Abstract

Zinc (Zn) deficiency is prevalent worldwide and is a barrier to achieving yield goals in crops. It is also now recognized as a leading risk factor for disease in humans in developing countries. In general, soil application of 5–17 kg of Zn ha−1 year−1 as zinc sulphate (ZnSO4) or more is recommended. However, in developing rice growing countries of Asia, ZnSO4 of desired quality is not readily available and is also quite expensive, so the farmers generally fail to apply Zn, resulting in rice crop yield loss. Availability of Zn-coated urea guarantees not only the availability of quality Zn but also ensures its application. Field experiments were therefore conducted during the rice seasons of 2005 and 2006 at the Indian Agricultural Research Institute, New Delhi, to evaluate the relative efficiency of 0.5, 1.0, 1.5 and 2.0% Zn as ZnSO4- or zinc oxide (ZnO)-coated ureas for rice. Soil application of ZnSO4 was also compared in 2006. Rice grain and straw yields, Zn concentrations in grain and straw, and Zn uptake by rice increased with the level of Zn coating onto urea. Crop response was the highest with 2.0% ZnSO4-coated urea, and higher than with the same rate of ZnO-coated urea, possibly related to the higher water solubility of Zn in ZnSO4. Crop response with ZnSO4-coated urea was also higher than with the same rate of ZnSO4 and urea applied separately to the soil. However, apparent recovery data suggest that 1.0% coating with ZnSO4 may be a better choice from the point of view of the utilization of applied Zn. Increased Zn concentrations in rice grain due to application of Zn-coated urea is important from the point of view of Zn nutrition of humans, since rice is the staple food in developing countries of Asia. Also, increased Zn concentrations in rice straw is of importance as regards cattle nutrition since in developing countries of Asia rice straw is the major feed for farm cattle.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Zinc deficiency in soils is prevalent worldwide both in temperate and tropical climates (Katyal and Vlek 1985; Marschner 1995; Adriano 2001; Normon et al. 2003; Fageria et al. 2003; Prasad 2006). It is especially widespread in high pH calcareous soils (Liu et al. 1983; Katyal and Vlek 1985) and is a major barrier to achieving yield goals in developing countries. An analysis of 233,000 samples taken from different states showed that 47% of Indian soils are deficient in Zn (Takkar 1996). In India, Zn deficiency is widespread in the rice–wheat cropping system belt of north India, which has high pH calcareous soils (Prasad 2005). Increase in soil pH is associated with increased sorption of Zn on soil hydroxides, carbonates and organic matter and decreased absorption by plant roots (Rupa and Tomar 1999).

Zinc deficiency in rice is characterized by burnt dark brown patches of plants and was first reported by Nene (1966). Response of rice to Zn has been reported by several workers in India (Sarkar et al. 1983; Singh et al. 1983; Singh and Abrol 1986; Agarwal and Gupta 1994), Philippines (Yoshida et al. 1973) and China (Liu et al. 1983; Shihua and Wenqiang 2000). Zinc is now recognized as the fifth leading risk factor in developing Asian countries (Anonymous 2007) and efforts are underway to reduce Zn deficiency in soils as it is not only a barrier to achieving crop yield goals but also results in low Zn content in grains and straw leading to poor Zn nutrition of humans and animals, a subject which has recently received considerable attention (Schardt 2006).

In general, recommendations for soil application of Zn for crops vary from 5 to 17 kg Zn ha−1 in the form of ZnSO4 (Mikkelson and Brandon 1975; Fenster et al. 1984). This product is quite costly, so small farmholders in Asia skip it resulting in reduced crop yields. Another factor that discourages the farmers from applying Zn in India is spurious ZnSO4·7H2O sold by unscrupulous traders. An attempt is therefore currently being made by the fertilizer industry in India to produce Zn-coated urea (also referred to as zincated urea), that would force the farmers to apply Zn to rice along with nitrogen that they mostly apply. ZnSO4·H2O is generally used for coating urea because it contains 33% Zn and therefore lesser quantities are needed for coating. In addition to ZnSO4·H2O, ZnO which contains 80% Zn is also being investigated for coating urea. The present investigation was therefore conducted to study the relative efficiency of ZnSO4- and ZnO-coated ureas for rice.

