Abstract

The base hypothesis for the assessment of fire resistance of timber structures by simple calculation models is that for temperatures above 300°C, timber is no longer able to sustain any load. Consequently, the determination of the location of the 300°C isotherm, the char depth, is decisive for the result of fire resistance calculation methods. The charring rate (CR) of timber is dependent of numerous factors, such as wood species (density, permeability and composition), moisture content and direction of heat transfer (parallel or perpendicular to the grain). Eurocode 5, Part 1–2, presents several methods for the calculation of fire resistance of timber structures that are divided into simplified and advanced. In this paper simplified and advanced methods are compared regarding the calculation of the char depth and residual cross section strength. Finite element simulations have been performed, employing the proposed timber properties of Eurocode 5 using the finite element code SAFIR. The influence of parameters such as timber density and moisture has been investigated. The results obtained with finite element calculations were then compared with Eurocode 5 simplified models. Some inconsistencies between the two methods have been observed. Proposals are presented to overcome some of the inconsistencies as well as to extend the applicability of the models.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Fire resistance of wooden members or structures is strongly dependent of the rate at which wood burns. Therefore, codes of practice such as Eurocode 5 Part 1–2 [1], referred to in this paper as EC5, specify models for the calculation of the amount of charred timber after a certain period of time.

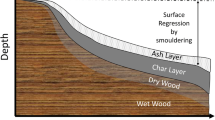

Charred timber is bounded by the transition between the pyrolysis layer, the zone where thermal degradation of timber and char formation are actually occurring, and the char layer, a zone of cracked charcoal that has no significant strength or stiffness. This transition is usually considered to be located at the 300°C isotherm, defined as the char-line. Char depth is the distance between the outer surface of the original member and the position of the char-line. The rate at which char depth advances in the material is called the charring rate (CR) and is an essential characteristic of the fire resistance of wooden structures because it allows the determination of the size of the residual section of timber. CR of timber is dependent of numerous factors, such as wood species, density, moisture, permeability, composition, or direction of the heat transfer (parallel or perpendicular to the grain). However, only some of these factors can be actually considered in practical applications.

EC5 allows the use of simplified and advanced methods for the calculation of the amount of charred timber. Simplified methods use the CR model that is based on the fact that, although the CR slightly decreases with time, in practice it can be considered constant. Cross section strength is then calculated assuming that the properties of the residual timber are similar to room temperature properties (see for example [2] for a more detailed description of EC5 simplified methods).

Advanced methods, use a more sophisticated analysis and design procedures that supposedly lead to more accurate predictions of the fire behavior of structures. The method proposed in EC5 for the determination of distribution of temperature within structural sections is a conduction model based on thermal properties of timber. Following the thermal calculation, a structural calculation is then performed taking into account the progressive degradation of mechanical properties of timber from 20 to 300°C for the calculation of the cross section strength.

The present work investigates the influence of moisture content and density on the CR calculated using the constant CR and the conduction models of EC5. In addition, a comparison of the residual cross section strength calculated using simplified rules and advanced methods is also carried out. Some proposals for improving the consistency between the different models of EC5 are presented. The study was carried out based on numerical simulations using the finite element code SAFIR [3], which is a special-purpose finite element code, developed at University of Liege for studying structures subjected to fire.

2 Eurocode 5 Models for Charring Rate and Thermal Analysis

For the calculation of thermal fields within structural elements, EC5 allows the use of a conduction model based on the solution of partial differential equations describing two- or three-dimensional, transient heat transfer incorporating thermal properties that vary with temperature. However, effects such as mass transfer within the elements or structure, reaction energy released inside the timber due to pyrolysis or degradation of material, cracking of charcoal, which increases the heat transfer in the char layer, are not explicitly accounted for. EC5 presents conductivity values for the char layer that are apparent in order to take into account increased heat transfer due to shrinkage cracks above about 500°C resulting in increased convection and radiation. In addition, specific heat capacity values include the energy necessary to evaporate the water, in the form of a peak between 99 and 120°C.

