, carbon (C) and P levels were 75%, 70%, 50% and 30%, respectively, of their initial levels. The nutrients from straw decomposition in the previous season provided 33% N and 8% P for the subsequent season of rice production. A previous study on the effects of straw management (in species such as maize, soybean, wheat, sorghum and cotton) on decomposition patterns in a sandy soil in Mississippi, USA, showed that placement on the soil surface and burial at a 150 mm depth resulted in 36–66% and 69–80% annual reductions, respectively, in the mass of the straw residue (Ghidey and Alberts 1993). Using 14C-labeled rice straw, Wang et al. (1999) showed that the decomposition rate of the C within straw was fast in the early stage but slow in the late stage, with values ranging from 3.3 × 10−3 d−1 to 7.1 × 10−3 d−1, and that the C mineralization rate in wet soil was 1.2–1.5 times greater than that in dryland soil (70% of the maximum field capacity) after 112 days of incubation under laboratory conditions. Shaffer and Ma (2001) showed that aerobic conditions would increase the decomposition rate of soil organic C in dryland areas compared with wetland areas and indicated that flooding would reduce the mineralization of soil organic C. The difference between the two experimental results may be due to differences in climatic conditions and straw composition in the different test areas. Nakajima et al. (2016) showed that under 100% water-filled pore space (WFPS), the straw decomposition of rice straw increased as the temperature increased; specifically, after 24 weeks of culture under constant temperatures of 5 °C, 15 °C and 25 °C, the percentages of release were 22.2%, 33.5% and 46.2%, respectively. Straw decomposition followed a power function of time (days) (Pal and Broadbent 1975). Under laboratory conditions, the amount of gas (CO2 and/or CH4) emissions produced by the organic decomposition of microorganisms can also be used as an indicator of the decomposition rate (Devêvre and Horwáth 2000; Zhou et al. 2014). Rice straw is composed mainly of cellulose, hemicellulose and lignin (Pan et al. 2017; Wu et al. 2014). The greatest decomposition rate was observed for hemicellulose, followed by cellulose and lignin, the last of which had the lowest decomposition rate (Gong et al. 2018). Many studies have shown that silica, polysaccharides and lignin can form complex rigid structures that inhibit the decomposition of straw lignin (Eremeeva et al. 2001; Pan et al. 2010; Wu et al. 2014).

At present, studies on the regular patterns of rice straw decomposition have focused mainly on the current rice growing season or the years after straw return (Ferreira et al. 2016; Fores et al. 1988; Pal and Broadbent 1975). However, relatively few studies on the nutrient decomposition of rice residue and changes in fiber composition for more than 1 year exist. The parameters and models of straw decomposition in other regions have limited reference for Northeast China because of its unique geographical location. In this study, the nylon mesh bag method was used to monitor the changes in nutrient and fiber composition of rice straw residue for 5 consecutive years. In this area, the study of rice straw decomposition can conserve agricultural production costs, improve farmland ecological environments and provide theoretical support for the sustainable development of ecological agricultural environments.

Materials and methods

Study site description

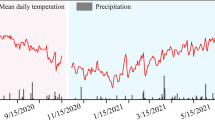

This experiment was conducted at the research and practice station of plant studies at Northeast Agricultural University. The center of the farm is located in Xingfu township, Xiangfang district, Harbin city, Heilongjiang Province, China; the geographic coordinates are 45°34′–45°46′N, 126°22′–126°50′E, and the elevation is 171.7 m above sea level. The study area has a cold temperate continental climate, with rain and high temperature occurring in the same season. The annual precipitation is between 500 and 550 mm, the frost-free period is approximately 140 days, and the ≥ 10 °C cumulative temperature is approximately 2700 °C. For rice production, a continuous cropping system with one growing season every year was adopted; the rice seedlings were transplanted in late May, with paddy rice harvesting occurring at the end of September. The soil is a Phaeozem, and the content of sand, silt and clay particles was 19.6%, 67.9% and 12.5%, respectively. The air temperature and rainfall at the study site are shown in Fig. 1.