Materials and methods

The field experiments were conducted during the rainy seasons (July–November) of 2005 and 2006 at the research farm of the Indian Agricultural Research Institute, New Delhi, India. To avoid residual effects, the experiment in 2006 was conducted in a separate site in the same field. The Institute farm is located at 28°58′N, 77°10′E with an elevation of 228 m a.s.l. There are reports that response of rice to Zn fertilizers is related to the water soluble Zn content in them (Slaton et al. 2005), and Westfall and Gangloff (2001) observed that Zn fertilizers must contain at least 50% water soluble Zn. Chemical analysis of available nutrients for the experimental soil was conducted by using the Subbiah and Asija (1956) procedure for determination of available N, Olsen’s method for available P (Olsen et al. 1954), the 1 M ammonium acetate method for available K determination (Hanway and Heidel 1952), and the chromic acid oxidation method for organic C (Walkey and Black 1934). The experimental soil was low in available N (230 kg N ha−1), medium in available P (18.6 kg P ha−1) and K (228 kg K ha−1), and also medium in organic C content (0.54%). The pH of the soil was 8.2 (1:2.5 soil:water ratio) and DTPA-extractable Zn (Lindsay and Norvell 1978) in the soil was 0.68 mg kg−1 soil. The critical level of “DTPA-extractable” Zn for rice grown on alluvial soils in the rice–wheat belt of North India varies from 0.38–0.90 mg kg−1 soil (Takkar et al. 1997).

There were nine treatments consisting of eight combinations of two coating materials (ZnSO4 and ZnO) and four levels of Zn coating (0.5, 1.0, 1.5 and 2.0% w/w of prilled urea) and a no Zn control. In 2006, one additional treatment of separate soil applications of 5 kg Zn ha−1 as ZnSO4 was also added to the soil surface (broadcast and incorporated), which is the general recommendation for rice in India (Rattan et al. 1997). It was incorporated in soil after final puddling and before transplanting of rice. The field experiment was conducted in a randomized block design with three replications All plots received 120 kg N ha−1 as urea. ZnSO4 and ZnO-coated urea was obtained from the Indo-Gulf Fertilizers, Jagdishpur (UP), India.

The experimental field was disk-ploughed twice, puddled thrice with a puddler in standing water and levelled. At final puddling, 26 kg P ha−1 as single superphosphate and 33 kg K ha−1 as KCl was broadcast. Nitrogen at 120 kg N ha−1 as prilled urea or Zn-coated urea was band applied in two equal splits, half 10 days after transplanting (DAT) and the other half at panicle initiation (40 DAT). Thus, Zn in zincated urea was band applied. When applied at the site, Zn-coated urea supplied 1.3, 2.6, 3.9 and 5.2 kg Zn ha−1 for the 0.5, 1.0, 1.5 and 2.0% coatings, respectively. To make up for the short fall of N in Zn-coated ureas, calculated amounts of additional N as prilled urea were added in plots receiving Zn-coated ureas.

Two to three 25-day-old seedlings of basmati (aromatic) rice variety ‘Pusa Sugandh 5’ were transplanted on hills spaced at 20 × 10 cm2 in the second week of July in both years of study. ‘Pusa Sugandh 5’, a derivative of Pusa 3A × Karnal Basmati, is a semi-dwarf (90–100 cm height), high yielding basmati rice variety released in the year 2004 by the Indian Agricultural Research Institute, New Delhi, for commercial cultivation.

Rice was harvested in the first week of November in both the years of study. Ten hills were randomly selected in each plot for measuring plant height and fertile tillers hill−1 10 days before harvest and the average values were computed. Similarly, 10 panicles were randomly selected from each plot for recording the data on yield attributes (panicle length, panicle weight, grains panicle−1 and 1,000-grain weight). At harvest, grain and straw yield was recorded for each plot of the experiment, and samples of grain and straw were drawn from each plot for the chemical analysis for Zn concentrations. Zinc in grain and straw samples was analysed on a di-acid (HClO4 + HNO3 in 3:10 ratio) digest on an Atomic Absorption Spectrophotometer (Prasad et al. 2006). Thereafter, the uptake of the Zn was calculated by multiplying Zn concentrations with their respective plot yield of grain and straw of rice.

Apparent recovery (AR) of applied Zn was calculated by using the following expressions as suggested by Fageria and Baliger (2003):

where,

-

ARzn refers to apparent recovery of zinc

-

UZn refers to the Zn uptake in zincated urea plot (kg ha−1)

-

UPu refers to the Zn uptake in uncoated urea plot (kg ha−1)

-

Zna refers to the amount of Zn applied (kg ha−1).

All the data obtained from rice crop for the consecutive 2 years were statistically analysed using the F-test as per the procedure given by Gomez and Gomez (1984). LSD values at P = 0.05 were used to determine the significance differences between treatment means.