Charring rate models use the CR concept to calculate the residual section of a wooden structural element as a function of fire exposure time. EC5 allows the use of two different CRs: the one-dimensional design CR under standard fire exposure, β0, and the notional CR, βn. When using the one-dimensional CR, calculation of cross-sectional properties should be based on the actual char depth including corner roundings. The use of the notional CR allows consideration of rectangular residual cross sections. For CR comparisons, the one-dimensional CR, β0, will be considered in the current work and compared with the conduction model because this eliminates unnecessary complications linked to geometrical considerations and allows concentrating purely on the thermal models.

The CR values given in EC5 for softwoods and hardwoods are presented in Table 1. CR values presented in EC5 are independent of density for softwoods with densities above 290 kg/m3 and for hardwoods with densities above 450 kg/m3. For hardwoods the CR varies linearly for densities between 290 and 450 kg/m3.

3 Charring Rate Calculation

3.1 Influence of Density

The CR is usually considered to change with timber density [4–7], despite some authors didn’t find significant correlation between CR and density [8]. However, this dependence is only marginally considered in the CR models of EC5 as shown in Table 1.

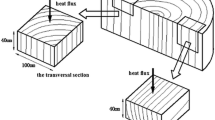

The values of Table 1 have been compared with values obtained by the conduction model. This model does not make any distinction between hardwood and softwood, but density is taken into account.

For calculations of char depth using the conduction model, the coefficient of heat transfer by convection was assumed to be 9 W/m2 K on unexposed surfaces and 25 W/m2 K on surfaces heated with the standard time-temperature curve, according to Eurocode 1, Part 1–2 [9]. The surface emissivity of timber was taken as 0.8. Thermal conductivity, specific heat capacity and density ratio were used with values defined in EC5. Moisture content of timber, w, was considered equal to 0.12. Densities of 200, 290, 450, 600, 800 and 1,000 kg/m3 were investigated.

The curves showing the evolution of the char depth with time are slightly non-linear. The CR is the first derivative of the curves. Because of the nearly linear character of the curves, average CRs were calculated for 30 and 60 min (taken as the secant value from the origin). From here, the secant CR used for comparison purposes is the secant CR at 60 min. Using this procedure, the values of CR were calculated and presented in Table 2. It is apparent that significant differences exist for different densities.

Comparison of calculated CR values with EC5 CR model for softwoods shows good agreement for densities around 450 kg/m3. For lower densities the EC5 conduction model shows faster CRs. For hardwoods the results of CR model and conduction model are in agreement for densities around 800 kg/m3.

The potential regression curve that fits to the results of the conduction model presented in Table 2 reads:

where ρ 12 is the density of wood with 12% moisture content and the coefficient r2 = 0.998. Considering that 0.49 is close to 0.5 and that the CR of timber with density 450 kg/m3, β 450, is 0.68 (see Table 2), Equation (1) can be approximated by \( \beta_{\rho } = \beta_{450} \sqrt {{{450} \mathord{\left/ {\vphantom {{450} {\rho_{12} }}} \right. \kern-\nulldelimiterspace} {\rho_{12} }}} . \) Numerical calculations are in agreement with the theory of heat transfer in materials with constant thermal properties that indicates that the thermal propagation speed is proportional to the square root of thermal diffusivity:

The results obtained numerically were further compared with experimental measurements performed previously at the University of Liege for tropical hardwoods and some softwoods [10]. Comparison of the conduction model with experimental data is presented in Figure 1. The EC5 CR value for hardwoods is also plotted. It can be observed that the conduction model forms an upper envelope of the experimental values while EC5 value is an average value.

3.2 Influence of Moisture

The moisture content has a pronounced effect on the thermal behavior of timber. Thermal conductivity of solid timber depends on moisture content [11–14] but the effects of changes in conductivity of timber below 300°C on the CR are not significant. Temperature in timber will remain approximately constant at about 100°C until all the water has been evaporated and this is the main phenomenon whereby moisture influences the CR. Density of timber is also affected by the moisture content. The CR of timber is dependent on moisture content as was referenced for example by [4, 15, 16].

