Abstract

Agility can be viewed as a need to encourage the enterprise-wide integration of flexible and core competent resources so as to offer value-added product and services in a volatile competitive environment. Since flexibility is considered a property that provides change capabilities of different enterprise-wide resources and processes in time and cost dimensions, supply chain flexibility can be considered a composite state to enterprise-wide resources to meet agility needs. Enterprise modeling frameworks depicting these composite flexibility states are difficult to model because of the complex and tacit interrelationship among system parameters and also because agility thrives on many business objectives. In view of this, the modeling framework presented in this paper is based on analytical network process (ANP) since this methodology can accommodate the complex and tacit interrelationship among factors affecting enterprise agility. The modeling framework forms a three-level network with the goal of attaining agility from the perspective of market, product, and customer as the actors. The goal depends on substrategies that address the characteristics of the three actors. Each of these substrategies further depends on manufacturing, logistic, sourcing, and information technology (IT) flexibility elements of the enterprise supply chain (SC). The research highlights that, under different environmental conditions, enterprises require synergy among appropriate supply chain flexibilities for practising agility. In the present research, the ANP modeling software tool Super Decisions™ has been used for relative prioritization of the supply chain flexibilities. We demonstrate through sensitivity analysis that dynamic conditions do require adjustments in the enterprise-wide flexibility spectrum.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Framework for enterprise agility

Nowadays enterprises utilize information and communication technology (ICT) not only as a survival tool, but also as a tool that gives them the capability to push uncertainty in the market. This has become their competitive strategy. Mastering change and utilizing ICT capability for proactive management of change are the two significant characteristics of enterprises thriving on uncertain and dynamic business environments. Responsiveness and customization have become the new strategic priorities in place of cost and conformance quality, which are now order qualifiers only. The paradigm shift has been from economy of scale to a contradictory complex strategic intent for economy of scale on cost in conjunction with economy of scope in customer fulfillment. The model of manufacturing that thrives on change and management of change with matching responsiveness for customer fulfillment is called agile manufacturing. A brief résumé of agility is given here with a view to conceptualize the agility paradigm.

Intensification of global competition acts as motivation for performance improvement initiatives in enterprises. Competitiveness comes as a consequence of performance improvement with regard to cost, product reliability, quality, and service dependability. At the same time, enterprises have been continuously observing increases in the demand for customized products. There have been observable changes in the average product life cycles also. As a consequence, enterprise strategies focus on reductions in the trade-off between flexibility and cost (De Meyer et al. 1989). This particular competitive strategy is termed a lean strategy. The lean paradigm is generally associated with efficiency-based performance improvement in intra-enterprise activities. Later, Ferdows, and De Meyer (1990) observed reversal of the order of strategic objectives of enterprises, which now place greater emphasis on flexibility compared to cost efficiency. Vokurka and Fliedner (1998) extended this model and placed responsiveness and time competence at higher strategic priorities than flexibility but below cost efficiency. Dynamic markets, shortening product life cycles, and product proliferation make the lean paradigm inappropriate for competitiveness. Under such circumstances, new synergistic strategy beyond this cost-flexibility trade-off maturity emerges through the integration of core competencies of multiple enterprises. This new post-lean paradigm was given the name agility (Goldman et al. 1995). For the lean paradigm, the precedence of cost ahead of flexibility as the strategic objective underlines the need for enterprise initiatives focused on substrategies that boost cost efficiency. In the agile paradigm, higher-order flexibility maturity that fulfils the twin requirements of scope and speed with least trade-off on cost is needed. Vokurka and Fliedner’s (1998) agility improvement model has been reinvented below (Fig. 1), accounting for the divergence of flexibility maturity into lean and agile paradigms. These two require different set of tools/practices/substrategies to attain a different state of flexibility maturity.

Goldman et al. (1995) posit that strategic concerns for agility are based on four cardinal principles: (a) enriching the customer, (b) mastering change and uncertainty, (c) cooperation, and (d) leveraging the impacts of people, information, and technology. These four principles essentially belong to the domain of dynamic enterprise-wide flexibility management. Wadhwa and Chopra (2000) also emphasized the dynamic reconfiguration of flexible structures as a route towards agility. Wadhwa and Rao (2003) indicate the benefits of exploiting flexibility in supply chains towards lead-time reduction, which leads to enterprise agility. Similarly, Chan et al. (2004) indicate that flexibility in business processes adds to agile performance in supply chains. Wadhwa and Rao (2004) show the commonality between manufacturing and supply chain flexibility and further posit that its exploitation can be beneficial for time-based performance. Earlier Browne et al. (1984) had discussed various types of flexibilities in the flexible manufacturing systems (FMS) context and indicated their usefulness towards time-focused performance. Wadhwa and Browne (1989) showed how flexible systems allow control of the flow of entities (material, resources, information, etc.) towards lead-time reductions. Stecke (1992) led several works to show how flexibility can be exploited to improve time-related performances through better planning and control decisions. These references support the notion that, while agility is a strategic need, resource flexibilities in conjunction with suitable planning and control mechanisms act as its facilitators. This helps in establishing synergy among the enterprise resources responsible for improvements in lead-time and cost-based performance.

Agility comes by way of change proactivity (Kidd 1995; Sharifi et al. 2001). Management for agility is focused on business scope beyond what is obtainable from flexibility of intra-enterprise resources. Gunasekaran (1998) indicates virtual manufacturing (VM) as one such mechanism for achieving enterprise agility. VM enables inter-enterprise consolidation of core competencies that help to attain superior enterprise performance in an agile environment. Similarly, Yusuf et al. (1999) indicate that core competence is beneficial for agility in multiple ways. It provides capability for multiventuring, helps to access a wide spectrum of markets, and also strongly enrich customer valuing of end products. Agile product design (APD) is another strategic initiative that improves agility by enabling the enterprise to adapt to the changing customer choices. It has been made possible by way of modular design changes in product specifications (Yang and Li 2002). Similarly, enterprises can attain agile performances by way of appropriate supply chain reconfiguration (Naylor et al. 1999). Another such substrategy that improves agility is knowledge management (KM). Soliman and Youssef (2001) posit that next-generation agile manufacturers will rely heavily on KM for their operations specifically through innovations in design and manufacturing. Mass customization (MC) concepts promote capabilities for technological innovations to approach customers with individually designed products and services. It broadly encompasses the ability to provide customized products and services at the mass-market economy and thus serves as a pathway for agility (Silveira et al. 2001).

Since there are multiple variables in the market, a distinct framework is required for individual enterprises for achieving agility. In their framework Sharifi and Zhang (1999) suggest the use of comparative assessment of the need for agility and the present enterprise agility level, gap analysis, and the evolution of required business practices as the path for achieving agility, whereas in his approach Gunasekaran (1999) considers a synergistic integration of strategies, systems, people, and technology for agility. Retaining competitive position in an agile business environment requires that the enterprise supplies not only the product but a solution to individual customer requirements (Goldman and Nagel 1993; Kidd 1995). In addition to specific market characteristics, customer preferences for diversified product ranges, mass customization and short product life cycles are the few product-related characteristics specific to agile environment. This makes product and its characteristic other very important concerns for agility. In addition, successful practice of agility requires that enterprises are able to function well within a dynamic, turbulent, and competitive market environment. Therefore, market characteristics become the third important aspect for agility. Yusuf et al. (1999) in their comprehensive definition of agility also indicate market, product, and competition as the three important actors for agility. Mishra and Wadhwa (2003) suggested a framework for attaining agility based on the characteristics of these actors (Fig. 2). Exploration of all actor characteristics indicates appropriate success factors. These success factors consequently require the selection of appropriate agility enablers in the form of required resource capabilities. Gunasekaran (1999) posits that successful enterprise performance is possible by way of synergy among agility-enabling resources while performing the required business processes. These business processes should be designed to fulfill all of the actor requirements with least trade-off. As agility comes through the integration of internal as well as external core competencies, integrated supply chain management is best capable of addressing the concerns of an agile enterprise system. We follow the framework suggested by Mishra and Wadhwa (2003) to model agility. While doing this, we consider flexibility as a measure of resource competency. Here flexibility represents capability to adjust against environmental changes with least trade-off in cost and time performance measures. Attaining enterprise agility thus becomes the management of core competencies where different enterprise-wide flexibility elements are decision alternatives. This is explained in Sect. 2, where the enterprise supply chain acts as the platform for modeling.