Results

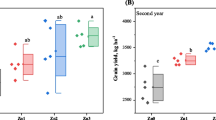

Grain yield

Data on yields are in Table 1. In 2005, a significant increase in grain yield of rice over prilled urea was obtained with 1.0, 1.5 and 2.0% ZnSO4 and with 2.0% ZnO-coated urea. In 2006, a significant increase in rice grain yield was obtained with 1.0, 1.5 and 2.0% coating with ZnSO4 or ZnO-coated urea and with soil application of ZnSO4. Also, the 2.0% coating with either Zn source gave higher grain yield of rice than 1.0% coating of Zn. In both years, the percentage increase in grain yield of rice was always greater with ZnSO4-coating than with ZnO-coating. The better response of rice to ZnSO4 was due to it being 100% water soluble as compared to ZnO, which is insoluble in water [a 4% commercial product AdNano® ZnO20 dispersion in water has only 5.4 ppm of Zn ions in solution (via internet)]. Slaton et al. (2005) also reported that Zn fertilizer ZnSO31 having 100% water soluble Zn (WSZn) produced significantly more rice grain than ZnOxS36 containing only 14% WSZn. Water soluble Zn is more mobile and can easily absorbed by rice plant roots. Giordano and Mortvedt (1972) reported that the movement of Zn fertilizer 4 weeks after application was 20 mm for ZnSO4 and 5 mm for ZnO.

Straw yield

A significant increase in straw yield of rice was obtained only in 2006 when all the Zn-coated ureas and soil application of ZnSO4 produced significantly more straw than uncoated urea, and 2.0% ZnSO4-coated urea produced significantly more than 0.5 and 1.0% ZnSO4- and ZnO-coated ureas. The highest straw yield of rice was recorded with 2.0% ZnSO4-coated urea during both years.

Zinc concentrations in grain

Data on zinc concentrations are in Table 2. In 2005, Zn concentrations in rice grain were significantly increased over prilled urea with 1.0, 1.5 and 2.0% ZnSO4-coated urea and 1.5 and 2.0% of ZnO-coated urea. Further, Zn concentrations in grain were higher with a ZnSO4-coating of 2.0% than 1% ZnSO4. In 2006, all Zn-coated ureas significantly increased Zn concentrations in rice grain and, at all levels of coatings, ZnSO4-coated urea recorded significantly higher Zn concentrations in rice grain. Also, there was a stepwise significant increase in ZnSO4-coatings from 0.5 to 2.0%. Application of 2.0% ZnSO4-coated urea also gave significantly higher concentrations of Zn in grain than separate soil application of ZnSO4. The highest Zn concentrations in rice grain was recorded with 2.0% ZnSO4-coated urea in both years and was 44 mg kg−1 in 2005 and 50.8 mg kg−1 in 2006.

Zinc concentrations in straw

In 2005, all Zn-coated ureas except 0.5% ZnO-coating of prilled urea were similar and gave significantly higher Zn concentrations than prilled urea. Also, the difference between successive levels of Zn coatings, i.e. 1.0 to 1.5% and 1.5 to 2.0%, was significant for both ZnSO4 and ZnO. However, the difference between 0.5 and 1.0% coating was significant for ZnSO4- but not for ZnO-coated urea. Zn concentrations in straw with 2.0% ZnSO4-coated urea did not differ significantly from those obtained with separate soil applications of ZnSO4. Nevertheless, the highest Zn concentrations in rice straw was recorded with 2.0% ZnSO4-coated urea in both years and was 88.8 mg kg−1 in 2005 and 96.1 mg kg−1 in 2006.

Zinc uptake in grain

Data on Zn uptake and Zn apparent recovery by rice are in Table 3. In 2005, coating urea with 1.5 or 2.0% ZnSO4 or ZnO-coated urea were similar and gave significantly higher Zn uptake by rice grain than prilled urea. In 2006, all coating levels except the 0.5% ZnO-coating increased Zn uptake in rice grain. Also, coating urea with 2.0% ZnO or ZnSO4 was similar with separate soil application of ZnSO4 and gave significantly higher Zn uptake by rice grain than 1.0% coating with ZnSO4 or ZnO. Nevertheless, the highest Zn uptake in rice grain was recorded with 2.0% ZnSO4-coated urea and was 220 g Zn ha−1 in 2005 and 268 g Zn ha−1 in 2006.