Experimental setup

The nylon mesh bagging method was used to study the decomposition and nutrient release patterns of rice straw under field conditions for 6 years. The nylon mesh bags used were 250 mm long and 200 mm wide and had a standard mesh number (the diameter of the mesh was 0.183 mm). The straw samples were air-dried, cut to approximately 100 mm in length and placed into the nylon mesh bags, which were then sealed with nylon thread. Each bag contained 60.0 g of air-dried straw (55.2 g oven-dry mass). Each year during the experiment, tillage was conducted on May 20, the field was subject to ponding on May 22 and seedlings were transplanted on May 30. The row spacing was 300 mm, and the plant-to-plant spacing was 130 mm, with 3 seedlings per hill. On May 26, 2010, rice straw-filled nylon mesh bags were buried in the center of the paddy field, and a position mark was made in the field. The mesh bags did not overlap each other and were arranged vertically in the horizontal direction. The distance from the upper end of the mesh bag to the soil layer was 50–100 mm. To prevent damage to the mesh bags caused by tilling the soil, on May 20 each year, the mesh bags were removed, placed into a container that contained soil and covered with a soil layer that was 50 mm thick, after which the container was placed in the field. After the soil was tilled, the net bags were put back into the field. The whole process lasted no more than 2 days. The rice straw composition was as follows: 39.9% C, 6.6 mg g−1 N, 1.8 mg g−1 P, 12.2 mg g−1 K, 42.2% cellulose, 26.4% hemicellulose and 6.0% lignin. The initial soil fertility (0–150 mm) conditions were as follows: 2.2 g kg−1 total N, 0.7 g kg−1 total P, 16.5 g kg−1 total K, 26.5 mg kg−1 nitrate-N, 2.0 mg kg−1 ammonium-N, 86.8 mg kg−1 available P, 340.0 mg kg−1 available K and 26.2 g kg−1 organic matter. The basal fertilizer included 150 kg ha−1 urea (N: 46%), 150 kg ha−1 diammonium phosphate (N: 18%, P2O5: 46%) and 100 kg ha−1 potassium sulfate (K2O: 30%), and the topdressing included 150 kg ha−1 urea (N: 46%) and was applied at the tillering stage (25 days after planting). Other management practices were the same as those used in rice production (Yan et al. 2016).

Sampling, methods of analysis and calculations The initial nutrient content and fiber composition of the rice straw were determined before the straw was returned in the experiment. Sampling of the nylon bags was performed once a month during the rice growing period starting on June 26 in the first year of rice straw return (year 2010). In the second to fifth years (2011–2014), two samplings were performed—on May 26 and September 26. In the 6th year of the study, the last sampling was performed on May 26, 2015. Thus, a total of 13 samplings were performed, with 3 bags per sampling, which resulted in a total of 39 bags. After the samples were removed, they were rinsed with water and cleaned by removing the rice roots that penetrated the net bags. The samples were then oven dried, weighed, crushed and transferred to paper bags for future use.

Several methods were applied to measure the different components of the rice straw.

C was measured both by oxidation with potassium dichromate and by titration with ferrous ammonium sulfate (Nelson 1982).

Total N content was measured by digestion with H2SO4–H2O2 and the Kjeldahl method (Buchi B-324, Switzerland) (Barker and Volk 1964).

Total P content was measured by using the colorimetric method with molybdenum in sulfuric acid (Hitachi UV-2900, Japan).

Total K was measured by digestion with H2SO4–H2O2 and the flame photometry method (Sherwood F-P410, England).

The fiber composition was measured via an Ankom A200i type semiautomated fiber analyzer (USA).

Filter bag technology was first used along with a neutral eluent to extract the neutral detergent fiber (NDF) content, and a filter bag was then used along with an acidic fiber eluent to extract the acid detergent fiber (ADF) content. The same filter bag was subsequently used along with an acidic lignin eluent to extract the acid detergent lignin (ADL) content. The hemicellulose content within the straw residue represented the difference between the NDF and ADF, the cellulose content represented the difference between the ADF and ADL and the lignin content represented the ADL within the straw residue.

The following calculations were performed:

where m0 is the initial straw mass or nutrient content and m1 is the mass or nutrient content in the straw residue on a given sampling date.

Statistical analysis

All the data were subjected to a normality test prior to a one-way analysis of variance (ANOVA) using IBM SPSS Statistics 21.0 (SPSS Inc., Shanghai, China). To compare the treatment means, Duncan’s multiple range test was used at a significance level of P < 0.05. Graphs were constructed using Origin 9.0 software (Origin Lab Inc., Guangzhou, China) (Yan et al. 2018).

Results

Dynamics of rice straw mass

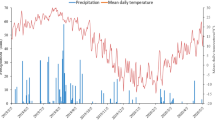

Figure 2 shows the dynamics of the rice straw mass and the percent release over time. The results showed that the mass of the straw decreased gradually as the decomposition rate increased gradually over time. The straw decomposed mainly during the rice growing season (late May–late September), whereas the decomposition of the returned straw changed little during the non-rice growing season (late September to the end of May in the following year). The straw mass decreased by 15.1 g, 6.3 g, 4.6 g and 3.9 g after the first, second, third and fourth months, respectively, which corresponded to percentages of release of 27.4%, 11.3%, 8.3% and 6.1%, respectively. By the end of the first year, the total rice straw mass decreased by 30.7 g, and the percentage of release was 55.6%, with the average straw decomposition accounting for 13.9% per month. In the second year, the percentage of release was 11.4%, which accounted for 25.6% of the residual amount after the first year’s decomposition. In the third year, the percentage of release was 9.3%, which accounted for 28.6% of the residual amount after the first 2 years of decomposition. The residual rate of rice straw decomposition followed a strong linear trend over time (1–5 years; see Table 1). The relationship was as follows: y = 49.27 − 7.75x, R2 = 0.944, where y is the residual rate of straw and x is the straw decomposition time (year).