Framework for enterprise agility (Mishra and Wadhwa 2003)

Strategic decision-making processes usually lack analytical validation. These are composed of multiple variables and require consideration of multiple criteria as inputs for decision-making. Here we find that solution through mathematical reasoning is not possible without too much of abstraction. Coupled with this, there also exist cognitive elements, which need managerial considerations in the decision problem. ANP is a suitable tool for modeling such situations with a complex decision environment (Sarkis 2003). ANP provides the flexibility to accommodate a multiattribute decision-making (MADM) environment, which is typical of any strategic decision-making process. ANP, its application area, and the process steps in modeling with ANP are discussed in Sect. 3.

Analysis of the decision problem reveals that it follows a network hierarchy with goal, actors, actor criteria, and alternatives as the four hierarchical decision levels. We also observe interdependency among network nodes at the intermediate level. Section 4 describes the modeling framework for enterprise agility in terms of flexibility. The calculation procedure for the relative importance of the flexibility elements for the goal of enterprise agility is discussed in Sect. 5. We then explore the effect of change of variables on the importance of alternative priority under the heading ‘Sensitivity analysis’ in Sect. 6. We further discuss the issue of decision flexibility in agile supply chains from a knowledge management (KM) perspective in Sect. 7. Conclusions are given in Sect. 8.

Actor-based modeling for agility is a contribution of this research effort. It helps in prioritizing the SC capability matrix for agility in terms of enterprise SC flexibility elements. Furthermore, sensitivity analysis of enterprise flexibility elements in a dynamic business environment adds an entirely new focus to management research concerned with agility.

2 Flexibility construct for agility

Agile manufacturing is the consequence of proactive management of change made possible through an enhanced level of proactive change capability. As indicated above, this is made possible through the application of substrategies that minimize the trade-off between cost and scope. ICT, VM, integrated SCM, and reconfiguration in conjunction with synergy of people, technology, and processes are some of the options available to address this trade-off. Based on the conceptual model developed in the preceding section, the following statements about agile manufacturing can be postulated.

-

a.

Customer preference is of utmost concern for agile enterprises,

-

b.

Agile enterprise structure is conceived by dynamic market characteristics,

-

c.

A specific product characteristic is required for agility to be practised,

-

d.

That value addition processes in the enterprise needs to be monitored all along the supply chain/network of the whole enterprise,

-

e.

Agile enterprises are composed of change-capable entities.

These postulations form the basis for modeling strategic options for attaining agility. Wadhwa and Browne (1989) indicated that lead-time reduction can be achieved by exercising effective control on the flow of entities through a flexible system. We extend this notion of time reduction in the wider perspective of an enterprise that is composed of multiple flexible systems. Hence, it can be concluded that agility can be improved by better synchronization of entity flows through enterprise-wide supply chains. In their agility capability improvement model Vokurka and Fliedner (1998) stressed the need to prioritize strategic options for achieving agility. They also indicated flexibility maturity as a precondition for agility. We infer that a higher level of flexibility maturity is desirable for enterprise agility. As indicated in Sect. 1, agile enterprises utilize flexibility maturity to provide scope in enterprise performance. This provides improved efficiency in operations and at the same time also adds to customer enrichment. An agile enterprise as indicated above is characterized by its ability to perceive and adapt to change. Adapting to change comes through the utilization of flexible resources such as people, facilities, systems, and processes. The postulates above also indicate that customer, market, and product characteristics are the three most important concerns for agile enterprises. Therefore, for lasting agility, the substrategies must focus on the requirements of these actors.

In an enterprise, there are several tiers of flexibility. Lower-order flexibility in manufacturing system needs proper infrastructure support to provide proportionate higher-order output flexibilities. Since output flexibilities, i.e., flexibility maturity, depends greatly on method of delivery and enterprise processes, these become very important for the enterprise. Beach et al. (2000) emphasize that knowledge of the trade-off that exists between different flexibility dimensions could help in the formulation of an appropriate manufacturing strategy. Research efforts on the effects of advanced manufacturing technology on flexibility tend to be divided. Jaikumar (1986) and Upton (1995, 1997) in their research separately observed that there was very little or negative effect of advanced manufacturing technology on the flexibility of plants in the USA. However, this literature indicates the association of the degree of managerial emphasis placed on flexibility with the observed flexibility at the plant level. Wadhwa and Rao (2002), while exploring stages of flexibility maturity, indicate the use of flexibility for resolving conflicts among organizational objectives. They further suggest exploiting flexibility towards performance improvement. However, since flexibility is not free, judicious use of flexibility is important.

Scully and Fawcett (1993) suggest that decision issues affecting competitive position relate to cost, quality, delivery dependability, flexibility, and innovation. Olhager and West (2002) relate gain in competitiveness in all these competitive priorities with maturity in manufacturing flexibility. While suggesting a unified framework for manufacturing and supply chain flexibilities, Wadhwa and Rao (2004) envisage the evolution of dynamic decision points to control multiple entity flows for improving lead-time performance measures. These papers help us to infer that a similar strategy is needed to manage the complexity associated with an agile business environment. Thus, a methodology for agility should focus on management of not only manufacturing but also an enterprise-wide supply chain consisting of change-capable resources. Leslie et al. (2001) proposed production system, market, logistics, supply, organizational, and information system as the six types of flexibility elements needed to represent the change capability in an enterprise supply chain. They consider production system flexibility as the ability to configure assets and operations to react to emerging customer trends (product changes, volume, mix) at each node of the supply chain. Since change capability comes through utilization of flexible resources, resource-based differentiation of enterprise flexibilities makes the modeling of the total value addition process transparent. In this research paper, enterprise-wide change capability is evaluated in terms of different types of flexibilities of the resources constituting the enterprise supply chain. It consists of: (i) sourcing (SF), (ii) product development (PDF), (iii) manufacturing (MF), (iv) logistics (LF), and (v) information technology (ITF) flexibility elements. Here the notion of flexibility is to provide multiple options (scope) in the corresponding dimension with least variances in time and cost performance measures.

For brevity, an agile enterprises can be considered as one that has an agile supply chain. For agility, the method of delivery of all of the above flexibilities should be aimed towards leanness and responsiveness in the supply chain. Viswanadham and Srinivasa (1997) indicated supply chain process and the order to delivery processes as the two very important business processes of an enterprise that directly involve the customer. Wadhwa and Rao (2000) proposed the utilization of both design and manufacturing flexibility towards lead-time performance improvements. Consequently, lead-time reduction results in improved agility.