EC5 specific heat and density ratio curves were defined for service class 1, which corresponds to a moisture content of approximately 0.12. However, density ratio is defined in EC5 as a function of the moisture content, indicating that this curve could be used also for moisture contents different from 0.12. Using this last assumption, the CR was calculated with the conduction model for timber with different moisture contents. The base densities considered were 290, 450 and 600 kg/m3 with 12% moisture. Thus, dry density of timber is 260, 400 and 535 kg/m3, respectively. Moisture contents were equal to 0.0, 0.12 and 0.24 (see Table 3). In addition, in order to compare two situations with the same overall density but with two different moisture contents, dry timber with dry density of 450 kg/m3 was also considered (see Table 3). The calculated average CRs after 60 min are presented in Table 3. There is no significant influence of the moisture content, which indicates that variations of the CR with moisture that have been reported in the literature cannot be reproduced with the conduction model proposed in EC5.

3.3 Possible Model Improvements

3.3.1 Influence of Moisture Content in the Conduction Model

The effect of moisture when using the conduction model can be taken into account using a modified heat capacity curve that depends of moisture. In the modified conduction model, the proposed values for specific heat capacity are based on the assumption that the heat capacity of timber with a moisture content w, cw, is given by Equation (3) [17], in which the effect due to wood–water bond was neglected, the liquid water specific heat capacity is 4,190 J/kgK and c0 represents the heat capacity of dry timber. It was further considered that specific heat values proposed by EC5 include 12% water. Equation (3) was then used to calculate the heat capacity of dry timber.

The new expression for the temperature dependent specific heat (see column 3 in Table 4), was based on the following considerations: (i) from 20 to 99°C, Equation (3) is used, with the appropriate value for the dry timber c0; (ii) from 120°C and beyond, it is assumed that the heat capacity given by EC5 is of dry timber; and (iii) from 99 to 120°C, the term that multiplies w was adapted in order to make the contribution linked to evaporation proportional to the moisture content. The factor that multiplies the moisture content in column 3 of Table 4, for temperatures between 99 and 120°C, can also be approximated by summing, on one hand, the specific heat capacity of liquid water with, on the other hand, the energy consumed in water evaporation (2,250 kJ/kg) divided by the temperature interval (21°C). The modified specific heat curves multiplied by the density ratio for 0, 12 and 24% moisture are presented on Figure 2.

The influence of the moisture content on the CR of timber was recalculated for the same densities and moisture previously analyzed, now using the conduction model with the modified properties. The relation between CR and moisture for all cases is shown in Figure 3.

The differences between the different CRs are now much bigger: 11–14% reduction of the CR is observed when the moisture changes from 12 to 24%, and 22 to 26% increase if the moisture changes from 12 to 0%. It can also be observed that the change of the moisture content (from case 400–0 to 450–12) produces a larger variation of the CR than the corresponding change in density (from case 400–0 to 450–0).

A moisture-normalized CR, k z,w, is defined here as the ratio between the CR at a specific moisture content and the CR at w = 0.12, for the same dry timber density. The relation between the moisture-normalized CR and the moisture content was obtained by regression analysis as being

The results obtained using Equation (4) were compared with results given in references [15] and [16] and shown in Figure 4. It can be seen that the results of Equation (4) fall within the range of available results.

With the moisture-normalized CR, it is possible to obtain the CR at any moisture content, in the range 0–0.24, from the CR of timber with w = 0.12, independently of timber density.