Dynamics of rice straw composition

Dynamics of rice straw nutrient composition

Table 2 shows the dynamics of the straw composition during decomposition. The results showed that the nutrient composition during the first 2 years changed dramatically but then stabilized. First, the initial C content in the returned straw was 39.9%, after which this percentage decreased gradually and reached the lowest value of 27.4% after 2 years of decomposition. No significant change in C content was observed during the following 3 years of decomposition. Second, the initial N concentration in the returned straw was 6.6 mg g−1, and after the first year of straw decomposition, it reached 8.6 mg g−1, which was significantly greater. The N concentration decreased to 4.2 mg g−1 after 2 years of straw decomposition but slightly increased during the next 3 years. Third, the initial P concentration in the returned straw was 1.8 mg g−1; however, this concentration decreased to 0.8 mg g−1 after the first year of straw decomposition, after which it then increased gradually and remained within a rather constant range of 1.0–1.2 mg g−1 after 2 years of decomposition. The differences in P concentration over time were never significant. The K concentration in the straw exhibited nearly the same trends as did the P concentration. The lowest K concentration was 1.6 mg g−1, which occurred after 1 year of decomposition, but increased to 2.0 mg g−1 after 2 years, after which it remained within a rather constant range of 2.9–3.0 mg g−1 during the following 3 years. Taken together, the results of this study showed that the nutrient contents of the straw gradually reached equilibrium after 3–5 years of straw decomposition. The equilibrium concentrations of C, N, P and K were 288 mg g−1, 5.1 mg g−1, 1.2 mg g−1 and 3.0 mg g−1, respectively. In addition, the results showed that the C/N ratio changed over time (year) and was 39.2 in the first year after straw return, which was significantly lower than that at the other times, and after 2 years of decomposition, the value fluctuated between 54.7 and 65.2. The difference in the C/N ratio between the initial values and the subsequent years was not significant.

Dynamics of the fiber composition of rice straw

The initial percentage of cellulose content in the rice straw was 42.2%, after which it increased to 49.0% after 1 year of decomposition, remained stable from 31.4 to 39.3% after 2 years of decomposition and reached 35.9% at the equilibrium of decomposition. The initial percentage of hemicellulose content in the rice straw was rather high at 26.4%, after which it decreased to 22.7% after 1 year of decomposition, decreased to the lowest (11.2%) after 2 years of decomposition, remained stable from 13.2 to 15.0% thereafter and reached 13.3% at the equilibrium of decomposition. The lignin content in the straw initially constituted 5.9% and accounted for 7.1–9.6% of the mass of the straw during the first to fourth years, after which it decreased to 4.1% after 5 years of straw decomposition. No obvious patterns were detected in terms of the differences in lignin content in the straw.

Table 3 shows the changes in straw composition during the first year after straw return. The data in the table show that the C content in the returned straw initially constituted 39.9% but decreased to the lowest (30.3%) after 1 month of straw decomposition. Subsequently, the C content in the straw slightly increased and remained between 33.0 and 35.0%. The N content in the straw tended to gradually increase throughout the entire period of rice growth; the N content in the straw was initially 6.6 mg g−1 but increased to 8.6 mg g−1 at rice harvest (on September 26, 2010), which represented an increase of 35.8%. The P content in the rice straw was initially 1.8 mg g−1 but decreased to 0.5 mg g−1 after 1 month of decomposition, which represented a decrease of more than 70.2%; subsequently, the P concentration in the straw increased gradually. The K content in the straw was initially 12.2 mg g−1 but decreased to 1.4 mg g−1 after 1 month, which represented a decrease of 88.5%; during the following 3 months, the K concentration in the straw continued to decrease slowly and remained stable from 0.8 to 1.0 mg g−1. The C/N ratio of the rice straw was initially 60.7 but then decreased to 43.6 after 1 month of decomposition, after which it remained between 39.4 and 49.3. The percentage of cellulose in the rice straw initially constituted 42.2%, after which it gradually increased over time and peaked during the late stage of rice growth (August 26–September 26). However, the hemicellulose in the straw showed a dynamic trend with an initial decrease to the lowest value of 21.3% after 2 months of decomposition followed by an increase to 23.1% at rice harvest. The lignin content in the straw was relatively low, but it increased gradually during the first rice growing season and reached 9.0% after 4 months of decomposition.