Continuously reducing product life cycles is a characteristic of agile manufacturing environments. Enterprises that can introduce products in quick and planned successions are able to exploit this capability in creating opportunities for itself. Agile supply chains possess a higher level of product design flexibility maturity, which enables these enterprises to make changes in development cycle even at late stages of product development (Tomke 1997). Responsiveness through product design and scope in product design through product modularity are two important measures of product design flexibility that provide opportunities in terms of changing product configuration and adapting to customer taste. Since an actor-based agility framework requires a customer/market-focused supply chain, emphasis is placed on the customization of supply networks, which not only aims towards customer enrichment but also reduces warehousing and inventory costs (Anderson et al. 1997; Harland and Scharlaken 1997).

The ability of purchasing to adapt changing material requirements provides a higher level of responsiveness and agility in the organization (Swafford et al. 2000). Higher levels of SF supports an organization’s ability to deliver products and services in a timelier and effective manner (Tan et al. 1998). This improves the customer enrichment dimension of the enterprise performance, which is one of the most important agility dimensions. Narasimhan and Das (1999) link synergy between purchasing and manufacturing for agility.

Manufacturing flexibility represents capability of the manufacturing system to process multiple product lines. Capability to reconfigure manufacturing system in multiple alternative options helps to provide large and customized product variety at low cost, with shorter lead times, and in varying lot sizes (Narasimhan and Das 1999). It enables organizations to align manufacturing strategy with changes in the business environment.

Delivery dependability and customer responsiveness through cost-effective logistics function can be achieved through a higher level of logistics flexibility. Logistics function is critical for time-based competitive strategies (Fawcett and Clinton 1996). Responsiveness and scope dimensions in agility can be significantly impacted by greater logistics flexibility that includes a dynamic logistics structure and multimodal transport system supported by matching product structure.

Integrated supply chain management helps individual SC flexibilities to support the synergy in their change capabilities for adapting the enterprise against business environment. Wadhwa and Rao (2003) discuss the exploitation of flexibility under various decision-information synchronization (DIS) scenarios. They indicate that decision-focused models are important for increasing flexibility benefits on lead-time reductions and hence agility. IT flexibility in the supply chain agility construct provides the medium for such a synergistic integration of individual supply chain elements. Since ICT has proved to redefine the scope of enterprise management towards the cost, customization, responsiveness, and customer fulfillment dimensions, IT flexibility is considered the vehicle for agile enterprise management.

We propose here a flexibility construct for agility in supply chains. It consists of sourcing, product development, manufacturing, and logistics as basic supply chain flexibility elements. These are supported by IT flexibility as a support flexibility dimension. A valid construct for the agility framework should address the required change capabilities of the enterprise. Agility is synonymous with dynamic markets, high customer expectations, and intense competition. For this, enterprises need to deploy resources in the most effective way to satisfy continuously changing customer requirements. At the same time, the design, manufacturing, and life cycle aspects of the product should also support the attainment of enterprise objectives. In addition, enterprises must also be able to align resources and inventories in order to match dynamic market requirements. As indicated above, we consider the market, product, and customer as the three important actors for agility. Accordingly, we construct a framework for agility that supports alignment of strategic objectives with the characteristics of these actors. Since the framework deals with the requirement of enterprise change capabilities in the time, cost, and robustness dimensions, we find it logical to associate enterprise-wide flexibility elements, i.e., SF, PDF, MF, LF, and ITF, as the basic constructs of supply chain agility. Figure 3 shows this flexibility construct for supply chain agility. This construct appreciates the methodology suggested by Mishra and Wadhwa (2003), which is also based on the requirement of agility actors.

Referring to Fig. 3, it is observed that the requirements of individual agility actors indicate the candidate substrategies needed to be implemented by the enterprise. Attaining enterprise agility is a multipath activity. However, successful exploration of agility demands that it should follow a path that requires less trade-offs. This means that a selective approach for improvement based on the relative importance of the substrategies should be followed. As complexity abounds, the evaluation of the relative importance of these substrategies demands a consolidated framework. The framework given in Fig. 2 suggests synergistic consideration of the design of the enterprise capability matrix. Since a complex interrelationship exists among the different substrategies, evaluating the importance of different substrategies and the corresponding flexibility elements requires the implementation of a methodology that is able to model this interrelationship. In addition, since trade-offs exist among various performance measures dictated by the agility actors, the process of achieving agility should also be guided by the relative importance of the agility actors. Flexibility is conventionally measured as change capability in terms of the scope, time, and cost dimensions. The methodology should therefore indicate the appropriate enterprise matrix in terms of flexibility elements as building blocks for the enterprise supply chain. These supply chain flexibilities should collectively address the dynamic requirements of the agility actors.

From the above analysis of the concerns of enterprise agility, we observe that the methodology for agility is a complex decision problem that involves multiple variables and their interdependence. These require the application of a multiple-criteria approach along with consideration of their trade-off. Accordingly, we select ANP as the tool for analysis.

3 Analytic network process (ANP)

Saaty (1980) introduced the analytic hierarchy process (AHP) for selecting the best among several alternatives to fulfill objectives in an MADM environment. AHP considers a hierarchic structure of nodes in a multiple-layer decision problem with the assumption of independence of higher-level node from the lower-level nodes as well as independence of nodes at the same level. However, ANP allows interrelationships of nodes in a network instead of a hierarchy. A group of elements having similar properties constitutes a cluster. A network is constituted of elements, which reside in different clusters, and interrelationships exist among the elements of the same group as well as among elements belonging to different groups. This makes ANP a comprehensive tool capable of analysis of decision problems, which usually have a network structure. It is a process that allows the inclusion of all the factors and criteria, tangible or intangible, that can affect the decision problem in one or more ways. Influence is a central concept in the ANP. ANP modeling allows both types of interactions: among the elements of a cluster (inner dependence) as well as among the nodes belonging to different clusters (outer dependence). Such feedback best captures the complex effects of interplay in human society, especially when risk and uncertainty are involved (Saaty 2001). Applied research shows limited application of the ANP tool until recently. Saaty (2001) suggests ANP to be very suitable in situations with a complex decision-making environment. One of the advantages of ANP is that it supports the utilization of group decision-making instruments to evaluate the interdependence among various decision variables which otherwise cannot be correlated because of the lack of a formal relationship.

A decision network consists of a structure containing interlinked subsystem, components, and elements in these components. Representation of the influences of nodes among one another in the same component/cluster or with the nodes or elements in another component or cluster takes the form of a block matrix whose element are the principal eigenvector of the influences of the participating members of the group. The mutual influence structure of all the elements in the network is called a supermatrix. These are essentially composed of block matrices formed by comparisons among all the members of the components in the network. The elements in the supermatrix represent the disjointed influence of members. The calculation of stable limit priority of the influence of the members in the network is done by first transforming the supermatrix into a stochastic matrix in which the individual column vectors sum to unity.

3.1 Calculation of priority in ANP

For calculating a stable dependence relationship among the elements of the network, Saaty (2001) suggests the following procedure

-

a.

Pairwise comparison of all the nodes for their effect on nodes connected to it. This is done for all the nodes, including those that have inner as well as outer dependence in the network, and is followed by the determination of the relative importance of the clusters in the network and the eigenvectors from these dependence relationships. Inconsistency may emerge during this comparative judgment. Such inconsistency is to be removed before proceeding further as it may lead to an inconsistent conclusion.

-

b.

Making the supermatrix column stochastic by weighting the elements in the supermatrix by the relative weight of the block to which they belong, such that the column sum becomes unity for all the columns of the supermatrix. Weighting for stochasticity makes convergence of the supermatrix feasible. This converged supermatrix represents the limit priority of the nodes in the network.

-

c.