Zinc uptake in straw

In 2005, Zn uptake by rice straw was similar with all Zn coatings (except the 0.5% ZnO coating) and was significantly higher than with prilled urea alone (Table 3). In 2006, all Zn coatings gave significantly higher Zn uptake and were higher with coatings of ZnSO4 than ZnO. Further, Zn uptake by rice straw increased with each successive level from 0.5 to 2.0% with either Zn source coated onto urea prills. Coating urea with ZnSO4 at 2.0% resulted in the highest Zn uptake for both years, and it was also superior to separate soil application of ZnSO4.

Total (grain + straw) Zn uptake by rice

Since rice straw accounted for about 80% of Zn taken up by rice crop, total Zn uptake by rice followed nearly the same pattern as Zn uptake by rice straw. Total Zn uptake by rice was the highest with 2.0% ZnSO4-coated urea.

Apparent recovery of Zn (ARZn)

As expected, apparent recovery of applied Zn decreased with an increase in the level of Zn coating onto urea (therefore decreasing the rate of applied Zn). In both years, the highest ARZn was recorded with the 0.5% Zn coating, and it was always higher at each level of urea coatings with ZnSO4 than ZnO. Also, the differences in ARZn between the ZnSO4 and ZnO coatings onto urea declined as the level of Zn coatings increased.

Discussion

Results of this present study showed that a significant increase in rice grain yields was obtained when urea was only coated with a minimum of 1% Zn (supplying 2.6 kg Zn ha−1 equivalent to 13 kg ZnSO4 ha−1) or more. The highest grain and straw yield of rice was obtained with 2.0% Zn-coated urea, and at that level of coating was similar to that from the separate broadcast and incorporation of ZnSO4. However, Zn concentrations in grain and straw of rice increased with successive increases in the level of coating and the highest values were obtained with 2.0% Zn coating. This was also true for Zn uptake. As regards Zn concentrations and uptake by rice, concomitant application of Zn and urea as Zn-coated urea was more effective than their separate soil application as is the general practice. Application of Zn-coated urea also had the advantage of split application and banding of Zn close to the growing rice plants, which increased its uptake before applied Zn reacted with water and CO2 in soil solution and converted it to ZnCO3, which makes it less available to plants as pointed out by Yoshida et al. (1971).

An advantage of band application over broadcast soil application of Zn has been reported by Vitosh et al. (1981) and Grewing et al. (1988), who also observed that much smaller doses are required when Zn is banded. For example, Grewing et al. (1988) suggested band application of 1.0–5.5 kg ZnSO4 ha−1 as against 5.6–11.0 kg ZnSO4 ha−1 for broadcast and incorporation. No reports on split application of Zn were found. In the present study, split application was necessitated because the material tested was Zn-coated urea and urea is split applied. However, the results obtained showed that split application of Zn had no disadvantage especially when small doses are applied.

The mobility of Zn in plants is low (Mengel and Kirkby 1987) and Zn in older leaves becomes highly immobile (Rinne and Langston 1960). This would explain why the concentration of Zn in rice straw was nearly twice that in rice grain. Zinc uptake by rice straw was still higher than Zn uptake in rice grain because straw yield was more than twice the grain yield in both the years of study. Lakshmanan et al. (2005) also reported that Zn uptake in rice grain (variety Pusa Basmati 1) varied from 130 to 162 g ha−1 while in straw it varied from 797 to 931 g ha−1.

As regards the relative value of the coating materials, ZnSO4 is water-soluble and therefore readily available, making its effects visible in the plants, while ZnO is sparingly soluble and is not readily available. Water solubility of zinc sources is considered an important criterion for Zn availability (Slaton et al. 2005). Westfall and Gangloff (2001) observed that the effectiveness of six granulated Zn fertilizers decreased as the per cent water soluble Zn decreased in them, and concluded that at least 50% water-soluble Zn was considered desirable. To obtain this, Zn fertilizer manufacturers are producing mixtures of ZnSO4 and ZnO, which are referred to as Zn oxysulphates. Mikkleson and Brandon (1975) and Nayyar et al. (1990) also showed that ZnO was inferior to ZnSO4, both in grain yield and Zn uptake. However, the solid phase equilibria studies by Lindsay (1991) showed that, even in calcareous soils of pH 8.0, ZnO would maintain a Zn concentration of approximately 10−4 M Zn2+ or higher; higher than that maintained by soil Zn (10−11 M). This concentration is much higher than the critical limit of 10−7 to 10−8 M Zn suggested by Carrol and Loneragan (1969) for plant growth. Thus, Zn from ZnO-coated urea will also make Zn available to rice. The results of the present study show that Zn availability from ZnO-coated ureas to rice is much slower and becomes available only at later growth stages, and thus remained more in straw than in grain.