Nutrient release and fiber composition of rice straw

Nutrient release of rice straw

Figure 3 shows the dynamics of the total nutrient residue amount and the nutrient release rate of the returned straw. The data in the figure show that the total amount of C, N, P, and K in the straw decreased gradually, the release rate increased gradually, and the nutrient release occurred mainly during the early stage after straw return. Figure 3a shows the dynamics of the total amount of C and the decomposition of the straw. The first month after straw return was the fastest stage of decomposition of organic C in the straw, with the percentage of release reaching 44.9%. During the first and second years after straw return, the percentages of organic C release were 62.5% and 77.8%, respectively. Moreover, the cumulative percentages of organic C release from the straw were 83.2%, 83.7% and 84.1% when the straw underwent decomposition for 3 years, 4 years and 5 years, respectively.

The total amount of N in the straw and the percentage of release are shown in Fig. 3b. The N content in the straw was initially 362.8 mg, which gradually decreased during the process of straw decomposition. The decomposition of N in the straw occurred mainly during the first and second years, with the cumulative percentages of release reaching 37.9% and 79.1%, respectively. In particular, the percentage of N release was 34.9% during the first 2 months of the first year, which accounted for 92.2% of the percentage of N release from the straw during the first year after straw return. The release rates of N in the straw were 82.4%, 82.5% and 82.2% when the straw underwent decomposition for 3 years, 4 years and 5 years, respectively.

Figure 3c, d show the dynamics of the total amount of P and K and their percentages of release from the returned straw. The data in the figure show that the release of P and K from the straw occurred mainly during the first month after straw return, with the total release rate of P and K reaching 77.1% and 91.7%, respectively. The release of P and K subsequently entered a slow release stage, during which the percentage of P released from the straw remained between 79.3% and 85.1%, whereas the percentage of K release remained between 93.8% and 94.9%.

During the first month of straw decomposition, the nutrient release rates were as follows: the fastest release rate was observed for K, followed by P, C and N, the last of which had the slowest release rate. During the first year after straw return, the nutrients were released in the following order: K > P > C > N. Moreover, during the first year of straw decomposition, N was released primarily during the first 2 months after straw return, whereas C, P and K were released mainly during the initial month after straw return. Beginning with the second rice growth stage, the nutrient contents in the straw remained generally consistent with those at the end of the last rice growing period, indicating that the straw barely underwent decomposition in the autumn of the previous year until the following spring at the study site. The release of K and P essentially remained stagnant after the first year of straw return; however, a large amount of C and N was released during the second year of straw decomposition. The nutrient content dynamics in the straw with time (0–5 years) are shown in Fig. 4. The model of nutrient change in straw over time is listed in Table 4. The dynamic changes in C and N in the straw represent exponential decay models whose equations are y = 81.328 * exp(− x/0.665) + 18.672 (R2 = 0.996) and y = 81.328 * exp(− x/1.001) + 18.672 (R2 = 0.965), respectively. The P and K contents in the straw as indicated by the time change equation are y = 20.37 * x^0.196 (R2 = 0.996) and y = 7.136 * x^0.325, (R2 = 0.999), respectively, where y is the residual rate of straw and x is the straw decomposition time (year).

Fiber component release of rice straw

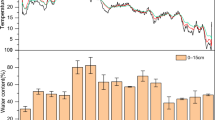

Figure 4a shows the dynamics of the total amount of cellulose and the percentage of release from straw over time. The data in the figure show that the release of cellulose from straw occurred mainly during the first and second years after straw return. The percentage of release of cellulose in the straw during the first year reached 45.6% but decreased by 11.4% per month on average during the rice growing period. The percentage of cellulose release constituted 74.3% after 2 years of release but decreased by 7.2% per month on average during the second rice growing period. The release of cellulose from the straw subsequently underwent a slow stage, with the percentage of release reaching 81.0% after 5 years of decomposition.

Hemicellulose in the rice straw accounted for 26.4% of the total amount of straw (see Table 1). Although the hemicellulose content was significantly less than that of cellulose, its percentage of release was greater than that of cellulose. Figure 4b shows that hemicellulose release from the straw occurred mainly during the first and second years after straw return. Moreover, the percentage of hemicellulose release from the straw in the first year reached 61.7% and decreased by 15.4% per month on average during the rice growing period. The hemicellulose release constituted 85.6% with 2 years of decomposition, with an average decreasing rate of 6.0% per month during the second rice growing period. The release rate of hemicellulose in the straw was subsequently maintained between 86.3% and 88.7%.