Checking for irreducibility, cyclicity, and primitivity of the supermatrix (W). This is required in order to apply an appropriate procedure to approach convergence and to estimate the limit priority. For a stochastic, reducible, and primitive matrix, the largest eigenvalue λ max = 1 is a simple and unique root of unity, and in this case \( {\mathop {{\text{lim}}}\limits_{k \to \infty } }{\text{W}}^{k} = {\text{we}}^{{\text{T}}} ; \) where w is the right principal eigenvector of W and because W is stochastic, eT = (1, ...., 1) is its left eigenvector. Convergence is established simply by raising the supermatrix to very high powers.

-

d.

In the cyclic case (imprimitive) with length c, there are other roots with modulus equal to 1. In this case the limit calculation is based on

$$ {\mathop {{\text{lim}}}\limits_{k \to \infty } }\,{\text{W}}^{k} = {\left( {1 \div c} \right)} \times {\left( {\text{I} + \text{W} + \cdots + \text{W}^{{c - 1}} } \right)}\,{\left( {\text{W}^{c} } \right)}^{\infty } \;c \ge 2 $$ -

e.

For the reducible case with multiple roots of λ = 1 with multiplicity n 1, the limit matrix is given by

$$ {\mathop {{\text{lim}}}\limits_{k \to \infty } }\,{\text{W}}^{{\text{k}}} = n_{1} {\sum\limits_{k = 0}^{n_{1} } {( - 1)} ^{k}} \frac{{n_{1} !}} {{{\left( {n_{1} - k} \right)}}}\frac{{\Updelta ^{{(n_{1} - k)}} (\lambda )}} {{\Updelta ^{{(n_{1} )}} (\lambda )}}(\lambda \text{I} - \text{W})^{{ - k - 1}} \left| {_{{\lambda = 1}} } \right. ,$$where \( \Updelta (\lambda ) \cong {\text{Det}}(\lambda {\text{I}} - {\text{W}}) = \lambda ^{n} + p_{1} \lambda ^{{n - 1}} + \cdots + p_{n}. \)

To save space, the proof of the above derivation, which is purely mathematical in nature, is not elaborated here; the interested reader is referred to Saaty (2001). Elaborate computer algorithms are now available for obtaining the limit matrix solution, which was previously very difficult even for a moderately size matrix. In practice, algorithms are used for the evaluation of the limit matrix in the three cases indicated above. These first check the cyclicity by raising the matrix to a few successively high powers. If it is observed to converge at more than one value but with different limits, this signifies cyclicity and the average of the priority values from these are considered as the limiting value for the matrix. If raising to successively high powers creates convergence with the same solution, the limit matrix is supposed to have been reached.

3.2 Sensitivity analysis in ANP

For analyzing changes in the environmental condition, new supermatrices have to be made with the changed local priority of the nodes each time there are changes in the interrelationship between two or more elements. The evaluation of stable priorities of the network elements requires that this procedure be repeated as and when input relationships change. This type of analysis is done to model the time-dependent decision environment when the local priority vector may change too often. For a complex dynamic system in which changes in the interrelationship are usual within the planning horizon, recalculation of the limit priority becomes time consuming. On the other hand, enterprises can utilize changes in the environment as opportunities if they are able to adapt to these environmental changes through quick adjustments in appropriate strategic priorities. Thus, analysis of the effect of changes in the relative importance of nodes on the performance measure can serve as guidelines for continual performance improvement. In this case sensitivity analysis is carried out to investigate the effect of changes in the interrelationship among decision nodes on the goal of the decision network. Under dynamic conditions, when the structure of the network is itself changing, such rearrangements of nodes indicate opportunities in the sense that the best alternative structure indicated by sensitivity analysis signifies improvement in the decision domain.

3.3 ANP: some applications

Since ANP is a relatively new tool, little literature on the application of ANP is available. A few papers that have been published in the area of business decisions should be mentioned here. Meade and Sarkis (1999) discussed the ANP model for evaluating project alternatives for agile manufacturing processes. They applied this to a case problem. Their analysis is based on four control hierarchies signifying cost, time, robustness, and scope as the parameters on which agility index is evaluated. They assume interdependence at the agile attribute enabler level. The relative priority of the alternative projects is calculated on the basis of the aggregate priority of the alternatives for these four control criteria.

Earlier Meade et al. (1997) applied ANP in a business case for strategic alliance formation. They show that different strategic priorities are appropriate at different stages of the product life cycle. They posit that such an analysis links operational and tactical measures with the strategic objectives and helps to minimize risks in alliance formation by selecting appropriate strategic alternatives.

Saaty (2001) also investigates real-life decision problems in the domain of politics, business, society, and defense strategy. In one such case example, he discusses the strategic aspects of marketing a new drug by a pharmaceutical firm. Different strategic areas that affect this decision were considered. The ANP analysis explored various decision alternatives. The analysis was based on benefit, cost, and risk control criteria. The decision alternative rated the new drug appreciably higher than the old one. The actual management decision as reported was to launch the new drug with higher incentives and promotions, while continuing with the old drug without incentives and promotions. It was further claimed that the actual decisions were consistent with the ANP model.

Saaty (2001) also discusses an industrial network problem concerned with the evaluation of the market share of the top three fast food restaurant chains. It considered advertising, quality, and other as the three clusters in deciding the outcome of ANP analysis. Some of the important criteria included in the model were nutrition, taste, and portion in quality, creativity, promotion, and frequency in advertising and price, location, speed, menu, reputation, etc. in the other cluster. The nodes in these clusters show inner as well as outer dependences. Their outcome nearly matches the actual market share of the three food chains. More literature on ANP and real-life decision problem can be found on two websites: superdecisions.com and creativedecisions.net. The ANP modeling tool Super Decisions™, available at these websites, also discusses the modeling of several real-life situations as case examples.

4 ANP modeling of a supply chain for agility

We have proposed in Sect. 3 that the enterprise matrix for agility should be based on actors of agility. Since market, product, and customer are identified as the three most important actors of agility, the strategy for agility should focus on the requirements of these actors. Identification of the requirements of the actors is associated with their characteristics. The characteristics of the actors indicate a set of substrategies that aim to address the specific requirements of these actors. Substrategies require appropriate enterprise capabilities indicating their direct association with appropriate types of supply chain flexibilities. We deduce from these facts that the goal of attaining enterprise agility actually depends on the individual goals of the agile actors. The goal for each of the agility actor depends on a set of substrategies specific to the actor, and each of these substrategies further depends on appropriate SC flexibility elements.

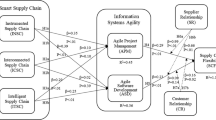

Thus, we observe that the goals of agility for each of the actors form a three-level network. It contains the individual agility goals, their individual success factor cluster at the middle level and a common alternative cluster at the bottom level. The success factor clusters contain nodes that represent substrategies focused on the respective actor characteristics. It is also observed that substrategies in a particular subnetwork influence one another, i.e., they show inner dependence. These interdependence relationships are indicated by a two-way arrow connecting the nodes in the success factor cluster. The alternative cluster contains the flexibility dimensions. The resulting network and the nodes it contains are shown in Fig. 4. Prefixes used in the figure show the association of the cluster and nodes with the concerned subnetworks. In ANP terminology, flexibility elements contained in the alternative cluster are sink nodes that reside at the bottom level of the network and no arrows go out of these nodes. The resulting network is called an insufficiently connected network. The calculation of a stable dependence vector for the nodes in these networks may show degeneracy; see Saaty 2001; Adams 2004, who have suggested various algorithms for stable priority calculation in these cases.

We discuss below actor-based mapping of flexibility, the concern of inner dependence among the substrategies, and the resulting network structure of attaining agility.