Zinc deficiency is now recognized as the fifth leading risk factor for disease in humans in developing countries (Anonymous 2007) and some efforts are therefore being made to produce cereal varieties that can absorb more Zn (Welch and Graham 1999) so that nutritional demands of Zn of humans are more easily met, especially in developing countries of Asia where rice forms the staple diet. The results of our research show that use of Zn-coated urea could help in this direction.

Conclusions

It is concluded that ZnSO4, because of it being soluble in water, is a better material than ZnO for coating urea and a 1.0% coating may be sufficient for higher productivity of rice, increased Zn concentrations and uptake by rice grain, and also a higher recovery of applied Zn.

References

Adriano DC (2001) Trace elements in terrestrial environments—biogeochemistry, bioavailability and risks of metals, 2nd edn. Springer, New York, Berlin, Heidelberg

Agarwal HP, Gupta ML (1994) Effect of copper and zinc on copper nutrition to rice. Ann Agric Res 15:162–166

Anonymous (2007) Help eliminate the fifth leading disease risk factor in developing countries. Fert & Agric. International Fertilizer Agency, Paris

Carroll MD, Loneragan JF (1969) Response of plant species to concentrations of zinc in solution. II. Rates of zinc absorption and their relation to growth. Aust J Agric Res 20:47–463

Fageria NK, Baligar VC (2003) Methodology for evaluation of lowland rice genotypes for nitrogen use efficiency. J Plant Nutr 26:1315–1333

Fageria NK, Slaton NA, Baligar VC (2003) Nutrient management for improving lowland rice productivity and sustainability. Adv Agron 80:63–152

Fenster WE, Rehm GW, Grava J (1984) Zinc for Minnesota soils. Minnesota Agric Expt Ser AG-FS-0720

Giordano PM, Mortvedt JJ (1972) Rice response to Zn in flooded and non-flooded soil. Agron J 64:521–524

Gomez KA, Gomez AA (1984) Statistical procedures for agricultural research, 2nd edn. An International Rice Research Institute Book. Wiley, New York

Grewing J, Gelderman R, Fixen P (1988) Fertilizer recommendations guide. South Dakota Coop Ext Serv EC 750

Hanway JJ, Heidel H (1952) Soil analysis methods as used in Iowa state college soil testing laboratory. Bulletin 57, Iowa State College of Agriculture, USA

Katyal JC, Vlek PLG (1985) Micronutrient problems in tropical Asia. Fert Res 7:131–150

Lindsay WL (1991) Inorganic equilibria affecting micronutrients in soil. In: Mortvedt JJ, Cox FR, Shuman LM, Velch RM (eds) Micronutrient in agriculture. Soil Science Society of America (SSSA), Madison, Wis., USA, pp 89–112

Lindsay WL, Norvell WA (1978) Development of DTPA soil test for zinc, iron, manganese and copper. Soil Sci Soc Am J 42:421–428

Lakshmanan R, Prasad R, Jain MC (2005) Yield and uptake of micronutrients by rice as influenced by duration of variety and nitrogen fertilization. Arch Agron Soil Sci 51:1–14

Liu Z, Zhu QQ, Tang LH (1983) Micronutrients in the main soils of China. Soil Sci 135:40–46

Marschner H (1995) Mineral nutrition for higher plants. Academic Press, New York

Mengel K, Kirkby EA (1987) Principles of plant nutrition. Lang Druck, Liebefeld, Bern, Germany

Mikkelson DS, Brandon DM (1975) Zinc deficiency in California rice. Calif Agric 29:8–9

Nayyar VK, Takkar PN, Bansal RL, Singh SP, Kaur NP, Sadana US (1990) Micronutrients in soils and crops of Punjab. Research Bulletin, Department of Soils, Punjab Agricultural University, Ludhiana, India

Nene YL (1966) Symptoms, causes and control of khaira disease of paddy. Bull Indian Phytopath Soc 3:97–101

Norman RJ, Wilson CE Jr, Slaton NA (2003) Soil fertilization and mineral nutrition in US mechanized rice culture. In: Smith CW, Hilday RH (eds) Rice origin, history, technology and production. Wiley, NJ, USA, pp 331–412

Olsen R, Cole CV, Watanabe FS, Dean LA (1954) Estimation of available phosphorus in soils by extraction with sodium bicarbonate. Circular 939 United States Department of Agriculture, Washington, DC