Figure 4c shows the dynamics of the total amount and release rate of lignin in the straw over time. The figure shows that the lignin content in the straw accounted for 5.9% of the total straw (see Table 1) and was significantly lower than that of cellulose and hemicellulose in the straw. The percentage of lignin release from the straw during the first year reached 30.5% and decreased by 7.6% per month on average during the rice growing period. The cumulative percentage of cellulose release was 60.1% after 2 years of release and decreased by 7.4% per month on average during the second rice growing period. The total amount of lignin did not significant change during the third year of straw decomposition, which led to a cumulative percentage of release of 62.4% after 3 years of straw decomposition. The cumulative percentages of lignin release reached 71.6% and 82.8% during the fourth and fifth years, respectively.

Figure 4 shows that the fastest release rate was observed for hemicellulose, followed by cellulose and lignin, the last of which was the slowest. The first and second years after straw return were the main periods for cellulose, hemicellulose and lignin decomposition. Subsequently, no changes were observed in the hemicellulose or cellulose decomposition, whereas lignin underwent decomposition again during the fourth and fifth years. A dynamic model of the fiber composition in the straw with time (year) is shown in Table 5, and an exponential decay model works well for cellulose and hemicellulose. The equations are y = 81.328 * exp(− x/0.966) (R2 = 1.00) and y = 90.132 * exp(x/0.807) (R2 = 1.00), respectively. The linear model fitting lignin changes with time has a stronger effect. The equation is y = 84.723 − 15.140x (R2 = 0.843), where y is the residual rate of the straw and x is the straw decomposition time (year).

Discussion

Characteristics of nutrient dynamics in rice straw

In this long-term study, using the nylon mesh bag method, we studied the decomposition dynamics of rice straw under natural production conditions and carried out a 5-year monitoring to determine the nutrient content and fiber composition of straw residue during different periods. The decomposition of crop straw in the field is affected by various factors, such as temperature, moisture, culture time and soil microbes (Pal and Broadbent 1975; Nakajima et al. 2016), and the most influential factors in rice production in Northeast China are temperature and culture time. Upon its return to the soil, straw undergoes a long and complex decomposition process via the activities of soil microorganisms and enzymes. The breakdown of organic matter by microorganisms is regulated by the chemical composition and moisture of the straw, the temperature and both the microbial activity and nutrient availability in the surrounding soil environment (Nakajima et al. 2016; Shaffer and Ma 2001; Sierra 1997). In this study, the low temperature during winter (6 months) in Northeast China severely inhibited the straw decomposition, whereas the high temperature and sufficient rainfall during the summer (May–October) promoted straw decomposition. Many researchers have reported an overall straw decomposition trend of “first fast and then slow” (Ferreira et al. 2016; Pal and Broadbent 1975; Smith and Douglas 1971), which is consistent with the results of this study. Nutrient release was relatively fast during the first year of straw decomposition but then slowed each year thereafter, which may have been related to the gradual depletion of the readily decomposable matter in the straw (Ghidey and Alberts 1993). In this study, the loss of rice straw mass occurred mainly during the first 3 years after straw return. Specifically, the rice growing period was the main period of straw decomposition, while in the non-rice growing season, the straw mass changed little from the autumn of the previous year to the following spring, mainly because the lower environmental temperature inhibited the activity of most microorganisms and was also related to the straw structure. The temperature of the study area is shown in Fig. 1. The average temperature in each year from April to October during the test period was 7.1 °C, 15.6 °C, 22.5 °C, 23.8 °C, 22.2 °C, 15.8 °C and 7.0 °C, and the rainfall amount was 22.1 mm, 76.7 mm, 80 mm, 154.3 mm, 112.6 mm, 38.3 mm and 27.3 mm, respectively. Most studies have shown that straw decomposition increases with increasing temperature in natural environments (Nakajima et al. 2016). In this study, there was almost no decomposition of straw in the field from October to April of the following year, indicating that the minimum temperature for straw decomposition under natural conditions was approximately 7.0 °C.

During straw decomposition, an abundance of C, N, P and K, as well as a variety of trace elements, is released in the soil and act as an effective complement to the nutrients required for plants (Yadvinder et al. 2010). Fores et al. (1988) studied rice straw decomposition in Spain and found that the nutrient loss rate in rice straw followed the pattern of P > C > N and that the fastest rate of nutrient decomposition occurred during the first 15 days. In our study, nutrient decomposition occurred mainly during the first month of the first year after straw return, and the nutrient release rate presented a descending order by which K > P > C > N. The reason for these differences may be due to the differences in climate and test sampling intervals between the two test sites. The difference in the short-term nutrient release rates was related to the states of the nutrients in the rice straw. K occurs mainly in the ionic state and is soluble in water; thus, it has the fastest release. Although P occurs mainly in an insoluble organic state, its dissolution and release can be promoted by the secretion of a certain amount of organic acids by roots (Wang et al. 2013). C occurs mainly in the form of a variety of compounds that undergo variable rates of decomposition (Guixiang et al. 2016; Tang et al. 2016). In this study, C nutrient dynamics in the rice straw monitored for 5 years showed that the release of C and N occurred mainly during the first 2 years after straw return, accounting for 92.5% and 96.3% of the total amount in the straw, respectively. The dynamics also showed that the release of P and K occurred mainly during the first month after straw return, with the amounts accounting for 90.6% and 96.7% of the total amounts added, respectively, which was consistent with the results of Saha et al. (2010). The relative content of P in the rice straw decreased gradually, which indicated that P was continuously decomposed in the returned straw (Yadvinder et al. 2010). Furthermore, with 80% of total K uptake by the crop present in the straw (Yu et al. 2010), straw return also increased the source of K in the soil. The K carried within the returned straw has the same nutrient effect as chemical K fertilizers; thus, straw can partially replace chemical K fertilizers (Gupta et al. 2007; Yadvinder-Singh et al. 2004).