4.1 Actor: market

The market environment may display the following characteristics (Fig. 5):

Case a: The enterprise is operating in an expanding market (EM). This condition is synonymous with the growth phase of a product life cycle. Under such a condition, the strategy should focus on the front-end expansion of the supply chain. The ability of the enterprise to restructure the market side of their supply chain depends on their logistic flexibility. As IT flexibility is the prime mover of all flexibility types, IT flexibility becomes the next desirable flexibility element for market-based agility. At the same time, since manufacturing flexibility resides at the core of the value addition process, this also needs to be included as a bottom node for market agility.

Case b: The market environment is dynamic. It is represented in the network by a dynamic market (DM). This condition is synonymous with the transient phase of the product life cycle. It is particularly true when a new product that can replace an existing product has been introduced into the market by a competitor. Under such a condition, success depends upon the capability of the enterprise to restructure the whole supply chain to exploit any opportunity that applies in any geographical region by way of relocating the resources or by restructuring the supply chain. Accordingly, all the flexibility elements except product development flexibility will be considered to find an appropriate strategic option.

Case c: The condition of fragmented market (FM) exists. This case is representative of a situation where opportunities exist for the enterprises only by way of product differentiations and the creation of niches. For continuous success under such conditions, the enterprise must provide multiple options to the customer in terms of product variety and service. Therefore, manufacturing flexibility and product development flexibility become the two most import flexibility elements.

It is important to mention here that the nodes representing the three strategies (EM, DM, and FM) are interrelated. Looped arrows on the success factor cluster in Fig. 5 indicate this interdependence. The ANP methodology discussed in Sect. 5 takes this interdependence into consideration.

4.2 Actor: product

The product may display the following characteristics (Fig. 6):

Case a: For complex product structure (CPS), production cost becomes appreciable. Under such conditions, manufacturing strategy should focus on reduction in production cost and so manufacturing flexibility becomes the most important flexibility element whereas IT and sourcing flexibility are the support flexibility elements.

Case b: For stable product ranges (SPR) with intense competition, the lean paradigm and a continuous improvement philosophy is required. The enterprises under such condition require management of the entire value chain. Therefore, under these conditions a total system philosophy is needed to reduce cost continuously and, as a result, all the flexibility elements become important.

Case c: When the product belongs to a diversified range (DR), flexibility on the distribution side of the supply chain is most needed. Enterprise management under such a situation has to bear the burden of higher inventory-related cost so as to maintain the desired service level. Here manufacturing postponement provides opportunities to reduce cost by way of aggregation and a just-in-time (JIT) philosophy in supply chain. Therefore, manufacturing and IT flexibility become the relevant support flexibility dimensions.

Case d: When the product offer is intended to retain the customer base, strategic initiatives require ascertaining quality over product life (QPL) in their product offer. This necessitates the development of enterprise core competence that guarantees higher product and service reliability. High conformance quality, product recall options, and quick redesign are also needed for strategic robustness. Accordingly, product development flexibility with support from IT, manufacturing, and logistic flexibility become important in this case.

Similar to the case of the market actor network, interdependence also exists among the four nodes in the success factor cluster here (Fig. 6). This also needs to be considered in the ANP solution methodology.

4.3 Actor: customer

The product may display the following characteristics (Fig. 7):

Case a: For customer enrichment (CR), the value addition processes needs to be done by core competent business units, so that the best possible product offering can be made to the customer. This requires efficient management of total product lifecycle. In such a case all the factors, viz. product-development, manufacturing, logistics, sourcing, and IT flexibility, becomes important.

Case b: To ward off delay and inefficiency due to delays in information flow/workflow when the product is complex requires that systems and enterprise processes are seamlessly integrated (SI) and that redundancy is minimized. This requires that IT and manufacturing have a robust interface for enterprise-wide integration.

Case c: Enterprises thrive if they are able to reach the customer first through quick and innovative product launches. Through this, business units try to attain the status of market leader. This is called the first-to-market (FTM) philosophy. This requires that development time for new products is short. Advantages are gained when the product structure is modular. This helps to reduce time and effort required for product modifications by way of changes in only a few product modules one after another. Concerns in this case are product development, IT, and manufacturing flexibility.

Case d: Customer requires customization in product specification, service, and delivery options. This stage is represented in the network by comprehensive customization (CC). The idea of CC is to guarantee the success of the enterprise by appropriately designing the manufacturing and support process. It enables a product offering with well-defined information and service delivery mechanism in order to provide a solution to the customer for which the product is acquired. For CC, customers are involved in the value addition process at an early design stage, thereby minimizing the risk of product failure.

By embracing a strategy of customer-driven product design and manufacturing or mass customization, enterprises aim to sustain competitiveness by creating opportunities for themselves. Here IT, product development, manufacturing, and logistics flexibility become important.

Similar to the two actor networks discussed earlier, here also interdependence exists among the nodes of the success factor cluster (Fig. 7).

Figures 5, 6, and 7 show the subnetworks associated with market, product, and customer as agility actors. All three of these networks have a common structure with inner dependence among nodes of the substrategy cluster. The digit prefixed with the nodes in these figures helps better visualize the dependence of the goal on these alternatives.

It is important to notice that the model considered is simpler than what is required if it is to depict the actual relationships among network nodes. Two factors are responsible for using abstraction in the ANP modeling: because a certain amount of abstraction makes it comprehensible for the survey audience to establish the actual relationship among network nodes and, for larger models where there are many network nodes, a certain amount of abstraction may not affect the outcome appreciably; in fact, it simplifies the evaluation of alternative priorities. However, the level of abstraction in the model details should not be extensive as this may result in an incorrect outcome. It is also required that, before the outcome is implemented, the network structure and relationship among the ANP nodes be validated by empirical or survey studies. Furthermore, application in an actual decision environment will require that this model be customized to the needs and environment of the specific enterprise.

This research has opted for model simplification also to illustrate the application methodology of the ANP framework for achieving enterprise agility. It tries to evolve a systematic approach that relates strategy with bottom-line resource flexibilities. Much of the actual detail has been omitted to make the presentation of the methodology easy to appreciate. As such, future research opportunities may focus on more comprehensive network node connections as well as on the issue of the inclusion of more nodes in the ANP model. For example, in the proposed model alternative clusters contain only flexibilities elements, which can be extended to include operational alternatives that provide these flexibilities. Likewise, future research should also consider the interdependence of nodes present in different success-factor clusters.

We now illustrate the solution methodology for the proposed ANP model.

5 Priority calculation

The procedure suggested in Sect. 3.1 is now followed to determine the stable priority in the subnetworks. Since all three actor subnetworks are similar, the procedure will be demonstrated for the customer subnetwork and the results of other two will be used directly in calculating the overall priority of the alternatives.

5.1 Pairwise comparison of substrategy nodes connected to the goal node

From Fig. 7, we infer that the goal of customer agility depends on four nodes viz. 1321 CR, 1322 SI, 1323 FTM, and 1324 CC. Hence, taking two at a time, a total of six pairwise comparisons are needed for elicitation of the priorities of the above nodes for achieving customer agility. The following questions are asked of the stakeholders for this purpose. Of the two substrategies 1321 CR and 1322 SI, for example, compared with 1322 SI, what is the relative impact of 1321 CR on node ‘13 customer’ for achieving enterprise agility? Saaty (2001) has suggested a scale of 0–9 for this purpose. The values of 9, 7, 5, 3, 1 corresponds to extreme, very strong, strong, moderate, and equal importance, respectively. If for example 1321 CR is equally to moderately more important than 1322 SI for achieving customer agility, 1321 CR gets a score of 2.0 in comparison to 1322 SI. A reciprocal value is then assigned to the reverse comparison of the nodes. For example since the score of 1321 CR in comparison to 1322 SI is 2.0, the score of 1322 SI in comparison to 1321 CR will be 1/2.0 (i.e., 0.50). An importance value of 1 is assigned to a node when it is compared with itself. Italicized entries in Table 1 presents the relative ratio scale for the dependence of substrategies for achieving customer agility. Numbers in the matrix indicate the importance of a row element on the column element. For the purpose of calculating the local priority of nodes in the ‘132 success factor’ cluster (the eigenvector in terms of the matrix algebra) any of the methods suggested by Saaty (1980) can be used. A few are mentioned here:

-

Power method: involves first raising the matrix to a very large power and then calculating the sum of the row elements. Finally the local priority vector is calculated by the normalization of the new column vector, i.e., the sum of row elements. In it, the priority vector is obtained by dividing each element of the sum-of-rows column by the total of the sum-of-row-elements column. If the value so obtained for two consecutive powers of the matrix is within a permissible limit, the normalized values represent the eigenvector for the matrix.