3.3.2 Charring Rate Model

The CR values proposed by EC5 are independent of density for softwoods and show only a small dependence of density for hardwoods with low densities. Therefore, there is some inconsistency between the results of the CR model and the conduction model. To reduce the differences between the CR and the conduction models of EC5, a modified CR model is proposed. This modified CR includes the influence of moisture as introduced in Sect. 3.3.1., to maintain consistency between models. The proposal involves modifying the basic CR calculated for timber with 0.12 moisture and density of 450 kg/m3, β450,12, by multiplying it by two factors: one that depends of timber density and another that depends on moisture. The density term is derived from the results obtained from the numerical analysis. In fact, this correction term already exists in EC5 for panels and a similar expression also existed in the pre-standard version of EC5 for softwood densities below 290 kg/m3.

For moisture, the results of the modified conduction model, see Equation (4), were used to calculate the modification factor.

The CR, β ρ,w, for timber with moisture content, w, and density at 12% moisture, ρ, can thus be obtained from β 450,12 as:

3.3.3 Comparison of Conductive and Charring Rate Models

The results obtained with the proposed improvement of both models are presented in Figure 5. The evolution of the CR with timber density is plotted for moisture contents of 0, 12 and 24%, for both the CR and conductive (CO) models. With suggested improvements more accurate CR values are obtained. In addition, there is increased consistency between conduction and CR models.

4 Calculation of Residual Cross Section Strength

For the calculation of the residual strength of timber cross-sections, two different simplified rules are presented in EC5: (i) the reduced properties method (RPM) that accounts for the reduction of the mechanical properties within the residual cross section; and (ii) the reduced cross section method (RCSM) that reduces the uncharred residual section to account indirectly for the effect of temperature on the mechanical properties of wood. In each case, calculation of the residual cross section is based on the CR concept. In addition, an advanced calculation method (ACM) is presented where temperature dependent strength and stiffness were used to calculate the residual strength of a cross section with a given temperature distribution. In this work the residual strength of a timber section calculated using the RCSM is compared with that obtained using the ACM.

4.1 Comparison of RCSM and ACM

In Figure 6, the principles of the RCSM are illustrated for the case of one-dimensional behavior. The two curves shown indicate the temperature profile after a certain period of time and the corresponding relative strength using EC5 reduced properties. The total strength of a cross section submitted to a compression force is proportional to the area below the relative strength curve. The RCSM is based on the calculation of a distance deff which leads to an equivalent uniform stress (shaded area) within the cross-section where the strength of timber remains unchanged (relative strength equal to 1.0). The distance deff can be calculated as the sum of two terms: (i) dchar, that is the char depth; and (ii) d0, that is the equivalent charred timber. Since the differences between dchar when different methods of calculation are used have been described previously in this paper, the term d0 will be subsequently analyzed.

The equivalent charred timber is calculated in EC5 by the equation

It can be observed from Equation (6) that the equivalent charred timber as presented in RCSM is independent of the type of stress while in the ACM the strength reduction with increasing temperature is different for compression, tension, and shear. The behavior of equivalent charred timber with time was investigated for three timber densities (moisture content equal to 0.12) 290, 380 and 450 kg/m3. Thermal properties of wood used in ACM analysis were as described in previous sections. The wood strength reduction with temperature was as described in Annex B of EC5 [9]. The numerical calculations consist on calculating the relative strength curve, as indicated in Figure 6, and then, calculate deff. The results are plotted in Figures 7 and 8 for the cases of compression and tension, respectively, and compared with Equation (6). Two main findings can be observed: first, there are some differences between the compressive and tensile behavior observed when the ACM is used; and, second, the differences between RCSM and ACM are also important, especially in the case of compression.

The results obtained indicate that the RCSM method gives a reasonably good approximation for tensile stresses and for the case of timber with 450 kg/m3. In the case of compressive stresses the differences were much bigger.

To improve the coherence of both methods different expressions for the calculation of equivalent charred timber are proposed for compression and tension. This includes modification of the threshold value of 7 mm and the correction parameter k0. For the correction parameter a square root curve was proposed for the first 30 min instead of the linear approximation for the first 20 min indicated in EC5. The proposed threshold value for tension is 10 mm:

For compression the threshold value that is proposed is 18 mm.

where t is the time of fire exposure in minutes. The proposed equations were plotted in Figures 7 and 8 as solid lines. It can be observed that beyond 30 min, the proposed equations slightly underestimate the equivalent charred timber obtained using the ACM.