The C/N ratio of rice straw is generally 50–60, and that of organic matter for microbial decomposition is between 20 and 30; therefore, straw return would increase the C/N ratio in the soil environment (Gök and Ottow 1988). In this study, the C/N ratio in rice straw had an initial value of 60.7. During the rice growing season in the first year after straw return, rapid decomposition occurred. Subsequently, the C content of the returned straw first decreased and then increased to a steady level, whereas the N content tended to gradually increase; thus, changes occurred in the C/N ratio in the straw residue. The C/N ratio decreased to 37.9 after 1 year of straw decomposition and was maintained in the range of 54.9–64.7 after 2 years of decomposition. Straw return can increase the rate of microorganism multiplication, which leads to an insufficient N source for microbial metabolism; thus, N is replenished from the soil, which results in the fixation of inorganic N (Gök and Ottow 1988; Kanamori and Yasuda 1979; Rao and Mikkelsen 1976). We previously reported that the mineral N content in the soil solution was significantly decreased during the rice growing period after straw was returned to the field (Yan et al. 2018). During the early stage after straw return, changes in soil temperature and the C/N ratio may lead to changes in straw decomposition because of the impact on microbial composition, whereas the late stage of straw decomposition is affected to a greater degree by microbial biomass C (Guixiang et al. 2016). This result was consistent with the law of the reduction in the C/N ratio of rice straw in the early stage of this study. The release of C from rice straw is also accompanied by N mineralization and fixation by soil microbes (Cheng et al. 2016; Lim et al. 2015), which leads to changes in the C/N ratio in the soil environment. The C/N ratio of rice straw changed significantly in the short term, but the C/N ratio in the soil changed minimally.

Dynamic characteristics of fiber composition in rice straw

Amino acids, soluble polysaccharides, organic acids and mineral nutrients in the straw were released quickly, resulting in a rapid decrease in straw quality during the early stage after straw return (Ferreira et al. 2016; Pal and Broadbent 1975; Smith and Douglas 1971). However, the straw decomposition rates in different climate regions were significantly different. This straw matter provides an abundant source of C and nutrients for microorganisms, thereby increasing the number of microorganisms and enhancing their activity. However, the hemicellulose, cellulose and lignin content in rice straw undergoes slow decomposition because of their structural complexity (Pan et al. 2017). The results of this study showed that the variation trend of the fiber composition of the returned straw was consistent with that of the straw mass and that the fiber decomposed the most during the first year after straw return, which then gradually slowed over time. A significant difference was observed in the fast decomposition period and in the percentage of release among the fiber components of the returned straw. The percentage of release of various components during the early stage after straw return (the first year to the second year) presented an order of hemicellulose > cellulose > lignin, which was consistent with the results of Gong et al. (2018). Studies have also shown that silica, poorly soluble polysaccharides and lignin in rice straw can form complex rigid structures that would lead to the inhibition of lignocellulose in straw during decomposition (Eremeeva et al. 2001; Li et al. 2009; Wu et al. 2014). With the prolonging of decomposition, hemicellulose and cellulose were depleted, which left nondecomposable cellulose residue. Lignin in the rice straw decomposed slowly; however, compared with cellulose and hemicellulose, lignin decomposed significantly faster during the late decomposition stage (fourth to fifth years).

Conclusions

Straw return can increase sources of soil nutrient supplies and is of great significance for the sustainability of rice production to explore the dynamics of straw decomposition in Northeast China. In this study, a localization experiment was carried out in the field under natural conditions. The results showed that the straw decomposition dynamics were fast and then slow. Nutrient release occurred mainly during the first 3 years after straw was returned to the field, and the cumulative release reached 77.0%. After the first year, the amount of straw released reached 55.6%, after which the straw residue decreased at a rate of 7.8% per year. N release occurred mainly during the first 2 months of the first year and during the second year, and significant C decomposition occurred during the first month of the first year and during the second year. The major fraction of P and K release was observed during the first month of the first year. In the northeastern region, returning rice straw to the field can appropriately reduce the amount of K fertilizer and phosphate fertilizer applications needed.