-

Another method to obtain an approximate value for the local priority is to normalize the elements in each column. The average of these new row elements represents the local priorities.

-

Evaluation of the local priority as the normalized sum of each row is another very simple method for calculating the eigenvector.

-

A near-accurate result for the local priority vector (the eigenvector) can also be obtained by the normalization of the geometric mean of the row elements.

We follow the last one to evaluate the local priority of nodes in the comparison matrix. The resulting calculations are shown in the sixth and seventh column of Table 1.

5.1.1 Checking for the inconsistency in comparative judgment

Inconsistency checks for comparative judgments augment the confidence of ANP analysis. The judgment process becomes more complex as the number of nodes in the cluster increases. An estimate of the error in judgment represents inconsistency in the priority calculation. Inconsistency checks require the evaluation of the following (Saaty 1980):

-

The largest or principal eigenvalue (λ max) of an n × n comparison matrix, calculated by adding the products of column sum of each column of the comparison matrix with the local priority vector of their respective row for the whole matrix.

-

The variance of the error in judgment. For comparison among n nodes, the variance of the error is given by (λ max − n)/(n − 1). This is called the consistency index (CI) for the comparison matrix.

-

The random consistency index (RCI), derived from a very large sample of randomly generated reciprocal matrices of the same size (i.e., n × n) using the scale 1/9, 1/8,..., 1,...., 8, 9. The value of the RCI for different matrix sizes is given in Table 2.

-

The ratio of CI and RCI, which is called the consistency ratio (CR). A CR value of 0.10 or less is assumed to provide acceptable consistency of the comparison matrix. If it is higher, perturbation of an element in the comparison matrix is needed until the value of the CR falls within this limit.

The last two rows of Table 1 illustrate the method for the calculation of λ max, CI, RCI, and CR with reference to the ‘132 success factors’ cluster. This serves as an example for checking the consistency of relative judgments.

5.2 Paired comparison of substrategy nodes for inner dependence

In the cluster ‘132 success factors’ of the customer agility subnetwork (Fig. 7), inner dependence exists. Pairwise comparisons as above are also done here for evaluating the relative importance of the nodes in the cluster for augmenting the other node with respect to the control node to which they are connected. The question that is asked for evaluating the inner dependence, for comparative evaluation for example, is: what is the relative impact of 1322 SI as compared with 1324 CC on node 1321 CR for its effect on the node ‘13 customers’? Four comparison matrices for each of the nodes in the cluster ‘132 success factors’ are needed for evaluating this inner dependence. Table 3 gives the matrix of inner dependence for the node 1321 CR. As in the case above, a consistency check was also performed here. Similar comparisons are also required for the three remaining nodes of the ‘132 success factors’ cluster.

5.3 Paired comparison of alternatives for nodes in the ‘success factors’ cluster

For each of the nodes in the ‘132 success factors’ cluster pairwise comparisons are carried out among the alternatives for their relative impact on each of the success factor nodes. The question asked, in the evaluation process for example, is: what is the relative impact of alternatives ITF in comparison with alternative MF for its effect on node 1321 CR in attaining the goal of customer-based agility. A comparison matrix for evaluating the priorities of the alternative nodes with respect to 1321 CR is given in Table 4. Consistency checking of the comparison matrix is then carried out. Similar evaluations are also required for calculating the priorities of the alternatives for the three remaining nodes of the ‘132 success factors’ cluster.

5.4 Estimation of relative weights of the clusters in the network

As discussed in Sect. 3, stable relative priorities of nodes in the ANP model are given by the corresponding elements in the limit matrix. This limit matrix is calculated by the power method from a stochastic supermatrix. The supermatrix contains multiple block matrices whose elements represent the relationship among the nodes of the clusters/blocks. As a result a column of entries in a supermatrix usually sum to more than 1. Therefore, to make the supermatrix stochastic, the individual block entries are divided by their relative weights from among the interdependent blocks. The relative weight assigned to the blocks represents the relative importance of the block for the control nodes residing above these blocks. It is because of this that comparisons among the clusters are required.

In the present network, since the ‘132 success factors’ cluster is connected with itself as well as the ‘alternatives’ cluster, such a calculation is needed to evaluate the relative importance of the ‘132 success factors’ and the ‘alternatives’ clusters for the goal node in the customer agility network. Also for network, which has a sink, the individual sink node is supposed to be influenced by itself. This makes the block containing the sink node an identity and thus creates a condition for achieving stochasticity by multiplying the block entries with the cluster weight assigned to them. Here pairwise comparison among the clusters and consistency check as discussed in Sect. 5.3 is also required for the evaluation of the cluster weights. In the present case, the two clusters ‘132 success factor’ and ‘alternatives’ are considered equally important, just to resolve the stochasticity requirement, because of the absence of any other perceivable influence. Therefore, their relative priority becomes 0.5 each.

Another way to solve the network problem with a sink node is to exclude the sink node from the supermatrix and solve the ANP problem. Limit priorities of the relevant component so obtained are then used to calculate the priorities of the sink node as is done in the case of simple hierarchies. This method has the advantage that it reduces the network complexity and thus improves the correctness of the judgment. Also separating the sink from the rest of the network renders it sufficiently connected and removes the chances of degeneracy in the limit matrix calculation.

5.5 Supermatrix formation and limit matrix calculation

Now the values of e-Vectors obtained in Sects. 5.1–5.4 are used to form the supermatrix. The supermatrix is an n × n matrix where n represents the number of nodes in the supermatrix for which comparison has been made. In this case since there is one goal node, four ‘success factors’ nodes, and five ‘alternatives’ nodes; the supermatrix is a 10 × 10 matrix. The entries in the supermatrix represent the importance of the row elements on column elements. The procedures indicated in Sect. 3.1 are followed with a view to evaluate the priority of the alternative in achieving the strategic goal of ‘customer-focused agility’. The relative priorities of the nodes with respect to the nodes they are connected have been already calculated. These values are used to form the entries in the supermatrix. The resulting supermatrix for ‘13 customer’ based agility is given in Table 5. In the supermatrix, entries signify the priority or importance of the row element with respect to the column element; for example, the values of the importance of different nodes with respect to the 1321 CR node calculated in Table 3 has been shown as italicized entries in Table 5. A value of zero in the supermatrix signifies that the column element does not have a direct dependence on the row element.

As discussed above, weighting the elements of this supermatrix is required for stochasticity to be attained. Table 6 is the resulting weighted supermatrix obtained after the process of weighting the values in the supermatrix with the cluster weight (0.5 each for success factor cluster as well as the alternative cluster in this case). For example, since the relative importance of the cluster ‘132 success factors’ is 0.5, the values of the entries for the nodes of the cluster ‘132 success factors’ with respect to the 1321 CR node, shown as italicized entries in Table 6, have been changed to only half of their value in the unweighted supermatrix of Table 5.