5 Conclusions

Advanced and simplified methods are presented in EC5 to calculate fire resistance of timber structures. Both models have some limitations, but most important, they have some inconsistencies. This paper presents proposals to overcome some of the inconsistencies as well as to extend their applicability.

A modified specific heat capacity curve has been proposed for the conduction model allowing considering different moisture contents.

An expression to calculate the CR as a function of density and moisture content has been suggested for the CR model that is compatible with the conduction model.

Modified expressions for use with the RCSM were proposed to improve the consistency with the ACM.

References

EN 1995-1-2:2004. Eurocode 5: Design of timber structures—Part 1–2: General—Structural fire design. CEN, Brussels, Belgium, 2004

König J (2005) Structural fire design according to Eurocode 5—design rules and their background. Fire Mater 29:147–163. doi:10.1002/fam.873

Franssen J-M SAFIR. A thermal/structural program modelling structures under fire, Engineering Journal, A.I.S.C., 2005: 42 (3), pp. 143–158.

White RH, Erik V, Nordheim EV (1992) Charring rate of wood for ASTM E 119 fire exposure. Fire Technol 28(1):5–30. doi:10.1007/BF01858049.

White RH, Tran HC (1996) Charring rate of wood exposed to a constant heat flux. Slovak Republic, s.n. wood & fire safety—3rd International scientific conference, pp 175–183

Njankouo JM, Dotreppe J-C, Franssen J-M (2004) Experimental study of the charring rate of tropical hardwoods. Fire Mater 28:15–24. doi:10.1002/fam.831

König J, Walleij L (1999) One-dimensional charring of timber exposed to standard and parametric fires in initially unprotected and postprotection situations. Swed Inst Wood Technol Res Rapport I 9908029

Frangi A, Fontana M (2003) Charring rates and temperature profiles of wood sections. Fire Mater 27:91–102. doi:10.1002/fam.819

EN 1991-1-2:2002. Eurocode 1: Actions on structures—Part 1–2: General actions—Actions on structures exposed to fire. CEN, Brussels, Belgium, 2002

Njankouo JM, Dotreppe J-C, Franssen J-M (2005) Fire resistance of timbers from tropical countries and comparison of experimental charring rates with various models. Construct Build Mater 19(5):376–386. doi:10.1016/j.conbuildmat.2004.07.009

Gu H, Hunt JF (2007) Two-dimensional finite element heat transfer model of softwood. Part III. Effect of moisture content on thermal conductivity. [ed.] Society of Wood Science and Technology. Wood Fiber Sci 39:159–166

FPL Thermal conductive properties of wood, green or dry, from −40° to +100°C: A literature review. Madison, Wisconsin, USA: Forest Products Lab., 1977. Report FPL-9

Parker WJ (1985) Development of a model for the heat release rate of wood—a status report. U.S. Dep. Commerce. Report NBSIR 85-3163

Ragland KW, Aerts DJ (1991) Properties of Wood for Combustion Analysis. Bioresour Technol 37:161–168. doi:10.1016/0960-8524(91)90205-X.

Schaffer EL (1967) Charring rate of selected woods transverse to grain. Forest Products Laboratory. Madison, Wisconsin, USA: s.n., 1967. Research paper FPL 69

Hietaniemi J (2005) A probabilistic approach to wood charring rate. VTT Building and Transport. Kivimiehentie, Finland: VTT Information Service, Project n. R4SU00235, 2005. VTT Working Papers 31.

FPL Wood handbook. Wood as an engineered material. Madison, Wisconsin, USA: Forest Products Laboratory, 1999.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Cachim, P.B., Franssen, JM. Assessment of Eurocode 5 Charring Rate Calculation Methods. Fire Technol 46, 169–181 (2010). https://doi.org/10.1007/s10694-009-0092-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10694-009-0092-x