Prasad R (2005) Rice-wheat cropping system. Adv Agron 86:255–339

Prasad R (2006) Zinc in soils and in plant, human and animal nutrition. Indian J Fert 2:103–119

Prasad R, Shivay YS, Kumar D, Sharma SN (2006) Learning by doing exercises in soil fertility (A practical manual for soil fertility). Division of Agronomy, Indian Agricultural Research Institute, India

Rattan RK, Datta SP, Saharan N, Katyal JC (1997) Zinc in Indian agriculture. Fert News 42(12):75–89

Rinne RW, Langston RC (1960) Effect of growth on redistribution of some mineral elements in peppermint. Plant Physiol 35:210–215

Rupa TR, Tomar KP (1999) Zinc desorption kinetics as influenced by pH and phosphorus in soils. Commun Soil Sci Plant Anal 30:1951–1962

Sarkar AK, Leelabhai KS, Murali Mohan GV, Subbiah VV, Subbarao IV, Deb DL (1983) Zinc fertilization of flooded rice in vertisols of Hyderabad. J Nuclear Agric Biol 12:96–99

Schardt D (2006) The zincing feeling—zinc in human nutrition—special rept nutrition action health-letter, http://www.findarticles.com

Shihua T, Wenqiang F (2000) Nutrient management in the rice-wheat cropping system in the Yangtze river flood plain. In: Hobbs PR, Gupta RK (eds) Soil and crop management practices for enhanced productivity of the rice-wheat cropping system in the Sichuan province of China. Rice-Wheat Consortium for the Indo-Gangetic Plains, New Delhi, India, pp 24–34

Singh BP, Singh AP, Sakal R (1983) Differential response of crops to zinc application in calcareous soil. J Indian Soc Soil Sci 31:534–538

Singh MV, Abrol IP (1986) Transformation and availability of zinc in alkali soils. Fert News 31(7):17–27

Slaton NA, Normon RJ, Wilson CE Jr, (2005) Effect of Zn source and application time on Zn uptake and grain yield of flood irrigated rice. Agron J 92:272–278

Subbiah BV, Asija GL (1956) A rapid procedure for the determination of available nitrogen in soils. Curr Sci 25:259–260

Takkar PN (1996) Micronutrient research and sustainable agricultural productivity in India. J Indian Soc Soil Sci 44:562–581

Takkar PN, Singh MV, Ganeshmurthy AN (1997) A critical review of plant nutrient supply needs, efficiency and policy issues for Indian agriculture for the year 2000: micronutrients and trace elements. In: Kanwar JS, Katyal JC (eds) Plant nutrient, supply efficiency and policy issues: 2000–2025. National Academy of Agricultural Sciences, New Delhi, India, pp 238–264

Vitosh ML, Warncka DD, Knezek BD and Lucas RE (1981) Secondary and micronutrients for vegetables and field crops. Michigan Coop Ext Serv Bull E-486

Walkey AJ, Black IA (1934) An examination of the Degtjareff method for determination soil organic matter and a proposed modification of the chromic acid titration method. Soil Sci 37:29–38

Welch R, Graham RD (1999) A new paradigm for world agriculture: meeting human, needs. Productive, sustainable, nutritious. Field Crops Res 60:1–10

Westfall D, Gangloff B (2001) Zinc fertilizers—is there a difference? Agron News 21(6):8

Yoshida S, Ahu JS, Forna DA (1973) Occurrence, diagnosis and correction of zinc deficiency of lowland rice. Soil Sci Plant Nutr 19:83–94

Yoshida S, Forna DA, Bhadra Chalam A (1971) Zinc deficiency of the rice plant on calcareous and neutral soils in the Philippines. Soil Sci Plant Nutr 17:83–87

Acknowledgements

The authors duly acknowledge the partial financial support received from the Indo-Gulf Fertilizers Limited, Jagdishpur, Uttar Pradesh, India. Our sincere thanks are also due to the Joint Director Research and the Director, Indian Agricultural Research Institute, New Delhi, for their advice and support. Dr. Rajendra Prasad is grateful to the Indian National Science Academy for granting him INSA Honorary Scientist Position.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Shivay, Y.S., Kumar, D., Prasad, R. et al. Relative yield and zinc uptake by rice from zinc sulphate and zinc oxide coatings onto urea. Nutr Cycl Agroecosyst 80, 181–188 (2008). https://doi.org/10.1007/s10705-007-9131-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10705-007-9131-5