The limit supermatrix is obtained by the power method, as indicated in Sect. 3. Table 7 shows the resulting limit matrix deduced from Table 6. When the network contains sink nodes as well, the limit matrix is obtained by solving the weighted matrix excluding the sink nodes (Saaty 2001). For the purpose of network modeling and priority calculation, the ANP software package Super Decisions™ (2003) has been used. While calculating the limit matrix, this tool checks whether the network is insufficiently connected; such networks are characterized by all zero entries in the columns belonging to the sink nodes. It then resolves the stochasticity problem by excluding the sink nodes from the network for the purpose of limit matrix calculation. It is because of this fact that none of the sink node columns under ITF, LF, MF, PDF, or SF in Tables 6 and 7 show stochasticity.

5.6 Calculation of alternative priorities for the customer network

From the supermatrix given in Table 7, the limit priorities of the sink nodes ITF, LF, MF, PDF, and SF for customer agility as given under the ‘13 customer’ column are observed to have the values 0.237, 0.020, 0.105, 0.132, and 0.006, respectively. Since elements in the limit matrix represent weighted values obtained by multiplying the priority weights of the cluster to which they belong, the actual priorities for the above nodes require normalization. Table 8 provides the procedure for calculating the normal limit priorities for the alternative nodes. These values are placed in Table 9 (italicized entries) for evaluating the final priorities of the different flexibility types. Similarly, final priorities of different substrategy nodes in the success-factor cluster for the customer agility goal can be evaluated by normalization of the corresponding values from the limit matrix. These values for the CR, SI, FTM, and CC substrategies finally come out to be 0.234, 0.205, 0.215, and 0.345, respectively.

5.7 Priority of the actors for agility goal

The agility goal network is constituted by the three control subnetwork formed by the three agility actors: ‘11 market’, ‘12 product’, and ‘13 customer’. Therefore, comparison as above is carried out for the evaluation of their relative priorities for the goal of attaining agility. To save space, we simply state the values of the actor priorities for the agility goal to be 0.50, 0.30, and 0.20, respectively, for the market, product, and customer subnetworks. These values are shown in parenthesis along with the corresponding actor subnetworks in Table 9.

5.8 Overall priority of alternatives for agility goal

The present network consists of three subnetworks: market, product, and customer. So alternatives must be evaluated for their suitability on the basis of the aggregation of their individual priority in the three subnetworks. Since agility requires synergy among enterprise strategies, frameworks should establish this synergy by prioritizing the decision alternatives on the basis of the importance of both the actors and substrategies.

Therefore, alternatives are first prioritized for their importance in the individual subnetworks and then the overall priority is calculated by normalizing their weights for the top-level goal of achieving enterprise agility as given in Table 9. This table also contains the alternative priorities for the market and product agilities. For calculating these priorities, the procedure for the customer network was repeated separately for market and product networks. The total priority weight of the alternatives for the goal of achieving enterprise agility is obtained by multiplying the individual priorities in the subnetworks by the relative importance of the subnetworks and then summing them up row wise. The calculation steps are shown in the last column of Table 9. The final priorities for the flexibility elements as given in the last column are 0.310, 0.227, 0.236, 0.135, and 0.093 for ITF, LF, MF, PDF, and SF, respectively. The Super Decisions™ software package also provides the values of the alternative priorities in the individual subnetworks as well as in the top-level network.

5.9 Final alternative priorities: some interpretations

Enterprises undertake action programs for the fulfillment of their strategic objectives. Enterprise performance measures are identified from the relative importance of its strategic objectives. These action programs are actually a set of strategic initiatives that aim to improve these performances. This framework prioritizes the strategic initiatives in terms of flexibility improvement programs. The priority data from Table 9 has been used to draw Fig. 8, which shows the network-wise priorities of different flexibility elements. From Fig. 8, we infer that flexibility priorities for individual actors differ widely; for example, to attain the characteristic of product agility, improvement program should place approximately 39% (the highest) stress on MF followed by 19%, 18%, 16%, and 8% on ITF, LF, SF, and PDF, respectively. In the case of customer agility, action programs should place 48% (the highest) stress on ITF followed by PDF (26%) and MF (20%), while requiring only 4% on LF and 1.2% on SF. Similarly, for market agility, action programs need to place highest importance on LF (33%) followed closely by ITF (32%), while the other three, namely MF, PDF, and SF, receive 15%, 12% and 9%, respectively. To attain overall enterprise agility, strategic initiatives should place approximately 31% (the highest) stress on ITF, 23% on LF, 24% on MF, 14% on PDF, and 9% on SF.

6 Sensitivity analysis

Agile business environments are volatile. We also observe that not only the environment but also enterprises undergo continuous change. Environmental changes must be monitored and corrective actions taken so that these changes are utilized as opportunities. Environmental changes require strategic shifts for the enterprise. This can be carried out either by way of rearrangements in the priorities of the strategic options being availed by the enterprise or by introducing new strategic initiatives to take care of the changed situation. Thus, a shift in priorities of the agile actors will require an appropriate shift in their strategic initiatives; for example, if environmental changes require that strategic initiatives towards market agility be increased, the enterprise faces the situation of deciding the nature of adjustment and the corresponding changes in the flexibility priorities.

Under these situations, sensitivity analysis can be used for evaluating the evolving scenario. This serves as a tool to identify the required change in the enterprise matrix, substrategy, and alternative option for the impending environmental changes. Likewise, if the enterprise wants to analyze the effect of changes in strategies on the alternative priority, this can be done by plotting the trends in the flexibility priorities against the changes in substrategies. Changes in the importance of any of the nodes change the supermatrix. As a consequence, the evaluation of new priorities requires recalculation of the limit supermatrix. Super Decisions™ allows sensitivity analysis of the network for changes in the priority of variables while keeping the relative importance of other nodes in the cluster unchanged. The following example cases demonstrate the utility of sensitivity analysis in indicating the strategic shift needed due to changes in the variables for enterprise management.

Case 1: Market-centric agile environment. Under this condition the priority of ‘11 market’ will have to be increased; accordingly there will be changes in the corresponding priorities of the different nodes in the network. Figure 9 shows a sensitivity graph of the trends in flexibility alternative priorities (plotted along the y-axis) for corresponding changes in the market priority (x-axis). From this sensitivity graph, the following things can be concluded:

-

Under extreme priority of market, the trend shows a shift in alternative priority, and logistics flexibility becomes the most important alternative option in place of IT flexibility. This means that at this stage there should be marked changes in the strategic initiatives to attain the condition of strategic fit.

-

Increasing needs of market agility can be accommodated by a trade-off between manufacturing and logistic flexibility, since increasing market agility requires higher priority values for LF, while requiring that MF decreases continuously.

-

When the priority for the market is lower than 50%, manufacturing flexibility is the second most important alternative, while ITF is still the highest priority flexibility element.

-

Sourcing and product development flexibility are not very sensitive to changes in market priority.

-

For the majority of scenarios, IT flexibility remains the most important option. This underlines the fact that, for market agility, strategic initiatives needs to be primarily focused on IT.

Case 2: Product-centric agile environment. In this case, the priority of ‘12 product’ will increase and consequently there will be changes in the priority of the other nodes. Figure 10 shows the sensitivity graph for ‘12 product’ and this underlines the following indications.

-

For product priorities beyond 50%, manufacturing flexibility becomes the most important strategic alternative.