References

Abera G, Wolde-meskel E, Bakken LR (2012) Carbon and nitrogen mineralization dynamics in different soils of the tropics amended with legume residues and contrasting soil moisture contents. Biol Fertil Soils 48:51–66

Barker AV, Volk RJJAC (1964) Determination of ammonium, amide, amino, and nitrate nitrogen in plant extracts by a modified Kjeldahl method. Anal Chem 36:439–441

Cheng W et al (2016) Changes in the soil C and N contents, C decomposition and N mineralization potentials in a rice paddy after long-term application of inorganic fertilizers and organic matter. Soil Sci Plant Nutr 62:212–219

China NBoSotPsRo (2016) China statistical yearbook-2016. China Statistics Press

Devêvre OC, Horwáth WR (2000) Decomposition of rice straw and microbial carbon use efficiency under different soil temperatures and moistures. Soil Biol Biochem 32:1773–1785

Eremeeva T, Bikova T, Eisimonte M, Viesturs U, Treimanis A (2001) Fractionation and molecular characteristics of cellulose during enzymatic hydrolysis. Cellulose 8:69–79

Ferreira DA et al (2016) Contribution of N from green harvest residues for sugarcane nutrition in Brazil. GCB Bioenergy 8:859–866

Fores E, Menendez M, Comin F (1988) Rice straw decomposition in rice-field soil. Plant Soil 109:145–146

Ghidey F, Alberts E (1993) Residue type and placement effects on decomposition: field study and model evaluation. Trans ASAE 36:1611–1617

Gök M, Ottow J (1988) Effect of cellulose and straw incorporation in soil on total denitrification and nitrogen immobilization at initially aerobic and permanent anaerobic conditions. Biol Fertil Soils 5:317–322

Gong Z, Deng N, Song Q, Li Z (2018) Decomposing characteristics of maize straw returning in songnen plain in long-time located experiment. Trans Chinese Soc Agric Eng 34:139–145 (in Chinese with English abstract)

Guixiang Z, Zhang J, Lin C, Zhang C, Zhenghong Y (2016) Temperature and straw quality regulate the microbial phospholipid fatty acid composition associated with straw decomposition. Pedosphere 26:386–398

Gupta R, Ladha J, Singh J, Singh G, Pathak H (2007) Yield and phosphorus transformations in a rice–wheat system with crop residue and phosphorus management. Soil Sci Soc Am J 71:1500–1507

Hansen EM, Munkholm LJ, Melander B, Olesen JE (2010) Can non-inversion tillage and straw retainment reduce N leaching in cereal-based crop rotations? Soil Tillage Res 109:1–8. https://doi.org/10.1016/j.still.2010.04.001

Kanamori T, Yasuda T (1979) Immobilization, mineralization and the availability of the fertilizer nitrogen during the decomposition of the organic matters applied to the soil. Plant Soil 52:219–227

Lefroy R, Chaitep W, Blair G (1994) Release of sulfur from rice residues under flooded and non-flooded soil conditions. Aust J Agric Res 45:657–667

Li Q, He Y-C, Xian M, Jun G, Xu X, Yang J-M, Li L-Z (2009) Improving enzymatic hydrolysis of wheat straw using ionic liquid 1-ethyl-3-methyl imidazolium diethyl phosphate pretreatment. Bioresour Technol 100:3570–3575

Liang CG, Ye ZX, Cheng ZF, Qiang WY (2006) Estimating the quantity of crop residues burnt in open field in China. Res Sci 28:9–13 (in Chinese with English abstract)

Lim SS, Kwak JH, Lee KS, Chang SX, Yoon KS, Kim HY, Choi WJ (2015) Soil and plant nitrogen pools in paddy and upland ecosystems have contrasting δ15N. Biol Fertil Soils 51:231–239

Mandal KG, Misra AK, Hati KM, Bandyopadhyay KK, Ghosh PK, Mohanty M (2004) Rice residue- management options and effects on soil properties and crop production. J Food Agric Environ 2:224–231

Nakajima M et al (2016) Modeling aerobic decomposition of rice straw during the off-rice season in an Andisol paddy soil in a cold temperate region of Japan: effects of soil temperature and moisture. Soil Sci Plant Nutr 62:90–98

Nelson DW (1982) Total carbon, organic carbon and organic matter. Methods Soil Anal 9:961–1010

Nigussie A, Kissi E (2011) Impact of biomass burning on selected physicochemical properties of nitisol in Jimma zone, Southwestern Ethiopia. Int Res J Agric Sci Soil Sci 1:394–401

Pal D, Broadbent F (1975) Influence of moisture on rice straw decomposition in soils. Soil Sci Soc Am J 39:59–63