-

Increase in product priority requires a continuously increasing priority of manufacturing flexibility even at the cost of IT flexibility priority. This underlines the fact that, for product-based agility, manufacturing flexibility serves as the core competence while IT flexibility adds value integration across enterprises.

-

Increasing needs of MF and SF for higher product-based agility can be best achieved by trading off the priorities of ITF, LF, and PDF, which decrease on increasing needs for product-based agility.

7 A flexibility vision: knowledge management (KM)-based agile supply chains

In a simple business sense, knowledge management (KM) can be seen as creation, sharing, adaptation, application, and advancement of knowledge in enterprises to improve their performance. In our opinion, flexibility-driven enterprises possess maximum potential for improvement. Agile enterprises must deal with change effectively and, for this, flexibility is a core competence (Wadhwa and Rao 2000). The response to changes requires sharing of present and evolving knowledge. Proactive management of knowledge is needed in enterprises where the flexibility types and levels need to change in order to respond to external changes more effectively. Tiwana (2000) views KM as the ability to create and retain greater value from core business competencies. However, knowledge can only be derived through the collection and analysis of information and then, in turn, by disseminating the results to appropriate entities within the organization. Intellectual and knowledge-based assets are usually divided into two types: explicit and tacit (Nonaka and Takeuchi 1995). While explicit knowledge represents documented knowhow, the knowhow or knowledge residing in the memories of individuals is tacit. The critical success factors are therefore that the enterprise is able to identify and collect the right knowledge and also that it has the competency to document what it collects and analyze.

One of the future flexibility challenges will be to facilitate processes for evolving KM-driven agile supply chains that can translate flexibility into the desired agile competency. In any SC, the mode of knowledge sharing to be adopted is an important strategic issue. This may affect the overall performance of the system significantly. It requires transforming the way traditional supply chains operate. One way of looking at knowledge is that it allows for making predictions, casual associations, or predictive decisions about what to do, unlike the information that simply gives us facts. The management of knowledge through systematic sharing in supply chain is assuming a larger role in partner organizations around the world. The chains need to respond quickly to knowledge-based decisions and need to be more effective in real-time performance. In order to evaluate knowledge sharing for effective SCM, there is a need for user-friendly network models that may encourage greater collaborative knowledge sharing. ANP could be a useful model since it utilizes both explicit as well as implicit knowledge in comparative judgment. The present state of flexibility research needs ANP-based decision architectures to deal with both explicit and tacit knowledge. The KM-based agile supply chain concept depicted in Fig. 11 shows one such direction. In traditional chains, typically each supply chain node is an autonomous node that takes knowledge decisions motivated by self-optimization at the local level. Due to a clear lack of collaborative knowledge sharing and the associated concurrency, such decisions often become counterproductive. In our experience, sometimes such isolated decisions also lead to poor local performance due to the supply chain dynamics. We have thus proposed the KM architecture for agile supply chains in this regard. This architecture uses knowledge in both forms, i.e., explicit (e.g., expert system, information systems) and tacit (e.g., SCM decision makers, experience layer, etc). A dynamic decision environment necessitates that the decision alternative are identified on the basis of output that is coherent with opinions given by all three factors: expert systems, experience layer, and benchmarked cases. Accordingly the enterprise can better utilize its decision flexibility for improvements in dynamic and situation-specific agile business requirements.

Expert systems are designed for a situation-specific decision context and hence are myopic as far as the enterprise-wide SCM decision domain is concerned. Here the inputs from expert system, benchmarking cases, as well as sensitivity analysis can augment the decision maker in the selection of an appropriate decision alternative. It is this concern for decision flexibility that requires effective KM support in evolving agile supply chains and hence new architectures such as that shown in Fig. 11.

8 Conclusions

Management of enterprise agility to respond to changes in the environment requires continual shifts in the decision domain. This research paper highlights the agility paradigm and the required substrategies for agility to be practised. The present research also proposes an actor-based framework for developing agility in enterprises. Such a framework makes it possible to model the change capability of the enterprise, which can be considered crucial for agile enterprises. The actor-based design of the enterprise matrix on the supply chain flexibility construct is actually the salient point of this research. Enterprise-wide supply chain design based on this flexibility construct makes it possible to include all enterprise processes that have a significant bearing on enterprise performance. A complex decision domain is characterized by the presence of multiple variables that cannot be measured appropriately. In these situations, even an abstract solution of the decision problem is difficult to achieve. In such a case, ANP has been applied as a tool to indicate the strategic options available to the enterprise in terms of the flexible capability of enterprise-wide resources. This research paper also indicates the use of sensitivity analysis as a tool to investigate the effect of different variables in the agility decision domain. Sensitivity analysis can also help the enterprise to indicate the shift required in the enterprise focus when there are changes taking place in the environment. It can also indicate the effect of the utilization of a new strategic option on the importance of existing enterprise resources. The case examples discussed in Sect. 6 also demonstrate that different environmental conditions necessitate the prioritization of the appropriate supply chain flexibilities to mange the agile capabilities of the enterprise effectively.

Agility is a complex strategic issue; as such, a complex ANP structure can only model the details of the actual system. In this respect, the ANP model proposed herein is quite simple. This was primarily because we intended to illustrate more clearly the utility of ANP in a complex decision environment. This also enabled us to illustrate our supply chain flexibility-based framework for enterprise agility. Future research should consider these limitations. Further research is possible by extending the framework to include another layer in the decision network below the flexibility cluster in terms of the time, cost, and scope dimensions. It may also include operational alternatives as another cluster in the ANP structure. Such a consideration will make the analysis of flexibility more accurate and will have less abstraction; consequently, it will have more applicability. Future research opportunities are also available in the direction of the validation of the ANP structure for achieving enterprise agility. In the relative comparison phase of the ANP problem solution, the use of a fuzzy-logic algorithm is also expected to provide better consistency for more-complex decision problems.

References

Adams W (2004) Abstract, available as http://www.creativedecisions.net/papers/papers_etc/calcwhite-paper.pdf, cited in June, 2004

Anderson LD, Britt EF, Favre JD (1997) The seven principles of supply chain management. Supply Chain Manage Rev 1(Spring):31–43

Beach R, Muhlemann AP, Price DHR, Paterson A, Sharp JA (2000) A review of manufacturing flexibility. Eur J Oper Res 122:41–57

Browne J, Dubois D, Rathmill K, Sethi SP, Stecke KE (1984) Classification of flexible manufacturing systems. FMS Mag 2:114–117

Chan FTS, Chung SH, Wadhwa S (2004) A heuristic methodology for order distribution in a demand driven collaborative supply chain. Int J Prod Res 42(1):1–19

Da Silveira G, Borenstein D, Fogliatto FS (2001) Mass customization: literature review and research directions. Int J Prod Res 72:1–13

De Meyer A, Nakane J, Miller JG, Ferdows K (1989) Flexibility: the next competitive battle: the manufacturing futures survey. Strategic Manage J 10:135–144

Fawcett SE, Clinton SR (1996) Enhancing logistics performance to improve the competitiveness of manufacturing organizations. Prod Inventory Manage J 37:40–46

Ferdows K, De Meyar A (1990) Lasting improvements in manufacturing performance: in search of a new theory. J Oper Manage 9:168–183

Goldman SL, Nagel RN (1993) Management, technology and agility: the emergence of a new era in manufacturing. Int J Technol Manage 8:18–38

Goldman SL, Nagel RN, Preiss K (1995) Agile competitors and virtual organizations: strategies for enriching the customer. Von Nostrand Reinhold, New York, pp 3–60

Gunasakeran A (1998) Agile manufacturing: enablers and implementation framework. Int J Prod Res 36(5):1223–1247