Pan M, Zhou D, Zhou X, Lian Z (2010) Improvement of straw surface characteristics via thermomechanical and chemical treatments. Biores Technol 101:7930–7934

Pan M, Gan X, Mei C, Liang Y (2017) Structural analysis and transformation of biosilica during lignocellulose fractionation of rice straw. J Mol Struct 1127:575–582. https://doi.org/10.1016/j.molstruc.2016.08.002

Ponnamperuma F (1984) Straw as a source of nutrients for wetland rice. Org Matter Rice 117:136

Raison RJ (1979) Modification of the soil environment by vegetation fires, with particular reference to nitrogen transformations: a review. Plant Soil 51:73–108

Rao DN, Mikkelsen D (1976) Effect of rice straw incorporation on rice plant growth and nutrition. Agron J 68:752–756

Saha PK, Miah M, Hossain A, Rahman F, Saleque MA (2010) Contribution of rice straw to potassium supply in rice-fallow-rice cropping pattern Bangladesh. J Agric Res 34:633–643

Shaffer M, Ma L (2001) Carbon and nitrogen dynamics in upland soils. In: Shaffer MJ, Ma L, Hansed S (eds) Modeling carbon and nitrogen dynamics for soil management. Lewis Publishers, Boca Raton, pp 11–26

Sierra J (1997) Temperature and soil moisture dependence of N mineralization in intact soil cores. Soil Biol Biochem 29:1557–1563

Smith JH, Douglas CL (1971) Wheat straw decomposition in the field. Soil Sci Soc Am J 35:269–272

Tang S, Cheng W, Hu R, Guigue J, Kimani SM, Tawaraya K, Xu X (2016) Simulating the effects of soil temperature and moisture in the off-rice season on rice straw decomposition and subsequent CH4 production during the growth season in a paddy soil. Biol Fertil Soils 52:1–10

Tirol-Padre A, Tsuchiya K, Inubushi K, Ladha JK (2005) Enhancing soil quality through residue management in a rice-wheat system in Fukuoka, Japan. Soil Sci Plant Nutr 51:849–860

Wang Z, Zhu P, Huang DM (1999) Straw 14C decomposition and distribution in humus fractions as influenced by soil moisture regimes. Pedosphere 9:275–280

Wang J-G, Li Z-X, Cai C-F, Yang W, Ma R-M, Zhang G-B (2013) Effects of stability, transport distance and two hydraulic parameters on aggregate abrasion of Ultisols in overland flow. Soil Tillage Res 126:134–142

Wu W, Wang Z, Jin Y, Matsumoto Y, Zhai H (2014) Effects of LiCl/DMSO dissolution and enzymatic hydrolysis on the chemical composition and lignin structure of rice straw. Biomass Bioenergy 71:357–362

Yadvinder S, Gupta RK, Jagmohan S, Gurpreet S, Gobinder S, Ladha JK (2010) Placement effects on rice residue decomposition and nutrient dynamics on two soil types during wheat cropping in rice–wheat system in northwestern India. Nutr Cycl Agroecosyst 88:471–480

Yadvinder-Singh BS, Ladha JK, Khind CS, Khera TS, Bueno CS (2004) Effects of residue decomposition on productivity and soil fertility in rice–wheat rotation. Soil Sci Soc Am J 68:854–858

Yan C et al (2016) Effects of straw retention and phosphorous fertilizer application on available phosphorus content in the soil solution during rice growth. Paddy Water Environ 14:61–69. https://doi.org/10.1007/s10333-015-0478-y

Yan C, Du TT, Yan SS, Dong SK, Gong ZP, Zhang ZX (2018) Changes in the inorganic nitrogen content of the soil solution with rice straw retention in northeast China. Desalin Water Treat 110:337–348. https://doi.org/10.5004/dwt.2018.22340

Yu C, Qin J, Xu J, Nie H, Luo Z, Cen K (2010) Straw combustion in circulating fluidized bed at low-temperature: transformation and distribution of potassium. Can J Chem Eng 88:874–880

Zhou W, Hui D, Shen W (2014) Effects of soil moisture on the temperature sensitivity of soil heterotrophic respiration: a laboratory incubation study. PLoS ONE 9:e92531

Acknowledgements

This work was financially supported by the National Science Foundation of China, the Study on the Regulation Mechanism of Straw Retention on Phosphorus Availability and Phosphorus Fractions in Soil in Cold Regions (31601270), the Heilongjiang Postdoctoral Financial Assistance (HBH-Z16027), and the “Young Talents” Project of Northeast Agricultural University.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Yan, C., Yan, SS., Jia, TY. et al. Decomposition characteristics of rice straw returned to the soil in northeast China. Nutr Cycl Agroecosyst 114, 211–224 (2019). https://doi.org/10.1007/s10705-019-09999-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10705-019-09999-8